Académique Documents

Professionnel Documents

Culture Documents

3 Capacity Planning Unit POM Hand Out 3

Transféré par

divyaimranDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

3 Capacity Planning Unit POM Hand Out 3

Transféré par

divyaimranDroits d'auteur :

Formats disponibles

CAPACITY PLANNING

Capacity is measured with different para meters in different industries Automobile Steel Beer Nuclear power Airline Hospitals No. of cars Metric tonnes Cases Megawatts Seat miles Bed-days

Capacity to produce is limited by acilities a!ailable "echnology employed "ime period. #t is difficult to change capacity in short time. Hence capacity building should be planned carefully and properly. #t is a strategic decision Capacity planning is influenced by: $. Mar%et trends &. Mar%et locations '. Mar%et si(e ). "echnological inno!ations *. +roduct,ser!ice design -. +rocess inno!ation .. /0pansion of e0isting unit 1. 2ptimal si(e 3. Alternati!es $4. 5e!enue.6 cost capital $$. "rade off $&. 7emand prediction 1: Common Definition of Capacity Planning A process to predict the types, quantities, and timing of critical resource capacities that are needed within an infrastructure to meet accurately forecasted workload

2: elect a Capacity Planning P!ocess "#ne! "his person will be responsible for designing6 implementing6 and maintaining the process $: Identify %ey &esou!ces To 'e (easu!ed irst tas%s will be to identify the infrastructure resources whose utili(ations or performance need to be measured.

7r. M 82"//S9A5AN MBA ## S/M +2M &4$& Hand 2ut - ' Page 26

CAPACITY PLANNING

"his determination is made based on current %nowledge about which resources are most critical to meeting future capacity needs. ): (easu!e t*e Cu!!ent +tili,ations of t*e &esou!ces "he resources identified should be measured as to their utili(ations or performance. "hese measurements pro!ide two %ey pieces of information: ; A utili(ation baseline from which future trends can be predicted and analy(ed "he <uantity of e0cess capacity a!ailable for each component -: Compa!e Cu!!ent +tili,ations to (a.imum Capacities 7etermine how much e0cess capacity is a!ailable for selected components. "he utili(ation or performance of each measured component should be compared to the ma0imum usable capacity. "he ma0imum usable is almost always less than the ma0imum possible. /: Collect (eaningful 0o!1load 2o!ecasts f!om &ep!esentati3e +se!s "his is one of the most critical acti!ities in the entire capacity planning process6 and it=s the one o!er which you ha!e the least control. 4: T!ansfo!m 2o!ecasts into &esou!ce &e5ui!ements After the wor%load forecasts are collected6 pro>ected changes need to be transformed into resource re<uirements. Sophisticated measurement tools Senior analyst=s e0pertise "he wor%sheets to pro>ect the estimated timeframes during which wor%load increases will occur. 6: (ap &e5ui!ements "nto 7.isting +tili,ations "he pro>ected resource re<uirements deri!ed from the wor%load pro>ections are mapped onto the charts of e0cess utili(ation. "his mapping will show the <uantity of new capacity that will be needed by each component to meet e0pected demand. 8: P!edict 0*en t*e *op 0ill 'e "ut of Capacity "he mapping of the <uantity of additional capacity needed to meet pro>ected wor%load demands will also pinpoint the timeframe during which these upgraded resources will be re<uired. 19: +pdate 2o!ecasts and +tili,ations "he process of capacity planning is not a one-shot e!ent but rather an ongoing acti!ity. #ts ma0imum benefit is deri!ed from continually updating the plan and %eeping it current. "he plan should be updated at least once per year. Shops that use this methodology best update their plans

7r. M 82"//S9A5AN MBA ## S/M +2M &4$& Hand 2ut - ' Page 27

CAPACITY PLANNING

e!ery <uarter. A firm?s producti!e capacity is the total le!el of output or production that it could produce in a gi!en time period. Capacity utilisation is the percentage of the firm?s total possible production capacity that is actually being used. Capacity utilisation @AB C actual output per month @or per annumB 0 $44A DDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDDD ma0imum possible output per month @or per annumB Capacity +tilisation #f a firm could produce $&44 units per month6 but is actually producing -44 per units per month6 Capacity utilisation A C @-44 units per month 0 $44A B , $&44 units per month C *4A 2inancial implications A firm?s le!el of capacity utilisation determines how much fi0ed costs should be allocated per unit6 so as a firm?s capacity utilisation increases6 the fi0ed costs @and therefore also6 total costsB per unit will decrease. or e0ample6 if the firm abo!e had fi0ed costs of E$&6444 per month6 the fi0ed costs per unit would be E&4 per unit at *4A capacity utilisation6 but only E$4 per unit at $44A capacity utilisation. A firm should be most efficient if it is running at $44A capacity utilisation. Howe!er6 if a firm is running at full capacity6 there are a number of potential drawbac%s. "here may not be enough time for routine maintenance6 so machine brea%downs may occur more fre<uently and orders will be delayed #t may not be possible to meet new or une0pected orders so the business cannot grow without e0panding its scale of production Staff may feel under e0cessi!e pressure6 leading to increased mista%es6 absenteeism and labour turno!er #f the factory space is o!ercrowded6 wor% may become less efficient due to the untidy wor%ing conditions #t may be necessary to spend more on staff o!ertime to satisfy orders6 increasing labour costs Causes of under-utilisation of capacity New competitors ta%ing mar%et share or causing o!er-supply in the mar%et all in mar%et demand due to changes in consumer tastes or fashion Fnsuccessful mar%eting G one or more aspect of the mar%eting mi0 may simply mean that the firm is not successful Seasonal demand G this is especially apparent in the tourist industry where firms li%e hotels and leisure par%s are full in the summer but see much lower utilisation at other times of the year

P!oblems a!ising f!om lo# capacity utilisation

7r. M 82"//S9A5AN MBA ## S/M +2M &4$& Hand 2ut - ' Page 28

CAPACITY PLANNING

Higher fi0ed costs per unit reduced profitabilityH if prices were raised to co!er these costs6 this would probably lead to reduced sales Spare capacity can portray a negati!e image6 - signifying loss of popularity Staff can become bored and demorali(ed if they don?t ha!e as much to do6 especially if they fear losing their >obs

'enefits of lo# capacity utilisation A firm may ha!e more time for maintenance and repairs and for staff training6 to prepare for an upturn in trade "here may be less stress for employees than if they were wor%ing at full capacity "he firm can cope with new ordersH firms in e0panding mar%ets may e0pect to ha!e low utilisation whilst they build their sales A unit manufacturing electric motors has . stations. #ndi!idual capacity of critical station is $444,wee%. #f actual output is 144,wee%6 find System capacity and System efficiency A lamp manufacturing line has ' stations with indi!idual capacities of respecti!ely. Actual output is 16$44,shift. ind System capacity and System efficiency $46444636444 and $46*44

7r. M 82"//S9A5AN

MBA ## S/M

+2M &4$&

Hand 2ut - '

Page 29

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Planning For Plant StartupDocument91 pagesPlanning For Plant StartupGustavo Gonzalez ServaPas encore d'évaluation

- Cold Chain in PharmaDocument4 pagesCold Chain in PharmaChandan Ahire100% (1)

- Plan Crusher PlantDocument14 pagesPlan Crusher PlantBujjibabu Katta100% (2)

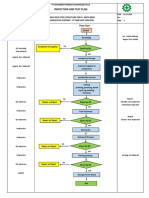

- Inspection and Test Plan: Flow Chart Start IncomingDocument1 pageInspection and Test Plan: Flow Chart Start IncomingSinden AyuPas encore d'évaluation

- WellheadDocument2 pagesWellheadRicardo Paz SoldanPas encore d'évaluation

- Process Selection and Capacity PlanningDocument54 pagesProcess Selection and Capacity Planningankita_16jansingh0% (1)

- Integrating Petroleum Supply ChainDocument32 pagesIntegrating Petroleum Supply ChainGunjan ChakrabortyPas encore d'évaluation

- DBM To WattDocument2 pagesDBM To WattImtiaz AhmedPas encore d'évaluation

- Unit - 1 Production Operations and Automation StrategiesDocument33 pagesUnit - 1 Production Operations and Automation StrategiesVarunPas encore d'évaluation

- A4 80Document2 pagesA4 80alwezalokPas encore d'évaluation

- 10 Fema-It-Ipr Hand OutDocument12 pages10 Fema-It-Ipr Hand OutdivyaimranPas encore d'évaluation

- 12 Japanese Manufacturing Systems POM Handout 12Document12 pages12 Japanese Manufacturing Systems POM Handout 12divyaimranPas encore d'évaluation

- P1Bab01 Essentials of Management: Vel Tech DR - RR & DR - SR Technical University Department of MbaDocument16 pagesP1Bab01 Essentials of Management: Vel Tech DR - RR & DR - SR Technical University Department of MbadivyaimranPas encore d'évaluation

- MBA I Unit NotesDocument18 pagesMBA I Unit NotesdivyaimranPas encore d'évaluation

- Multiple Choice Questions Unit-I: Operations Management Question Bank Unit-1Document5 pagesMultiple Choice Questions Unit-I: Operations Management Question Bank Unit-1divyaimranPas encore d'évaluation

- Body LanguageDocument11 pagesBody LanguagedivyaimranPas encore d'évaluation

- 11 Maintenance Management POM Handout 11Document3 pages11 Maintenance Management POM Handout 11divyaimranPas encore d'évaluation

- Production and Operations Management at IFFCO KandlaDocument44 pagesProduction and Operations Management at IFFCO KandlaChandan Pahelwani100% (1)

- Minimum Wages in Tamil NaduDocument3 pagesMinimum Wages in Tamil NaduVidhiya AmbigapathyPas encore d'évaluation

- Class7 Module3 140316Document13 pagesClass7 Module3 140316Jaison C.S.Pas encore d'évaluation

- Green Electronics: Save Environment, It Will Save You!!! We Are Doing Our Bit What About YOU???Document19 pagesGreen Electronics: Save Environment, It Will Save You!!! We Are Doing Our Bit What About YOU???ayeshasweet100% (1)

- Top 100 Indian Pharma CompanyDocument3 pagesTop 100 Indian Pharma CompanyThavasi NadarPas encore d'évaluation

- GE1452 Process Planning and Cost EstimationDocument7 pagesGE1452 Process Planning and Cost EstimationK.ThiruvasagamoorthyPas encore d'évaluation

- Procurement of Raw MAterialsDocument30 pagesProcurement of Raw MAterialsSneha ShriyanPas encore d'évaluation

- Super Strong Super Sulit!: Other Construction ProductsDocument3 pagesSuper Strong Super Sulit!: Other Construction ProductsRejoice SamboPas encore d'évaluation

- Bulk Deformation ProcessDocument67 pagesBulk Deformation ProcessJith ViswaPas encore d'évaluation

- Specification of KIRBY KLM 2100 PanelDocument2 pagesSpecification of KIRBY KLM 2100 PanelKishore Kumar0% (1)

- Millat Equipment Limited InformationDocument49 pagesMillat Equipment Limited InformationMaria Mohni67% (6)

- Nippon Vinilex 2000 Water-Based Wall Sealer: DescriptionDocument2 pagesNippon Vinilex 2000 Water-Based Wall Sealer: Descriptionlimitless853Pas encore d'évaluation

- U03 Cost Management Terminology and ConceptsDocument15 pagesU03 Cost Management Terminology and ConceptsHamada Mahmoud100% (1)

- Toyota & GM - Group 1Document12 pagesToyota & GM - Group 1Aditi MurarkaPas encore d'évaluation

- Optimization of Surface Roughness and Material Removal Rate in Turning of Aisi D2Document3 pagesOptimization of Surface Roughness and Material Removal Rate in Turning of Aisi D2Fikri SiplhoPas encore d'évaluation

- Tech LeaderDocument6 pagesTech LeadermachineCanPas encore d'évaluation

- Daftar Nomor Sertifikat 2018Document73 pagesDaftar Nomor Sertifikat 2018Bagus SatriyoPas encore d'évaluation

- CH 17Document48 pagesCH 17Afşin BakkalPas encore d'évaluation

- Assignment ERPDocument10 pagesAssignment ERPSameer ZaidiPas encore d'évaluation

- Flange BearingsDocument4 pagesFlange BearingsigusukPas encore d'évaluation