Académique Documents

Professionnel Documents

Culture Documents

HRSG Fundamentals

Transféré par

chatuusumitavaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

HRSG Fundamentals

Transféré par

chatuusumitavaDroits d'auteur :

Formats disponibles

S.

Heat Recovery Steam Generators

The link between the gas turbine and the steam cycle in a combined cycle is the Heat Recovery Steam Generator (HRSG). In the HRSG, heat from gas turbine exhaust is used to generate steam in the steam cycle. The HRSG is made up of several heat exchangers for feed water heating, water vaporization and steam superheating, while at the same time cooling the gas turbine exhaust. There is often more than one pressure level in the steam side of the HRSG. An Example of HRSG Source

P1.1 Literature

Horlock, J.H.; 1992 "Combined Power Plants" ISBN 0- 08-040502-9 Kehlhofer, R.; Warner, J.; Nielsen, H and Bachmann 1999 Combined-Cycle Gas and Steam Turbine Power Plants ISBN 0-87814-736-5 Weston, K, 1992 "Energy Conversion The EBook", http://www.personal.utulsa.edu/~kenneth-weston/

P1.2 Acknowledgements

Author: Catharina Erlich, KTH, 2005, updated 2006 1

Reviewer: Marianne Salomn, 2006 Reviewer: Vitali Fedulov, 2005

P1.3 Prerequisites:

At least one year of studies in an engineering program at university level; Basic Thermodynamics (at least 160 LU = 4 weeks of fulltime studies); S1B2 Steam Cycles; S1B3 Gas Turbine Cycles.

P1.4 LU and TU

Learning Units: 3 Teaching Units:1

S.2 Educational Objectives

After having studied the chapter, the student should be able to: Sketch the different HRSG layouts (single pressure and dual pressure) both in a flow scheme and in a heat transfer-temperature diagram; Analyze a combined cycle thermodynamically, through heat balances in the HRSG; Understand the importance of parameters introduced for HRSG design, such as the pinch point temperature difference.

S.3 Single Pressure HRSG

In a single-pressure HRSG, the heat recovery from gas turbine exhaust is normally done in three steps: In the economizer, low value heat from the exhaust gas is used for heating the pressurized feed water; In the evaporator, medium value heat from the exhaust is used for boiling the pressurized water, which generates saturated steam; In the superheater, high value heat from the exhaust is used for superheating the steam generated in the evaporator.

Economizer To the stack Feed water pump

Drum

Evaporator

Circulation pump Superheater Gas turbine Exhaust

Superheater

Superheated Steam

HRSG Flow Diagram

S.4 Heat Transfer Diagram and Heat Balances

The three steps of heat recovery in the HRSG can be illustrated in a temperature-heat transfer diagram. The aim of such a diagram is to facilitate analysis of different parameters in the HRSG. The upper line illustrates the cooling of exhaust gas from inlet to outlet in the HRSG. The lower line illustrates the water-tosteam process, where evaporation takes place at constant temperature. The area between the exhaust profile and the water profile is a measure of the heat loss in the HRSG. An important design parameter is the pinch point temperature difference, tPP. In many HRSG designs, the feed water exiting the economizer has a somewhat lower temperature than the saturation temperature of the drum; this is called the approach temperature. Different parameters of importance for analyzing the combined cycle are found through heat balances in the HRSG.

Economizer

Temperature tg2 tg3

Stack tg4

tg1

Gas turbine exhaust

tsh hsh

Superheater

tfw hfw

ts Evaporator hs1 (saturation)

Economizer

tpp

hs2

Heat transferred

To the stack tg4 Feed water pump

hfw

tg3

hs1 Drum hs2 hs1

Evaporator

tg2 Superheater Gas turbine Exhaust

Superheater

Circulation pump hsh hs2

tg1

Superheated Steam

P4.1 Measure of heat loss in the HRSG

In an ideal heat exchanger, the temperature difference between the two media on each heat exchanger side approaches zero, i.e. T � 0. In a real heat exchanger, the temperature difference can never become zero, because the possible size of the heat exchanger surface area is limited. The larger the temperature difference between the two media, the lower the efficiency of the heat exchange, and thus less heat is recovered. The lower the heat recovery (and thus efficiency), the higher the exit temperature of the cooled medium. IDEAL HEAT EXCHANGE

In the HRSG of a combined cycle, the water vaporization at constant temperature constitutes the largest heat loss. The larger the area between the exhaust profile and the water profile, the higher the exhaust temperature out from HRSG, i.e. the stack temperature.

HEAT EXCHANGE IN A HRSG

P4.2 Pinch point temperature difference, tPP

The pinch point temperature difference (tPP) is the difference between the temperature of the exhaust exiting the evaporator (tg3) and the temperature of water evaporation (ts):

tPP = tg3 - ts

4

The water evaporation takes place at constant temperature (isothermal process) at the pressure prevailing in the drum. Without considering pressure losses in the water/steam tubes, the pressure in the boiler drum equals the pressure after the feedwater pump. The pinch point temperature difference, tPP , is usually between 5C and 15C. The lower the pinch point temperature difference, the higher the cost for the heat exchanger.

On the other hand, the lower the pinch point temperature difference, the more heat is recovered from the flue gas to the water-to-steam process. The aim in introducing the pinch point temperature difference into HRSG designs is to avoid a temperature cross situation. A temperature cross situation results when part of the economizer and part of the evaporator virtually HEAT the EXHAUST GAS, as illustrated below. The temperature cross situation is thermodynamically impossible.

Temperature

Gas turbine tg1 exhaust

tg2 tg3

Economizer

tsh

Superheater

Stack tg4

Evaporator

ts

tfw

Heat transferred

Observe that all temperatures, tg4, tFW, tg1 and tsh, may be very reasonable.

The temperature cross situation can occur if the engineer assumes a stack temperature for his/her calculations without checking the pinch point temperature difference. It is thus important for all HRSG designers to always base their calculations on the pinch point temperature difference and not on the stack temperature.

P4.3 Approach temperature

The approach temperature is defined as the temperature difference between the saturation temperature and the economizer outlet temperature, i.e.

tappr = ts teco,out

The purpose of keeping the economizer outlet temperature somewhat lower than the saturation temperature is to avoid evaporation in the economizer. Evaporation would cause tube erosion and other problems, since most economizers are not designed to handle two-phase flows (such a heat exchanger would cost significantly more!) The approach temperature range is typically between 5C and 12C.

P4.4 Heat balances in the HRSG

The heat recovered from the flue gas can be balanced both from the exhaust side viewpoint and from the water profile viewpoint according to:

mgtcpg(tg1- tg4) Gas side Qrecovered mst(hsh- hfw)

Steam side

(A)

Heat balances for each component in the HRSG are as follows (without the economizer approach temperature): Economizer: mgt cpg (tg3 tg4) = mst (hS1 hfw) (B) 6

Evaporator: mgt cpg (tg2 tg3) = mst (hS2 hS1) Superheater: mgt cpg (tg1 tg2) = mst (hsh hS2)

(C)

(D)

Caution! The specific heat, cp, is temperature dependent and thus taken as an average value between the two gas temperatures in each equation, i.e. cp for the gas passing in the economizer is NOT the same as for the gas in the superheater (for example). The enthalpies hS1 and hS2 are found in water/steam saturation tables for the pressure prevailing in the boiler drum. Without consideration of pressure losses, the drum pressure equals the steam turbine inlet pressure. Heat balances for each component in the HRSG with the economizer approach temperature: Economizer: mgt cpg (tg3 tg4) = mst (happr hfw) Evaporator: mgt cpg (tg2 tg3) = mst (hS2 happr) (B)

(C)

HEAT BALANCE FOR THE SUPERHEATER AND EVAPORATOR For overview calculations of a combined cycle, the gas temperature, tg2, is seldom needed. The pinch point temperature difference, on the other hand, is important to estimate, and if it is already defined, a heat balance may give other parameters of importance - for example, the steam flow. Thus, by combining equations (C) and (D), a very convenient heat balance is obtained:

mgt cpg (tg1 tg3) = mst (hsh hs1)

where tPP = tg3 - ts

Temperature tg2 tg3

Stack tg4

tg1

Gas turbine exhaust

tsh hsh

Superheater

tpp

ts hs2

tfw hfw

hs1 (saturation)

Economizer

Evaporator

Heat transferred

7

S.5 Multi-Pressure HRSG

More heat from the exhaust gas can be recovered to the steam cycle, if several pressure levels in the steam cycle are introduced. The increased heat exchange efficiency of a multi-pressure HRSG results in a lower stack temperature compared to a single pressure HRSG. For an HRSG with two pressure levels, the two pressures cannot be close in value; the pressure difference should be distinctive.

HRSG with Two Pressure Levels

P5.1 If several pressure levels in the steam cycle are introduced

By introducing two pressure levels in the HRSG, the area between the exhaust profile and the water profile decreases, as illustrated in the picture to the right. This area represents the heat losses in the HRSG. Hypothetically, an infinite number of pressure levels introduced on the water side would result in the heat transfer profile for water becoming a straight line. However, the efficiency increase becomes smaller 8

for each new pressure level introduced. In addition, each pressure level increases the cost of the HRSG installation; therefore, introducing more than 3 pressure levels in the HRSG is seldom profitable.

P5.2 Lower stack temperature compared to a single pressure HRSG

Example: A certain combined cycle working a certain turbine connected to a single pressure HRSG with certain steam data (pressure and temperature) and condenser pressure has a stack exhaust temperature of 120C. Modifying this certain cycle (same gas turbine as above) to a dual pressure HRSG, with high pressure steam (same pressure and temperature as above) and low pressure steam (constituting 20% of the total steam flow - the rest is high pressure steam), the stack temperature of the exhaust is 80C. The combined cycle with the dual pressure HRSG will have a higher steam mass flow and a higher steam turbine output, for the same gas turbine and thus the same energy available in the exhaust.

P5.3 The pressure difference should be distinctive

The lower pressure should be low (3-5 bars), so that water vaporization can take place with low value exhaust heat. Water at 5 bars boils at 150C. The higher pressure should be relatively high (for example, 50 bars), so that the steam turbine power is maximized. The distribution between high pressure and low pressure steam should be such that about 70-90% of the total steam should be at high pressure.

S.6 Supplementary Firing

Supplementary firing of gas turbine exhaust will increase the temperature, and thus more steam can be produced in the steam cycle. The supplementary fuel can be solid, liquid or gaseous and can be chosen independently of the gas turbine. Supplementary firing comes with several advantages, particularly in a cogeneration plant. 9

Supplementary firing does not increase the combined cycle efficiency, since the fuel supplied is only used in the steam cycle part. This means that supplementary firing generally causes lower cycle efficiency. HRSG with Supplementary Firing

P6.1 Advantages

Supplementary firing gives higher power output in the steam cycle. It gives flexible operation possibilities, thanks to a varying -ratio for heat production (-ratio is the ratio between the power and the heat produced). The steam cycle can work independently in case of a gas turbine breakdown.

P6.2 Combined cycle efficiency for supplementary firing

The combined cycle efficiency for supplementary firing is:

CC = & GTel STel & Q fuel ,GT + Q sf

S.7 Summary

The HRSG is the link between the gas turbine cycle and the steam turbine cycle, where hot gas turbine exhaust is cooled while transferring heat to the steam cycle. The HRSG consists of, in a single pressure configuration, an economizer, evaporator and superheater. An important design parameter is the pinch point temperature difference, which prevents a temperature cross situation from occurring in the HRSG. More than one pressure level in the HRSG leads to increased efficiency, since more energy can be recovered to the steam cycle (thus lowering the stack temperature).

+P

10

Supplementary firing gives important operation flexibility but generally decreases the combined cycle efficiency since the supplementary fuel is only used in the steam cycle part. This you must know

P7.1 This you must know

The layout of a single-pressure HRSG How to illustrate heat transfer in a HRSG in a temperature-heat transfer diagram Definition of pinch point temperature difference and why this is used Definition of approach temperature and why this is used Heat balances in the HRSG The aim of multi-pressure HRSG, and how to sketch the layout of a dual-pressure HRSG Advantages of supplementary firing and effect of this on the combined cycle efficiency

11

Vous aimerez peut-être aussi

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AD'EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&APas encore d'évaluation

- HRSG I&C Training ProgramDocument106 pagesHRSG I&C Training Programnardo antonio llanos matus100% (3)

- Thermax HRSGDocument12 pagesThermax HRSGrevenk100% (1)

- HRSG Cycle EfficiencyDocument4 pagesHRSG Cycle EfficiencySuzaimi Safei50% (2)

- HRSG Overview PDFDocument36 pagesHRSG Overview PDF55312714100% (6)

- HRSG SIMULATION V.GanapathyDocument59 pagesHRSG SIMULATION V.Ganapathyali100% (2)

- 90325.presentation (HRSG)Document17 pages90325.presentation (HRSG)Kumar Raja100% (2)

- HRSG Operator Training ManualDocument184 pagesHRSG Operator Training ManualXcdxtv100% (10)

- Optimizing Duct Burner ReliabilityDocument10 pagesOptimizing Duct Burner ReliabilityPajooheshPas encore d'évaluation

- HRSG 01 Basic DesignDocument40 pagesHRSG 01 Basic DesignPremadi SetyokoPas encore d'évaluation

- Song Hau 1 Thermal Power Plant (2X600Mw) : Document Submission Status: For ConstructionDocument20 pagesSong Hau 1 Thermal Power Plant (2X600Mw) : Document Submission Status: For ConstructionMinh Hoang NguyenPas encore d'évaluation

- 02B HRSGDocument50 pages02B HRSGrseclen100% (2)

- HRSG - Basic UnderstandingDocument30 pagesHRSG - Basic Understanding이영준100% (23)

- Power Plant TrainingDocument13 pagesPower Plant Traininganandtvr100% (1)

- HRSG PDFDocument248 pagesHRSG PDFaztec20100% (11)

- 2 Technology EvolutionDocument20 pages2 Technology EvolutionRokan Uddin100% (1)

- 5 - HRSG Proposal ProcessDocument28 pages5 - HRSG Proposal ProcessAlde MUPas encore d'évaluation

- HRSG StartupDocument20 pagesHRSG StartupKvvPrasad100% (1)

- Heat Recovery Steam Generator 5Document29 pagesHeat Recovery Steam Generator 5Hitesh SinglaPas encore d'évaluation

- Chapter 5 Steam TurbineDocument78 pagesChapter 5 Steam TurbineGloria Del Carmen MuñozPas encore d'évaluation

- Heat Recovery Steam GeneratorsDocument94 pagesHeat Recovery Steam GeneratorshoangpalestinePas encore d'évaluation

- Shuaiba North HRSG ManualDocument91 pagesShuaiba North HRSG Manualmartinp17171100% (7)

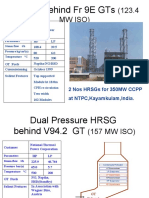

- Hrsgs Behind FR 9E GTS: (123.4 MW Iso)Document20 pagesHrsgs Behind FR 9E GTS: (123.4 MW Iso)api-19986783100% (1)

- CCPPDocument34 pagesCCPPphanindra100% (1)

- Combine Cycle Power Plant Design InformationDocument47 pagesCombine Cycle Power Plant Design Informationkalasivan0% (1)

- Duct Firing SystemDocument40 pagesDuct Firing Systemrahul_choubey_9Pas encore d'évaluation

- Once Through BoilerDocument9 pagesOnce Through Boilerbhuvi_patu12Pas encore d'évaluation

- HP-LP Bypass System AdvantagesDocument3 pagesHP-LP Bypass System Advantageskaruna346Pas encore d'évaluation

- Heat Recovery Steam Generator Operation ManualDocument45 pagesHeat Recovery Steam Generator Operation ManualReyes Sanchez100% (1)

- HRSG 2011 BrochureDocument12 pagesHRSG 2011 BrochureAndry SetiawanPas encore d'évaluation

- C1 CCPPDocument109 pagesC1 CCPPSubrahmanyan Edamana100% (1)

- Combined CycleDocument34 pagesCombined Cycleatulsemilo100% (2)

- Chapter 4 HRSGDocument39 pagesChapter 4 HRSGGloria Del Carmen Muñoz100% (1)

- Retrofitting Duct Burners For CO ControlDocument7 pagesRetrofitting Duct Burners For CO ControlarjmandquestPas encore d'évaluation

- Gas Turbine MaintenanceDocument47 pagesGas Turbine MaintenanceMohammad Ibnul Hossain100% (1)

- HRSG StartupDocument19 pagesHRSG Startuptpplant100% (1)

- Heat Recovery Steam GeneratorDocument69 pagesHeat Recovery Steam GeneratorAayushi Agarwal100% (5)

- Steam Turbines For Waste To EnergyDocument4 pagesSteam Turbines For Waste To EnergyMANIU RADU-GEORGIANPas encore d'évaluation

- Combined Cycle FundamentalsDocument76 pagesCombined Cycle FundamentalsVinnu89% (9)

- An Overview of FBC Boiler: Compiled BY S.S.AcharyaDocument56 pagesAn Overview of FBC Boiler: Compiled BY S.S.AcharyaMusycal Fynnc100% (1)

- 220021enc Combined Cycle Power Plant OverviewDocument27 pages220021enc Combined Cycle Power Plant OverviewBalajirao Samatham100% (4)

- Boiler Water Training PDFDocument113 pagesBoiler Water Training PDFAnonymous vUMhaMzYt100% (3)

- HRSG SimulationDocument57 pagesHRSG SimulationsatishchemengPas encore d'évaluation

- Alstom Gas Turbine PDFDocument29 pagesAlstom Gas Turbine PDFHatem Jafoura33% (3)

- 07b BurnersDocument16 pages07b BurnersTissa1969Pas encore d'évaluation

- Air Cooled Condenser ACC PDFDocument3 pagesAir Cooled Condenser ACC PDFHoney TiwariPas encore d'évaluation

- HRSG 2015 PPT-1Document81 pagesHRSG 2015 PPT-1chdi100% (10)

- Thermal Power Plant: Pre-Operational ActivitiesD'EverandThermal Power Plant: Pre-Operational ActivitiesÉvaluation : 4 sur 5 étoiles4/5 (4)

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantD'EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryÉvaluation : 4 sur 5 étoiles4/5 (5)

- Circulating Fluidized Bed Technology: Proceedings of the First International Conference on Circulating Fluidized Beds, Halifax, Nova Scotia, Canada, November 18-20, 1985D'EverandCirculating Fluidized Bed Technology: Proceedings of the First International Conference on Circulating Fluidized Beds, Halifax, Nova Scotia, Canada, November 18-20, 1985P. BasuÉvaluation : 5 sur 5 étoiles5/5 (1)

- Fluidized Bed Boilers: Design and ApplicationD'EverandFluidized Bed Boilers: Design and ApplicationÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Boiler Control Systems Engineering, Second EditionD'EverandBoiler Control Systems Engineering, Second EditionÉvaluation : 4.5 sur 5 étoiles4.5/5 (15)

- Advanced Distillation Technologies: Design, Control and ApplicationsD'EverandAdvanced Distillation Technologies: Design, Control and ApplicationsPas encore d'évaluation

- Optimize Energy Efficiency of HRSGDocument5 pagesOptimize Energy Efficiency of HRSGfaanilasaaniPas encore d'évaluation

- REFRIGERATION EarlyDocument21 pagesREFRIGERATION EarlyIrfan FajriPas encore d'évaluation

- Comb CycleDocument13 pagesComb Cyclerain55555Pas encore d'évaluation

- Sepam Iec 61850 User ManualDocument76 pagesSepam Iec 61850 User ManualchatuusumitavaPas encore d'évaluation

- Functional EquationsDocument39 pagesFunctional EquationschatuusumitavaPas encore d'évaluation

- SCADA05 SCADAandSubstationControlCommunicationDocument14 pagesSCADA05 SCADAandSubstationControlCommunicationchatuusumitavaPas encore d'évaluation

- Xxpnentl LGRTHMDocument6 pagesXxpnentl LGRTHMElvisPas encore d'évaluation

- Ntse Stage - Ii: Mat Paper SolutionsDocument11 pagesNtse Stage - Ii: Mat Paper SolutionschatuusumitavaPas encore d'évaluation

- Iraq Restores Russian Firm's Contract For Al AdaimDocument4 pagesIraq Restores Russian Firm's Contract For Al AdaimchatuusumitavaPas encore d'évaluation

- MVT Mns VluethrmDocument2 pagesMVT Mns VluethrmchatuusumitavaPas encore d'évaluation

- NTSE Sample Paper EconomyDocument5 pagesNTSE Sample Paper EconomySahooashuPas encore d'évaluation

- MP State Ntse 2012-13 Stage - 1 (Mat)Document11 pagesMP State Ntse 2012-13 Stage - 1 (Mat)chatuusumitavaPas encore d'évaluation

- Favorite Quotes #2Document23 pagesFavorite Quotes #2ThamuzPas encore d'évaluation

- Iec 61850 Mark AdamiakDocument16 pagesIec 61850 Mark AdamiakcastrojpPas encore d'évaluation

- Harris, Sam - An Atheist ManifestoDocument9 pagesHarris, Sam - An Atheist ManifestoNny VelezPas encore d'évaluation

- Nseb2012 SolutionDocument1 pageNseb2012 SolutionSatyadev PolisettiPas encore d'évaluation

- Application of KKSDocument18 pagesApplication of KKSrawatbs2020Pas encore d'évaluation

- Explaining LogarithmsDocument117 pagesExplaining LogarithmsrcraktimcPas encore d'évaluation

- Vocabulary For TOEFL iBTDocument191 pagesVocabulary For TOEFL iBTquevinh94% (48)

- NEET UG CounsellingDocument1 pageNEET UG CounsellingchatuusumitavaPas encore d'évaluation

- NEET UG CounsellingDocument1 pageNEET UG CounsellingchatuusumitavaPas encore d'évaluation

- Effect of Friciton On Rolling Tire - Pavement InteractionDocument45 pagesEffect of Friciton On Rolling Tire - Pavement InteractionfullkulePas encore d'évaluation

- Complex SolnsDocument5 pagesComplex SolnsAntonio RaianPas encore d'évaluation

- Local Manufacturer Prequalification GuidelinesDocument3 pagesLocal Manufacturer Prequalification GuidelineschatuusumitavaPas encore d'évaluation

- 101 Problems in AlgebraDocument160 pages101 Problems in AlgebraTrishaii Cuaresma96% (28)

- Functional EquationsDocument39 pagesFunctional EquationschatuusumitavaPas encore d'évaluation

- A ApproximationsDocument8 pagesA ApproximationschatuusumitavaPas encore d'évaluation

- Cambridge Learner Guide For As and A Level PhysicsDocument54 pagesCambridge Learner Guide For As and A Level PhysicschatuusumitavaPas encore d'évaluation

- Av Average ValueDocument3 pagesAv Average ValuechatuusumitavaPas encore d'évaluation

- Comp Phys 1Document19 pagesComp Phys 1chatuusumitavaPas encore d'évaluation

- GujaratLabour and Employment Under Globalisation The Case of GujaratDocument9 pagesGujaratLabour and Employment Under Globalisation The Case of GujaratKamalDeep SidhuPas encore d'évaluation

- Calculus - An Intuitive and Physical ApproachDocument1 pageCalculus - An Intuitive and Physical Approachchatuusumitava0% (1)

- Creative LibrarianDocument13 pagesCreative LibrarianulorPas encore d'évaluation

- Lifecycle of A Butterfly Unit Lesson PlanDocument11 pagesLifecycle of A Butterfly Unit Lesson Planapi-645067057Pas encore d'évaluation

- Fcu Valve Honeywel PDFDocument6 pagesFcu Valve Honeywel PDFRyn YahuFPas encore d'évaluation

- Jazz PrepaidDocument4 pagesJazz PrepaidHoney BunnyPas encore d'évaluation

- Selecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationDocument35 pagesSelecting Appropriate Instructional Materials For Edukasyong Pantahanan at Pangkabuhayan/ Technology and Livelihood EducationJhenn Mhen Yhon100% (1)

- Corometrics 170 Series BrochureDocument3 pagesCorometrics 170 Series BrochureCesar MolanoPas encore d'évaluation

- Describe an English lesson you enjoyed.: 多叔逻辑口语,中国雅思口语第一品牌 公共微信: ddielts 新浪微博@雅思钱多多Document7 pagesDescribe an English lesson you enjoyed.: 多叔逻辑口语,中国雅思口语第一品牌 公共微信: ddielts 新浪微博@雅思钱多多Siyeon YeungPas encore d'évaluation

- Lic Nach MandateDocument1 pageLic Nach Mandatefibiro9231Pas encore d'évaluation

- Apps Android StudioDocument12 pagesApps Android StudioDaniel AlcocerPas encore d'évaluation

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- FS-C8025MFP Release NotesDocument22 pagesFS-C8025MFP Release NotesFirmware SM-SHPas encore d'évaluation

- Power-Miser 12 Water Heater ManualDocument32 pagesPower-Miser 12 Water Heater ManualClaudeVanDammPas encore d'évaluation

- Integration Plan Grade 9 Mapeh SeptemberDocument3 pagesIntegration Plan Grade 9 Mapeh Septemberbernie evaristo bacsaPas encore d'évaluation

- Chen 2021Document13 pagesChen 2021Aitor UzkudunPas encore d'évaluation

- Kazi Shafikull IslamDocument3 pagesKazi Shafikull IslamKazi Shafikull IslamPas encore d'évaluation

- Information Brochure: (Special Rounds)Document35 pagesInformation Brochure: (Special Rounds)Praveen KumarPas encore d'évaluation

- Libro INGLÉS BÁSICO IDocument85 pagesLibro INGLÉS BÁSICO IRandalHoyos100% (1)

- Analysis of Green Entrepreneurship Practices in IndiaDocument5 pagesAnalysis of Green Entrepreneurship Practices in IndiaK SrivarunPas encore d'évaluation

- 37270a QUERCUS GBDocument6 pages37270a QUERCUS GBMocanu Romeo-CristianPas encore d'évaluation

- 240-56062705 RTV Silicone Rubber Insulator Coating and Shed Extender Supplier StandardDocument10 pages240-56062705 RTV Silicone Rubber Insulator Coating and Shed Extender Supplier StandardJane ChatsiriphatthanaPas encore d'évaluation

- Puratattva No 41Document3 pagesPuratattva No 41ultimategoonPas encore d'évaluation

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDocument1 pageSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiPas encore d'évaluation

- The Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionDocument22 pagesThe Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionCrystal JenningsPas encore d'évaluation

- R67068.0002 2 HB Profibus-Schnittstelle en KueblerDocument42 pagesR67068.0002 2 HB Profibus-Schnittstelle en KueblerSabari StunnerPas encore d'évaluation

- Excavation Trench Permit Ex 1 F0206Document5 pagesExcavation Trench Permit Ex 1 F0206emeka2012Pas encore d'évaluation

- Business Statistics: Fourth Canadian EditionDocument41 pagesBusiness Statistics: Fourth Canadian EditionTaron AhsanPas encore d'évaluation

- Form No. 1 Gangtok Municipal Corporation Deorali, SikkimDocument2 pagesForm No. 1 Gangtok Municipal Corporation Deorali, SikkimMUSKAANPas encore d'évaluation

- Hayek - Planning, Science, and Freedom (1941)Document5 pagesHayek - Planning, Science, and Freedom (1941)Robert Wenzel100% (1)

- 09-11-2016 University Exam PaperDocument34 pages09-11-2016 University Exam PaperSirisha AsadiPas encore d'évaluation

- EE360 - Magnetic CircuitsDocument48 pagesEE360 - Magnetic Circuitsبدون اسمPas encore d'évaluation