Académique Documents

Professionnel Documents

Culture Documents

Heat HXer

Transféré par

Gade JyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Heat HXer

Transféré par

Gade JyDroits d'auteur :

Formats disponibles

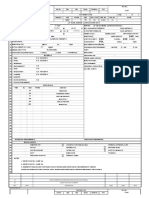

Heat Exchanger Specification Sheet

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 Annunziato - Marchionna Processo Rectisol Scambiatore E100

Size Surf/unit(eff.)

307 -- 1850 8,5

mm m

Fluid allocation Fluid name Fluid quantity, Total Vapor (In/Out) Liquid Noncondensable Temperature (In/Out) Dew / Bubble point Vapor/Liquid Density Viscosity Molecular wt, Vap Molecular wt, NC Specific heat Thermal conductivity Latent heat Pressure Velocity Pressure drop, allow./calc.

Hor Type BEM Connected in 1 parallel 1 series Shells/unit 1 Surf/shell (eff.) 8,5 m PERFORMANCE OF ONE UNIT Shell Side Tube Side 15a L2r 4 3,309 kg/s 4 4 0 0 kg/s 0 0 3,309 3,309 kg/s 0 0 0 0 kg/s -60 C C kg/m 39,58 mPa s 0,0141 28,23 -50,71 36,94 0,0146 28,23 -43,5 1130,64 0,2166 -50 1158,83 0,2375

1,13 2,024 1,981 kJ/(kg K) 1,144 0,0239 0,1776 0,1864 W/(m K) 0,0232 kJ/kg 23,911 25 23,48083 24,83006 bar 11,35 1,13 m/s 0,5 0,43017 0,35 0,16994 bar Ao based Fouling resist. (min) 0 0 0 m K/W Heat exchanged MTD corrected 43,1 7,1 kW C Transfer rate, Service Dirty Clean 725,6 715 725,6 W/(m K) CONSTRUCTION OF ONE SHELL Sketch Shell Side Tube Side Design/Vac/Test pressure 28 27 bar Design temperature 35 35 C Number passes per shell 1 6 3,18 3,18 Corrosion allowance mm 152,4 1 Connections 50,8 In mm 1 1 152,4 Size/rating 1 Out 38,1 Nominal Intermediate Tube No. 80 Tks-Avg 1,65 Length 1850 OD 19,05 mm mm Pitch 23,81 mm 30 Tube type Plain Tube pattern #/m Material Carbon Steel OD 323,85 Shell Carbon Steel ID 307,09 mm Shell cover Channel or bonnet Channel cover Carbon Steel Tubesheet-stationary Carbon Steel Tubesheet-floating Floating head cover Impingement protection None Cut(%d) 26,22 Baffle-crossing Carbon Steel H Spacing: c/c 135 Type Single segmental mm mm Baffle-long Seal type Inlet 278,98

T1 S2 T2 S1

Supports-tube Bypass seal Expansion joint RhoV2-Inlet nozzle Gaskets - Shell side Floating head Code requirements Weight/Shell Remarks

U-bend Tube-tubesheet joint Type Bundle entrance 1010 1164 Tube Side Flat Metal Jacket Fibe ASME Code Sec VIII Div 1 Filled with water 633,1 492,3

Type Exp. Bundle exit 2099 Flat Metal Jacket Fibe TEMA class Bundle kg/(m s)

R - refinery service 177,6

kg

200

Heat Exchanger Thermal Design

Mechanical Details - Setting Plan

Shell&Tube V7.1

Views on arrow A T1

A

211 130 T1 195 S2

2532 Overall 1455

T2

S2 312 349 312

313

313

T2

S1 130 370 1110

S1

Pulling Length 1530

75

75

70

280

150 2 Bolts Fixed

280

150 2 Bolts Sliding

Ref OD Wall S1 168 mm 7,1 mm S2 168 mm 7,1 mm T1 60 mm 3,9 mm T2 48 mm 3,7 mm

Nozzle Data Standard 150 ANSI Slip on 150 ANSI Slip on 150 ANSI Slip on 150 ANSI Slip on

Notes

Design Data Design Pressure Design Temperature Full Vacuum Corrosion Allowance Test Pressure Number of Passes Radiography PWHT Internal Volume

Units barg C mm barg

Shell 27, 35, 0 3,175 1 0 0 0,1358

Channel 28, 35, 0 3,175 6 0 0 0,0458

Annunziato - Marchionna Processo Rectisol Scambiatore E100

Aspen Shell & Tube Exchanger

70

Setting Plan

Design Codes 0 TEMA 0 Customer Specifications

BEM 307 - 1850

Drawing Number

Revision Date 20/06/2012 Dwg. Chk. App.

Empty 492 kg

Weight Summary Flooded 633 kg

Bundle 178 kg

201

Vous aimerez peut-être aussi

- LP Gas Amine Contactor Process DataDocument6 pagesLP Gas Amine Contactor Process DataEddy RainPas encore d'évaluation

- Steam CondenserDocument2 pagesSteam CondenserAlphaEcc EngineeringTeamPas encore d'évaluation

- Heat Exchanger Specification Sheet: MM M? M? Performance of One UnitDocument9 pagesHeat Exchanger Specification Sheet: MM M? M? Performance of One UnitGladys ZiSing LeePas encore d'évaluation

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDocument2 pagesHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamPas encore d'évaluation

- Air Exchanger TDDocument9 pagesAir Exchanger TDRajput PratiksinghPas encore d'évaluation

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetGreisly MarrugoPas encore d'évaluation

- Air Cooled Exchanger Specification for El Paso Exp West Cameron 62 A-Aux E132-2-36Document1 pageAir Cooled Exchanger Specification for El Paso Exp West Cameron 62 A-Aux E132-2-36Honey TiwariPas encore d'évaluation

- Lecture 04c - Shortcut Exchanger Design ProcedureDocument47 pagesLecture 04c - Shortcut Exchanger Design Proceduresds0% (1)

- Heat Exchanger CalcDocument34 pagesHeat Exchanger Calcميثة الغيثيةPas encore d'évaluation

- Liquid Valve CV CalcDocument4 pagesLiquid Valve CV Calcamit_kt1973Pas encore d'évaluation

- Condenser Calculation - Shell and TubeDocument3 pagesCondenser Calculation - Shell and TubedeeptimisraPas encore d'évaluation

- Shell and Tube Heat Exchanger DesignDocument5 pagesShell and Tube Heat Exchanger DesignDominic CareoPas encore d'évaluation

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriPas encore d'évaluation

- Understanding NPSHDocument34 pagesUnderstanding NPSHeliyanto budiartoPas encore d'évaluation

- Orifice SizingDocument1 pageOrifice SizingMarco D'OnofrioPas encore d'évaluation

- Observations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrDocument2 pagesObservations Water in DF Out DF Oil DF Flow Ml/s Flow ft3/hrUmair FareedPas encore d'évaluation

- Mean Metal Temperature CalculationDocument28 pagesMean Metal Temperature CalculationAvijit DasguptaPas encore d'évaluation

- Design of a Double Pipe Heat Exchanger CalculationsDocument2 pagesDesign of a Double Pipe Heat Exchanger CalculationsSaqib RaoufPas encore d'évaluation

- Calculation Sheet For Make - Up Water Tank: #Value!Document4 pagesCalculation Sheet For Make - Up Water Tank: #Value!thanh_79Pas encore d'évaluation

- Thermal 3TPH 12Kg FO Fired Boiler R0Document6 pagesThermal 3TPH 12Kg FO Fired Boiler R09913489806Pas encore d'évaluation

- Heat Exchanger DesignDocument48 pagesHeat Exchanger DesignJose SotoPas encore d'évaluation

- Vertical Separator SizingDocument8 pagesVertical Separator SizingAnonymous yLPPdPwPas encore d'évaluation

- Desuperheater Flow CalculationDocument1 pageDesuperheater Flow CalculationMechanicalVee18Pas encore d'évaluation

- Chapter 8 Steam CondenserDocument52 pagesChapter 8 Steam CondenserHải MâyPas encore d'évaluation

- Hybrid Cooling TowerDocument12 pagesHybrid Cooling TowerANIMESH JAINPas encore d'évaluation

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- Double FdexchangerDocument8 pagesDouble FdexchangerBoško IvanovićPas encore d'évaluation

- Final Energy Balance-Vizag DT 9-6-18Document6 pagesFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYPas encore d'évaluation

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988Pas encore d'évaluation

- Pipe Heat Transfer CalculationsDocument12 pagesPipe Heat Transfer CalculationsmansourotaibiPas encore d'évaluation

- TEMA E shell and tubes heat exchanger calculationDocument9 pagesTEMA E shell and tubes heat exchanger calculationjnmanivannanPas encore d'évaluation

- Perforated Pipe Distributor Sizing CalcuDocument6 pagesPerforated Pipe Distributor Sizing CalcuInggit Prillasari100% (1)

- BoilerCalcSteamPropDocument4 pagesBoilerCalcSteamPropMarc EdwardsPas encore d'évaluation

- h-101 TwiceDocument20 pagesh-101 TwiceAdela ShofiaPas encore d'évaluation

- Gas Line Pressure LossesDocument4 pagesGas Line Pressure Lossesyash saragiyaPas encore d'évaluation

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasPas encore d'évaluation

- XSteam Excel v2.6 USDocument12 pagesXSteam Excel v2.6 USOnkarabile MatomePas encore d'évaluation

- 91Document12 pages91Zoran DanilovPas encore d'évaluation

- Heater Lowers Methanol Temp from 95C to 40CDocument30 pagesHeater Lowers Methanol Temp from 95C to 40CHamdan ShdPas encore d'évaluation

- Shell and Tube VaporizerDocument17 pagesShell and Tube VaporizercontinentalflossPas encore d'évaluation

- Tube Rupture (Two Phase-Omega Method)Document1 pageTube Rupture (Two Phase-Omega Method)Saeid Rahimi MofradPas encore d'évaluation

- PV Elite 2020 Licensee: Tubesheet Check CalculationDocument8 pagesPV Elite 2020 Licensee: Tubesheet Check CalculationAbhishek LadPas encore d'évaluation

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyPas encore d'évaluation

- Htri 105 PDFDocument1 pageHtri 105 PDFhirenpatel_62Pas encore d'évaluation

- Calculation of time needed to mix liquids with pitch blade impellersDocument10 pagesCalculation of time needed to mix liquids with pitch blade impellershadiPas encore d'évaluation

- 882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDocument6 pages882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDavid Alemán Sánchez100% (1)

- CIS7:2014Document66 pagesCIS7:2014Ken ChuahPas encore d'évaluation

- Design of A Vapor-Liquid SeparatorDocument2 pagesDesign of A Vapor-Liquid SeparatorpowerveePas encore d'évaluation

- Psychrometric CalculatorDocument4 pagesPsychrometric CalculatorArie Emmanuel ListonPas encore d'évaluation

- Shell&Tube TEMAsheet 1Document1 pageShell&Tube TEMAsheet 1Rikiya FebriyanPas encore d'évaluation

- Fire Relief Dynamic StudyDocument2 pagesFire Relief Dynamic StudyImtinan MohsinPas encore d'évaluation

- Pipe and Fitting Calcs MasterDocument7 pagesPipe and Fitting Calcs MasterjnmanivannanPas encore d'évaluation

- Fluid Flow Basics OF Throttling ValvesDocument43 pagesFluid Flow Basics OF Throttling ValvesSandro AraújoPas encore d'évaluation

- HP Boiler Blowdown Hex - OPERATINGDocument1 pageHP Boiler Blowdown Hex - OPERATINGMuthuKumar ArunachalamPas encore d'évaluation

- Heat Exchanger Rating Data SheetDocument1 pageHeat Exchanger Rating Data SheetagusnnnPas encore d'évaluation

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetTrần Quang ThắngPas encore d'évaluation

- Heat Exchanger Specification Sheet SI UnitsDocument2 pagesHeat Exchanger Specification Sheet SI UnitssalamrefighPas encore d'évaluation

- MP Steam Boiler Package Familiarisation - Attachment 1Document12 pagesMP Steam Boiler Package Familiarisation - Attachment 1simba8661100% (2)

- Heat Exchanger Specification SheetDocument5 pagesHeat Exchanger Specification SheetNur Izzati KamrulnizamPas encore d'évaluation

- E 0211Document23 pagesE 0211Thinh ViproPas encore d'évaluation

- Abrasive Cutting Equipment: BenefitsDocument1 pageAbrasive Cutting Equipment: BenefitsGade JyPas encore d'évaluation

- (Ebook - PDF) Untold Windows Tips and Secrets (Ankit Fadia)Document22 pages(Ebook - PDF) Untold Windows Tips and Secrets (Ankit Fadia)nimitkhanna7100% (1)

- Coil BenderDocument1 pageCoil BenderGade JyPas encore d'évaluation

- Controlled Debris Removal System CDRSDocument1 pageControlled Debris Removal System CDRSGade JyPas encore d'évaluation

- 12 The Giving Tree - Shel SilversteinDocument2 pages12 The Giving Tree - Shel SilversteinGade JyPas encore d'évaluation

- Perodua Myvi Wiring Diagrams PDFDocument257 pagesPerodua Myvi Wiring Diagrams PDFGade Jy100% (2)

- 969poetry 2Document11 pages969poetry 2Kedar A. MalusarePas encore d'évaluation

- SPE/IADC 37589 Pressure Integrity Test InterpretationDocument14 pagesSPE/IADC 37589 Pressure Integrity Test InterpretationGade JyPas encore d'évaluation

- Coiled Tubing Pig Catcher / Detector: BenefitsDocument1 pageCoiled Tubing Pig Catcher / Detector: BenefitsGade JyPas encore d'évaluation

- Defects Per Capability Sigma Million Yield INDEX (CPK) LevelDocument1 pageDefects Per Capability Sigma Million Yield INDEX (CPK) LevelGade JyPas encore d'évaluation

- Coiled Tubing Connectors for BHAsDocument1 pageCoiled Tubing Connectors for BHAsGade JyPas encore d'évaluation

- SPE/IADC 37589 Pressure Integrity Test InterpretationDocument14 pagesSPE/IADC 37589 Pressure Integrity Test InterpretationGade JyPas encore d'évaluation

- Sand cleanout calculationsDocument2 pagesSand cleanout calculationsGade Jy100% (1)

- Understanding First Time and Rolled Throughput Yields PDFDocument3 pagesUnderstanding First Time and Rolled Throughput Yields PDFGade JyPas encore d'évaluation

- Control Chart Constants and FormulasDocument3 pagesControl Chart Constants and FormulasPankaj PriyadarshiPas encore d'évaluation

- Stainless Steel Applications For Pressure Vessels PDFDocument24 pagesStainless Steel Applications For Pressure Vessels PDFGade JyPas encore d'évaluation

- Options Intensive PDFDocument1 pageOptions Intensive PDFGade JyPas encore d'évaluation

- Stainless Steel Applications For Pressure Vessels PDFDocument24 pagesStainless Steel Applications For Pressure Vessels PDFGade JyPas encore d'évaluation

- SigmaXL Version 6.2 Workbook PDFDocument334 pagesSigmaXL Version 6.2 Workbook PDFGade JyPas encore d'évaluation

- Shining A Light On Coiled Tubing PDFDocument10 pagesShining A Light On Coiled Tubing PDFGade JyPas encore d'évaluation

- BJ HandbookDocument28 pagesBJ HandbookGade JyPas encore d'évaluation

- Caledyne Hest ManualDocument8 pagesCaledyne Hest ManualGade JyPas encore d'évaluation

- PSB 005Document2 pagesPSB 005Gade JyPas encore d'évaluation

- Texas Oil Tools: Product Service BulletinDocument2 pagesTexas Oil Tools: Product Service BulletinGade JyPas encore d'évaluation

- PSB 040Document2 pagesPSB 040Gade JyPas encore d'évaluation

- Technical Manual - 2000 USG Horizontal Lined Acid TankDocument20 pagesTechnical Manual - 2000 USG Horizontal Lined Acid TankGade JyPas encore d'évaluation

- CrossFit Games RulebookDocument17 pagesCrossFit Games RulebookGade JyPas encore d'évaluation

- PSB 009 PDFDocument5 pagesPSB 009 PDFGade JyPas encore d'évaluation

- Pages From Ashtanga Yoga As Taught-3Document1 pagePages From Ashtanga Yoga As Taught-3Gade JyPas encore d'évaluation

- Pages From Ashtanga Yoga As Taught-2Document1 pagePages From Ashtanga Yoga As Taught-2Gade JyPas encore d'évaluation

- PDF 11 46 12 04 02 2014 Esthetic Rehabilitation With Laminated Ceramic Veneers Reinforced by Lithium Disilicate PDFDocument5 pagesPDF 11 46 12 04 02 2014 Esthetic Rehabilitation With Laminated Ceramic Veneers Reinforced by Lithium Disilicate PDFAnnaAffandiePas encore d'évaluation

- India's Elite Anti-Naxalite Force CoBRADocument6 pagesIndia's Elite Anti-Naxalite Force CoBRAhumayunsagguPas encore d'évaluation

- Water Pollution in The PhilippinesDocument11 pagesWater Pollution in The PhilippinesJuliane MayorgaPas encore d'évaluation

- Worksheet A: Teacher's Notes: Level 2 (Upper Intermediate - Advanced)Document9 pagesWorksheet A: Teacher's Notes: Level 2 (Upper Intermediate - Advanced)Elena SinisiPas encore d'évaluation

- Double Your Income-Hustle & ConquerDocument54 pagesDouble Your Income-Hustle & ConquerHamza ElmoubarikPas encore d'évaluation

- Linux InstallationDocument4 pagesLinux InstallationRayapudi LakshmaiahPas encore d'évaluation

- Strategic Supply Chain Management (Om367, 04835) : Meeting Time & LocationDocument9 pagesStrategic Supply Chain Management (Om367, 04835) : Meeting Time & Locationw;pjo2hPas encore d'évaluation

- 978 0 387 95864 4Document2 pages978 0 387 95864 4toneiamPas encore d'évaluation

- Injectable Polyplex Hydrogel For Localized and Long-Term Delivery of SirnaDocument10 pagesInjectable Polyplex Hydrogel For Localized and Long-Term Delivery of SirnaYasir KhanPas encore d'évaluation

- Financial Mangement McqsDocument23 pagesFinancial Mangement Mcqsowaishazara67% (3)

- Low Intensity Laser Therapy in Bone Healing and OsteoporosisDocument80 pagesLow Intensity Laser Therapy in Bone Healing and OsteoporosisNguyễn Xuân PhongPas encore d'évaluation

- Philippine Duplicators 13th Month Pay ComputationDocument2 pagesPhilippine Duplicators 13th Month Pay ComputationDennis Jay Dencio ParasPas encore d'évaluation

- Mastering Physics CH 14 HW College Physics I LCCCDocument24 pagesMastering Physics CH 14 HW College Physics I LCCCSamuel100% (5)

- Opa An AssDocument8 pagesOpa An Assgvkreddyg100% (1)

- FiberPatrol PR US English R2 LR2Document4 pagesFiberPatrol PR US English R2 LR2osto72Pas encore d'évaluation

- BRM 2.Document10 pagesBRM 2.Sehar AzharPas encore d'évaluation

- Vsan 70 Monitoring Troubleshooting GuideDocument51 pagesVsan 70 Monitoring Troubleshooting GuideRosembert AvilaPas encore d'évaluation

- Pepsi - Consumer Behaviour StudyDocument6 pagesPepsi - Consumer Behaviour Studybhavin shahPas encore d'évaluation

- El Nido Resorts Official WebsiteDocument5 pagesEl Nido Resorts Official WebsiteCarla Naural-citebPas encore d'évaluation

- 20 - Technical Data & FormulationsDocument11 pages20 - Technical Data & FormulationsSnzy DelPas encore d'évaluation

- English Grammar: The differences between across, over and throughDocument1 pageEnglish Grammar: The differences between across, over and throughYuresh NadishanPas encore d'évaluation

- Ala CalculationDocument4 pagesAla CalculationAgus SupriadiPas encore d'évaluation

- NUS Physics PaperDocument6 pagesNUS Physics PaperBilin ZhuangPas encore d'évaluation

- Consultancy Project Assessment SheetDocument1 pageConsultancy Project Assessment SheetSadeeqPas encore d'évaluation

- Automata and Complexity Theory ModuleDocument104 pagesAutomata and Complexity Theory ModuleSurafelPas encore d'évaluation

- ASC EVOIPneo Mitel enDocument2 pagesASC EVOIPneo Mitel enService Level ManagementPas encore d'évaluation

- Pembangunan Modal Insan Perspektif Pengurusan IslamDocument26 pagesPembangunan Modal Insan Perspektif Pengurusan IslamMujiburrahmanPas encore d'évaluation

- HPE BOM Import Config for MSL2024 Storage SolutionDocument2 pagesHPE BOM Import Config for MSL2024 Storage SolutionBertrand FotuePas encore d'évaluation

- African Nations Cup ProjectDocument15 pagesAfrican Nations Cup ProjectAgbor AyukPas encore d'évaluation