Académique Documents

Professionnel Documents

Culture Documents

XE360 Equivalencias

Transféré par

DANIEL DIAZTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

XE360 Equivalencias

Transféré par

DANIEL DIAZDroits d'auteur :

Formats disponibles

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 1 / 11

Issue 01

Date of issue 17.05.2010

Description of modification Initial issue

TABLE OF CONTENTS

1. Purpose ............................................................................................................................................. 2 2. Scope of application......................................................................................................................... 2 3. Environment .................................................................................................................................... 3 4. Logistics ............................................................................................................................................ 4 4.1. Product labelling .............................................................................................................................. 4 4.2. Packaging and handling .................................................................................................................. 5 4.3. Anti-corrosion protection ............................................................................................................... 7 5. Quality .............................................................................................................................................. 7 5.1. Initial samples .................................................................................................................................. 8 5.2. Documentation ................................................................................................................................. 9 5.3. Special Characteristics .................................................................................................................... 9 5.4. Changes ............................................................................................................................................ 9 5.5. Processing of Complaints / Incoming Inspection........................................................................ 10 5.6. Exceptional Approvals .................................................................................................................. 10 5.7. Rework/Repairs ............................................................................................................................. 10 5.8. Audit ............................................................................................................................................... 11 5.9. List of test ....................................................................................................................................... 11 6. Other requirements ....................................................................................................................... 11 7. Supplier .......................................................................................................................................... 11 Stamp: ..................................................................................................................................................... 11

Drafted by: Malnari Vili

Reviewed by: Ale Grad

Approved by: Primo Miheli Marko Gorjup

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 2 / 11

1. Purpose

This document gives TPV's general requirements in respect of environment, quality and logistics and supplements the specific List of requirements for individual materials. Besides this document, the suppliers are also bound to meet TPV's general purchase conditions.

2. Scope of application

This document gives requirements for materials from the following product groups: Code of product group DESCRIPTION Content of product group 010101 Non-alloy structural sheet metal EN 10025: S235JR, S275JR, S355JO EN 10111: DD11, DD12, DD13, DD14; 010102 Soft non-alloy steel CDC 11-04-805: HES EN 10149-2: S315MC, S355MC, S420MC, S460MC, S500MC, S550MC, S600MC, S700MC; CDC11.04.002: HE280M, HE320M/D, HE360D, 010103 Micro-alloy HR steel HE400M, HE450M EN 10130: DC01, DC03, DC04, DC05, DC06; 010104 Soft cold-rolled steel sheet CDC 11-04-805: XE, XES EN 10268: H240LA, H280LA, H320LA, H360LA, H400LA; 010105 Micro-alloy cold-rolled steel sheet CDC 11-04-002: XE280D, XE320D, XE360D SEW 097: H260X (DP400), H270X (DP500), H300X (DP500), H310X-H340X (DP600), H380X (DP600) -do debeline 2,5 mm; HT450X, HT500X, HT600X, HT800H, HT1000X DP600, DP700, DP800 EN 10346: DX51D +Z, DX52D +Z, DX53D +Z, DX54 +Z; RENAULT: XE G10/10, XES G10/10 EN 10346: H260LAD +Z, H300LAD +Z, H340LAD +Z, H380LAD +Z, H420LAD +Z; RENAULT: XE235P +Z, XE260P +Z, XE280P +Z, XE280D +Z, XE320D +Z EN 10152: DC01 +ZE, DC03 +ZE, DC04 +ZE, H260LAD +ZE, H300LAD +ZE, H340LAD +ZE, H380LAD +ZE, H420LAD +ZE; RENAULT: XE235P +ZE, XE260P +ZE, XE280P +ZE, XE280D +ZE, XE320D +ZE UTOP2 856 1.2581, UTOPCO2 861 1.2885, UTOPMO2 851 1.2344, UTOPMO4 859 1.2345, UTOPMO7 254 1.2367, OCR6 933 1.4112, OCR8VMS 245, OCR12 812 1.2080, OCR12VM 834 1.2379, TOOLOX 33, TOOLOX 44

010106 010107

Cold-rolled multiphase steel sheet Hot rolled multiphase steel sheet

010108

Hot zinc steel

010109

Micro-alloy coated steel

010110

Electrogalvanized steel

010111 010112

Tool steels - plates Aluminium sheet

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 3 / 11

010113 010114 010115 010116 010201 010202 010203 010204 010205 010206 010207 010208 010301 010302 010303 010304 010305 010306 010701

Copper sheet Cold-rolled processed /steel (Al, Feran) Cold-rolled tinned steel sheet Stainless inox steel Seamless cold drawn tubes Seam cold drawn tubes Seam cold-rolled tubes Seam cold-rolled square and rectangular tubes Stainless tubes Galvanized tubes Aluminized tubes Aluminous tubes Steel wires in coils Steel wires in bars Coppered wires Galvanized wires Aluminized wires Welding wire Cold rolled profil

EN 10088: X5CRNI18-10, X6CR17 EN 10305-1: E215, E255, E355 EN 10305-2: E155, E195, E235, E275, E355 EN 10305-3: E155, E195, E235, E275, E355, E420 EN 10305-5: E155, E195, E235, E275, E355 EN 10088-3: 1.4301

EN 755-7 EN 10025-2; EN 10016 - 2: C9D, C10D, S235JR EN 10025-2 EN 10218 2; EN 10016 - 2 EN 785: SG2 EN 10277: S235JRC, E295GC, E335GC, S355J2C, C10, C15, C16, C35, C40, C45, C55, C60

3. Environment

All material deliveries shall comply with requirements laid down in the first paragraph of Article 59 and Article 33 of the EG regulation 1907/2006 (REACH). The supplier undertakes to monitor on regular basis substances entered in the SVHC list and to notify TPV d.d. in written and without delay about the content of these substances in materials and products supplied to TPV d.d. Unless TPV receives from the supplier a notification about the content of these substances, the supplied materials and products shall be considered as free of SVHC substances. Materials and components delivered to TPV d.d. shall be produced in compliance with the European directives 2000/53/EC and 2005/63/EC and related annexes. Prior to the first delivery, the supplier shall provide the data registration on chemical composition in the IMDS base available on http://www.mdsystem.com/ and shall send it through the system to the receiver i.e. TPV d.d. on its ID number 11962. The supplier shall regularly update any changes regarding the material, composition., and notify them to TPV d.d. Only exceptionally may the supplier provide the material composition on a form made by TPV and available on request in the ENVIRONMENT department. By submitting the material composition on a form, the supplier undertakes that all delivered materials shall comply with the requirements of the GADSL list in force available on http://www.gadsl.org/ which is the only valid list. At the first delivery, the supplier shall make out a signed and stamped declaration that his materials are free of substances bearing the identification code P above the permitted limit and those bearing the identification code D shall be declared with the name of the substance, CAS number and a percentage proportion of this substance in the material. Whenever there is a change in material composition the supplier shall notify TPV of any such changes.

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 4 / 11

Materials incorporated into products used in the food industry have to be safe, material substances must not be released to foodstuffs which are brought into contact with these products, therefore, all delivered materials shall be in compliance with the Regulation (2023/2006 ES) laying down rules on a good production practice for the group of materials and products from the Annex I to the ES Regulation No 1935/2004, intended to be in contact with foodstuffs. As compliance evidence, the supplier shall submit a signed and stamped declaration. The supplier undertakes to also observe and comply with the EU and RS legislation other than this mentioned in this List of requirements. For the purpose of protection against corrosion, the supplier shall use biodegradable products and shall send to TPV d.d. the safety data sheet for the used product.

4. Logistics 4.1. Product labelling

Every transport unit shall bear a label in accordance with Galia Odette or VDA 4902 standards. In the event this is not possible, the label shall contain at least the following data: Name of supplier, Material labelling (see Material labelling in the List of special requirements; there shall be a clear link between the material labelling featured on the label and the certificate). Material designation (see Material designation (dimensions) in the List of special requirements; the designation shall contain at least dimensions of material) The order of dimensions shall be as follows: Product group 0101xx Sheet metal in coils: thickness x width Steel metal in sheets: thickness x width x length Product group 0102xx Tubes in bundles: external diameter x wall thickness x length Right-angled tubes in bundles: width x height x wall thickness x length Product group 0103xx Wire in coil: diameter Wire in bars: diameter length Right-angled wire in bars: width thickness length Material SAP number (see SAP code in the List of special requirements), Supplier's batch (numerical and with bar code), Quantity (numerical and with bar code) Product group 0101xx Sheet metal in coils: Quantity in (kg) brutto/netto Steel metal in sheets: Quantity in (kg) brutto/netto Product group 0102xx Tubes in bundles: Quantity in (m) exceptionally in (piece) and in (kg) Right-angled tubes in bundles: Quantity in (m) or (piece) and in (kg) Product group 0103xx Wire in coil: Quantity in (kg) Steel wire in bars: Quantity in (m) or (piece) and in (kg) Number of packaging units (e.g. number of coils per transport unit), Date of production (numerical and with bar code).

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 5 / 11

In the event the product is considered as a safety part, the label shall contain the safety part symbol (see the List of special requirements, item 7.0, Safety part). The label shall be placed in a visible position.

4.2. Packaging and handling

The material shall be stored in a dry and closed place. During the transport, it shall not be exposed to adverse weather conditions e.g. rain, snow, moisture, otherwise it shall be properly protected. One transport unit shall contain only one batch of material.

PACKAGING MATERIAL

The supplier shall provide the customer with the packaging specification to show the type of packaging (cardboard, plastics, metal, wood) and the quantity per packaging unit. By giving a stamp and signature of the responsible person, the supplier confirms the compliance of the packaging with requirements in force within the EU (directive 94/62/EC and the associated decisions of European commission). The Supplier is entitled to change the packaging only after obtaining a written approval from TPV d.d. Packaging material to be used:

Type of material Plastic materials ABS, HDPE polyetylene of high density, LDPE polyetylene, PP polypropylene, PS polystyrene, PC EPS, PUR, PVC Paper and cardboard

YES NO X

Remarks

X X X

With customer's approval. Free of substances hindering the production of paper. Coatings shall be avoided (e.g. wax coating, paraffin eax coating, bitumen or oil coating, impregnated paper and cardboard). The Supplier commits that any wood packaging material (pallets, coils, shims,) made of wood in the rough and used for packaging of products and materials delivered to TPV d.d., shall comply with all technical requirements according to the norm ISPM 15. Use of other materials is permitted only upon a prior approval of the TPV Environment Division.

Wood

Steel strips Other

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 6 / 11

Any used packaging material shall be dry or protected against corrosion at the points which are in contact with steel.

PACKAGING METHODS

If not otherwise specified in the list of special requirements, the packaging methods are as follows: Type of material Steel in coils Packaging method (packaging label) (P0101/01) Coils shall be placed in a flat position on a wooden bars (100100mm) made for transport by forklifts (minimum free height of 100 mm, minimum free width of 600 mm) and wrapped with four strips. In case of several coils per a transport unit, the coils shall be separated with bars of 5050mm. Inner diameter of coil: 500-508 mm Outside diameter of coil: 1200-1450 mm (in case that maximum weight is achieved the outside diameter can be lower then prescribed). Maximum coil weight: 5000 kg (in case of weight excess a customer's approval is required). Maximum weight of transport unit (coil's width >120 mm): 5000 kg; Maximum weight of transport unit (coil's width <120 mm): 3500 kg; Maximum height of transport unit is 650 mm. This shall not apply for coils of 500mm. Recommended number of coils per transport unit in relation to the coil's height: Coil width (mm) >225 <225 <133 <88 <60 <42 Number of coils 1 2 3 4 5 6 Minimum number of wrapping strips per coil: Lengthwise (axial) min 1, transverse (radial) min 2. Recommended number of wrapping strips par coil in respect of coil's width: Coil height >250 mm <250 mm Nb of transversal bands min. 3 (120) min. 2 (180) Nb of lengthwise bands 2 1 (P0101/02) Plates shall be placed on the wooden cross-shaped bars (2x2) made for transport by forklifts (minimum free height 100 mm, minimum free width 600 mm) or on pallets wrapped with strips (2 transversal and 2 lengthwise). Maximum gross weight: 2500 kg. Tubes in bundles (P0102/01) Tubes shall be tied with metal strips lined with wood and formed into 4 or 6 angle bundles. Bundles shall be separated by wooden bars of 8080mm. Number of tying strips according to tube length: Tube length (m) Number of tying strips 5,5-6,5 5 3,5-5,5 4 1,5-3,5 3 < 1,5 2 Maximum width and height shall be 600 mm.

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

Steel sheets

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 7 / 11

Maximum weight of a bundle: 1500 kg. Guideline: to approach the weight of a bundle of 1500kg taking account of other restrictions. Wire in coils (P0103/01) The coil shall be tied with four steel strips and fasteners and placed on wooden cross-shaped bars pallet for transport by forklift (minimum free height of 100 mm, minimum free width of 600 mm). Steel strips and fasteners shall not cause any mechanical damage to wires. Maximum coil weight : 1200 kg Coil dimensions: Minimum inner diameter of coil: Din,min= 500 +50-0 mm, Maximum outside diameter Dout,max= 900 mm, Maximum coil height Hmax= 600 mm. The direction of uncoiling is anticlockwise.

Guideline: to approach the maximum weight or maximum outside diameter and height. Wires in bars (P0103/02) Bars shall be tied with metal strips into a bundle. Bundles shall be separated by bars of 8080mm. The metal strips shall not cause any damage to material. Maximum distance between strips shall be 1,7m (2 bindings at least). Maximum weight of a bundle: 1000 kg. Guideline: to approach the weight of a bundle of 1000kg.

4.3. Anti-corrosion protection

For anti-corrosion protection supplier shall apply requirements, referred in the standards namely in the chapter dealing with delivery conditions. In the event the standard does not define the duration of anti-corrosion protection, the minimum duration shall be 90 days from the day of production.

5. Quality

The responsibility for the quality of supplied products ordered by TPV lies fundamentally with the particular Supplier. The Supplier is also responsible for the analysis and follow-up of quality data at his sub-suppliers. The Supplier is bound to the goal of zero-defects and undertakes to optimize its performances continuously in pursuit of this goal.

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 8 / 11

Quality target for PPM indicators: - 6 months rolling PPM under 8.000 PPM for materials for internal and external visible parts, - 6 months rolling PPM under 2.000 PPM for materials for car body parts, - monthly PPM under 1/3 of 6 months rolling PPM, - no claims on safety characteristics. PPM is the rate of defective products (there are two kinds of defaults: technical and identification defaults) noticed at every level of the production process. PPM's are calculated on base of type packaging of delivered material, that means kilograms, meters, number of parts,

PPM monthly = 1month

QNC .10 QR

PPM 6 rolling _ month =

6 months

QNC .10 QR

1month

6 months

QNC = quantity of nonconforming products (pcs, kg, m, ) QR = quantity of delivered products (pcs, kg, m, ) Data extraction happens at the beginning of each month. Data processing begins in the morning of the third working day. Each monthly processing, the system completely actualizes data. All the indicators are computed on the last twelve months. This dynamic conception explains the possible variations on indicators from a month to another, particularly when data are consulted at a quite consolidated level. Nonconforming product: A product will be declared as nonconformity only if it does not meet TPV specifications; as a consequence, these nonconforming products will not be used, or will be reworked before use or will be replaced by the plant. For example in case of corrosion: if supplier did not respect specified treatment or protection, declaration will be made, if supplier respected the specifications, declaration will not be made, action will be to improve specifications. Rework or replacement: Products reworked or replaced will be declared as nonconformity only if this is suppliers responsibility. Analysis agreed with the supplier will define the responsible for rework or replacement (supplier or TPV plant); the supplier can participate in this analysis. Quantity of nonconforming products: Only exact quantity (number, kg, m, ) of nonconforming products, agreed with the supplier, and counted by TPV or supplier, will be declared. Estimation based on a sample can not be used to declare before counting by the supplier.

5.1. Initial samples

Initial samples are produced completely on full production conditions that will be tested by the producer for all specified characteristics. The results will be documented in initial sample reports (submission level 3 in PSW including all enclosures) and compared to the specifications. The initial sample approval by TPV and functional tests shall be carried out at the TPV production site.

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 9 / 11

Initial samples must be presented to TPV according to the Timing plan. Any variation must be agreed upon with TPV in writing. Initial sample parts must be clearly marked to prevent confusion and the receiver of these Initial Samples.

5.2. Documentation

The Supplier shall file and retain all order and quality related documents and records in accordance with the respective legal provisions and customer specified requirements. The Supplier shall make these documents available to TPV for inspection upon demand. The period for which any documents related to safety characteristics must be preserved is 15 years minimum. In individual cases longer periods may be agreed to. If any customer to TPV claims any requirements exceeding the above regulations the Supplier shall fulfil these requirements too. The Supplier must keep records on extra costs that he might incur in his compliance with the requested delivery reliability. These records must be regularly shown to TPV accompanied by documentary evidences. When becoming obvious to the Supplier that the fulfilment of any agreed term is likely to be failed (e.g. agreed quality characteristics, deadlines, delivery quantities), the Supplier is committed to inform TPV about the situation and the particular circumstances without delay. In the interest of finding a quick solution the Supplier is committed to disclose the pertinent data and facts. An inspection certificate DIN EN 10204, 3.1b has to be enclosed to the deliveries.

5.3. Special Characteristics

Special Characteristics documentation proceeding to be agreed in accordance with VDA volume 1 or requirements from final customers. If not otherwise stated, TPV will mark all special characteristic in specific list of demand with following marking:

R S

Safety S and R

R

Regulatory

5.4. Changes

Prior to making any change regarding production processes, material or bought-out parts for the products, moving of production sites, or changes regarding processes or equipment for inspection the Supplier shall advise TPV so early that it can be checked if the changes could have detrimental effects. Engineering changes must only be executed according to specifications made in writing and after TPV has given its confirmation. Verbal agreements are not effective. The Supplier shall acknowledge to TPV the receipt of any written change request (specification, notice of engineering change ....) stating the date planned for implementation in serial production within 2 weeks.

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 10 / 11

The Supplier must use an appropriate system in order to ensure that all concerned internal functions know and work in accordance with the latest engineering release level. Records must be kept about the distribution of the relevant documents and the implementation of the changes. Engineering changes in products require submission of new initial samples. At any modification on the product and/or the production process the Supplier undertakes to present on his own, without special order, new initial samples and IMDS data records.

5.5. Processing of Complaints / Incoming Inspection

The supplier implements an inspection concept to meet the goals and specifications under his own responsibility. The customer will inspect the delivered products after receipt only with regard to quantity, identity and noticeable damages. As for the rest the customer is exempted from the obligation of inspection and complaint against the supplier. The customer must report to the supplier without delay the defects described above, as soon as they are discovered during a regular business process flow. In so far the supplier waives his right to object to a belated complaint. On request, the supplier will support TPV with a visit to the TPV facilities in less than 48 hours. In case any material or product is being rejected by the TPV goods receiving department or during the production process, the Supplier will forthwith receive a written complaint report. The Supplier shall answer to all points of the complaint report adequately and in due time, and shall return the report to TPV (8-D status report). If the first reply to the complaint report is not made in writing within 24 hours, the complaint is considered to be admitted. Due to any particular supply situations or existing contractual supply obligations, every case of complaint may require actions to be taken immediately (sorting / rework). In this case, the Supplier at his expense undertakes to make forthwith qualified staff available to carry out the required immediate actions at the TPV plant. If necessary, staff of TPV may take care of putting the immediate measures into action until the arrival of the workers sent by the Supplier, preventing TPV from performing tasks as intermediary. All extra expenses incurred because of complaints made to bought-out parts/material will be charged to the Supplier - after clear allocation to their cause.

5.6. Exceptional Approvals

If any materials or products deviate from the standards, exceptional approvals for a determined period or quantity of parts might be possible provided that the functional performance, durability and safety of the products are not affected adversely. The Supplier must submit TPV a written request for the exceptional approval which must be approved by responsible of TPV (agreed with the TPVs procedures). Verbal arrangements are not permissible and ineffective.

5.7. Rework/Repairs

If, for a limited period of time, any repairs/rework on the products may be required to comply with the specifications, the kind of repairs/rework, the inspection and approval of the parts and the extent of the necessary repairs/rework (production quantity, period of time) must be communicated to and approved by TPV in writing.

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

LIST OF REQUIREMENTS FOR MATERIALS GENERAL REQUIREMENTS

No.: 108148 Supplier: Issue: 01 Page 11 / 11

Rework: All activities performed to adjust a product with failures due to manufacturing or assembly to conform subsequently to the quality requirements or to make them in the first place retroactively appropriate for the use intended by the customer and then complies with them. Repair: Measure taken on a non-conforming product with the aim that the product shall meet the requirements for the intended use though it possibly does not meet the original requirements.

5.8. Audit

TPV reserves the right to carry through audits at the Suppliers in order to assess the effectiveness of the Management System as well as in pursuit of specific improvement programs (System audit, process audit, product audits.) TPV accepts reasonable restrictions claimed by the Supplier to keep its trade secrets. The audits will be carried through on site in coordination with the supplier. The audit results will be used as a basis for the sourcing decision on one hand and to set up aimed action catalogues in pursuance of specific improvement programs on the other. Audits carried through by reputable customers and certificates by accredited companies awarded in accordance with the specifically applying standards in force will be accepted.

5.9. List of test

EN 10204 3.1 acceptance report for each delivery for tubes, wires and coils with special characteristics and EN 10204 2.2 acceptance report for each delivery for coils without safety characteristics Manufacturer issues the compliance confirmation with order indicating the results of specific test For tubes: Seam must be 100% controlled and without defect Eddy Current test

DOBAVITELJ / SUPPLIER: Datum/Date: __________________________

Podpis/Signature: ___________________________

Stamp:

PODPIS DOBAVITELJA: Supplier signature: The original document is archived in electronic form and available on the J drive in the folder ZVEZEK ZAHTEV This document is owned by TPV d.d. Any reproduction or distribution of this document is prohibited. 2010 TPV d.d.

Vous aimerez peut-être aussi

- Automatic Gearbox ZF 4HP 20Document40 pagesAutomatic Gearbox ZF 4HP 20Damien Jorgensen100% (3)

- Eurocode 3: Design of Steel Structures "ReadyDocument26 pagesEurocode 3: Design of Steel Structures "Readywazydotnet80% (10)

- BS en 12542-2020Document72 pagesBS en 12542-2020Luís Silva100% (1)

- 2016 IT - Sheilding Guide PDFDocument40 pages2016 IT - Sheilding Guide PDFlazarosPas encore d'évaluation

- Forex Day Trading SystemDocument17 pagesForex Day Trading SystemSocial Malik100% (1)

- Project Formulation and Appraisalpdf PDFDocument12 pagesProject Formulation and Appraisalpdf PDFabhijeet varadePas encore d'évaluation

- SecuritizationDocument46 pagesSecuritizationHitesh MorePas encore d'évaluation

- Ball-Valves ISO17292 EN1983515 530 Series PDFDocument21 pagesBall-Valves ISO17292 EN1983515 530 Series PDFGeorge_Wabag_2014Pas encore d'évaluation

- Aliping PDFDocument54 pagesAliping PDFDirect LukePas encore d'évaluation

- TII-HZI-50021252 - 1.0 - TII 16.20 Requirements For Contractors Technical DocumentsDocument14 pagesTII-HZI-50021252 - 1.0 - TII 16.20 Requirements For Contractors Technical DocumentsBorn ToSin0% (1)

- Segregation in CastingDocument17 pagesSegregation in CastingAsmaa Smsm Abdallh78% (9)

- Dominion Wargame RulesDocument301 pagesDominion Wargame Rules4544juutf100% (4)

- EdisDocument227 pagesEdisThong Chan100% (1)

- Study of Sheet Metal Stamping ProcessesDocument93 pagesStudy of Sheet Metal Stamping ProcessesDANIEL DIAZPas encore d'évaluation

- oSIST prEN 13445 11 2019Document12 pagesoSIST prEN 13445 11 2019Sama UmatePas encore d'évaluation

- Artistic CraftDocument5 pagesArtistic CraftDANIEL DIAZPas encore d'évaluation

- Exotic DVM 11 3 CompleteDocument12 pagesExotic DVM 11 3 CompleteLuc CardPas encore d'évaluation

- S 0100 1520 201 - 1 PDFDocument15 pagesS 0100 1520 201 - 1 PDFAliZenati100% (1)

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7D'EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Pas encore d'évaluation

- 3604 2Document17 pages3604 2Tiffany WilsonPas encore d'évaluation

- (DIN 28050 - 2009-09) - Behà Lter Und Apparate - Maximal Zulã Ssiger Druck - 1, 0 Bar Bis +0, 5 Bar - Technische Lieferbedingungen - 0001.de - enDocument8 pages(DIN 28050 - 2009-09) - Behà Lter Und Apparate - Maximal Zulã Ssiger Druck - 1, 0 Bar Bis +0, 5 Bar - Technische Lieferbedingungen - 0001.de - enNaveen Suresh KumarPas encore d'évaluation

- NIQS BESMM 4 BillDocument85 pagesNIQS BESMM 4 BillAliPas encore d'évaluation

- Specification For PE Pipes FittingsDocument32 pagesSpecification For PE Pipes FittingsFlorian_AngererPas encore d'évaluation

- Technical Specification - LPG HeaterDocument94 pagesTechnical Specification - LPG Heaterhbsheen100% (1)

- Final Drawing: Anti-Fouling SystemDocument11 pagesFinal Drawing: Anti-Fouling SystemThomas LiontosPas encore d'évaluation

- SPC-0804.02-20.22 Rev D2 General Requirements For Air Cooled Heat Ex ChangersDocument20 pagesSPC-0804.02-20.22 Rev D2 General Requirements For Air Cooled Heat Ex ChangersBernardo Ortiz100% (1)

- 6 - Linetrap - 400kv - 10mH - 3150 - A - R - 0Document17 pages6 - Linetrap - 400kv - 10mH - 3150 - A - R - 0Hassan KhaterPas encore d'évaluation

- Formula:: High Low Method (High - Low) Break-Even PointDocument24 pagesFormula:: High Low Method (High - Low) Break-Even PointRedgie Mark UrsalPas encore d'évaluation

- J-21 Rev1Document28 pagesJ-21 Rev1Hoàng Minh ÁiPas encore d'évaluation

- Student Management SystemDocument232 pagesStudent Management Systemslu_mangal73% (37)

- Module 1 Lesson 2Document31 pagesModule 1 Lesson 2Angela Rose BanastasPas encore d'évaluation

- BS en 12952-2-2011Document42 pagesBS en 12952-2-2011Mokhammad Fahmi Izdiharrudin100% (1)

- prEN 14700-FD-2013-11-Consumiveis para Revestimentos DurosDocument15 pagesprEN 14700-FD-2013-11-Consumiveis para Revestimentos DurosRicardo FernandesPas encore d'évaluation

- MR For Gate Valve Cast 301015Document43 pagesMR For Gate Valve Cast 301015AHMEDMALAHYPas encore d'évaluation

- SAILOR 6310 MF HF 150W Examination Module B Telefication PDFDocument7 pagesSAILOR 6310 MF HF 150W Examination Module B Telefication PDFНиколай филюкPas encore d'évaluation

- Famous Little Red Book SummaryDocument6 pagesFamous Little Red Book SummaryMatt MurdockPas encore d'évaluation

- BS en 10152 - 2017Document24 pagesBS en 10152 - 2017Артем Титов100% (2)

- Din en Iso 14341Document15 pagesDin en Iso 14341Rahul AherPas encore d'évaluation

- En 10168 Inspection InformationDocument12 pagesEn 10168 Inspection InformationStefano Squadrani100% (2)

- BIAN How To Guide Developing Content V7.0 Final V1.0 PDFDocument72 pagesBIAN How To Guide Developing Content V7.0 Final V1.0 PDFميلاد نوروزي رهبرPas encore d'évaluation

- EN 10224-A1 - Aço - Tubagens PDFDocument15 pagesEN 10224-A1 - Aço - Tubagens PDFnmcarlosPas encore d'évaluation

- Sandwich Panel Declaration-of-performance-Hilti-SF-DoP-009-EN-Declaration-of-performanceDocument17 pagesSandwich Panel Declaration-of-performance-Hilti-SF-DoP-009-EN-Declaration-of-performancegraziella njeimPas encore d'évaluation

- Esp e Ing SBT 00030 - Eng - R3Document15 pagesEsp e Ing SBT 00030 - Eng - R3thiagoPas encore d'évaluation

- PGC202 Instruction Manual PDFDocument68 pagesPGC202 Instruction Manual PDFpitPas encore d'évaluation

- Ed P 11.06 I 01Document15 pagesEd P 11.06 I 01neymarronPas encore d'évaluation

- Product Catalog THFDocument48 pagesProduct Catalog THFEdy Quispe QuentaPas encore d'évaluation

- EPD Structural Steel Sections and Merchant BarsDocument14 pagesEPD Structural Steel Sections and Merchant BarsadrianocostalopesPas encore d'évaluation

- EXXI 4001-00-00 VD MAN 0091 - AAX Instrucciones Equipos Auxiliares Sello GasDocument21 pagesEXXI 4001-00-00 VD MAN 0091 - AAX Instrucciones Equipos Auxiliares Sello GasrodolfostiPas encore d'évaluation

- Material Specification Report With EN 10204 Material Certificate From Raw Material SupplierDocument7 pagesMaterial Specification Report With EN 10204 Material Certificate From Raw Material SupplierNadia WilsonPas encore d'évaluation

- TOB DoP 12 EN 130816 HBS-4590-4890-RukoDocument2 pagesTOB DoP 12 EN 130816 HBS-4590-4890-RukoatesarikPas encore d'évaluation

- En Hes880 Re BDocument20 pagesEn Hes880 Re Belectutor.smPas encore d'évaluation

- SAILOR 6222 VHF DSC Class A EC Type Examination Module B NEMKO PDFDocument3 pagesSAILOR 6222 VHF DSC Class A EC Type Examination Module B NEMKO PDFlucas barriosPas encore d'évaluation

- Hot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsDocument3 pagesHot-Rolled Flat Products For Cold Forming From Low-Pearlite Fine Grained SteelsBielXDPas encore d'évaluation

- SRR30SAB CE HlklemoveDocument5 pagesSRR30SAB CE HlklemoveManohar T MPas encore d'évaluation

- BAS40-00-V To BAS40-06-V: Small Signal Schottky Diodes, Single & DualDocument5 pagesBAS40-00-V To BAS40-06-V: Small Signal Schottky Diodes, Single & DualtomscribdasdfPas encore d'évaluation

- Din en 1172 e 2010-07Document16 pagesDin en 1172 e 2010-07Niko Zurabishvili100% (1)

- Fidic Subcontract Tunnel ProjectDocument96 pagesFidic Subcontract Tunnel ProjectMadtewslPas encore d'évaluation

- Castel Product Handbook EngDocument176 pagesCastel Product Handbook EngtomakagsxrPas encore d'évaluation

- Po 0042327Document2 pagesPo 0042327juandlc3368Pas encore d'évaluation

- Encore LT Manual Powder Spray Systems: Customer Product Manual Part 1604857-17Document97 pagesEncore LT Manual Powder Spray Systems: Customer Product Manual Part 1604857-17Wilfredo MolinaPas encore d'évaluation

- Products Handbook 2009Document170 pagesProducts Handbook 2009vickersPas encore d'évaluation

- Solenoid ValvesDocument56 pagesSolenoid ValvesxvahnxxPas encore d'évaluation

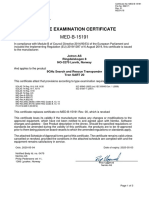

- Ec Type Examination Certificate: MED-B-15191Document3 pagesEc Type Examination Certificate: MED-B-15191khoasunpacPas encore d'évaluation

- Certificate MED B 15191R1 SART20Document3 pagesCertificate MED B 15191R1 SART20marine f.Pas encore d'évaluation

- 13A26Document33 pages13A26Luis MorenoPas encore d'évaluation

- Ic 4048Document16 pagesIc 4048Thinh DoPas encore d'évaluation

- LE HD4 (EN) E 1VCP000005-0902aDocument8 pagesLE HD4 (EN) E 1VCP000005-0902aMahyar MashayekhiPas encore d'évaluation

- LS 145-10.T01 - 10 Welding of Piping (EN)Document7 pagesLS 145-10.T01 - 10 Welding of Piping (EN)Kreshna Wisnu BrataPas encore d'évaluation

- CD40106BPWDocument16 pagesCD40106BPWEddiemerckxPas encore d'évaluation

- DT-090.20 Manual 20-1218-101 (Infeed) - PL PDFDocument38 pagesDT-090.20 Manual 20-1218-101 (Infeed) - PL PDFshellockPas encore d'évaluation

- Murrelektronik GMBH 07-02-23 - (5) China RoHS 2 50EEP - DoC - Z - ADocument1 pageMurrelektronik GMBH 07-02-23 - (5) China RoHS 2 50EEP - DoC - Z - AtarikduitPas encore d'évaluation

- Declaration of Performance CFS 0761 CPD 0210 EN Declaration of Performance IBD WWI 00000000000003746527 000Document1 pageDeclaration of Performance CFS 0761 CPD 0210 EN Declaration of Performance IBD WWI 00000000000003746527 000G GPas encore d'évaluation

- Plug Diverter ValveDocument8 pagesPlug Diverter ValveArif Abu FarhanaPas encore d'évaluation

- BI 0611 PTN 49703 Shipping PumpsDocument3 pagesBI 0611 PTN 49703 Shipping PumpsSelva KumarPas encore d'évaluation

- INSTA SBC EN 1401-1 2021 Oct UKDocument17 pagesINSTA SBC EN 1401-1 2021 Oct UKStayvros ParasitosPas encore d'évaluation

- European Technical Approval ETA-10/0416: BM TRADA CertificationDocument20 pagesEuropean Technical Approval ETA-10/0416: BM TRADA CertificationPaulPas encore d'évaluation

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryD'EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryPas encore d'évaluation

- Power Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryD'EverandPower Boilers & Heat Exchangers World Summary: Market Values & Financials by CountryPas encore d'évaluation

- Metal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryD'EverandMetal Tanks (Heavy Gauge) World Summary: Market Values & Financials by CountryPas encore d'évaluation

- Examining The Origin of Soshu-Den OldDocument11 pagesExamining The Origin of Soshu-Den OldDANIEL DIAZPas encore d'évaluation

- Examining The Origin of Soshu-DenDocument13 pagesExamining The Origin of Soshu-DenDANIEL DIAZPas encore d'évaluation

- Yakiire (Edge Hardening) and CurvatureDocument1 pageYakiire (Edge Hardening) and CurvatureDANIEL DIAZPas encore d'évaluation

- Sword Forging CompetitionDocument3 pagesSword Forging CompetitionDANIEL DIAZPas encore d'évaluation

- FSV Phase2 Overview ReportDocument79 pagesFSV Phase2 Overview ReportDANIEL DIAZPas encore d'évaluation

- Metal Forming Fundamentals and ApplicationsDocument3 pagesMetal Forming Fundamentals and ApplicationsDANIEL DIAZPas encore d'évaluation

- Blockchains: Architecture, Design and Use CasesDocument26 pagesBlockchains: Architecture, Design and Use Caseseira kPas encore d'évaluation

- Amendments To The PPDA Law: Execution of Works by Force AccountDocument2 pagesAmendments To The PPDA Law: Execution of Works by Force AccountIsmail A Ismail100% (1)

- Faa Data On B 777 PDFDocument104 pagesFaa Data On B 777 PDFGurudutt PaiPas encore d'évaluation

- Aakriti 1Document92 pagesAakriti 1raghav bansalPas encore d'évaluation

- Feasibility Study For Cowboy Cricket Farms Final Report: Prepared For Prospera Business Network Bozeman, MTDocument42 pagesFeasibility Study For Cowboy Cricket Farms Final Report: Prepared For Prospera Business Network Bozeman, MTMyself IrenePas encore d'évaluation

- Gaming Ports MikrotikDocument6 pagesGaming Ports MikrotikRay OhmsPas encore d'évaluation

- Frellwits Swedish Hosts FileDocument10 pagesFrellwits Swedish Hosts FileAnonymous DsGzm0hQf5Pas encore d'évaluation

- Editan - Living English (CD Book)Document92 pagesEditan - Living English (CD Book)M Luthfi Al QodryPas encore d'évaluation

- CiscoDocument6 pagesCiscoNatalia Kogan0% (2)

- Haier in India Building Presence in A Mass Market Beyond ChinaDocument14 pagesHaier in India Building Presence in A Mass Market Beyond ChinaGaurav Sharma100% (1)

- CS-6777 Liu AbsDocument103 pagesCS-6777 Liu AbsILLA PAVAN KUMAR (PA2013003013042)Pas encore d'évaluation

- MSC-MEPC.2-Circ.17 - 2019 Guidelines For The Carriage of Blends OfBiofuels and Marpol Annex I Cargoes (Secretariat)Document4 pagesMSC-MEPC.2-Circ.17 - 2019 Guidelines For The Carriage of Blends OfBiofuels and Marpol Annex I Cargoes (Secretariat)DeepakPas encore d'évaluation

- ADC of PIC MicrocontrollerDocument4 pagesADC of PIC Microcontrollerkillbill100% (2)