Académique Documents

Professionnel Documents

Culture Documents

JCB

Transféré par

Kocic BalicevacTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

JCB

Transféré par

Kocic BalicevacDroits d'auteur :

Formats disponibles

JCB BACKHOE LOADER | 3CX SITEMASTER

MAX. ENGINE POWER MAX. BACKHOE DIG DEPTH: MAX. LOADER CAPACITY: 63kW (85hp) or 68.6kW (92hp) 5.97 metres (19ft 7in) 1.0m3 (1.32yd3)

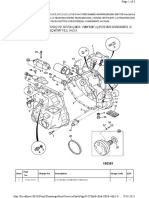

H G F

D B K A C

STATIC DIMENSIONS

JCB Backhoe Loaders feature heavy duty one piece mainframe, componentised driveline and fully enclosed engine compartment. All fluid and component compartments are lockable using the ignition key. Machine model A Total travel length B Axle centreline distance C Slew centre to rear axle centre distance D Stabiliser feet clearance E F Kingpost clearance Steering wheel centre height 3CX Sitemaster m (ft-in) 5.62 (18-5) 2.17 (7-1) 1.36 (4-6) 0.37 (1-2) 0.52 (1-8) 1.94 (6-4) 2.91 (9-6) H Total travel clearance J K Rear frame width Shovel width Machine model 3CX Sitemaster m (ft-in) 3.61 (11-10) 2.36 (7-9) 2.35 (7-8) 2.24 (7-4) 2.23 (7-4)

A Product of Hard Work

J* Rear frame width K* Shovel width * Narrow option

G Cab roof height

JCB BACKHOE LOADER | 3CX SITEMASTER

GROUND LINE ANGLES STEERING

Full power hydrostatic system utilising the main hydraulic pump via a steering priority valve. In the event of engine failure, emergency steering is maintained. Machine model Axles Steering turns lock to lock

A

3CX Sitemaster Steer drive 234 m (ft-in) 8.1 (26-7) 10.4 (34-1) 6.9 (22-8) 9.5 (31-2)

Kerb kerb turning circle unbraked

C

Kerb kerb loader clearance circle unbraked Turning circle braked Loader clearance circle braked

(Depending on tyre size, ground conditions etc.)

A B C

Approach angle 66 Interference angle/ramp to ground plane 120 Departure angle 20

OPERATING WEIGHTS

Operating weight includes machine equipped with 610mm excavator bucket, Extradig 6-in-1 shovel with forks and full fuel tank. Machine model Weight 3CX Sitemaster kg (lb) 8070 (17800)

ENGINE SUPPORT SYSTEM

Engine support system is designed for ease of daily checks, routine maintenance and longer service intervals. Fuel type Diesel. Fuel filter Replaceable spin-on cartridge plus water/sediment separator prefilter. Air cleaner Dual, dry element type with self cleaning internal air intake precleaner. Oil filter and lubrication Full flow, spin-on type filter. Cooling system Hot climate specification, pressurised 14.5 psi (1.0 bar) suction fan. Pressurised recovery tank with integral filler neck.

ENGINE

Four cylinder, direction injection diesel. Water pump, spin-on oil filter, fuel filter, water sediment separator prefilter, dual element air cleaner with internal precleaner, cold start aid. Machine model Manufacturer Aspiration Displacement No. of cylinders Rated engine RPM Power ratings Gross ISO/TR 14396 and SAE J1995 SAE Net ISO 9249 SAE J1349 Maximum torque Gross ISO/TR 14396 and SAE J1995 SAE Net ISO/TR 9249 and SAE J1349 Max. torque RPM Nm (lbf ft) Nm (lbf ft) 320 (236) 315.6 (232.7) 1200 390 (287.6) 382 (281.8) 1300 kW (HP) kW (HP) 63 (85) 61.6 (82.6) 68.6 (92) 67.2 (90.1) 3CX Sitemaster JCB Naturally aspirated 4.4 Ltr 4 2200 3CX Sitemaster JCB Turbocharged 4.4 Ltr 4 2200

ELECTRICAL AND INSTRUMENTATION

12 volt negative ground, utilising wiring and connectors meeting IP69 water ingress test standard. Central fuse panel. Gauges Tachometer, engine coolant temp, fuel level, hourmeter, clock. Warning system Audible and visual system for engine oil, water in fuel, transmission oil temperature and pressure, park brake, air cleaner, alternator. Battery 115 A/hr. Pre-wire Radio speakers (cab), beacon (all). Horn Controlled from both front and rear. Alternator 95 amp standard. Front working lights 2 twin beam fixed position. Rear working lights 4 adjustable.

A Product of Hard Work

JCB BACKHOE LOADER | 3CX SITEMASTER

JCB TORQUE LOCK (Optional)

An industry exclusive, JCB Torque Lock enables an operator to dramatically reduce travel time and improve fuel efficiency during roading operations. Torque Lock incorporates a clutch which, when engaged, enables a direct connection between the engine and gearbox. By locking up the torque converter slippage is eliminated. Torque Lock engages automatically in 4th gear (Powershift models) or A mode (Autoshift models). Not available on Synchroshuttle models.

REAR AXLE

JCB rear axles are designed and built specifically for backhoe loaders and accept a wide variety of tyre combinations. Machine model Type Limited slip Axle ratings Static load rating Dynamic load rating 3CX Sitemaster JCB Epicyclic hub reduction with torque proportioning Option kg (lb) 21000 (46296) 7000 (15432)

TRANSMISSION

The JCB Transmissions are designed and built specifically for JCB Backhoe Loaders. They feature synchronised shifting in all gears. Powershuttle between forward and reverse. Ground speeds are designed to maximise production. An optional 4 speed powershift transmission enables effortless and fast gear changes. Gears are selected through a twist grip control on the column mounted forward/reverse lever. Machine model Manufacturer Type Torque converter Torque lock Torque converter ratio Gears forward/reverse Gear selection Shuttle control F/R Travel speeds Tyres equipped front 12.5x18 rear 18.4x26 T219 JCB S/M Gear 1 Gear 2 Gear 3 Gear 4 5.6 (3.5) F / 5.6 (3.5) R 9.0 (5.6) F / 9.0 (5.6) R 19.2 (11.9) F / 19.2 (11.9) R 5.3 (3.3) F / 5.3 (3.3) R 9.8 (6.1) F / 9.8 (6.1) R 22.6 (14.0) F / 22.6 (14.0) R

CAB

Excellent visibility (and safety) is provided by the extra large tinted glass areas of 6.4 sq m (70 sq ft). Cab frame is ROPS and FOPS approved for maximum operator protection. ISO standard 3471 and 3449 (SAE J1040 and J231).

3CX Sitemaster JCB Syncroshuttle 305mm (12") N/A 3.0:1 4/4 Manual Power shuttle kph (mph)

3CX Sitemaster JCB Powershift 305mm (12") Option 2.52:1 4/4 Powershift Power shuttle kph (mph)

A fully adjustable seat with lumbar support combines with ergonomically positioned controls to minimise operator fatigue. The in-cab noise levels are the lowest in the business for maximum operator comfort. A radio location is provided as standard plus twin speakers for stereo sound. Cab provides easy access through a two door frame. Rear side windows open either partially or fully for extra ventilation. Standard features include: lap seat belt, 3 speed fresh air/recycle heater, front and rear screen wash/wipers, front and rear horn, exterior mirrors, and flat easy-clean floor. The instrument panel is positioned to the right-hand side for ease of viewing from either the loading or excavating position and has an optional lockable cover for vandal proofing. Engine speed, fuel and coolant temperature gauges, (and clock on cab builds) are mounted in the panel. A high performance air conditioning system is optionally available on turbo builds providing the operator with a cool working environment when working in high temperatures. Mechanical suspension seat gives the operator a comfortable operating position. An optionally available heated air suspension seat gives the operator the ultimate comfort with automatic compensation for weight.

34.8 (21.6) F / 34.8 (21.6) R 38.3 (23.8) F / 38.3 (23.8) R

FRONT AXLE

JCB front axles are designed and built specifically for backhoe loaders and accept a wide variety of tyre combinations. Machine model Type Axle ratings Static load rating Dynamic load rating Oscillation angle Steering ram 3CX Sitemaster JCB 4WD steer drive with torque proportioning kg (lb) 16500 (36375) 5500 (12125) 16 Powered track rod JCB Precision Control offers smooth, low effort and productive operation, while reducing operator fatigue. Excavator control joysticks are integrated into the seat, which provides increased legroom, improved job visibility and hydraulic excavator ergonomics. A proportional switch is mounted in the joystick to operate JCBs Extradig. An optional joystick mounted switch is also available to operate auxiliary attachments. The low effort mechanical loader control incorporates an optional proportional roller to operate loader mounted attachments. Best in class hydraulic modulation combined with the greatest digging performance, means that the JCB Precision Control is unmatched in any backhoe loader. *Not available on naturally aspirated engines.

A Product of Hard Work

JCB PRECISION CONTROL (Optional)

JCB BACKHOE LOADER | 3CX SITEMASTER

LOADER DIMENSIONS

P

LOADER ATTACHMENTS

S R

Y V

N M

Q X

LOADER DIMENSIONS 6-in-1 Shovel

m (ft-in) M Dump height N Load over height O Pin height P R S T V Pin forward reach Max. reach at full height Reach at full height fully dumped Dig depth Dump angle Jaw opening width Q Reach at ground (toe plate horizontal) 2.74 (9-0) 3.20 (10-6) 3.45 (11-4) 0.36 (1-2) 1.37 (4-6) 1.15 (3-9) 0.78 (2-7) 0.10 (0-4) 45 43 0.95 (3-1) Section width W Fork length X Reach at ground Y

LOADER ATTACHMENTS Forklift Performance and Data

6-in-1 Shovel mounted forks m (ft-in) 0.08 (0-318) 1.1 (3-7) 2.66 (8-9) 2.25 (7-5) 2.92 (9-7) 0.2 (0-8) 2.17 (7-3) kg (lb) 1000 (2205) Quickhitch mounted forks m (ft-in) 0.08 (0-318) 1.1 (3-7) 2.03 (6-8) 1.72 (5-8) 3.27 (10-9) 0.2 (0-8) 1.03 (3-4) 2000 (4410)

Reach at full height Fork spacing min Fork spacing max SWL @ 500mm load centres

Z Fork lift height

U Rollback at ground

LOADER PERFORMANCE LOADER ATTACHMENTS Direct Mount

Loader buckets are listed according to size and application. All buckets are drilled to accept optional auxiliary cutting edge or teeth. Flat top box section provides rigidity and assists in bucket levelling. 6-in-1 Shovel Capacity SAE Width mm (ft-in) 2235 (7-4) 2350 (7-8) Rated m3 (yd3) 1.0 (1.32) 1.0 (1.32) Struck m3 (yd3) 0.83 (1.09) 0.83 (1.09) JCB loaders provide parallel lift self levelling on the up and down cycle enhancing load retention and use of optional pallet forks. High capacity buckets combined with high lift and breakout forces maximise productivity. Machine model Loader breakout of shovel Loader breakout arms Lift capacity to full height A* Lift capacity to full height B* Clamping force (A* and B*) * Type A shovel = 2235mm (7'4") / Type B shovel = 2350mm (7'8") kgf (lbf) kgf (lbf) kg (lb) kg (lb) kgf (lbf) 3CX Sitemaster 6531 (14398) 4732 (10432) 3229 (7119) 3169 (6986) 2940 (6480)

A Product of Hard Work

JCB BACKHOE LOADER | 3CX SITEMASTER

BRAKES

The JCB braking system ensures effective, fade-free braking. The self-adjusting, multi-disc arrangement is inboard mounted and is oil immersed for minimum maintenance and a long operating life.

HYDRAULIC SYSTEM

The Open Centre system uses twin gear pumps and Hydraulic Speed Control (HSC) with a power modulation valve that automatically varies hydraulic power to match digging conditions for extra performance and power.

A 3 position switch allows the selection of 2 wheel drive with two wheel braking; 2 wheel drive with four wheel braking or 4 wheel drive with four wheel braking. All machines are fitted with servo assisted brakes as standard for low effort braking. Twin brake pedals provide tighter turning circle and enhanced steering control on slippery ground. Automatic compensation ensures straight machine braking. Disc diameter: 220 mm (8.7 in). Friction area: 129,000 sq.mm (200 sq. in) per brake. For syncroshuttle transmissions, the independent parking brake is mounted on the input shaft of the rear axle and will hold the machine on 1:3 gradients. It is an over-centre type, adjustable within the cab, with transmission disconnect to prevent premature brake pad wear. Park brake disc diameter: 280mm (11 in). Friction area 5416 sq. mm (8.4 sq.in). For powershift transmissions, the integral park brake is a ball and ramp, oil immersed type located within the transmission and will hold the machine on 1:3 gradients. It is an over-centre type, adjustable within the cab, with transmission disconnect to prevent premature brake pad wear. There are 5 friction brake discs having an outside diameter of 127mm (5 in). Frictional area per brake disc is 47.65 sq. cm (7.39 sq. in) giving a total frictional area of 476.5 sq. cm (73.9 sq. in).

Open centre hydraulic system using simple and reliable high efficiency gear pumps. A Power Modulation Valve automatically varies the hydraulic power to match digging conditions to improve performance and efficiency automatically dumps one pump when 4th gear selected on powershift models. The HSC switch enables controlled use of hydraulic response depending upon application. Easily used, ergonomically positioned levers give excellent control of the loader and backhoe, thus reducing operator fatigue. An independent pump powers the Extradig dipper so that it can extend or retract without breaking the digging cycle. This allows faster cycle times and simultaneous use of the telescopic and normal excavator actions in operations such as grading and bank dressing. A full flow 10 micron filter ensures that oil stays free of contaminants. Engine Pump flows at 2200rpm Main pump output Second pump output System working pressure Backhoe and loader Naturally aspirated l/min (gal/min) 73 (16) 51 (11.5) bar (lbf/sq in) 251 (3650) Turbo l/min (gal/min) 79 (17.5) 57 (12.5) bar (lbf/sq in) 251 (3650)

TYRES

Front 12.0 x 18, 10PR Industrial 12.5 x 18, 10PR Industrial 335/80 x 18, Radial Traction 400/70 x 18, Radial Industrial 16.9 x 28, 12PR Traction or Industrial 18.4 x 26, 12PR Traction or Industrial 16.9 x 28, Radial Traction 480/80 x 26, Radial Industrial

SERVICE CAPACITIES

Machine model Cooling system Fuel tank Engine oil with filter Transmission with filter Rear axle Front drive axle Hydraulic system incl. tank 3CX Sitemaster ltr (gal) 18.5 (4.1) 160 (35.2) 15 (3.3) 16 (3.5) 16 (3.5) 16 (3.5) 132 (29)

Rear

JCB SMOOTH RIDE SYSTEM (Optional)

The JCB Smooth Ride System (SRS) consists of a dry nitrogen and oil filled accumulator installed in line with the loader lift cylinders. When activated, the Smooth Ride System allows the loader arms to float. This action counteracts variations in road or site surfaces and provides the operator with a smooth ride. The JCB Smooth Ride System is manually controlled, via a rocker switch on the instrument panel, for maximum benefit and user flexibility.

JCB POWERSLIDE (Optional)

Exclusive to JCB, this option enables the excavators sideshift carriage to be hydraulically powered across the rearframe by the operation of a pedal or joystick mounted proportional switch (Precision Control) in the cab. With this feature there is no need to push the carriage across with the bucket avoiding ground damage and the need to relocate the whole machine.

A Product of Hard Work

JCB BACKHOE LOADER | 3CX SITEMASTER

BACKHOE BUCKETS Standard Profile Bucket

JCB backhoe buckets are designed specifically for use on JCB machines with pin positions to maximize tearout, load retention and straight wall digging characteristics. Width* mm (in) 305 (12) 400 (16) 457 (18) 610 (24) 800 (32) 950 (37) Rated m3 0.06 (218) 0.09 (3) 0.12 (414) 0.17 (6) 0.24 (812) 0.30 (10 2)

1

BACKHOE DIMENSIONS

m (ft-in) A SAE max dig depth Teeth 3 3 3 4 5 5 B SAE 2ft flat bottom Maximum dig depth with deep profile bucket Reach ground level to rear wheel centre Ext Ret Ext Ret Ext Ret Ext Ret Ext Ret Ext Ret Ext Ret Ext Ret Ext Ret Ext Ret 5.46 (17-11) 4.24 (13-11) 5.43 (17-10) 4.21 (13-10) 5.97 (19-7) 4.75 (15-7) 7.87 (25-10) 6.72 (22-1) 6.52 (21-5) 5.37 (17-7) 3.66 (12-0) 2.74 (9-0) 7.09 (23-3) 5.94 (19-6) 6.35 (20-10) 5.53 (18-2) 4.72 (15-6) 3.84 (12-7) 4.32 (14-2) 3.44 (11-3) 1.16 (3-10) 1.05 (3-5) Speed 201

Capacity SAE (ft3) Struck m3 (ft3) 0.05 (134) 0.07 (212) 0.09 (3) 0.13 (412) 0.17 (6) 0.21 (7 4)

1

Weight (+ teeth) kg (lb) 102 (225) 109 (240) 116 (256) 140 (310) 162 (355) 198 (435)

C Reach ground level to slew centre D Reach at full height to slew centre E Side reach to centre line of machine SAE operating height

* Including sidecutters. Width less sidecutters deduct 25mm (1in).

BACKHOE BUCKETS Deep Profile Bucket

F Width* mm (in) 305 (12) 457 (18) 610 (24) 800 (32) 950 (37) 1100 (43) 0.09 (3) 0.16 (5 2) 0.23 (8) 0.30 (1012) 0.38 (12) 0.48 (38)

1

Capacity SAE Rated m3 (ft3) Struck m3 (ft3) 0.07 (212) 0.13 (4 2) 0.18 (614) 0.24 (812) 0.30 (1012) 0.34 (12)

1

Weight (+ Teeth) kg (lb) 102 (225) 122 (269) 142 (314) 163 (359) 183 (403) 203 (448) Teeth 3 3 4 5 5 6 J H Total kingpost travel Narrow rear frame option Bucket rotation SAE loadover height G Maximum loadover height

* Including sidecutters. Width less sidecutters deduct 25mm (1in). Capacity in cu.yd.

BACKHOE PERFORMANCE

kgf (lbf) Bucket tearout Dipper tearout Speed Power Ext Ret Ext Ret 5385 (11847) 6228 (13701) 2255 (4961) 3225 (7095) kg (lb) Lift capacity of bucket pivot at full reach 719 (1582) 1451 (3192)

A Product of Hard Work

JCB BACKHOE LOADER | 3CX SITEMASTER

D

F G

C E

A Product of Hard Work

JCB BACKHOE LOADER | 3CX SITEMASTER

A GLOBAL COMMITMENT TO QUALITY

JCBs total commitment to its products and customers has helped it grow from a one-man business into Britains largest privately owned manufacturer of backhoe loaders, crawler excavators, wheeled excavators, telescopic handlers, wheeled loaders, dump trucks, rough terrain fork lifts, industrial fork lifts, mini/midi excavators, skid steer loaders and tractors. By making constant and massive investments in the latest production technology, the JCB factories have become some of the most advanced in Europe. By leading the field in innovative research and design, extensive testing and stringent quality control, JCB machines have become renowned all over the world for performance, value and reliability. And with a global sales and service network of over 400 distributors and agents, the company exports over 70% of its production to all five continents. Through setting the standards by which others are judged, JCB has become one of Britains most impressive success stories.

JCB cares for the environment. This paper has been produced without the use of elemental chlorine chemicals in the bleaching process.

JCB Sales Limited, Rocester, Staffordshire ST14 5JP. Tel: 01889 590312. Fax: 01889 590588. Web: http://www.jcb.com

JCB reserves the right to change specifications without notice. Illustrations shown may include optional equipment and accessories. The JCB logo is a registered trademark of J C Bamford Excavators Ltd. 9999/4920 12/05 Issue 5

A Product of Hard Work

Vous aimerez peut-être aussi

- Backhoe 3cxDocument16 pagesBackhoe 3cxBrendan BoycePas encore d'évaluation

- 2CX Spec Issue2Document16 pages2CX Spec Issue2aiulica20Pas encore d'évaluation

- 5664 3 4CX Eco T4 FINALDocument8 pages5664 3 4CX Eco T4 FINALAndrei AndreiPas encore d'évaluation

- JCB Tracked Robot Loaders 190T1110TDocument6 pagesJCB Tracked Robot Loaders 190T1110TFajrin M. NatsirPas encore d'évaluation

- JCB Shuttle transMISSIONDocument3 pagesJCB Shuttle transMISSIONDipal PracaschandraPas encore d'évaluation

- JCB 4cx TRANSMISSIONDocument1 pageJCB 4cx TRANSMISSIONJakes SchmidtPas encore d'évaluation

- Daf-Brochure LF PDFDocument28 pagesDaf-Brochure LF PDFIonut AnghelutaPas encore d'évaluation

- Mla628 120,12 06Document634 pagesMla628 120,12 06Razvan MitruPas encore d'évaluation

- JCB Telehandlers Spec 4024d5Document28 pagesJCB Telehandlers Spec 4024d5jakalae5263Pas encore d'évaluation

- 2DXL Super Loader Brochure PDFDocument8 pages2DXL Super Loader Brochure PDFSandeep KumarPas encore d'évaluation

- Volvo Workshop Manuals XC90 AWD V8-4.... Formation Specifications Page 5947Document2 pagesVolvo Workshop Manuals XC90 AWD V8-4.... Formation Specifications Page 5947Lisandro SisternaPas encore d'évaluation

- Manitou MT-X 625 (EN)Document2 pagesManitou MT-X 625 (EN)Manitou100% (2)

- Series IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebDocument20 pagesSeries IV MKII Rigid Hauler Tractors Broch18281215 EnglishWebAlejandro QuiñonezPas encore d'évaluation

- Euro 3 Euro 3: Chassis 6x6Document4 pagesEuro 3 Euro 3: Chassis 6x6Dwanny VHPas encore d'évaluation

- J CB Backhoe Loader 3CX: Static DimensionsDocument7 pagesJ CB Backhoe Loader 3CX: Static DimensionsDwi100% (1)

- 700649en A 1217 M MH Range-BdDocument36 pages700649en A 1217 M MH Range-BdManitouPas encore d'évaluation

- 3335 K 39 6X4 ChassisDocument8 pages3335 K 39 6X4 ChassisSeban JosephPas encore d'évaluation

- 6 PDFDocument4 pages6 PDFHernan LopezPas encore d'évaluation

- 9812/7600 F5-6-1 Clutch Input PS750 449/13160,449/13100,449/13090Document3 pages9812/7600 F5-6-1 Clutch Input PS750 449/13160,449/13100,449/13090herosk100% (1)

- 9812/0010 F2-2-3 458/10980, AXLE ARM & HUB ASSY: Item Part # Change No Description Usage Code QTYDocument2 pages9812/0010 F2-2-3 458/10980, AXLE ARM & HUB ASSY: Item Part # Change No Description Usage Code QTYFilipposPas encore d'évaluation

- Read On.: Excavator Operating Weight Class 30 TonnesDocument4 pagesRead On.: Excavator Operating Weight Class 30 TonnesCristhianAlexanderAguilarChavezPas encore d'évaluation

- Manitou M Series (EN-US)Document4 pagesManitou M Series (EN-US)Manitou100% (1)

- Service Manual: Publication NoDocument10 pagesService Manual: Publication NoMeyer CA0% (1)

- Dokumen - Tips - Hiab 071 Operators Manual Tervensbullsten 071 Operators Manual Hiab 140 PartsDocument3 pagesDokumen - Tips - Hiab 071 Operators Manual Tervensbullsten 071 Operators Manual Hiab 140 PartsOctavio50% (2)

- BCA Sheet Manitou RepairDocument71 pagesBCA Sheet Manitou Repairbumatio lati100% (1)

- JCB Tracked Excavator JS130 L T.A.B.: Static DimensionsDocument6 pagesJCB Tracked Excavator JS130 L T.A.B.: Static DimensionsKovacs Zsolt-Istvan100% (1)

- BMW f650 Funduro Gs Dakar Price List 15609Document19 pagesBMW f650 Funduro Gs Dakar Price List 15609fartogoPas encore d'évaluation

- NPR400 Ark0775Document4 pagesNPR400 Ark0775Johnny DoePas encore d'évaluation

- Manitou ES4 (EN)Document4 pagesManitou ES4 (EN)ManitouPas encore d'évaluation

- Daihatsu Rocky 1990Document15 pagesDaihatsu Rocky 1990Mac PirxPas encore d'évaluation

- Manitou ES8 (EN)Document4 pagesManitou ES8 (EN)ManitouPas encore d'évaluation

- Kamaz Civil VehiclesDocument84 pagesKamaz Civil VehiclesTudor Costin100% (1)

- 9812/7600 F5-4-1 Mainshaft, Clutch Components, PS750 449/13160,449/13100Document2 pages9812/7600 F5-4-1 Mainshaft, Clutch Components, PS750 449/13160,449/13100heroskPas encore d'évaluation

- JCB 535 95 THL05Document16 pagesJCB 535 95 THL05brett harris100% (1)

- WWW Brettstruck Com Au PBR TRUCK 2014Document207 pagesWWW Brettstruck Com Au PBR TRUCK 2014ali4299Pas encore d'évaluation

- TJ 810D 1110D EngDocument14 pagesTJ 810D 1110D EngDavid StepićPas encore d'évaluation

- E20 22 27SR - GBDocument8 pagesE20 22 27SR - GBPredrag ZoricPas encore d'évaluation

- JCB Compact Excavator Range (US) August 2011Document24 pagesJCB Compact Excavator Range (US) August 2011JCB North America100% (2)

- Idoc - Pub - Iveco Abs Fault Codespdf PDFDocument6 pagesIdoc - Pub - Iveco Abs Fault Codespdf PDFIonuț-Cătălin FrăsinPas encore d'évaluation

- E17 E19 E20 en BrochureDocument12 pagesE17 E19 E20 en Brochurepedrorainha2537Pas encore d'évaluation

- Frd-Furukawa: F-Series Hydraulic BreakersDocument28 pagesFrd-Furukawa: F-Series Hydraulic BreakersManuel Alcedo MeleroPas encore d'évaluation

- JS 360 LC SpecDocument8 pagesJS 360 LC SpecMarceloAndresCortésCastilloPas encore d'évaluation

- Mercedes Benz 1b452Document52 pagesMercedes Benz 1b452ahmed_eng_1500Pas encore d'évaluation

- Sandvik DP1100: ApplicationDocument4 pagesSandvik DP1100: ApplicationAnbarasanPas encore d'évaluation

- Mccormick c60 c75 c85 c95 c105 C Max Workshop ManualDocument8 pagesMccormick c60 c75 c85 c95 c105 C Max Workshop ManualdingleberryspotifyPas encore d'évaluation

- Ariens Sno Thro 924 Series Snow Blower Parts ManualDocument28 pagesAriens Sno Thro 924 Series Snow Blower Parts ManualBradCommander409100% (1)

- Manitou MSI 30 T (EN)Document2 pagesManitou MSI 30 T (EN)ManitouPas encore d'évaluation

- Service Manual: Publication NoDocument23 pagesService Manual: Publication NoCharlon ButtigiegPas encore d'évaluation

- Volkswagen Workshop Manual (6-Speed Manual Gearbox 0A8)Document210 pagesVolkswagen Workshop Manual (6-Speed Manual Gearbox 0A8)jerryalfaPas encore d'évaluation

- MST PDFDocument12 pagesMST PDFMeleștean MihaiPas encore d'évaluation

- Unic URW 547Document2 pagesUnic URW 547Foromaquinas100% (1)

- John Deere 7830Document5 pagesJohn Deere 7830Ramiro GonzálezPas encore d'évaluation

- 303 14 PDFDocument38 pages303 14 PDFTuan TranPas encore d'évaluation

- TransmissionDocument22 pagesTransmissionrefei100% (1)

- Manitou MLT-X 1040 (EN)Document2 pagesManitou MLT-X 1040 (EN)ManitouPas encore d'évaluation

- Pernos Cat PDFDocument72 pagesPernos Cat PDFTania VélezPas encore d'évaluation

- Iveco Ad380Document2 pagesIveco Ad380mr.bouncePas encore d'évaluation

- Bremach T-Rex Flyer - UkDocument2 pagesBremach T-Rex Flyer - UkJohn DavisPas encore d'évaluation

- S+SIWP RFP App I (I) - MFS (Salalah)Document78 pagesS+SIWP RFP App I (I) - MFS (Salalah)Kocic Balicevac100% (1)

- Example 3 Chapter-8: Temperature Profile in A Water Injection WellDocument2 pagesExample 3 Chapter-8: Temperature Profile in A Water Injection WellKocic BalicevacPas encore d'évaluation

- Conservation of Linear MomentumDocument1 pageConservation of Linear MomentumKocic BalicevacPas encore d'évaluation

- 2.1 - Normal DataDocument19 pages2.1 - Normal DataKocic BalicevacPas encore d'évaluation

- 1.4 - Measurement Systems AnalysisDocument45 pages1.4 - Measurement Systems AnalysisKocic BalicevacPas encore d'évaluation

- Time Series Analysis: CTL - SC1x - Supply Chain & Logistics FundamentalsDocument14 pagesTime Series Analysis: CTL - SC1x - Supply Chain & Logistics FundamentalsKocic BalicevacPas encore d'évaluation

- Introduction To Inventory Management: CTL - SC1x - Supply Chain & Logistics FundamentalsDocument13 pagesIntroduction To Inventory Management: CTL - SC1x - Supply Chain & Logistics FundamentalsKocic BalicevacPas encore d'évaluation

- SC0x W10R1 Final CleanDocument48 pagesSC0x W10R1 Final CleanKocic BalicevacPas encore d'évaluation

- Basic Measures and GraphsDocument11 pagesBasic Measures and GraphsKocic BalicevacPas encore d'évaluation

- CH 09Document25 pagesCH 09Kocic BalicevacPas encore d'évaluation

- SC0x W10R2 Final CleanDocument12 pagesSC0x W10R2 Final CleanKocic BalicevacPas encore d'évaluation

- W1L2 WorksheetDocument36 pagesW1L2 WorksheetKocic BalicevacPas encore d'évaluation

- Dire Wolf Industries Annual Costs by Category Total Annual Cost $ 5,001,800Document10 pagesDire Wolf Industries Annual Costs by Category Total Annual Cost $ 5,001,800Kocic BalicevacPas encore d'évaluation

- CH 13Document28 pagesCH 13Kocic BalicevacPas encore d'évaluation

- Oman Standard Specifications For Road and Bridge Construction 2010Document3 pagesOman Standard Specifications For Road and Bridge Construction 2010Kocic BalicevacPas encore d'évaluation

- SU-40 Design Vehicle DimensionsDocument1 pageSU-40 Design Vehicle DimensionsKocic BalicevacPas encore d'évaluation

- WB-40 Design Vehicle DimensionsDocument1 pageWB-40 Design Vehicle DimensionsKocic BalicevacPas encore d'évaluation

- Galfar: Off Plot Delivery Contract - C-31/0603 Area Location Engineering & Contracting S.A.O.GDocument4 pagesGalfar: Off Plot Delivery Contract - C-31/0603 Area Location Engineering & Contracting S.A.O.GKocic BalicevacPas encore d'évaluation

- Raci ChartDocument2 pagesRaci ChartJuan Carlos Lekuona-Muñoz CarrilloPas encore d'évaluation

- OGSS AL C Index and ChecklistDocument134 pagesOGSS AL C Index and ChecklistKocic BalicevacPas encore d'évaluation

- S CurveDocument4 pagesS CurveKocic BalicevacPas encore d'évaluation

- Project Earned Value Analysis1Document4 pagesProject Earned Value Analysis1Kocic BalicevacPas encore d'évaluation

- Game TheoryDocument49 pagesGame TheoryKocic BalicevacPas encore d'évaluation

- Work Method Statement ToolkitDocument16 pagesWork Method Statement ToolkitKocic BalicevacPas encore d'évaluation

- Doug PolkDocument2 pagesDoug Polkshiva balram0% (1)

- Super Metroid (USA) - TextDocument40 pagesSuper Metroid (USA) - TextCarlos EnriquePas encore d'évaluation

- Specific Features of The Decathlon PDFDocument5 pagesSpecific Features of The Decathlon PDFBrandy MalonePas encore d'évaluation

- Smiles 4 Mod Test 2ADocument4 pagesSmiles 4 Mod Test 2ABiljana NestorovskaPas encore d'évaluation

- Duct Tape WeaponsDocument12 pagesDuct Tape WeaponsMatthew ToppingPas encore d'évaluation

- BMTC Bus Routes and NumbersDocument15 pagesBMTC Bus Routes and Numberssantoshkumar.sm3533% (3)

- YONEX SUNRISE India Open 2024 - M - Q Report Version 3 - Friday, 22nd December 2023Document13 pagesYONEX SUNRISE India Open 2024 - M - Q Report Version 3 - Friday, 22nd December 2023cicipdendra005Pas encore d'évaluation

- Unit 5: Q2e Listening & Speaking 1: Audio ScriptDocument5 pagesUnit 5: Q2e Listening & Speaking 1: Audio ScriptHanaa Bin Merdah100% (1)

- Bagan Turnamen Futsal Ikna 2022: F I N A LDocument2 pagesBagan Turnamen Futsal Ikna 2022: F I N A LNOVIANA RODZIYAH 21.93.0273Pas encore d'évaluation

- Luksong TinikDocument4 pagesLuksong TinikAlexie Almohallas100% (1)

- PTO Installation DddpptoqsiDocument3 pagesPTO Installation DddpptoqsiStephen RivettPas encore d'évaluation

- Triphasic Tactical Workout Creator Single User Powered by Sorinex EquipmentDocument50 pagesTriphasic Tactical Workout Creator Single User Powered by Sorinex EquipmentTj NewsomPas encore d'évaluation

- Pe3 SyllabusDocument6 pagesPe3 SyllabusJoel Castelo88% (8)

- Chapter 11 Solution MazurDocument17 pagesChapter 11 Solution MazurKate KlopfensteinPas encore d'évaluation

- Hydraulic Fitting CatalogDocument165 pagesHydraulic Fitting CatalogDian Pramadi100% (1)

- Rodatechbanda de TiempoDocument141 pagesRodatechbanda de Tiemporefaccim.comprasPas encore d'évaluation

- C400HDocument147 pagesC400HKINTOLOBOPas encore d'évaluation

- Volleyball Injuries: S - S I IDocument6 pagesVolleyball Injuries: S - S I IGABRIELA SaNCHEZ AGUDELOPas encore d'évaluation

- Unit 2 - Fashion CategoriesDocument6 pagesUnit 2 - Fashion CategoriesDeepali B MudalgiPas encore d'évaluation

- Refereeing Basics Course PDFDocument52 pagesRefereeing Basics Course PDFapi-496743421100% (1)

- TF2 Pokemon SetsDocument11 pagesTF2 Pokemon SetsDarkArchAngel75Pas encore d'évaluation

- Master Class 6 How Not To Lose in ChessDocument81 pagesMaster Class 6 How Not To Lose in ChessLouie Jay L Bahian100% (2)

- Aparna WestSide BrochureDocument24 pagesAparna WestSide BrochuremechnicalstudentPas encore d'évaluation

- B Com Part III 2011 ResultDocument13 pagesB Com Part III 2011 ResultIndiaresultPas encore d'évaluation

- Diet Template FAQDocument17 pagesDiet Template FAQLouis TrầnPas encore d'évaluation

- Red BullDocument15 pagesRed BullVishakha TyagiPas encore d'évaluation

- 1Kklwtq Aygo Hatchback 5 Doors 1.0 L (68 HP) 5 Speed Multimode X-CiteDocument8 pages1Kklwtq Aygo Hatchback 5 Doors 1.0 L (68 HP) 5 Speed Multimode X-CiteRaduRouaPas encore d'évaluation

- Chrono Series - Wikipedia BookDocument95 pagesChrono Series - Wikipedia BookEdelylaPas encore d'évaluation

- BSC LifeScienceDocument29 pagesBSC LifeSciencedevil3003Pas encore d'évaluation

- Skoda Felicia ManualDocument2 pagesSkoda Felicia ManualSusana Corvillo Arroyo25% (4)