Académique Documents

Professionnel Documents

Culture Documents

APEGBC-Designing Guards For Buildings

Transféré par

rongerabbitTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

APEGBC-Designing Guards For Buildings

Transféré par

rongerabbitDroits d'auteur :

Formats disponibles

TableofContents

1.0 2.0 3.0 4.0 5.0

Introduction............................................................................................................. 1 ReviewofCodesandStandards.............................................................................2 DesignConsiderations............................................................................................. 5 ContinuityofResponsibility.................................................................................... 6 Acknowledgements................................................................................................. 8

APPENDIXACODEREFERENCES...................................................................................... 9 APPENDIXBGUIDEFORTESTINGOFGUARDS.............................................................11 APPENDIXCCASESTUDIES........................................................................................... 12 APPENDIXDMODELSPECIFICATIONFORGUARDS.....................................................17

1.0 1.1

Introduction Background

1.1.1 Guardsaretypicallyconsideredassecondaryornonstructuralelementsofa buildingastheydonotsupporttheprimarystructure;however,guardsplaya significantroleinpublicsafety. 1.2 PurposeandScope 1.2.1 Thepurposeofthisdocumentistoserveasadesignguideforindividual practitionerswhenpreparingdrawingsandspecificationsinthedesignand implementationofguardsusedinbuildings. 1.2.2 Specificrequirementsforguardsmaydifferbetweenauthoritieshaving jurisdiction.Itwillbetheresponsibilityofthedesignertobefamiliarwithlocal requirements. 1.2.3 Thisdocumentisnotintendedtobeusedasthestandardforguarddesign.Itis uptotheindividualdesignertoperformtherequiredduediligenceinpreparing thedrawingsandspecifications.Thisdocumentmustnotbeusedinawaythat reducesanyrequirementspecifiedinanyapplicablecode,bylaworstandard.

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

2.0 2.1

ReviewofCodesandStandards TheNationalBuildingCodeofCanada2010(NBCC2010)isanobjectivebased code.Therelevantobjectivesandfunctionalstatementswithrespecttoguards areasfollows: Objectives: OS2StructuralSafety OS3SafetyinUse OP2StructuralSufficiency Functionalstatements F10:Tofacilitatethetimelymovementofpersonstoasafeplaceinan emergency. F20:Tosupportandwithstandexpectedloadsandforces. F30:Tominimizetheriskofinjurytopersonsasaresultoftripping, slipping,falling,contact,drowningorcollision.

2.2

Thefollowingsummarizesselectedcriteriarelevanttothedesignofguardsas presentedintheBritishColumbiaBuildingCode(BCBC2012)whichisbasedon theNBCC2010.SeeappendixAforexcerptstakenfromthecodesandstandards referencedbelow. BCBC2012DivisionBPart3Requirements:Forcommercialoccupancies. Appliestoareasforwhichaccessisprovidedforpurposesotherthan maintenance. Requiresthataguardbeprovidedataheightofnotlessthan1070mm fromthefinishedfloorwhereanelevationdifferencegreaterthan600 mmexists. Thesizeofopeningsmustnotallowthepassageofaspheregreaterthan 100mmindiameter. Attachmentsoropeningslocatedbetween140mmand900mmabove thefinishedfloormustnotfacilitateclimbing. Handrailswhererequiredmustbegraspable(ifcircular:30mm40mm indiameter;orifsquare:100mm125mmperimeterand45mm maximumcrosssectionaldimension)andmustbebetween865mmand 965mmabovethefinishedfloor. Handrailsmustbedesignedtoresistaconcentratedloadof0.9kNanda uniformloadof0.7kN/mappliedinanydirection. BCBC2012DivisionBPart4Requirements:Forstructuraldesigncriteria.

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

Theminimumspecifiedhorizontalloadmustbe3.0kN/mforguards locatedatinameansofegress, aconcentratedloadof1.0kNwheregatheringofmanypeopleis improbable,or auniformloadof0.75kN/moraconcentratedloadof1.0kNinother locations. NOTE:Thesedifferencescanbecriticaltoboththedesignoftheguardsandthe structuretowhichtheguardsareattached.Theserequirementsshouldbevery carefullystatedinthedesignrequirements. Individualelementsbeloworwithintheguardmustbedesignedfora loadof0.5kNappliedoveranareaof100mmx100mmnottobe consideredconcurrentwiththehorizontalguardload. Averticalloadof1.5kN/mappliedatthetopoftheguardmustbe resistedbutneednotbeconsideredtoactsimultaneouslywiththe horizontalload. BCBC2012DivisionBPart9Requirements:Forresidentialoccupancies. TheserequirementsaresimilartothosedescribedinPart3andPart4as referencedabove. WorkSafeBCrequirements:Protectionofworkers. Theselegalrequirementsapplytoallworkplacesandarisefromthe OccupationalHealthandSafetyRegulation.Enforcementofthese regulationsfallsunderthejurisdictionofWorkSafeBC. Theserequirementsareintendedtoprovidesafeenvironmentsfor workersinareasthatarenotspecificallyaccessibletothepublicas definedintheaboveBCBCreferences. Aguardrailconsistsofatopraillocated102cmto112cmabovethe worksurfaceandanintermediateraillocatedmidway. Itmustbedesignedtowithstandaloadof0.55kNappliedperpendicular tothespaninahorizontalorverticaldirection. ItmustnotbemadeoffibreorwireropewithoutBoardapproval. CAN/CSB12.20M89STRUCTURALDESIGNOFGLASSFORBUILDINGS Thisisalimitstatesdesigncode.Thecodeaddressesthebrittlenatureof glasswhereusedasastructuralmaterialbystipulatingthatsupport membersbedesignedwitharedundantloadpath.Theunderlying principalbeingthatifonememberfailsacascadingorcatastrophic failuremechanismdoesnotdevelop.

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

Freestandingglassguardsmusthaveatopcapwhichspansovertwoor morepanelsandbedesignedtoresistthefactoredloadafterfailureof alternatepanels. Thedeflectionoftheguardatthepointofapplicationoftheload,withall panelsintactmustnotexceed40mm.

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

3.0 3.1

DesignConsiderations Aguardismeanttopreventanindividualfromfallingfromahigherelevationto alowerelevation.Aguardshouldalsocreateasenseofsafetyamongbuilding occupants. Designofaguardmustconsiderthefollowing: 1. Whereisaguardrequired 2. Dimensionalrequirements 3. StrengthDesignincludingtheloadpathtotheprimarystructure. 4. Serviceability(deflection/graspability/climbability) 5. RelationshiptoBuildingEnvelope 6. Aesthetics

3.2

3.3

Whenusingaluminum,considerationshouldbemadeforthelossoftemperand associatedreductioninstrengthwhereweldedconnectionsareused.Referto CAN/CSAS157StrengthDesignofAluminumforBuildings. Specialconsiderationmustbegiventotheuseofglassasguardelements.Some meansofstructuralredundancymustbebuiltintothesystemtoprevent progressivecollapseoftheassemblyfollowingthefailureofaglassmember.In particular,whenusingtemperedglassthereexistsapotentialforspontaneous breakageduetoimpurities(alsoreferredtoasNickelSulfideinclusions).Referto thedesignguidespublishedbytheGlazingContractorsAssociationofBC(now FenestrationBC)entitled:GlassDesigntoHumanImpactLoadandGlass GuardsandBalustrades. Considerationshouldalsobegiventowindowsactingasguardswherethesill extendsbelow1070mmofthefinishedfloor.Inthisinstancethewindowmust betreatedasawallseparatingtheelevationdifferenceandbedesignedto withstandtheappropriateguardload.Furtherconsiderationshouldbegivento operablesasheswheretheremaybeariskoffallingthroughtheopenwindow. Suchwindowsmustbeequippedwithalimitertorestrictthesizeoftheopening. Although,theremaybecaseswhereoperablewindowsarerequiredtoallow egressduringafireinwhichcasetherecanbetwocontradictorycode requirements. Inthecasesofuniquearchitecturaldesigns,nontraditionalconstruction methodsoruseofexoticmaterials(i.e.artglassorreclaimedtimber)wherethe availablecodesandstandardsdonotprovideadequateguidancethedesigner mayemploydestructivetesting.Aguidefortheloadtestingofguardshasbeen developedandincludedinappendixB.

3.4

3.5

3.6

Version1.0May3,2013 2013APEGBC.Allrightsreserved. 5

4.0 4.1

ContinuityofResponsibility Thesupplyandinstallationofguardsofteninvolvesmultipletradedisciplines.In turntheremaybeseveraldesignprofessionalinvolvedinthedesignoversight forindividualelementsoftheguard.Forexampleatypicalglassbalustrademay includeaspecialtyfittingsupplier,aglasssupplier,aglazinginstaller,a miscellaneousmetalssubcontractoraswellasamillworker.Considerthefigure below: Wood rail - Millwork Steel stanchion Miscellaneous metals Connection to base structure

Glass Panel - supply and installation

Specialty glass Fittings 4.2 Asaresulttherecanbeadiscontinuityarisingfromthediffusionofdesign oversight.Eachelementmaybetheresponsibilityofadifferentdesign professionalwithlittleornocoordinationbetweenthem.Notwithstanding, designoversightultimatelyrestswiththearchitect.Structuraldesignofguards andtheirattachmentsiscoveredundertheArchitecturalsectionoftheBCBC LettersofAssurance. Whenpreparingshopdrawings,thedesignprofessionalmustbecarfultodefine theirscopeofworkclearlywhileatthesametimeensuringthatconnecting elementsaresuitableforthecompletedsystem.Forexample,ifreviewingshop drawingsfortheglasselementsonly,itshouldbeclearlystatedthatthedesign oftheglassisbasedonthecontinuityoftherailandthattherailmustbe designedaccordingly.Inthisinstance,thedesignerprovidingaletterof assurancefortheglazingcomponentmayinsistthathehavecopiesoftheletters ofassuranceprovidedfortheguardrail,stanchionsandconnectionstobase structure.

4.3

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

4.4

Designersmayoverseeindividualelements.However,itistheresponsibilityof thedesignertoensurethatacompetentloadpathexistsandthatacomplete guardassemblyispossible.Takingprofessionalresponsibilityforonecomponent inanassemblydoesnotnullifytheresponsibilitytoalsoensurethatother componentsfittogethertocreateacompletestructuralassemblyincludingan appropriateattachmenttothebasestructure. ShopdrawingsshouldbepreparedinaccordancewiththeGuidelinesonShop DrawingspublishedbyAPEGBC.Thefollowingbasicelementsmustbeidentified ontheshopdrawings: Clearlyshowtheelementsforwhichdesignresponsibilityisassumed(e.g. usedarkerlinetypes). Showthecompletedguardassemblyandclearlyidentifythestructural functionandrequirementforthosecomponentsforwhichdesign responsibilityisassumedtobebyothers. Identifytheintendedloadpathtothebasestructure. Showreactionloads. Showconnectiondetails. Providegeneralnotesindicatingmaterialsused,designcodesreferenced, anddescriptionofthescopeofwork. Provideaplandrawingshowingtheextentandlocationofitems.

4.5

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

5.0

Acknowledgements Thefollowingindividualshavecontributedtothedevelopmentofthese Guidelines: JimMutrie,P.Eng.,JonesKwongKishi RobertJirava,P.Eng.,RDJStructuralDesignsLtd. ThorTandy,P.Eng,UNISOLEngineeringltd. GaryW.Berkeley,P.Eng.,BerkeleyVadoczEngineeringInc. LeonardPianalto,P.Eng.,ReadJonesChristoffersen

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

APPENDIXACODEREFERENCES Thefollowingparagraphsaretakeninwholeorinpartfromthecodesandstandards referenced.Thereadershouldrefertothedocumentfortheexactandmostcurrent wording.Thesecitationsareprovidedforreferenceonlyandshouldnotbedirectly relieduponfordesigncalculations. Part3Requirements 3.3.1.18.Guards 3.3.2.9 3.4.6.5.Guards 3.4.6.4.(9)forloadsonhandrails Part4Requirements 4.1.5.15.LoadsonGuards [SeeAppendixA] Part9Requirements 9.8.8.Guards 9.8.8.1.RequiredGuards [SeeAppendixA] [SeealsoArticle9.7.5.3.] Table9.8.8.2 WorkSafeBCrequirements Section4.54oftheRegulationprovidesthefollowingdefinitions: Insections4.54to4.63 Insections4.55guardraillocationsareprescribedasfollows: Section4.58(4)oftheOHSRegulation("Regulation")states: RefertoWorksafeBCOHSregulations. CAN/CSB12.20M89STRUCTURALDESIGNOFGLASSFORBUILDINGS 7.1GlassGuardsandBalustrade Appendix A3.1 Glass can be used as a structural material, as it is both strong and rigid. Themaindistinguishingcharacteristicofglassisitsbrittleness.Consequentlywhenglass is used as a structural component it must be designed to withstand the design loads, to accommodate all movements of its supporting members and have a redundancy of at leastonefailsafeloadpathintheeventofthefailureofacomponent. AppendixA5.GlassGuardsandBalustrades Version1.0May3,2013 2013APEGBC.Allrightsreserved. 9

A5.1 When a brittle material with variable mechanical properties like glass is used as a structural component with the potential for catastrophic consequences in the event of failure,bothincreasedloadfactorsandalternativeloadpathsarerequiredinthedesign. For glass guards and balustrades the standard addresses these factors by the requirement for alternate lights be assumed failed in the strength determination, and a rigidcontinuousguardovertwoormorelights. A5.2 Glass guards may have exposed edges and as glass edges are intrinsically weak, especially with thin glass, the designer should give consideration to hard body impact at the edges and provide protection if necessary. Examples of hard body impact include stonesandfloorcleaningequipment. A5.3 The fixing of the glass at the base must ensure that all bending moments can be resisted and that rotation is minimized. An expanding grout may be used to fix glass. Whensupportingfinsofglassareusedtheymustbefixedbyfrictionboltsoradhesivein accordancewithestablishedengineeringprincipals.

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

10

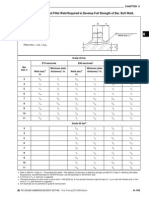

APPENDIXBGUIDEFORTESTINGOFGUARDS Scope Whilesuppliersoftenstatethattheirtestingshowsthatguardshavemorecapacitythan required;thetestingmethodsused,theloadlevelsappliedandthefailuremodearenot alwaysprovidedorevident.ThisAppendixisintendedtoaddressthesequestions. DesignofGuards 1) GuardsmustbedesignedtotheapplicableCSAdesignstandard(s)forthematerial(s) usedintheirconstructionfortheloadingspecifiedinNBC4.1.5.15. 2) Inlieuofthedesignrequirementsin1),guardsdesignmaybeacceptedonthebasis ofloadtestingcomplyingwiththefollowingparagraphs. 3) AllguardsmustbetestedinaccordancetoClause13ofCSAS15705unlessthere areequivalenttestingrequirementintherelatedmaterialstandard. 4) ASTME985mayalsobereferencedfordefiningtestmethodspertinentto permanentmetalrailingsystemsandrails. 5) Guardsmustbetestedinanapprovedtestinglaboratory(orequivalentasdeemedby theProfessionalEngineer)underthesupervisionofaProfessionalEngineer.some manufacturesmaybeabletoinstallgoodtestingsetupsandthereforenotneedthe useofatestinglaboratorybutthentheP.Eng.shoulddirectthetestandcertifythat thetestingequipmentmeetstherequirementsofASTME935. 6) ThetestingmustbecarriedoutinaccordancewithASTME935StandardTest MethodsforPerformanceofPermanentMetalRailingSystemsandRailsforBuildings latesteditionassuggestedbyClause13.2.2ofCSAS15705.Railingsmustbetestedby methodsA,B,CandDifapplicable. 7) TheloadstobeusedinthetestsmustbebasedonthespecifiedloadsfromNBC 4.1.5.15. 8) TheappliedforcesfortheultimatelimitstatetestingasrequiredbyClause13.2.1.2 mustbe: a) Afactoredloadof1.67timesthespecifiedloadwithoutanyyieldingofthe assembly(=0.9) b) Afactoredloadof2.0timesthespecifiedloadifthefailuremodeisductile(= 0.75). c) Afactoredloadof2.25timesthespecifiedloadifthefailuremodeisbrittle(= 0.67). 9) TheresistanceoftheGuardmustbetakenasthecharacteristicresistancein accordancetoClause13.3.2.1. 10) ForglassguardsrefertoASTME2353StandardTestMethodsforPerformanceof GlassinPermanentGlassRailingSystems,GuardsandBalustrades. Version1.0May3,2013 2013APEGBC.Allrightsreserved. 11

APPENDIXCCASESTUDIES Thefollowingcasestudiesareintendedtoillustratedifferentscenariosthatmaybe encounteredwithanengineeredguardassembly.Thesecasesarefictitiousandare intendedtoprovideanecdotalprecedentsinpartitioningdesignresponsibilityamong differentstakeholdersintheconstructionteam. Scenario1:TraditionalnewconstructionprojectinvolvingaPart3buildingwithan architectandbasebuildingstructuralengineer.ThebuildingisatypicalLowerMainland concretetowerwithguardssurroundingexteriorbalconies.Theworkisproceeding underapermitgrantedbytherespectiveauthorityhavingjurisdiction.Theguards proposedforthisprojectincludealuminumpostsandtoprailwithglassinfill. KeyRolesdefiningareasofprofessionalresponsibility: 1. ArchitectContractiswiththeOwner;hassignedthelettersofassurance(Schedule B)assumingresponsibilityforthearchitectsscopewhichincludesthepurviewover structuraldesignandattachmentofguardcomponents. 2. BaseBuildingStructuralEngineerContractiswiththeArchitect;hassignedletters ofassurance(ScheduleB)assumingresponsibilityforthestructuralintegrityofthe basebuildingincludingeffectsofsecondarycomponentssuchasguardsandtheir attachmentstothebasebuilding. 3. SpecialtyStructuralEngineerContractiswiththesupplier/subcontractorwhois inturncontractedtothegeneralcontractor;hassignedaletterofassurance (ScheduleSinaccordancewithbulletinK). Keyinteractionsduringthecourseofconstruction: 1. Architecturaldrawingsandspecificationsprovidegeneraldetailsofformincluding shape,color,overalldimensionsandmaterialsofconstructionfortheproposed guards. 2. Generalcontractorengagesasubcontractortoprovideaproposedsystemto generallyconformtotheArchitecturalspecifications.Thesubcontractorprovides shopdrawingsdetailingallaspectsoftheproposedguard.Aninitialsubmissionmay notbestampedasitmaybeincompleteandintendedtosolicitfeedbackfromthe architectaboutspecificdesigncharacteristicsthatmaybeentirelyaesthetic. 3. Oncesuchdetailsareagreedupon,thesubcontractorwillsubmitasetofshop drawingsthatbearthesealofaprofessionalengineerregisteredinBritishColumbia. Theseshopdrawingsshouldincludeallrelevantdetailstoshowthestructural functionoftheassemblyincludingmaterialsused,fasteners,andhowtheguard interactswiththebasebuildingincludingindicationoftheforcestransferredtothe basebuilding.TheseshopdrawingsareforwardedontotheArchitectviathe GeneralContractor. 4. DesignbySpecialtyEngineertoprovideconnectiontotheprimarystructureand mustincludethedesignofcollateralsecondaryelementsasnecessarytopassthe Version1.0May3,2013 2013APEGBC.Allrightsreserved. 12

loadthroughtotheprimarystructure.Ifconnectingtoasteelstud,forexample,the shopdrawingsmustindicatetherequirementfortheconnection(e.g.18gasteel studrequiredattheguardattachment). 5. SpecialtyEngineertofollowinstructionsforconnectiontoprimarystructureas providedbytheStructuraldrawings.Thisengineermustcontactthebasebuilding StructuralEngineerofRecordtodiscussanyanchorageconcerns. 6. TheArchitectwillreviewtheshopdrawingsandforwardasetofthedrawingstothe basebuildingStructuralEngineertoreviewtheguardsfortheireffectonthebase building.TheStructuralEngineerwillnotreviewthestructuraladequacyofthe guardassemblybuthewillreviewtheadequacyoftheproposedfastenersto transfertheguardloadstothebasebuilding. 7. Oncetheshopdrawingshavebeenreviewedandacceptedtheinstallationwill proceed.Duringtheinstallation,thespecialtyengineeractingforthesubcontractor shouldvisitthesiteathisdiscretiontoconductfieldreviewsasrequiredandas definedinBulletinK.Thescopeofthefieldreviewshouldalignwiththescopeof responsibilitydefinedinthesealedshopdrawings. 8. AtcompletionoftheinstallationthespecialtyengineerwillsubmittheScheduleS.If required,hewillcontactthebasebuildingstructuralengineertoclarifyanymatters thatrelatetothestructuralinteractionbetweentheguardassemblyandthebase building.Thisisadeclarationthatthespecialtyengineermakesinsigningthe ScheduleS.ThisisconsistentwiththefollowingstatementintheModelScheduleS BAssuranceofProfessionalDesignandCommitmentforFieldReviewwhichreadsas follows: IconfirmIhaveliaisedasrequiredwiththeappropriateRegisteredProfessionalsforthe purposesofmyservices. AdditionalComments Scenario1islikelythemostcommonthatwillbeencounteredintypicallowermainland constructionprojects.Thereareanumberofsimilarvariantsofthisscenariothat warrantfurtherdiscussionasfollows: Scenario1a: Newconstructionprojectwithguardassemblyincorporatingseveral engineeredcomponents.ThiswillbesimilartoScenario1yetmoredemandingforthe coordinatingprofessionalastherewillbeanumberofspecialtyengineersinvolvedin definingthecompletedassembly.Somecomponentswillinteractwiththebase building,whileotherswillinteractwithotherspecialtycomponents.Ensuringagainst conflictingrequirementsaswellasgapsinresponsibilitywillbeasignificantchallengein thisscenario. Amodificationtothedefinitionofthekeyplayersisasfollows: 1. MultipleSpecialtyStructuralEngineersContractswillbewithanumberofthe suppliers/subcontractorswhoareinturncontractedtothegeneralcontractor; eachhavesignedlettersofassurance(ScheduleSinaccordancewithbulletinK). Version1.0May3,2013 2013APEGBC.Allrightsreserved. 13

Scenario1b: AnothercommoncaseonPart4buildingsoccurswheretherearea varietyofguardelementsthatarefabricatedfroma"basic"material,saystructural steel.Forexample:commonsteelpicketedguard/handrailinaconcretestairwell,tobe fabricatedbythesteelfabricatororpossiblythemiscellaneousmetalsfabricatorif suchasubcontractisinplace. OftentheseitemscanfallintothelapofthebasebuildingStructuralEngineerwhichwill bethecaseifallthedetailsoftheguardassemblyareshownonthestructuraldrawings oronthearchitecturaldrawingswithsomestructuralcomments. Othertimesthefabricatorgoesaheadandpreparesshopdrawingsbasedonthe architect'sdrawings.Often,theshopdrawingscontainavarietyofstructuralproblems thatarerevealedfollowingreviewbytheStructuralEngineer. Itisrecommendedthataspecialtyengineerbeengagedinthesecircumstances.The requirementforengineeringshouldbenodifferentthanforotherpreengineered componentssuchasopenwebsteeljoistsorcommercialglazingassemblies. Thisshouldbemadeclearinthespecifications.Typicallymiscellaneousmetalsare definedintheDivision5specifications.However,anyprojectthatincludesguards shouldincludeaseparatespecificationtocoverallguardassemblies.Thiswouldcover architecturalguardassembliesthatmightbetypicallyencounteredinlivingspaceslike balconiesandmezzaninesaswellasutilitarianguardsthatmightbetypicallyseeninexit stairsandparkades. AppendixDcontainsanexamplegenericNMSMasterFormatSpecification. Scenario2: ProprietaryGuardsysteminvolvingapreengineeredguardassembly essentiallyorderedoutofacatalogue. KeyRolesdefiningareasofprofessionalresponsibility: 1. ArchitectContractiswiththeOwner;hassignedthelettersofassurance(Schedule B)assumingresponsibilityforthearchitectsscopewhichincludesthepurviewover structuraldesignandattachmentofguardcomponents. 2. BaseBuildingStructuralEngineerContractiswiththeArchitect;hassignedletters ofassurance(ScheduleB)assumingresponsibilityforthestructuralintegrityofthe basebuildingincludingeffectsofsecondarycomponentssuchasguardsandtheir attachmentstothebasebuilding. KeyInteractionsduringthecourseofconstruction: 1. Architecturaldrawingsandspecificationsprovideaspecificproducttobeinstalled. Shopdrawingsmayormaynotberequireddependingonthenatureoftheproduct andproject.However,itisstillessentialfortheStructuralEngineertobemade awareofthefasteningmethodandconfigurationsuchthathecanprovidesuitable basebuildingstructuretoresisttheguardloads. 2. Generalcontractorpurchasesproductandinstallsitasperthemanufacturers instructions. Version1.0May3,2013 2013APEGBC.Allrightsreserved. 14

3. guardsuppliermustprovidecapacitycriteriaandinstallationdetailsforallaspects includingbaseconnection(usehiltiproductsforexample). 4. Inthiscasethereisnoneedforaspecialtyengineerasthearchitectassumesthe designresponsibilityofthesystem.Theymayrelyonpreengineeringthathasbeen completedbythemanufacturer.ThiswillbeentirelyattheArchitectsdiscretion. Regardlessofwhatinformationthearchitectreliesupon,hewillassume responsibilityforassuringallbuildingcoderequirementsrelatedtotheguard assemblyincludingthosedefinedinPart4. Scenario3: Renovationprojectwithnoarchitect.Engineeractsasprimeconsultant, buildingenvelopeengineerandstructuralengineer. KeyRolesdefiningareasofprofessionalresponsibility: 1. PrimeconsultantengineerContractiswiththeOwner;hassignedthelettersof assurance(ScheduleB)assumingresponsibilityforthearchitectsscopewhich includesthepurviewoverstructuraldesignandattachmentofguardcomponents. 2. SpecialtyStructuralEngineerContractiswiththesupplier/subcontractorwhois inturncontractedtothegeneralcontractor;hassignedaletterofassurance (ScheduleSinaccordancewithbulletinK). KeyInteractionsduringthecourseofconstruction: 1. ThesewillsimilartotheinteractionsdefinedinScenario1. 2. Theprimeconsultantshouldincludeastructuralengineertocoverthereviewof structuraleffectstothebasebuilding.TheStructuralEngineerwillbeexpectedto signlettersofassurancetocoverthePart4requirementsofthepermitapplication. Scenario4: RenovationprojectwithnobasebuildingStructuralEngineer.Such projectsmightincludeasimplerenovationprojectwherethepermitapplicationismade byadesigner(i.e.notregisteredwithAIBC),ageneralcontractor,orHomerOwner. Suchprojectswouldtypicallyincludearesidentialrenovation(i.e.additionofbalconyor patio). KeyRolesdefiningareasofprofessionalresponsibility: 1. Designer,GeneralContractor,HomeOwnerTherearenolettersofassurance; permitisgrantedunderpurviewofthebuildinginspector(intheCityofVancouver thisissometimesreferredtoasafieldreviewpermit). 2. SpecialtyStructuralEngineerContractmaybewiththeOwner,GeneralContractor, OrSupplier;musttakeresponsibilityforthespecialtyitemaswellastheeffecton thebasebuilding. 3. BuildingInspectorRepresentsAuthorityHavingJurisdiction;willconductfield reviewstoensurepermitandbuildingcodecompliance;willrequestengineeringon variouscomponentsasheseesfitduringthecourseofhisinspections. KeyInteractionsduringthecourseofconstruction: Version1.0May3,2013 2013APEGBC.Allrightsreserved. 15

1. TheguardassemblywillbeinstalledbytheOwnerdirectlyorbyacontractor. 2. Oncecompleteandpriortograntingoccupancy(i.e.closingthepermit)thebuilding inspectormayrequestlettersofassurance.Theremaybeanumberofcomponents thatwillrequirelettersofassurancesuchasengineeredwoodproducts(e.g.truss joistglulamheader)orguards. 3. TheSpecialtyEngineershouldsubmitLettersofAssuranceincludingScheduleBand CB.TheselettersaredifferentfromtheScheduleSbecausetheywillrequirethat theengineertakeresponsibilityfortheconnectiontothebasebuildingandthe effectonthebasebuilding.TheLettersofAssurancewillbeaddressedtothe buildinginspector. 4. TheSpecialtyEngineershouldtakespecialprecautionsinaccuratelydefininghis scopeofresponsibilityashewilllikelybetheonlyprofessionalengineerinthe project.

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

16

APPENDIXDMODELSPECIFICATIONFORGUARDS Thefollowingisintendedtobeanexampleofaspecificationthatmightbeusedto definetherequirementsforaguardassembly.

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

17

DIVISION 10 - SPECIALTIES [PROJECT NAME] [PROJECT #]

Section 10 22 30 GUARD AND HAND RAILS Page 18

1.0 1.1

GENERAL WORKINCLUDED

1.1.1 Guards,guardrailsandhandrailsindicatedonthedrawings. 1.1.2 Glassinfillpanels. 1.2 1.2RELATEDWORK 1.2.1 Section09900FinishPainting 1.2.2 Section08800Glass 1.3 1.3REFERENCESTANDARDS(Mostrecentversionunlessnotedotherwise) 1.3.1 CAN/CSAS16.1,LimitStatesDesignofSteelStructures. 1.3.2 CAN/CSAS157,LimitStatesDesignofAluminumStructures. 1.3.3 CAN/CSAO86.1,LimitStatesDesignofWoodStructures. 1.3.4 CAN/CGSB12.20,StructuralDesignofGlassforBuildings. 1.3.5 CAN/CGSB12.1,Glass,Safety,TemperedorLaminated. 1.3.6 AmericanArchitecturalManufacturersAssociation. 1.3.7 ASTM A269, Specification for Seamless and Welded Austenitic Stainless Steel Tubing for GeneralService. 1.3.8 CAN/CSAG40.20/G40.21,GeneralRequirementsforRolledorWeldedStructuralQuality Steel. 1.3.9 CAN/CSAG164,HotDipGalvanizingforIrregularlyShapedArticles. 1.3.10 CSAW59,WeldedSteelConstruction(MetalArcWelding). 1.3.11 CSAW59.2,WeldedAluminum. 1.4 DESIGNCRITERIA 1.4.1 Loads and load factors are determined in accordance with the National Building Code and the bylaws of the local municipality. Resistances must be determined by the applicablematerialdesignstandards. <Spec note: Is loading for egress from assembly areas required? If so there can be significant loads transmitted to the base structure. This should be coordinated with the basebuildingstructuralengineer.> 1.5 SUBMITTALS 1.5.1 If requested, submit three (3) certified copies of mill reports covering chemical and mechanicalproperties,andcoatingdesignationofsteelusedinthiswork. 1.5.2 SubmitsamplesofframingandfastenercomponentstoConsultantifrequested. Version1.0May3,2013 2013APEGBC.Allrightsreserved. 18

DIVISION 10 - SPECIALTIES [PROJECT NAME] [PROJECT #]

Section 10 22 30 GUARD AND HAND RAILS Page 19

1.5.3 SubmitduplicatesamplesofjoiningandfinishestotheConsultantforapproval. 1.5.4 ProductData .1 Submit product data for mechanical fasteners, indicating sizes, shear, and pullover loading capacity where applicable. Provide data indicating thickness and type of corrosionprotectioncoating. Submit product data indicating suitability of explosive powder actuated fasteners for application.

.2

1.5.5 ShopDrawings .1 Shopdrawingsmustincorporateplans,allelevations,sectionsandfullsizedetailsforall work in this section. Completely detail items indicating all dimensions and methods of fixing, field jointing, attachment to building structure, size, thickness, gauges of metals andfastenersinaccordancewithAPEGBCGuidelineForShopDrawingPreparation. No work must be fabricated until the shop drawings and samples have been reviewed by the Consultant. The Consultants review must be for conformity to the design concept, for general arrangement only and such review must not relieve the Contractor ofanyoftheirresponsibilities. ShopdrawingsmustbesealedbyaProfessionalEngineer. TheEngineerwhosealedtheshopdrawingsmustprovideperiodicfieldreview.Written inspectionreportsoffieldreviewmustbesubmittedtotheConsultantpromptlyasfield reviewsaremade.

.2

.3 .4

1.5.6 SubmitevidenceofwelderqualificationsspecifiedinthisSection. 1.5.7 MaintenanceData: .1 .2 Submitdatacoveringthecare,cleaningandmaintenanceoffinishesforincorporationin maintenancemanuals. Letters of Assurance: The Engineer who sealed the shop drawings must submit to the Consultantwiththeinitialshopdrawingsubmission,anAssuranceofStructuralDesign andcommitmentforFieldReview. QUALITYASSURANCE

1.6

1.6.1 Contractor to provide proof of manufacturer training for installation of proprietary fastenersystems. 1.6.2 Welding must be by company certified by the Canadian Welding Bureau to CSAW47.192,CertificationofCompaniesforFusionWeldingofSteelStructures. Version1.0May3,2013 2013APEGBC.Allrightsreserved. 19

DIVISION 10 - SPECIALTIES [PROJECT NAME] [PROJECT #]

Section 10 22 30 GUARD AND HAND RAILS Page 20

1.6.3 Any glazed elements should be completed by Journeymen glaziers and be members in goodstandingwiththeprovincialglazingcontractorsassociation. 1.7 DELIVERY,STORAGEANDHANDLING

1.7.1 Exercise care in storing, handing and erecting all material and support all materials properly at all times so that no piece will be bent, twisted or otherwise damaged structurallyorvisually. 1.7.2 Correct damaged material and where damaged is deemed irreparable by the Consultant,replacetheaffecteditematnoadditionalexpensetotheOwner. 1.7.3 Fabricate large assemblies so they can be safely and easily handled to their place of installation. 1.8 MOCKUPGUARDANDHANDRAILS <Specnote:Deleteifnotrequired.> 1.8.1 Provide a complete mockup of a guardrail and or handrail on site for review by the Consultant.MakerevisionstomockupasrequiredbytheConsultant. 1.8.2 Mockup must include all components of the system, including typical joints and connectionhardware,andtypicaltieinstoadjoiningsystems,allfinishedasspecified. 1.8.3 Modify the mockup at no additional cost to the contract as may be required to meet designandperformancerequirements. 1.8.4 Mockup, if deemed to be in general conformance with the Specifications and Drawings bytheConsultant,mustremainonsiteasfinishedpartofthework. 1.9 SITECONDITIONS

1.9.1 Ensure temperature and ventilation conditions are maintained for various components andmaterialsofthesystem,asrequiredbymanufacturer. 1.9.2 Protect work of other sections and subtrades from damage resulting from work of this section. 1.9.3 Takenecessarycaretoavoiddamageofadjacentsurfaces. 1.9.4 Examinetheunderlyingvisiblesurfacesandadjoiningworkandreportdefectsattimeof installation,whichmightimpairtheworkofthissectiontotheConsultant,inwriting. 1.9.5 Commencementofworkmustimplyacceptanceofsurfaces. 1.9.6 Cooperatewithothertradestoaccommodatefixturesandattachmentsinthesystem. Version1.0May3,2013 2013APEGBC.Allrightsreserved. 20

DIVISION 10 - SPECIALTIES [PROJECT NAME] [PROJECT #]

Section 10 22 30 GUARD AND HAND RAILS Page 21

1.10

REVIEW

1.10.1 TheDesignEngineer,responsiblefortheproductionoftheshopdrawings,mustprovide periodicfieldreviewduringconstructionandmustsubmitreports. 1.10.2 Additional inspection and testing of materials workmanship may be carried out by a qualifiedindependentInspectionAgencyappointedbytheConsultant. .1 .2 ThecostofthisadditionalinspectionmustbepaidbytheOwner. Any testing or inspection required by the Consultant because of an error by the Contractor or due to departure from the contract documents by the Contractor, must bepaidforbytheContractor.

1.10.3 Reviewmustinclude .1 .2 .3 .4 .5 .6 .7 .8 .9 .10 Checkingthatmilltestreportsareproperlycorrelatedtomaterials. Sampling fabrication and erection procedures for general conformity to the requirementsofthespecification. Checkingthattheweldingconformstotherequirementsofthisspecification. Checkingfabricatedmembersagainstspecifiedmembershapes. Visual inspection of all welded connections including sample checking of joint preparationandfitup. Samplecheckingofscrewedandboltedjoints. Samplecheckingthattolerancesarenotexceededduringfituporerection. AdditionalinspectionandtestingofweldedconnectionsasrequiredbyCSAW59. GeneralInspectionoffieldcuttingandalternationsrequiredbyothertrades. Submission of reports to the Consultant, the Contractor, and the authorities having jurisdictioncoveringtheworkinspectedwithdetailsofdeficienciesdiscovered.

1.10.4 The Contractor must provide the necessary cooperation to insure that the review can proceed. 1.10.5 The review provided in this section does not relieve the Contractor of their responsibility for the performance of the contract. The Contractor is solely responsible for quality control and must implement their own supervisory and quality control procedures. 1.10.6 Materials or workmanship not conforming to the requirements of the contract Version1.0May3,2013 2013APEGBC.Allrightsreserved. 21

DIVISION 10 - SPECIALTIES [PROJECT NAME] [PROJECT #]

Section 10 22 30 GUARD AND HAND RAILS Page 22

documentsmayberejectedatanytimeduringtheprogressorwork.

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

22

DIVISION 10 - SPECIALTIES [PROJECT NAME] [PROJECT #]

Section 10 22 30 GUARD AND HAND RAILS Page 23

2. 2.1

PRODUCTS MATERIALS <Spec note: Specify materials in this section or refer to appropriate Section, i.e. 05500 MetalFabricationsor08800GlassandGlazing>.

2.2

ANCHORINGANDCONNECTION <Spec note: Specify connectors in this section (proprietary connectors, inserts, screws, welding)orrefertoappropriateSection,i.e.05500MetalFabricationor08800Glassand glazing.

2.3

FINISHES <Spec note: Specify finishes in this section (galvanized, chromium plated, or painted steel)ortoappropriateSection,i.e.Section09900Finishes)

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

23

DIVISION 10 - SPECIALTIES [PROJECT NAME] [PROJECT #]

Section 10 22 30 GUARD AND HAND RAILS Page 24

3. 3.1

EXECUTION GENERAL

3.1.1. Fabricationanderectionmustconformtotheshopdrawings.Modificationsrequiredto accommodate asbuilt conditions, other than minor dimensional changes, must be submittedforapproval. 3.2 PREPARATION

3.2.1 Prior to start of erection, examine the work of the other sections upon which the work ofthissectiondependsandreporttoConsultantanyunsatisfactoryconditions. 3.2.2 Examine and obtain all necessary measurements of previously executed work that may affecttheworktothisDivision. 3.3 ERECTION <Specnote:Addspecificinstallation/erectionrequirementshere,orrefertoappropriate Section>. 3.4 TOUCHUPANDCLEANING

3.4.1 Touchup rivets, field welds, bolts and burnt or scratched surfaces after completion of erection using primer for primed components and zincrich paint for galvanized componentstomatchoriginalfinish. 3.4.2 Touchupdamagedfinishes. ENDOFSECTION

Version1.0May3,2013 2013APEGBC.Allrightsreserved.

24

Vous aimerez peut-être aussi

- Dynamic Design For AnchorsDocument44 pagesDynamic Design For AnchorshoustonhimselfPas encore d'évaluation

- Certex - Product - Catalogue - Technical Section - Guides - Safe Use - Operating Instructions EtcDocument82 pagesCertex - Product - Catalogue - Technical Section - Guides - Safe Use - Operating Instructions EtcAmirPas encore d'évaluation

- CRL Srs Standoff Railing System: CRL Glass Rail Standoff Fittings Rs0B20 W/ Rectangular Back PlateDocument8 pagesCRL Srs Standoff Railing System: CRL Glass Rail Standoff Fittings Rs0B20 W/ Rectangular Back PlateHanmant OulkarPas encore d'évaluation

- AESA Catalogue LV 05-05 PDFDocument105 pagesAESA Catalogue LV 05-05 PDFtroyel9950% (2)

- SpliceDocument17 pagesSpliceSh MNPas encore d'évaluation

- Detailing StandardsDocument31 pagesDetailing StandardsJovito EdillonPas encore d'évaluation

- E Hconsulting CC: Civil and Structural DesignDocument4 pagesE Hconsulting CC: Civil and Structural DesignGaurav MalyaPas encore d'évaluation

- Astm GlazingDocument11 pagesAstm GlazingArturoGrizPas encore d'évaluation

- Snow Loads For Building - NBCC 2015: 1. Design Conditions and GeometriesDocument9 pagesSnow Loads For Building - NBCC 2015: 1. Design Conditions and GeometriesB100% (1)

- Basic Handrail Calcs..Document7 pagesBasic Handrail Calcs..bclarkeoobPas encore d'évaluation

- Roofing Binder EN PDFDocument285 pagesRoofing Binder EN PDFyuhimePas encore d'évaluation

- UFGS Metal Building SystemsDocument45 pagesUFGS Metal Building SystemsMayyouPas encore d'évaluation

- 2 Concept of Limit State DesignDocument3 pages2 Concept of Limit State DesignVinoth KumarPas encore d'évaluation

- Fortress Timber & Metal SDS Screws 2017 WebDocument36 pagesFortress Timber & Metal SDS Screws 2017 WebGabriel MacedoPas encore d'évaluation

- Garages Stubbie InstallDocument16 pagesGarages Stubbie InstallMattPas encore d'évaluation

- 2 - Modeling API IntroductionDocument47 pages2 - Modeling API IntroductionHoang Le KtbffhPas encore d'évaluation

- Some Info On TrussesDocument9 pagesSome Info On TrussesameensderajPas encore d'évaluation

- 4870 Future Tower III - H.O. To Serv.Document200 pages4870 Future Tower III - H.O. To Serv.Francis BautistaPas encore d'évaluation

- Nfrc100a 2010Document49 pagesNfrc100a 2010Amy ShepardPas encore d'évaluation

- Sfd-Csa-S16-14-60-117 Parte IiDocument58 pagesSfd-Csa-S16-14-60-117 Parte Iiedilberto lopezPas encore d'évaluation

- Star Building Systems - 2 - 1Document27 pagesStar Building Systems - 2 - 1NiranjanAryanPas encore d'évaluation

- Anchor Calculation - Case 2Document10 pagesAnchor Calculation - Case 2MdShahbazAhmedPas encore d'évaluation

- Pennar Purlins SectionsDocument4 pagesPennar Purlins Sectionsmyusuf123Pas encore d'évaluation

- Extended LECTUREDocument21 pagesExtended LECTUREbaraka100% (1)

- Aluminum CladdingDocument21 pagesAluminum CladdingLouie Jazper Jho MolinaPas encore d'évaluation

- Hilti Bolt Design For CanadaDocument120 pagesHilti Bolt Design For Canadadeepteck00Pas encore d'évaluation

- Advenser BIM Cad Services ProfileDocument22 pagesAdvenser BIM Cad Services Profilewebmaster9108Pas encore d'évaluation

- 2.0 CriticalSteelRatio ISO2394 C40 50Document4 pages2.0 CriticalSteelRatio ISO2394 C40 50klynchelle100% (1)

- CVEN3302 Structural Design CVEN3302 Structural DesignDocument404 pagesCVEN3302 Structural Design CVEN3302 Structural Designroy jackPas encore d'évaluation

- ColdSteel Manual V120Document87 pagesColdSteel Manual V120Terry CheukPas encore d'évaluation

- DESIGN CALCULATIONS - GL-03 13940 - 4.0m-R2Document16 pagesDESIGN CALCULATIONS - GL-03 13940 - 4.0m-R2msiddiq1Pas encore d'évaluation

- AESS - Steel StructureDocument56 pagesAESS - Steel Structurevirginia_aureliaPas encore d'évaluation

- Steel Members DesignDocument195 pagesSteel Members DesignStephen JamesPas encore d'évaluation

- Branz Advisory Trower PartitionsDocument6 pagesBranz Advisory Trower PartitionsMatt Stubbins100% (1)

- Temporary StructuresDocument65 pagesTemporary StructuresnisfibolahenkPas encore d'évaluation

- 17-10-23 Inhabit - Presentation Glass MakassarDocument41 pages17-10-23 Inhabit - Presentation Glass MakassarBINAZIRPas encore d'évaluation

- Blast Resistant Design of Steel StructuresDocument116 pagesBlast Resistant Design of Steel StructuresPetr KonupčíkPas encore d'évaluation

- Technical Calculation E1 UAL TowerDocument48 pagesTechnical Calculation E1 UAL TowermcbluedPas encore d'évaluation

- Angle Design AISC - CantileverDocument5 pagesAngle Design AISC - CantileverRajveer SinghPas encore d'évaluation

- BS5950-1:2000 - A Designer's Practical ViewDocument8 pagesBS5950-1:2000 - A Designer's Practical Viewmarianuid100% (1)

- Glass Aluminum Stainless Steel 2011Document36 pagesGlass Aluminum Stainless Steel 2011y2kareinPas encore d'évaluation

- Modeling Custom Shapes in STAAD PRODocument4 pagesModeling Custom Shapes in STAAD PROKiran KoraddiPas encore d'évaluation

- Unistrut CatalogDocument12 pagesUnistrut CatalogElia Nugraha AdiPas encore d'évaluation

- Astm E1300 16Document14 pagesAstm E1300 16AmulyaRajbharPas encore d'évaluation

- Civil Deisgn Report 620118389Document27 pagesCivil Deisgn Report 620118389Tajay BillingsPas encore d'évaluation

- Design and Analysis of Pre Engineered inDocument4 pagesDesign and Analysis of Pre Engineered inAnkur DubeyPas encore d'évaluation

- Flexible Moment Connections For Unbraced FramesDocument18 pagesFlexible Moment Connections For Unbraced FramesLAM COPas encore d'évaluation

- Hilti Manual For Bolt 1Document63 pagesHilti Manual For Bolt 1csengineer2Pas encore d'évaluation

- bALUMcvEMnJWIIl0GnYUGiNDcCw5RhPTIqDktZO6coSKW5Kthy PDFDocument8 pagesbALUMcvEMnJWIIl0GnYUGiNDcCw5RhPTIqDktZO6coSKW5Kthy PDFSudharsana PrayogaPas encore d'évaluation

- Analysis & Design of Innovative Industrial Roof: Arpita Nikam, Priyanka JoshilkarDocument9 pagesAnalysis & Design of Innovative Industrial Roof: Arpita Nikam, Priyanka Joshilkardino mohammedPas encore d'évaluation

- Wind Load-Components and Cladding ExampleDocument2 pagesWind Load-Components and Cladding ExampleMallesh NenkatPas encore d'évaluation

- Bottom LugDocument7 pagesBottom LugAjiri IvoviPas encore d'évaluation

- Egyptian Code For Tall BuildingsDocument60 pagesEgyptian Code For Tall BuildingshefnawyhbrcPas encore d'évaluation

- APEGBC-Designing Guards For Buildings PDFDocument26 pagesAPEGBC-Designing Guards For Buildings PDFhahaerPas encore d'évaluation

- Udlp-Tacom Welding Code, Almn (Ansi-Aws d1.2)Document120 pagesUdlp-Tacom Welding Code, Almn (Ansi-Aws d1.2)mtcengineering100% (2)

- Chapter 4: Design ConsiderationsDocument34 pagesChapter 4: Design ConsiderationsAnonymous b9fkTYfEoRPas encore d'évaluation

- Riser Guide E-Mar18Document129 pagesRiser Guide E-Mar18Luciano RezendePas encore d'évaluation

- Movable BridgeDocument263 pagesMovable BridgeCharbel Ghanem100% (1)

- Cigre 204Document17 pagesCigre 204edwinoria100% (2)

- Fac RuleDocument240 pagesFac RulematheusPas encore d'évaluation

- Rebar WeldDocument1 pageRebar WeldRomoex R RockPas encore d'évaluation

- Steel StructuresDocument1 pageSteel StructuresrongerabbitPas encore d'évaluation

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- Etabs Steel DesignDocument60 pagesEtabs Steel DesignChayanon Hansapinyo100% (2)

- Building and Construction MaterialsDocument121 pagesBuilding and Construction Materialskatalin21b100% (5)

- Strut & Tie ModelDocument67 pagesStrut & Tie Modelahmed adel100% (9)

- Eccentrically Braced FramesDocument8 pagesEccentrically Braced FramesrongerabbitPas encore d'évaluation

- A Model For The Post-Bachelor S Degree Education of Structural Engineers ASEE 2011 Paper VMar10 2011Document10 pagesA Model For The Post-Bachelor S Degree Education of Structural Engineers ASEE 2011 Paper VMar10 2011rongerabbitPas encore d'évaluation

- Trails and Cycling Map34816Document1 pageTrails and Cycling Map34816rongerabbitPas encore d'évaluation

- Green Building ProfileDocument15 pagesGreen Building ProfilerongerabbitPas encore d'évaluation

- User Manual 5E EMEA.889Document8 pagesUser Manual 5E EMEA.889SemaccaLHPas encore d'évaluation

- #142 Two-Stage Ejecting Structure - Technical Tutorial - MISUMIDocument2 pages#142 Two-Stage Ejecting Structure - Technical Tutorial - MISUMIgaliskribdPas encore d'évaluation

- Thickness: Sheets 1-6 MM, Plates 8-150 MM Dimension: 1020 X 2020 MM, 1270 X 2520 MM, 1520 X 3020 MM, or As RequestedDocument1 pageThickness: Sheets 1-6 MM, Plates 8-150 MM Dimension: 1020 X 2020 MM, 1270 X 2520 MM, 1520 X 3020 MM, or As RequestedmanulalsPas encore d'évaluation

- DOT VessalsDocument6 pagesDOT VessalsFrancisco AllendesPas encore d'évaluation

- Proposed Apartment Development in Kizingo: CorporationDocument10 pagesProposed Apartment Development in Kizingo: Corporationmusiomi2005Pas encore d'évaluation

- Ultratech TDS Leaflet - FixoblockDocument1 pageUltratech TDS Leaflet - FixoblockRabish APas encore d'évaluation

- Pre-Fabricated ConcreteDocument41 pagesPre-Fabricated ConcreteRoy Benedict BautistaPas encore d'évaluation

- XE360 EquivalenciasDocument11 pagesXE360 EquivalenciasDANIEL DIAZPas encore d'évaluation

- NIOP Trading Rules Book V 2013Document154 pagesNIOP Trading Rules Book V 2013Marito Morán CoelloPas encore d'évaluation

- Ficha Tecnica Gruas TabascoDocument18 pagesFicha Tecnica Gruas TabascoGarrido ChimPas encore d'évaluation

- Studi Kasus SCMDocument8 pagesStudi Kasus SCMMuflihul Khair0% (5)

- Air Cargo SecurityDocument49 pagesAir Cargo SecurityYudi AgustonoPas encore d'évaluation

- Analysis of Rates (AirfieldWorks)Document9 pagesAnalysis of Rates (AirfieldWorks)ကိုနေဝင်း88% (16)

- Vendor Managed InventoryDocument8 pagesVendor Managed InventoryPatrick Kok0% (1)

- OKI Land Range Transportation Plan 2030Document485 pagesOKI Land Range Transportation Plan 2030OKIRPFPas encore d'évaluation

- t90 9750enDocument7 pagest90 9750enMatyoJPas encore d'évaluation

- NDT Weld Visual Inspection ProcedureDocument4 pagesNDT Weld Visual Inspection ProcedureAvneet MaanPas encore d'évaluation

- BS 1494-1Document29 pagesBS 1494-1damirjohnPas encore d'évaluation

- Viega G3 INT K 2013Document26 pagesViega G3 INT K 2013ricochetoPas encore d'évaluation

- Rod Ends For The Food IndustryDocument4 pagesRod Ends For The Food IndustrycchnkvPas encore d'évaluation

- Airbus Family CCQMMF JOEB Report (120304)Document36 pagesAirbus Family CCQMMF JOEB Report (120304)pedatiPas encore d'évaluation

- Eurotech 735 Lathes SeriesDocument7 pagesEurotech 735 Lathes SeriesCNC SYSTEMSPas encore d'évaluation

- Insurance Service PPT MbaDocument23 pagesInsurance Service PPT MbaBabasab Patil (Karrisatte)100% (3)

- Pia Policy ProjectDocument118 pagesPia Policy ProjectRude RanaPas encore d'évaluation

- Ji MMMMMMMMMMDocument6 pagesJi MMMMMMMMMMGeorgian GradeaPas encore d'évaluation

- 2012 Interpretation of Regulations: Acceptable Methods of Achieving Compliance With Applicable Building Codes and RegulationsDocument367 pages2012 Interpretation of Regulations: Acceptable Methods of Achieving Compliance With Applicable Building Codes and RegulationsdreifersPas encore d'évaluation

- DL Sp3000uDocument788 pagesDL Sp3000uhusamwwePas encore d'évaluation