Académique Documents

Professionnel Documents

Culture Documents

Anchor Supports

Transféré par

tejasp8388Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Anchor Supports

Transféré par

tejasp8388Droits d'auteur :

Formats disponibles

Issue 02.

2006

LINDE STANDARD

Anchor supports

LS 545-15

for horizontal piping non-insulated and

heat-insulated

Part 1

Linde AG

Linde Engineering

Division

Orig.: TAW-N/Schmitt

Checked: TKC/Dieckmann

Appr.: TAW-N/Gaebel

Page 1 of 7

Replaces Issue 07.2004

Dimensions in mm / Unit of quantity: piece / Technical purchase specification LS 091-1XX

Contents

1

2

3

4

5

6

7

8

Page

Scope ............................................................................1

Normative references ..................................................1

General..........................................................................1

Piping DN 15 to 40 .......................................................2

Piping DN 50 to 150 .....................................................2

Piping DN 200 to 800 ...................................................4

Bore holes in the base plate for the screwed type...6

Weights .........................................................................7

Part designation: FPW(A;B;C;D), FPZW(A;B;C;D)

1

Scope

This standard is valid for anchor supports for horizontal non-insulated and heat-insulated piping. The anchor

supports may be welded or screwed onto the connected construction. Welded and screwed types have different

part designations.

Normative references

This standard contains provisions which, through undated references in this text, constitute provisions of other

publications. The normative references are cited at the respective part in the text and the publications are listed

below. Issues valid at the time of placement of order shall govern.

ISO 2768

General tolerances; tolerances for linear and angular dimensions without individual tolerance

indications

EN ISO 4017 Hexagon head screws product grades A and B

EN ISO 4032 Hexagon nuts, style 1 product grades A and B

EN ISO 7089 Plain washers normal series, product grade A

EN 10029

Hot rolled steel plates 3 mm thick or above tolerances on dimensions, shape and mass

LS 540-10

Material groups for piping supports

LS 546-01

Pipe clamps

General

3.1 Types:

A for DN 15

B for DN 15

C for DN 15

D for DN 100

to

to

to

to

800 and pipe insulation thickness < 60

800 and pipe insulation thickness > 60 < 100

800 and pipe insulation thickness > 100 < 160

800 and pipe insulation thickness > 160 < 220

3.2 FPW(A;B;C;D) designates the welded type.

FPZW(A;B;C;D) designates the screwed type.

3.3 Designation: Part name, fastening type, type, DN, standard, material

3.4 The material group shall be selected acc. to the operating temperature of the piping as per LS 540-10,

see selection diagram.

3.5 Welding seams:

If not given in the figures, all welding seams shall be continuous fillet and/or double

fillet welds resp. with a = 3 for DN 15 to 80 and a = 4 for DN 100 to 800.

3.6 General tolerances acc. to ISO 2768- c.

3.7 The admissible forces shall be taken from LS 545-15 Part 2.

Issue 02.2006

Linde AG - Linde Engineering Division

LS 545-15 Part 1

Page 2 of 7

3.8 If a pipe is reduced and supported from the same plane (e.g. pipes on racks), the height "H"

(also for the reduced pipe) shall be selected according to the insulation thickness of the larger DN.

3.9 From DN 100 to 800, stop pieces made of material equivalent to piping material are welded to the pipe.

The material of the stop pieces is given by the material group. In some cases the material may be different

to the pipe material. Then the contractor has to change the stop pieces according to the pipe material.

Piping DN 15 to 40

Fz

1

d1

Fy

2

3

6,7,8

Fx

150

60

drill holes in the steel structure

drilled during installation and cold galvanized

assembly weld

welded

screwed

Figure 1: Anchor support DN 15 to 40

Table 1: Constructional dimensions and structural dimensions

Item

1

Quantity

2

DN Pipe Pipe Clamp

Type A

15

20

25

32

40

da

LS 546-01

d1

21,3

26,9

33,7

42,4

48,3

22

27

34

43

49

2

1

Plate

8 x h x 150

EN 10029

h

Type

A B C

3

1

Plate

EN 10029

92 132 192 8 x 60 x 150

6

7

8

4

4

4

Screw

Nut

Washer

ISO 4017 ISO 4032 ISO 7089

5.6

St

St

Hot dip galvanized

M10 x 45

M10

10

Structural

Dimensions

H

Type

A B

C

116 156 216

119 159 219

122 162 222

127 167 227

130 170 230

Anchor supports welded to the connecting construction consist of items 1 to 3. Anchor supports screwed to the

connecting construction consist of items 1 to 3 and 6 to 8.

Issue 02.2006

Linde AG - Linde Engineering Division

LS 545-15 Part 1

Page 3 of 7

Piping DN 50 to 150

Fz

1

d1

Fy

h

s1

4

2

3

6,7,8

s2

m

assembly weld

Fx

s4

l1

welded during

installation

b1

60

250

drill holes in the steel structure

drilled during installation and cold galvanized

welded

screwed

Figure 2: Anchor supports DN 50 to 150

Table 2: Constructional dimensions

Item

1

Quantity

2

Pipe Pipe Clamp

DN

Type A

LS 546-01

da

d1

s4

50

65

80

60,3

76,1

88,9

61

77

89

10

10

10

100 114,3

125 139,7

150 168,3

115

140

169

10

10

10

2

2

Plate

s4 x e x m

EN 10029

m

e

Type

A

B

C

60 110 150 210

60 106 146 206

60 104 144 204

3

1

Plate

s1 x b1 x l1

EN 10029

s1

10

10

10

b1

l1

80 202

80 202

80 202

8

8

8

A

89

89

89

4

1

Plate

s2 x h x l1

EN 10029

h

Type

B

C

129 189

129 189

129 189

12

12

12

100 190

100 190

120 190

10

10

10

85

85

85

125 185 245 190

125 185 245 190

125 185 245 190

s2

D

-

80 106 146 206 266

80 104 144 204 264

100 107 147 207 267

l1

D

-

202

202

202

Issue 02.2006

Linde AG - Linde Engineering Division

LS 545-15 Part 1

Page 4 of 7

Table 3: Constructional dimensions and structural dimensions

Item

Quantity

DN Pipe

5

2

Plate

EN 10029

da

50

65

80

60,3

76,1

88,9

100 114,3 8 x 25 x 60

125 139,7 8 x 25 x 60

150 168,3 8 x 25 x 60

6

7

8

4

4

4

Screw

Nut

Washer

ISO 4017 ISO 4032 ISO 7089

5.6

St

St

Hot dip galvanized

Structural

Dimensions

H

Type

B C

176 236

183 243

190 250

M12 x 45

M12 x 45

M12 x 45

M12

M12

M12

12

12

12

A

136

143

150

D

-

M16 x 55

M16 x 55

M16 x 55

M16

M16

M16

16

16

16

163 203 263 323

176 216 276 336

190 230 290 350

Anchor supports welded to the connecting construction consist of items 1 to 5. Anchor supports screwed to the

connecting construction consist of items 1 to 8.

Piping DN 200 to 800

Fz

1

d1

Fy

s2

s1

4

2

3

6,7,8

m

assembly weld

Fx

s4

welded during

installation

b1

150

l1

l

drill holes in the steel structure

drilled during installation and cold galvanized

welded

screwed

Figure 3: Anchor supports DN 200 to 800

Issue 02.2006

Linde AG - Linde Engineering Division

LS 545-15 Part 1

Page 5 of 7

Table 4: Constructional dimensions

Item

1

Quantity

2

Pipe Pipe Clamp

DN

Type A

LS 546-01

da

d1

s4

200 219,1

250 273

300 323,9

350 355,6

400 406,4

220

273

324

356

407

10

10

10

10

10

140

180

200

220

240

2

2

Plate

s4 x e x m

EN 10029

e

Type

A

B

C

115 155 215

124 164 224

125 165 225

128 168 228

127 167 227

500

600

700

750

800

508

610

712

762

813

12

12

12

12

12

260

290

320

340

350

125

126

127

129

129

508

610

711

762

813

165

166

167

169

169

225

226

227

229

229

3

1

Plate

s1 x b1 x l1

EN 10029

A

85

85

85

85

83

4

1

Plate

s2 x h x l1

EN 10029

h

Type

B

C

125 185

125 185

125 185

125 185

123 183

D

245

245

245

245

243

290

280

280

280

270

80

80

80

80

80

120

120

120

120

120

240

240

240

240

240

468

458

458

458

458

s2

D

275

284

285

288

287

s1

12

12

12

12

12

b1

160

200

220

240

260

l1

290

280

280

280

270

10

10

10

10

10

285

286

287

289

289

15

15

15

15

15

280

310

340

360

370

468

458

458

458

458

12

12

12

12

12

180

180

180

180

180

l1

Table 5: Constructional dimensions and structural dimensions

Item.

Quantity

DN Pipe

5

4

Plate

EN 10029

da

6

7

8

4

4

4

Screw

Nut

Washer

ISO 4017 ISO 4032 ISO 7089

5.6

St

St

Hot dip galvanized

Structural

Dimensions

200

250

300

350

400

219,1

273,0

323,9

355,6

406,4

10 x 25 x 150

10 x 25 x 150

10 x 25 x 150

10 x 25 x 150

10 x 25 x 150

M16 x 55

M20 x 60

M20 x 60

M20 x 60

M20 x 60

M16

M20

M20

M20

M20

16

20

20

20

20

A

215

242

267

283

309

H

Type

B C

255 315

282 342

307 367

323 383

349 409

500

600

700

750

800

508

610

711

762

813

12 x 25 x 150

12 x 25 x 150

12 x 25 x 150

12 x 25 x 150

12 x 25 x 150

M24 x 70

M24 x 70

M24 x 70

M24 x 70

M24 x 70

M24

M24

M24

M24

M24

24

24

24

24

24

359

410

461

486

512

399

450

501

526

552

l

D

375

402

427

443

469

350

350

350

350

350

459

510

561

586

612

519

570

621

646

672

550

550

550

550

550

Anchor supports welded to the connecting construction consist of items 1 to 5. Anchor supports screwed to the

connecting construction consist of items 1 to 8.

Issue 02.2006

Linde AG - Linde Engineering Division

Drill holes in the base plate for the screwed type

d

LS 545-15 Part 1

w1

w2

Figure 4: Dimensions for the drill holes of item 3

Table 5: Diameters and distances between the drill holes

DN

Pipe

da

Structural dimensions

d

w1

w2

15

20

25

32

40

21,3

26,9

33,7

42,4

48,3

12

12

12

12

12

40

40

40

40

40

60

60

60

60

60

Section

HEA / HEB

100 - 120

100 - 120

100 - 120

100 - 120

100 - 120

110

110

110

110

110

Section

HEA / HEB

140 - 300

140 - 300

140 - 300

140 - 300

140 - 300

50

65

80

60,3

76,1

88,9

14 50

14 50

14 50

60

60

60

100 - 180

100 - 180

100 - 180

160

160

160

200 - 300

200 - 300

200 - 300

100

125

150

200

114,3

139,7

168,3

219,1

18

18

18

18

60

60

70

110

70

70

70

80

120 - 180

120 - 180

120 - 180

140 - 200

140

140

140

160

200 - 300

200 - 300

200 - 300

220 - 300

250

300

350

400

273

323,9

355,6

406,4

22

22

22

22

140

160

180

200

80

80

80

80

140 - 200

160 - 220

160 - 220

160 - 180

160

180

170

150

220 - 300

240 - 300

240 - 300

200 - 300

500

600

700

750

800

508

610

711

762

813

26

26

26

26

26

210

240

270

290

300

100

100

110

120

120

180 - 260

180 - 260

200 - 260

220 - 260

220 - 260

210

210

210

210

210

280 - 300

280 - 300

280 - 300

280 - 300

280 - 300

Page 6 of 7

Issue 02.2006

Linde AG - Linde Engineering Division

LS 545-15 Part 1

Page 7 of 7

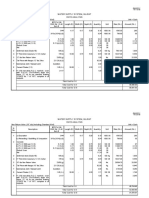

Weights

Table 6: Weights for anchor supports

DN

15

20

25

32

40

50

65

80

100

125

Welded anchor support FPW

Type

A

B

C

D

Weight

Weight

Weight

Weight

kg

kg

kg

kg

2,91

2,33

1,94

3,08

2,50

2,11

3,12

2,54

2,15

3,19

2,60

2,22

3,24

2,66

2,27

4,97

5,09

5,26

8,82

9,19

5,87

6,00

6,17

9,96

10,3

7,23

7,36

7,53

11,7

12,0

13,4

13,7

Screwed anchor support FPZW

Type

A

B

C

D

Weight

Weight

Weight

Weight

kg

kg

kg

kg

3,13

2,54

2,16

3,29

2,70

2,32

3,34

2,75

2,37

3,40

2,82

2,43

3,45

2,87

2,48

5,27

5,40

5,57

9,46

9,83

6,18

6,31

6,48

10,6

11,0

7,54

7,67

7,84

12,3

12,7

14,0

14,4

150

200

250

300

350

10,5

16,2

21,1

23,2

25,5

11,7

18,0

23,1

25,4

27,9

13,6

20,8

26,2

28,7

31,4

15,5

23,5

29,3

32,0

34,9

11,1

16,8

22,3

24,4

26,7

12,4

18,6

24,3

26,6

29,1

14,3

21,4

27,4

29,9

32,6

16,1

24,2

30,6

33,2

36,1

400

500

600

700

750

800

33,9

49,9

59,4

65,8

70,6

72,4

36,3

53,8

63,4

70,0

75,0

76,9

39,9

59,5

69,5

76,4

81,7

83,7

43,6

65,0

75,5

82,8

88,3

90,4

35,1

52,1

61,5

67,9

72,8

74,6

37,5

55,9

65,6

72,2

77,2

79,1

41,1

61,7

71,6

78,6

83,8

85,80

44,8

67,4

77,6

85,0

90,4

92,6

Revision: The screwed type FLZW(A;B;C;D) incorporated, editorially revised

Previous Issues: 3.71; 9.74; 9.82; 7.83; 10.83, 02.94, 04.95, 02.01, 07.04

Responsible department(s) for the technical content: TKC

LS-Class 2: For project specific use

Refer to protection notice ISO 16016

Vous aimerez peut-être aussi

- Datasheets For Bucket Type StrainerDocument2 pagesDatasheets For Bucket Type StrainerbecpavanPas encore d'évaluation

- Piping Line List Template 2018-05-29Document1 pagePiping Line List Template 2018-05-29Trevor KanodePas encore d'évaluation

- Y-Strainer Spears DatasheetDocument10 pagesY-Strainer Spears Datasheetmanoj_sitecPas encore d'évaluation

- Selection and Application of FlangesDocument11 pagesSelection and Application of FlangesbandithaguruPas encore d'évaluation

- Base and Hanger Spring Data SheetsDocument4 pagesBase and Hanger Spring Data SheetsxkokarcaxPas encore d'évaluation

- Pipes SupportDocument19 pagesPipes SupportoliveiralauroPas encore d'évaluation

- Flange Pipe SupportDocument1 pageFlange Pipe SupportindeskeyPas encore d'évaluation

- Valve Material ApplicationDocument16 pagesValve Material ApplicationMuhammadShabbirPas encore d'évaluation

- E 50B 4KG1 - Fire PDFDocument2 pagesE 50B 4KG1 - Fire PDFdocrafiPas encore d'évaluation

- PmsDocument94 pagesPmssdk1978100% (1)

- Notes: Pipe Spacing With 150# Flanges Dimension ADocument4 pagesNotes: Pipe Spacing With 150# Flanges Dimension Ahoke-14Pas encore d'évaluation

- Datasheet For Strainer.Document7 pagesDatasheet For Strainer.venka07Pas encore d'évaluation

- Tn-38 Bolt Torque Flanged JointsDocument37 pagesTn-38 Bolt Torque Flanged Jointshufuents-1Pas encore d'évaluation

- The CAESAR II Piping Model: How Good Is It?Document50 pagesThe CAESAR II Piping Model: How Good Is It?Mark MacIntyrePas encore d'évaluation

- OMV Pipe ClassDocument160 pagesOMV Pipe Classliviu_dovaPas encore d'évaluation

- PIP - Piping Material Specifications Collection - IHSDocument3 pagesPIP - Piping Material Specifications Collection - IHSmontanovillarroelfabiolalourdePas encore d'évaluation

- Steel Plug Valves 2016 1Document96 pagesSteel Plug Valves 2016 1EdinsonPas encore d'évaluation

- Data Sheet 18 - Fig Y2500 (SC) y Type StrainerDocument1 pageData Sheet 18 - Fig Y2500 (SC) y Type StrainerSteve NewmanPas encore d'évaluation

- Lift Check Valve: Straight, Flanged EndsDocument1 pageLift Check Valve: Straight, Flanged Endsadvantage025Pas encore d'évaluation

- HFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedDocument77 pagesHFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedVignesh Panchabakesan100% (1)

- Thermoplastic Support Catalog 1st Edition PDFDocument38 pagesThermoplastic Support Catalog 1st Edition PDFlaguna028Pas encore d'évaluation

- Specs Chart PDFDocument1 pageSpecs Chart PDFsojeckPas encore d'évaluation

- Line Number Format: Piping Specification Pipe Line IdentificationDocument2 pagesLine Number Format: Piping Specification Pipe Line IdentificationAkmal Hazuan SulaimanPas encore d'évaluation

- Floating and Trunnion Ball Valves PDFDocument15 pagesFloating and Trunnion Ball Valves PDFAlienshowPas encore d'évaluation

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaPas encore d'évaluation

- 6-76-0002 Bolt Tension For FlangesDocument33 pages6-76-0002 Bolt Tension For Flangesrovergamma100% (1)

- Curriculum Vitae: Sridhar VijayanDocument5 pagesCurriculum Vitae: Sridhar VijayanSridhar VijayanPas encore d'évaluation

- VMS PaliDocument61 pagesVMS Palichintan100% (2)

- Piping Flexiblility CalculationDocument8 pagesPiping Flexiblility CalculationAntoshalPas encore d'évaluation

- ANSI FlangeDocument10 pagesANSI FlangemechftpPas encore d'évaluation

- Piping Class PDFDocument4 pagesPiping Class PDFanil pkPas encore d'évaluation

- Data Sheet For Globe ValveDocument4 pagesData Sheet For Globe ValveShaaban Noaman100% (1)

- Spring Support Data Sheet-Process AreaDocument1 pageSpring Support Data Sheet-Process AreaArash AghagolPas encore d'évaluation

- JIS Flange InformationDocument3 pagesJIS Flange Informationmcoswald83Pas encore d'évaluation

- Expansion Calculation and Loop Sizing001Document2 pagesExpansion Calculation and Loop Sizing001Joseph R. F. DavidPas encore d'évaluation

- Control Building: For ApprovalDocument1 pageControl Building: For ApprovalRashidZamanPas encore d'évaluation

- SIF CalculatorDocument4 pagesSIF CalculatorKannaphat WattanaphanPas encore d'évaluation

- Pipeline Virtual AnchorDocument15 pagesPipeline Virtual AnchormaninventorPas encore d'évaluation

- Ball Valve DurcoDocument48 pagesBall Valve DurcoAlex VarHerPas encore d'évaluation

- Reinforcement Pad CalculationDocument4 pagesReinforcement Pad CalculationMohammad AbdullahPas encore d'évaluation

- Common Alloys SpecificationsDocument1 pageCommon Alloys SpecificationsSARATH KRISHNAKUMARPas encore d'évaluation

- TN10 Critical Line List SampleDocument2 pagesTN10 Critical Line List Sampleyulianus_srPas encore d'évaluation

- Eil Steam Trap StanderedDocument56 pagesEil Steam Trap StanderedVIVEK TIWARIPas encore d'évaluation

- BE-WI-248-01-F19 Datasheet Breather ValveDocument3 pagesBE-WI-248-01-F19 Datasheet Breather Valvemika cabelloPas encore d'évaluation

- ET de TubulacaoDocument214 pagesET de TubulacaoClarisse MendoncaPas encore d'évaluation

- Flange Leakage Check Calculation - Updated On 27-09-2009Document24 pagesFlange Leakage Check Calculation - Updated On 27-09-2009SamPas encore d'évaluation

- 500 SP PIP 018 Rev C (Check Valve)Document13 pages500 SP PIP 018 Rev C (Check Valve)anwar01Pas encore d'évaluation

- BP Variable Catalog 09VDocument52 pagesBP Variable Catalog 09VPetros IosifidisPas encore d'évaluation

- En 1092-1 PN-40 Steel Pipe FlangeDocument5 pagesEn 1092-1 PN-40 Steel Pipe FlangeHoria ZecheruPas encore d'évaluation

- 7-12-0033 Rev 4Document1 page7-12-0033 Rev 4cynidePas encore d'évaluation

- 10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old PoleDocument1 page10070-C63-XX-XXXX-ENB-0001-024 RTP03M 44MPS-Old PoleKrishna KnsPas encore d'évaluation

- Process Industry Practices PipingDocument5 pagesProcess Industry Practices PipingJhonny RinconesPas encore d'évaluation

- TB2-SDC-00100-P-G1-CAL-0002 RevB PDFDocument1 210 pagesTB2-SDC-00100-P-G1-CAL-0002 RevB PDFHanLe DuyPas encore d'évaluation

- PN03CL1S01Document4 pagesPN03CL1S01Amreusit SaschimbnumelePas encore d'évaluation

- Large Bore DetailsDocument85 pagesLarge Bore DetailsAmreusit SaschimbnumelePas encore d'évaluation

- Wall Thickness Calculations As Per ASME B31 3 PDFDocument2 pagesWall Thickness Calculations As Per ASME B31 3 PDFAnonymous cyKuQKPas encore d'évaluation

- 8202 2Document10 pages8202 2Yang WuPas encore d'évaluation

- HRC STD 6100 004 M 01 PDFDocument6 pagesHRC STD 6100 004 M 01 PDFEmir MujićPas encore d'évaluation

- F7121HDocument8 pagesF7121HSopon SrirattanapiboonPas encore d'évaluation

- Ladder Spec.Document20 pagesLadder Spec.Ramu NallathambiPas encore d'évaluation

- Pickling HandbookDocument32 pagesPickling HandbookPradeepPas encore d'évaluation

- Piping ScheduleDocument5 pagesPiping Scheduletejasp8388Pas encore d'évaluation

- Studs and Bolts Chart For BFVDocument1 pageStuds and Bolts Chart For BFVtejasp8388Pas encore d'évaluation

- Filler Metal Selection Guide Rev (1) - 1Document2 pagesFiller Metal Selection Guide Rev (1) - 1tejasp8388Pas encore d'évaluation

- Electrode CalculationDocument2 pagesElectrode Calculationtejasp8388100% (1)

- Blind Thickness CalculatorDocument2 pagesBlind Thickness Calculatortejasp8388Pas encore d'évaluation

- Fencing Details 0004Document1 pageFencing Details 0004tejasp8388Pas encore d'évaluation

- Gas TurbinesDocument9 pagesGas Turbinestejasp8388Pas encore d'évaluation

- Primavera P6 ManualDocument230 pagesPrimavera P6 ManualDionne Solito MonteloyolaPas encore d'évaluation

- Fencing Details 0001Document1 pageFencing Details 0001tejasp8388Pas encore d'évaluation

- SmagDocument28 pagesSmagcsvasukiPas encore d'évaluation

- 01 Introduction To Manufacturing and MachiningDocument10 pages01 Introduction To Manufacturing and MachiningTarun MehtaPas encore d'évaluation

- Piping Gist SHDDocument15 pagesPiping Gist SHDtejasp8388Pas encore d'évaluation

- Exchanger Modelling ProcedureDocument8 pagesExchanger Modelling Proceduretejasp838850% (2)

- Student Slides M2Document13 pagesStudent Slides M2captainhassPas encore d'évaluation

- 05 - 02 - Direct vs. Indirect Costs Introduction - For Web SiteDocument17 pages05 - 02 - Direct vs. Indirect Costs Introduction - For Web SiteTomce HristovskiPas encore d'évaluation

- Tutorial Lesson 3 - Working With Multiple Sections: FILE Menu: #Open,, #OpenDocument3 pagesTutorial Lesson 3 - Working With Multiple Sections: FILE Menu: #Open,, #Opentejasp8388Pas encore d'évaluation

- 7 Use of Chip Breaker in MachiningDocument16 pages7 Use of Chip Breaker in MachiningPRASAD326100% (1)

- Modern Steel Construction July 2010Document70 pagesModern Steel Construction July 2010Melissa FloresPas encore d'évaluation

- Galvanised Steel Cross Arm AssemblyDocument14 pagesGalvanised Steel Cross Arm AssemblyprabathnilanPas encore d'évaluation

- DTP - Deerfield River BridgeDocument5 pagesDTP - Deerfield River Bridgefdesdunes00Pas encore d'évaluation

- Moment Connections Bolted WeltedDocument6 pagesMoment Connections Bolted WeltedRavirajsinh JadejaPas encore d'évaluation

- Plate A516 and A387 - Pressure Vessel SteelsDocument16 pagesPlate A516 and A387 - Pressure Vessel SteelsaladinsanePas encore d'évaluation

- Structural Design and Detailed Drawing of A Steel Industrial Building - 510418108 - Debayan GhoshDocument67 pagesStructural Design and Detailed Drawing of A Steel Industrial Building - 510418108 - Debayan GhoshhelloPas encore d'évaluation

- Bop RFQ Cog FlareDocument51 pagesBop RFQ Cog Flarekoushik42000100% (1)

- Requirements For Overhead Cranes Rails: Annex 1Document21 pagesRequirements For Overhead Cranes Rails: Annex 1Fuad KhoirulPas encore d'évaluation

- Precious Metals Recovery BrochureDocument32 pagesPrecious Metals Recovery BrochureNelson GutierrezPas encore d'évaluation

- Ansi MH16 1-2012Document71 pagesAnsi MH16 1-2012mloredoPas encore d'évaluation

- Anchor Bolt TolerancesDocument3 pagesAnchor Bolt TolerancesRam BabuPas encore d'évaluation

- Concrete RepairDocument7 pagesConcrete RepairjjahaddinPas encore d'évaluation

- Reactor Vessel CladdingDocument23 pagesReactor Vessel CladdingAndres_Pastor1987Pas encore d'évaluation

- Steel Grades Properties Global StandardsDocument20 pagesSteel Grades Properties Global StandardsJonald PoquizPas encore d'évaluation

- Steelwise AISCDocument6 pagesSteelwise AISCAruna Kumari GPas encore d'évaluation

- OWNERISSUE110106IDocument16 pagesOWNERISSUE110106ISamPas encore d'évaluation

- Bridge Hand BookDocument51 pagesBridge Hand BookShreya JhaveriPas encore d'évaluation

- Safety Turnbuckle: Jonas OlssonDocument38 pagesSafety Turnbuckle: Jonas OlssonRyan FisherPas encore d'évaluation

- Piping Systems and AccessoriesDocument16 pagesPiping Systems and AccessoriesYoussef100% (1)

- Is 2830 2012 PDFDocument13 pagesIs 2830 2012 PDFK.s. Raghavendra KumarPas encore d'évaluation

- DIY Guide Rails Plans VSC ToolsDocument22 pagesDIY Guide Rails Plans VSC ToolsMiguel TravahoPas encore d'évaluation

- SAEJ403v001 - 1020-1045Document11 pagesSAEJ403v001 - 1020-1045Pablo CastroPas encore d'évaluation

- F 992 - 86 R01 - RJK5MG - PDFDocument3 pagesF 992 - 86 R01 - RJK5MG - PDFRománBarciaVazquezPas encore d'évaluation

- 1SV90904 904D11 Sie 00 ZZ DWG ST 00003Document1 page1SV90904 904D11 Sie 00 ZZ DWG ST 00003ghadeer mattarPas encore d'évaluation

- Hull Coating BreakdownDocument18 pagesHull Coating Breakdownswapneel_kulkarniPas encore d'évaluation

- BQ FencingDocument4 pagesBQ FencingMuhammad Ghazali100% (5)

- Steel Supply Sub-Grades To EC3Document22 pagesSteel Supply Sub-Grades To EC3Anonymous iS33V5Pas encore d'évaluation

- 11.rate Analysis GujratDocument46 pages11.rate Analysis GujratM Shahid100% (1)

- Thermoplastic Support Catalog 1st Edition PDFDocument38 pagesThermoplastic Support Catalog 1st Edition PDFlaguna028Pas encore d'évaluation

- Is 13291 1992Document12 pagesIs 13291 1992Anonymous UibQYvc6Pas encore d'évaluation

- Arizona, Utah & New Mexico: A Guide to the State & National ParksD'EverandArizona, Utah & New Mexico: A Guide to the State & National ParksÉvaluation : 4 sur 5 étoiles4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksD'EverandNew York & New Jersey: A Guide to the State & National ParksPas encore d'évaluation

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptD'EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptÉvaluation : 5 sur 5 étoiles5/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensD'EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensPas encore d'évaluation

- The Bahamas a Taste of the Islands ExcerptD'EverandThe Bahamas a Taste of the Islands ExcerptÉvaluation : 4 sur 5 étoiles4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoD'EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoÉvaluation : 5 sur 5 étoiles5/5 (1)