Académique Documents

Professionnel Documents

Culture Documents

30-09 Oko Finall

Transféré par

ZoebairDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

30-09 Oko Finall

Transféré par

ZoebairDroits d'auteur :

Formats disponibles

53

Design of hoppers using spreadsheet

C.O.C. Oo, E.O. DIvmuoovv, I.S. AIInov

Department of Mechanical Engineering, Faculty of Engineering, University of Port Harcourt,

Port Harcourt, Nigeria

Abstract

Oo C.O.C., Divruoovv E.O., Aiiov I.S., 2010. Design of hoppers using spreadsheet. Res. Agr. Eng., 56: 5358.

Tis paper presents a spreadsheet add-in for the design of mass ow conical and wedge hoppers. Te Jenikes hopper

design charts for mass ow were curve tted. Te relationships obtained were used together with other relevant expres-

sions to develop an add-in tool for the determination of the pertinent hopper design parameters (exit size, mass ow

rate, semi-included angle, ow factor, and critical applied stress) in the Microsoft Excel environment. Te add-in was

tested with experimental data, and results obtained were in agreement with those obtained in the literature.

Keywords: hopper design, curve tting, Jenikes hopper design charts, MS Excel add-in

Res. Agr. Eng. Vol. 56, 2010, No. 2: 5358

Te need for eective handling of large quantity

and variety of food materials produced industrially in

powdered form necessitated the introduction of hop-

pers for material handling. Te complexity surround-

ing hopper design is mostly due to the material ow

ability, which depends principally on the mechanical

behaviour of the stored material, semi-included an-

gle, ow factor and the critical applied stress.

Powder properties signicantly aect powder

behaviour during storage, handling and process-

ing (Pvivo 1978, Rnoovs 1990, Koi:o 1994,

S:si, Moivo 2004). Terefore, powder ow

property measurement is very important in han-

dling and processing operations, such as ow from

hoppers, transportation, mixing, compression, and

packaging. Jviv (1994) identied the properties

that aect material ow in storage vessels and their

measurement techniques. He also applied measured

property data to two-dimensional stress analysis to

develop charts and a mathematical model for de-

termining the minimum hopper angle and hopper

opening exit size for material ow from conical and

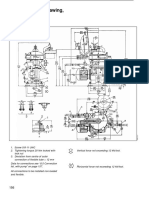

wedge-shaped hoppers (Fig. 1). Te geometrical

characteristics of the hopper aect the rate of ow of

the material out of the hopper (Bioo:vv, Sco::

1983, Gvirri:n 1991, Hoioicn 2002, Fi:zv:vic

et al. 2004). Jviv and Jonso (1969) explained

the various ways that grains might move during

emptying, and the ow patterns that are developed.

Te Jenikes hopper design methodology in-

volves: the experimental determination of the wall

friction angle and eective angle of internal fric-

tion, the determination of the semi-included angle

and ow factor (from the already known wall fric-

tion angle), and the eective angle of internal fric-

tion with the aid of the Jenikes charts, which cor-

relates the semi-included angle (), ow factor ( ),

wall friction angle (

w

) and the eective angle of in-

ternal friction () as illustrated in Fig. 2, where the

light dashed lines illustrate how to obtain the per-

tinent parameters (Gvovov 2001), the determina-

tion of the critical applied stress from a plot of the

mass ow function (MFF) and inverse of the ow

factor ( ), MFF = 1i (Fig. 3), and the calculation

of the minimum hopper angle and hopper exit size

(Gvovov 2001, Fi:zv:vic et al. 2004). Te main

shortcoming of the Jenikes hopper design proce-

dure is that parameter determination with the aid

of the Jenikes charts and the graphs of MFF = 1i is

always error prone, tedious and time consuming.

54

Vol. 56, 2010, No. 2: 5358 Res. Agr. Eng.

Te trend in contemporary engineering prac-

tice is the application of computer technology to

design processes that have well established proce-

dure such as the Jenikes hopper design procedure.

Spreadsheet solution of such design problems is

relatively simple and straightforward, especially

when the solution algorithm can be appended to

the spreadsheet. Te MS Excel environment allows

the appendage of computer programmes written in

Visual Basic for Applications (VBA), called MS Ex-

cel add-in tools (Livorv 2000).

Te purpose of this paper is, therefore, to design

the conical and wedge hoppers more eciently and

automatically by replacing the Jenikes charts with al-

gebraic polynomials, and applying relevant relation-

ships, including the Lagrange interpolation scheme,

to determine the relevant design parameters using

the MS Excel spreadsheet with an add-in.

MATERIAL AND METHODS

Te MS Excel curve tting tool is a popular tool

for automatic curve tting by computer (Livorv

2000, Mus:r 2000). It was used to curve t the

Jenikes charts. Te correlations for the semi-in-

cluded angle (

i

) and ow factor (

i

) as functions

of the wall friction angle (

w

) at specied eective

angle of internal friction (

i

) are listed in Tables 1

and 2, respectively.

d

l

(a) Conical hopper (b) Symmetrical slot or wedge hopper

w

Fig. 1. Conical and wedge hoppers showing

the semi-included angle (), diameter (d),

slot width (w), and length (l)

(a) (b)

Fig. 2. An illustration of the Jenikes hopper design chart

for the determination of the wall friction angle (

w

) and

ow factor ( )

W

a

l

l

f

r

i

c

t

i

o

n

a

n

g

l

e

,

w

(

P

a

)

F

l

o

w

f

a

c

t

o

r

,

f

f

(

-

)

Semi-included angle, (

o

)

Wall friction curves

Flow factor curves

w

ff

F

l

o

w

f

a

c

t

o

r

,

)

Semi-included angle, ()

W

a

l

l

f

r

i

c

t

i

o

n

a

n

g

l

e

,

w

(

P

a

)

Compacting stress,

c

(Pa)

acr

1/ff

MFF

U

n

c

o

n

f

i

n

e

d

y

i

e

l

d

s

t

r

e

s

s

,

a

(

P

a

)

Fig. 3. Graphical solution for the critical applied stress

(

acr

), which depends on the ow factor ( ) and mass ow

function (MFF)

Compacting stress,

c

(Pa)

U

n

c

o

n

n

e

d

y

i

e

l

d

s

t

r

e

s

s

,

a

(

P

a

)

55

Res. Agr. Eng. Vol. 56, 2010, No. 2: 5358

Te wall friction angle (

w

) and eective angle of

internal friction () are obtained experimentally. To

obtain the semi-included angle () and ow factor

( ) we substitute

w

into the correlations in Tables

1 and 2, and interpolate for and with serving

as the interpolation point. Tus, using the Lan-

grage polynomial interpolation scheme (Cnvv,

Civ 2002, Oo 2008), we get the following nu-

merical schemes for the semi-included angle and

ow factor as functions of the wall friction angle

and eective angle of internal friction:

3 3

0 0

( , )

j

w i

i j i j

j i

i

= =

=

| |

o o

|

u o o = u

|

o o

|

\ .

[

(1)

and

3 3

0 0

( , )

j

w i

i j i j

j i

i

ff ff

= =

=

| |

o o

|

o o =

|

o o

|

\ .

[

(2)

Experimentally, one obtains the unconned yield

stresses or applied stresses (

ai

) that correspond to

some compacting stresses (

ci

), where i = 0, 1, , n1

are the numbers of experiments conducted. Te

critical applied stress, which corresponds to the

unconned yield stress at the point of the intersec-

tion of the MFF and 1i curves (Fig. 3), is deter-

mined by the following expression:

ai

=

ai

ci

ff

; i = 0, 1,,n1 (3)

where:

ai

dierence between MFF and 1i at the data points,

the point at which

a

= 0 yields the desired crit-

ical applied stress,

c

=

ci

By using the Lagrange polynomial interpolation as

follows:

o

c

(

a

= 0) =

1 1

0 0

( )

n n

aj

ci

i j ai aj

j i

i

= =

=

| |

Ao

|

o

|

Ao Ao

|

\ .

[

(4)

Table 1. Semi-included angle as function of wall friction angle

Hopper type i Correlation (

i

[]) at

i

(

o

) R

2

Conical

0 0.0331

w

2

0.6781

w

+ 52.663 30 0.9981

1 0.0122

w

2

0.9024

w

+

47.814 40 0.9990

2 0.0027

w

2

1.0962

w

+ 46.10 50 0.9975

3 0.0033

w

2

0.9695

w

+ 43.343 60 0.9996

Wedge

0 0.0023

w

2

1.5646

w

+ 64.68 30 0.9997

1 0.0005

w

2

1.4802

w

+ 63.414 40 0.9996

2 0.0004

w

2

1.3416

w

+ 59.643 50 0.9998

3 0.00003

w

2

1.2155

w

+ 56.767 60 0.9997

Table 2. Flow factor as function of wall friction angle

Hopper type i Correlation (

i

[]) at

i

() R

2

Conical

0 0.00031

w

2

0.0065

w

+ 2.0707 30 0.9960

1 0.0001

w

2

0.005

w

+ 1.6251 40 0.9984

2 0.0004

w

2

0.0065

w

+ 1.4573 50 0.9975

3 0.00003

w

2

0.0056

w

+ 1.3474 60 0.9989

Wedge

0 0.00009

w

2

0.0059

w

+ 2.0648 30 0.9984

1 0.002

w

2

0.0112

w

+ 1.6083 40 0.9871

2 0.000002

w

3

+ 0.0002

w

2

0.009

w

+1.3027 50 0.9878

3 0.000003

w

3

+ 0.0003

w

2

0.0104

w

+1.2058 60 0.9938

56

Vol. 56, 2010, No. 2: 5358 Res. Agr. Eng.

we obtain the critical applied stress (

acr

):

( 0)

c a

acr

ff

(5)

Te outlet dimension (diameter [d] for conical hop-

per and width [w] for wedge hopper) depends upon

the semi-included angle ( []), material bulk density

( [kgim

3

]), critical applied stress (

acr

[Pa]), and ac-

celeration due to gravity (g [mis

2

]): d = f

d

(, ,

acr

, g)

and w = f

w

(, ,

acr

, g). Once the outlet width of the

wedge hopper is determined, its length (l), which

is always greater than three times the outlet width

(l > 3w), is readily chosen. Te exact expressions for

the outlet diameter and width of the hoppers can be

found in Jviv (1994), Gvovov (2001) and Fi:z-

v:vic et al. (2004). Te mass ow rate ( m ) also

depends upon the semi-included angle, bulk density

and acceleration due to gravity, and is given by the

Johanson equation (Jonso 1966, Jonso,

Kivvs:vunvv 1969, Hsiu et al. 2001).

Te hopper design is carried out using the fol-

lowing algorithm:

start

input data

i. experimentally determined wall friction an-

gle and eective angle of internal friction,

ii. experimentally determined compacting

stresses and corresponding unconned

yield stresses or applied stresses,

iii. bulk density, acceleration due to gravity,

compute (using the relevant relationships for the

design parameters: , ,

acr

, d or w and l),

output data (output the design parameters):

semi-included angle, ow factor, critical ap-

plied stress, discharge hopper diameter, or

discharge hopper width and length, and exit

mass ow rate,

stop.

Following the computational algorithm pre-

sented, a computer program was developed in MS

Excel VBA environment as an add-in.

RESULTS AND DISCUSSION

Te MS Excel add-in was tested with the input

data from measurements provided by Gvovov

(2001) for the conical hopper in respect of the com-

pacting and applied shear stresses, wall friction, ef-

fective angle of internal friction and at a bulk den-

sity of the powdered material of = 1,300 (kgim

3

)

(Table 3). Te data in Table 3 for the compacting

and applied stresses and the correlations in Table 2

Table 3. Experimental data from Gvovov (2001), (Pa)

SiNo. Measurement Value

1 Shear stress internal friction

ci

ai

i = 0

i = 1

i = 2

i = 3

2,400

2,000

1,600

1,300

970

910

850

780

2 Wall friction (

w

) Normal shearstress (v) Shear stress (u)

i = 0

i = 1

2,000

3,000

689

1,030

3 Eective angle of internal friction () Rise (y) Run (x)

1,000 1,730

Table 4. Conical hopper design parameters

SiNo. Quantity Units

Value

Excel add-in Gvovov (2001)

1 semi-included angle 27.83 28.000

2 ow Factor 1.83529 1.840

3 critical applied stress (

acr

) Pa 836.9751 830.000

4 discharge diameter of hopper m 0.16175 0.161

5 exit mass ow rate from hopper kgis 23.85734 23.86

57

Res. Agr. Eng. Vol. 56, 2010, No. 2: 5358

are used to obtain the critical applied stress. Te

data for the wall friction in Table 3 are curve t-

ted, and the slope of the resulting curve is used

to determine the angle of wall friction (

w

) where

tan / /

w

dv du v u d = , and the data for the ef-

fective angle of internal friction are similarly used

to determine the eective angle of internal friction

() where tan / / dy dx y x d = .

Te design parameters for the conical hopper

that the MS Excel add-in produced are tabulated

in Table 4 along with those obtained by Gvovov

(2001), using the same input data. It is seen that the

largest percentage relative error of 0.84 occurred

in the computed value for the critical applied stress

(

acr

). Tis, granted that the results by Gvovov

(2001) are error free, may be attributed to roundo

errors in the computational process. But this error

is quite acceptable for hopper applications. Table 5

shows the design parameters for the wedge hopper

based on the same input data used for the conical

hopper. Here, direct comparison cannot be made

as Gvovov (2001) did not consider the wedge hop-

per. However, one observes that all the parameters

increased except the equivalent discharge diameter

(d

e

= 0.121 m) and the mass ow rate of the wedge

hopper, which are less than those of the conical

hopper. Terefore, the results obtained conrm

that the replacement of the Jenikes chart by alge-

braic correlations aids in computerizing the hopper

design process, which is the trend in contemporary

engineering practice.

CONCLUSION

Tis work has eliminated the manual application

of the Jenikes hopper design charts for mass ow

as well as the graphical determination of the critical

applied stress. Algebraic polynomial correlations

have been generated to replace the Jenikes hopper

design charts, and a numerical scheme is used to

determine the critical applied stress. A spreadsheet

add-in tool in MS Excel environment has been de-

veloped for the automatic design of the conical and

wedge hoppers based on the Jenikes hopper design

scheme. Apart from the stand-alone application of

this spreadsheet add-in tool, it can also be integrat-

ed into a larger plant design software for improved

productivity. Of course, the add-in is also a veri-

table tool for the eective teaching of engineering

students how to design hoppers.

Ref erences

Bvioo:vv B.N., Sco:: H.C., 1983. Static and dynamic

silo loads using FEMs. Journal of Agricultural Engineer-

ing, 3: 299308.

Cnvv S.C., Civ R.P., 2002. Numerical Methods for

Engineers. 4

th

Ed. New Delhi, Tata McGraw-Hill.

Fi:zv:vic J.J., Bvviovv S.A., IQni T., 2004. Flow

property measurement of food powders and sensitivity

of Jenikes hopper design methodology to the measured

values. Journal of Food Engineering, 61: 399405.

Gvovov G.C., 2001. Solids owability. University of Akron.

Available at: www.ecgf.uakron.eduichemifcltyichaseisol-

idsNote.PDF (accessed August 2007)

Gvirri:n M.S., 1991. Cake formation in particulate systems.

New York, VCH Publishers.

Hoioicn R., 2002. Fundamentals of particle technology.

Loughborough, Midland Information Technology and

Publishing.

Hsiu S.S., Srio J., Tsi F.H., Kuo J.T., Cnou C.S., 2001.

Velocities in moving bed lter. Powder Technology, 114:

205212.

Jviv A.W., 1994. Storage and ow of solids. Bulletin No.

123, Engineering Experiment Station, University of Utah.

Jviv A.W., Jonso J.R., 1969. Bin loads. Journal of

Structural Division (ASCE), 94(ST4): 10111041.

Table 5. Wedge hopper design parameters

SiNo. Quantity Units Excel add-in value

1 semi-included angle 35.783

2 ow Factor 1.920

3 critical applied stress (

acr

) Pa 859.577

4 discharge width of hopper m 0.0808

5 discharge length of hopper m 0.242

6 exit mass ow rate from hopper kgis 18.886

w

58

Vol. 56, 2010, No. 2: 5358 Res. Agr. Eng.

Jonso J.R., 1966. Te use of ow-corrective inserts in

bin. Transactions of the ASME Journal of Engineering for

Industry. 88: 224230.

Jonso J.R., Kivvs:vunvv W.K., 1969. Flow corrective in-

serts in bins. Chemical Engineering Progress. 11: 7983.

Koi:o T.M., 1994. Te importance of storage, transfer

and collection. Chemical Engineering Progress, 90: 4454.

Livorv B.V., 2000. A guide to Microsoft Excel for scientist

and engineers. London, Butterworth-Heinemann.

Mus:r G., 2000. Correlations for some thermophysical

properties of air. Wageningen, NL, International Drying

Symposium.

Oo C.O.C., 2008. Engineering computational methods: an

algorithmic approach. Port Harcourt, University of Port

Harcourt Press.

Pvivo M., 1978. Flow ability of food powders and methods

for its evaluation A review. Journal of Food Process

Engineering, 1: 303328.

Rnoovs M., 1990. Principles of powder technology. New

York, John Wiley.

S:si M., Moivo M., 2004. Direct shear testing of

owability of food powders. Research in Agriculture En-

gineering, 1: 610.

Received for publication August 19, 2009

Accepted after corrections September 14, 2009

Corresponding author:

Oo C.O.C., Ph.D., University of Port Harcourt, Faculty of Engineering, Department of Mechanical Engineering,

PMB 5323 Port Harcourt, Nigeria

phone: + 234 (0) 803 553 6916, e-mail: chimaoko@yahoo.com

Vous aimerez peut-être aussi

- Credit Card Authorization Form WoffordDocument1 pageCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaPas encore d'évaluation

- Surge Protection Devices CatalogueDocument134 pagesSurge Protection Devices CatalogueNguyen Doan QuyetPas encore d'évaluation

- Cambridge: Global EnglishDocument34 pagesCambridge: Global EnglishLinh Nguyễn Thùy100% (1)

- v60 74Document7 pagesv60 74Vijaya KumarPas encore d'évaluation

- The Theoretical Partition Curve of The HydrocycloneDocument6 pagesThe Theoretical Partition Curve of The Hydrocyclonerez100% (1)

- Materials Science and Technology of Optical FabricationD'EverandMaterials Science and Technology of Optical FabricationPas encore d'évaluation

- Design of Hoppers Using Spreadsheet: Journal of Agricultural Engineering Research January 2010Document7 pagesDesign of Hoppers Using Spreadsheet: Journal of Agricultural Engineering Research January 2010ankur2061Pas encore d'évaluation

- Piaggio MP3 300 Ibrido LT MY 2010 (En)Document412 pagesPiaggio MP3 300 Ibrido LT MY 2010 (En)Manualles100% (3)

- Radmi 2009: Research and Development in Mechanical IndustryDocument6 pagesRadmi 2009: Research and Development in Mechanical IndustrySnezana VulovicPas encore d'évaluation

- Simulation of Plate With Crack Using Extended Finite Element MethodDocument4 pagesSimulation of Plate With Crack Using Extended Finite Element MethodVirender RawalPas encore d'évaluation

- Milani Lourenco Tralli 1-A Homogenization ApproachDocument38 pagesMilani Lourenco Tralli 1-A Homogenization ApproachvadalePas encore d'évaluation

- Pure Bending Analysis of Thin Rectangular Flat Plates Using Ordinary Finite Difference MethodDocument4 pagesPure Bending Analysis of Thin Rectangular Flat Plates Using Ordinary Finite Difference MethodsyammohansPas encore d'évaluation

- Static Analysis of Rectangular Plate With Internal Cut-Out Using Finite Element MethodDocument6 pagesStatic Analysis of Rectangular Plate With Internal Cut-Out Using Finite Element MethodKanak_KalitaPas encore d'évaluation

- 3144Document10 pages3144Mona AwadPas encore d'évaluation

- A Method of Approximate Tool Wear Analysis in Cold Roll FormingDocument6 pagesA Method of Approximate Tool Wear Analysis in Cold Roll FormingAly MahdyPas encore d'évaluation

- 1 Tutorial Questions Mee 309Document5 pages1 Tutorial Questions Mee 309Moshood AdeleyePas encore d'évaluation

- Finite Difference Calculations of The Deformations of Multi-Diameter Workpieces During TurningDocument7 pagesFinite Difference Calculations of The Deformations of Multi-Diameter Workpieces During Turningirinuca12Pas encore d'évaluation

- Experimental and Numerical Prediction of Springback and Side Wall Curl in U-Bendings of Anisotropic Sheet MetalsDocument12 pagesExperimental and Numerical Prediction of Springback and Side Wall Curl in U-Bendings of Anisotropic Sheet MetalsHamad Ul HassanPas encore d'évaluation

- Technical AssesmentDocument7 pagesTechnical AssesmentbikramjitpodderPas encore d'évaluation

- Analytical Prediction of Interrupted Cutting Periodic Motions in A Machine ToolDocument12 pagesAnalytical Prediction of Interrupted Cutting Periodic Motions in A Machine Tooltina1augmentosPas encore d'évaluation

- A Simple Numerical Method For Biaxial Bending Moment-Curvature Relations of Reinforced Concrete Column SectionsDocument9 pagesA Simple Numerical Method For Biaxial Bending Moment-Curvature Relations of Reinforced Concrete Column SectionsthduynguyenPas encore d'évaluation

- Simplified Method To Determine Contact Stress Distribution and Stress Intensity Factors in Fretting FatigueDocument8 pagesSimplified Method To Determine Contact Stress Distribution and Stress Intensity Factors in Fretting FatigueEfrén SánchezPas encore d'évaluation

- Evaluation of Loading Methods For Determination of Material and Elastic Constants of Cement Fiber BoardDocument5 pagesEvaluation of Loading Methods For Determination of Material and Elastic Constants of Cement Fiber BoardYP XuPas encore d'évaluation

- KSSC 3 2007 7 4 297 (C)Document13 pagesKSSC 3 2007 7 4 297 (C)ismael.lorandi623Pas encore d'évaluation

- Computer Simulation of Cumulative Fatigue Damage: Facta UniversitatisDocument9 pagesComputer Simulation of Cumulative Fatigue Damage: Facta UniversitatisBilly ChrisPas encore d'évaluation

- Stress Analysis of Bell Crank LeverDocument8 pagesStress Analysis of Bell Crank LeverAnonymous kTVBUxrPas encore d'évaluation

- Bin, Hopper and Conveyor DesignDocument14 pagesBin, Hopper and Conveyor DesignBrendan JonesPas encore d'évaluation

- J Tafmec 2020 102535Document36 pagesJ Tafmec 2020 102535Kris SmaczekPas encore d'évaluation

- Design of Vertical Wall Caisson BreakwatersDocument14 pagesDesign of Vertical Wall Caisson BreakwatersHRCPas encore d'évaluation

- Double Lap Joint ReportDocument9 pagesDouble Lap Joint Report130IME19Pas encore d'évaluation

- Prop TheoryDocument32 pagesProp Theorywera2516Pas encore d'évaluation

- Strength of LugDocument8 pagesStrength of LugnareniviPas encore d'évaluation

- J5. Modeling and Numerical Simulation of Fatigue Crack Growth in Cracked Specimens Containing Material Discontinuities SOM 2016Document14 pagesJ5. Modeling and Numerical Simulation of Fatigue Crack Growth in Cracked Specimens Containing Material Discontinuities SOM 2016AzherPas encore d'évaluation

- Wa0023.Document6 pagesWa0023.Samir AndresPas encore d'évaluation

- New Extrusion Process For Producing Twist Drills Using Split DiesDocument9 pagesNew Extrusion Process For Producing Twist Drills Using Split DiesaleksandraPas encore d'évaluation

- An Improved Model For Oblique Cutting and Its Application To Chip-Control ResearchDocument7 pagesAn Improved Model For Oblique Cutting and Its Application To Chip-Control ResearchipilakyaaPas encore d'évaluation

- Discrete Crack Modeling in Concrete StructuresDocument16 pagesDiscrete Crack Modeling in Concrete StructuresjahidPas encore d'évaluation

- Machine DesignDocument8 pagesMachine DesignSirajuddin APas encore d'évaluation

- IJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchDocument8 pagesIJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchInternational Journal of computational Engineering research (IJCER)Pas encore d'évaluation

- Simpli Fied Calculation of Effective Ange Width For Shear Walls With AngeDocument20 pagesSimpli Fied Calculation of Effective Ange Width For Shear Walls With AngeAbi IlamvazhuthiPas encore d'évaluation

- Probabilistic Assessment of Fracture Mechanics of Low Pressure Turbine Disk KeywayDocument8 pagesProbabilistic Assessment of Fracture Mechanics of Low Pressure Turbine Disk KeywayManoj Paul JohnPas encore d'évaluation

- Computational Statistics and Data Analysis: Stelios D. Georgiou, Stella Stylianou, Manohar AggarwalDocument10 pagesComputational Statistics and Data Analysis: Stelios D. Georgiou, Stella Stylianou, Manohar Aggarwal-Pas encore d'évaluation

- De Vathaire 81Document10 pagesDe Vathaire 81bobPas encore d'évaluation

- (WFD Paper) 22 CMSIM 2012 Dubey Kapila 1 241-256Document16 pages(WFD Paper) 22 CMSIM 2012 Dubey Kapila 1 241-256ChandreshPas encore d'évaluation

- Reconstruction of A Fracture Process Zone During Tensile Failure of Quasi-Brittle MaterialsDocument14 pagesReconstruction of A Fracture Process Zone During Tensile Failure of Quasi-Brittle MaterialsGabriel PatrunoPas encore d'évaluation

- Fleet AngleDocument16 pagesFleet AngleMoses Frank OduoriPas encore d'évaluation

- Static Structural Analysis of Rolling Ball BearingDocument8 pagesStatic Structural Analysis of Rolling Ball BearingMuhammad UmairPas encore d'évaluation

- Fracture Behaviour of Concrete - Post Cracking Behaviour - Tension Softening DiagramDocument27 pagesFracture Behaviour of Concrete - Post Cracking Behaviour - Tension Softening DiagramPrakash NanthagopalanPas encore d'évaluation

- Anjalib - 306 - Applications of Definite IntegralsDocument6 pagesAnjalib - 306 - Applications of Definite IntegralsAnjali BPas encore d'évaluation

- CORDIC Algorithm For Sinusoidal CalculationsDocument6 pagesCORDIC Algorithm For Sinusoidal CalculationsijeteeditorPas encore d'évaluation

- 03 ER Vukelic Format PDFDocument6 pages03 ER Vukelic Format PDFavenashaPas encore d'évaluation

- M20-8 - An Estimation of The High-Pressure Pipe Residual LifeDocument9 pagesM20-8 - An Estimation of The High-Pressure Pipe Residual Lifedobrica milovanovicPas encore d'évaluation

- Stability Prediction Maps in Turning of Difficult-To-Cut MaterialsDocument9 pagesStability Prediction Maps in Turning of Difficult-To-Cut Materialssundaramaks saravana muruganPas encore d'évaluation

- Pen Rchive Oulouse Rchive Uverte : O A T A O OataoDocument14 pagesPen Rchive Oulouse Rchive Uverte : O A T A O OataoZundali FirdausPas encore d'évaluation

- Shear Strength Model of Reinforced Concrete Circular Cross-Section MembersDocument6 pagesShear Strength Model of Reinforced Concrete Circular Cross-Section Membersswathi1717Pas encore d'évaluation

- Modelling Tooth-Shape Errors Using Random Variables: Ŕ Periodica PolytechnicaDocument6 pagesModelling Tooth-Shape Errors Using Random Variables: Ŕ Periodica PolytechnicaJigar M. UpadhyayPas encore d'évaluation

- MECH3310 Mechanics of Solids 2: The University of SydneyDocument8 pagesMECH3310 Mechanics of Solids 2: The University of SydneyJim LettermanPas encore d'évaluation

- Secondary Bending Joint PDFDocument19 pagesSecondary Bending Joint PDFPhilippeWojtowiczPas encore d'évaluation

- Paper NFCDocument23 pagesPaper NFCHaris FelicPas encore d'évaluation

- Discussion of "Strain of Concrete at Peak Compressive Stress For A Wide Range of Compressive Strengths" by B.de Nicolo, L.Pani and E.PozzoDocument5 pagesDiscussion of "Strain of Concrete at Peak Compressive Stress For A Wide Range of Compressive Strengths" by B.de Nicolo, L.Pani and E.PozzoHatef SardariPas encore d'évaluation

- Calculation of The Collapse Load of An ADocument13 pagesCalculation of The Collapse Load of An ALuminita GeorgetaPas encore d'évaluation

- MECH3310 Mechanics of Solids 2: The University of SydneyDocument8 pagesMECH3310 Mechanics of Solids 2: The University of SydneyJim LettermanPas encore d'évaluation

- International Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsDocument9 pagesInternational Standard: Hydraulic Turbines, Storage Pumps and Pump-Turbines - Model Acceptance TestsZoebairPas encore d'évaluation

- Structures and Mechanisms ClassificationsDocument1 pageStructures and Mechanisms ClassificationsminakirolosPas encore d'évaluation

- Spring-Supported Thrust BearingsDocument4 pagesSpring-Supported Thrust BearingsZoebairPas encore d'évaluation

- Datasheet TurbineDocument2 pagesDatasheet TurbineZoebairPas encore d'évaluation

- Installation and Operating Procedures: Manual Grease InterceptorsDocument8 pagesInstallation and Operating Procedures: Manual Grease InterceptorsZoebairPas encore d'évaluation

- Indigenous ManufacturersDocument6 pagesIndigenous ManufacturersZoebairPas encore d'évaluation

- 8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0Document1 page8.4 Basic Size Drawing, With Pump: Alfa Laval Ref. 557913 Rev. 0ZoebairPas encore d'évaluation

- CEE 331: Fluid Mechanics, Homework Set 2, SolutionsDocument7 pagesCEE 331: Fluid Mechanics, Homework Set 2, SolutionsZoebairPas encore d'évaluation

- Hy 25 ValvesDocument3 pagesHy 25 ValvesZoebairPas encore d'évaluation

- Construction Specification 71-Water Control Gates: Instructions For UseDocument2 pagesConstruction Specification 71-Water Control Gates: Instructions For UseZoebairPas encore d'évaluation

- DAMS CFD ModellingDocument2 pagesDAMS CFD ModellingZoebairPas encore d'évaluation

- Pennsylvania: Lehigh University'Document5 pagesPennsylvania: Lehigh University'ZoebairPas encore d'évaluation

- Module 1 Supply Chain Management in Hospitality IndustryDocument39 pagesModule 1 Supply Chain Management in Hospitality IndustryHazelyn BiagPas encore d'évaluation

- Unit 7 ActivitiesDocument8 pagesUnit 7 ActivitiesleongeladoPas encore d'évaluation

- 2011 Burris CatalogDocument56 pages2011 Burris CatalogMario Lopez100% (1)

- Davis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersDocument8 pagesDavis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersAngeloPas encore d'évaluation

- 1.2 The Basic Features of Employee's Welfare Measures Are As FollowsDocument51 pages1.2 The Basic Features of Employee's Welfare Measures Are As FollowsUddipta Bharali100% (1)

- Pascal Die Casting Machine SystemDocument20 pagesPascal Die Casting Machine Systemenascimento32Pas encore d'évaluation

- Program of ActivitiesDocument2 pagesProgram of ActivitiesVon Limuel LopezPas encore d'évaluation

- 20235UGSEM2206Document2 pages20235UGSEM2206Lovepreet KaurPas encore d'évaluation

- Engineering Geology: Wei-Min Ye, Yong-Gui Chen, Bao Chen, Qiong Wang, Ju WangDocument9 pagesEngineering Geology: Wei-Min Ye, Yong-Gui Chen, Bao Chen, Qiong Wang, Ju WangmazharPas encore d'évaluation

- Swot Matrix Strengths WeaknessesDocument6 pagesSwot Matrix Strengths Weaknessestaehyung trash100% (1)

- GE Uno Downlight Backlit BLDocument2 pagesGE Uno Downlight Backlit BLChen KengloonPas encore d'évaluation

- JCPS School Safety PlanDocument14 pagesJCPS School Safety PlanDebbie HarbsmeierPas encore d'évaluation

- Human Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test BankDocument4 pagesHuman Development and Performance Throughout The Lifespan 2nd Edition Cronin Mandich Test Bankanne100% (28)

- Mediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsDocument15 pagesMediator Analysis of Job Embeddedness - Relationship Between Work-Life Balance Practices and Turnover IntentionsWitty MindsPas encore d'évaluation

- Most Dangerous City - Mainstreet/Postmedia PollDocument35 pagesMost Dangerous City - Mainstreet/Postmedia PollTessa VanderhartPas encore d'évaluation

- Capacity Analysis of Kashmir Highway IslamabadDocument71 pagesCapacity Analysis of Kashmir Highway Islamabadm saadullah khanPas encore d'évaluation

- Matsusada DC-DC ConvertersDocument4 pagesMatsusada DC-DC ConvertersAP SinghPas encore d'évaluation

- World Trends in Municipal Solid Waste ManagementDocument11 pagesWorld Trends in Municipal Solid Waste ManagementNeima EndrisPas encore d'évaluation

- Manual HobartDocument39 pagesManual HobartВолодимир БроPas encore d'évaluation

- SQL - Day 2: Structured Query LanguageDocument10 pagesSQL - Day 2: Structured Query LanguageNight KingPas encore d'évaluation

- Bamboo People - An Interdisciplinary Unit For High SchoolDocument6 pagesBamboo People - An Interdisciplinary Unit For High SchoolChipo Jean MarundaPas encore d'évaluation

- PH-01 (KD 3.1) Filling Out Forms (PG20) - GFormDocument4 pagesPH-01 (KD 3.1) Filling Out Forms (PG20) - GFormLahita AzizahPas encore d'évaluation

- 1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Document880 pages1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Mike Marquez100% (2)

- Summative Test in Foundation of Social StudiesDocument2 pagesSummative Test in Foundation of Social StudiesJane FajelPas encore d'évaluation

- Conflict Management A Practical Guide To Developing Negotiation Strategies Barbara A Budjac Corvette Full ChapterDocument67 pagesConflict Management A Practical Guide To Developing Negotiation Strategies Barbara A Budjac Corvette Full Chapternatalie.schoonmaker930100% (5)

- Application Letter For Promotion T2 T3Document24 pagesApplication Letter For Promotion T2 T3FGacadSabadoPas encore d'évaluation