Académique Documents

Professionnel Documents

Culture Documents

Truss Bridge Design

Transféré par

Vũ Trí MinhCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Truss Bridge Design

Transféré par

Vũ Trí MinhDroits d'auteur :

Formats disponibles

DESIGN & INVESTIGATIVE PROJECT

Instructed by : Dr. Nguyn Th Tuyt Trinh

Prepared by : Ph Xun Thi

Class: Advanced Program of Civil Engneering K49

Student ID: 0912691

CONTENT:

I INPUT DATA AND BASIC DIMENSIONS OF SPAN STRUCTURE

1. Input data

2. Basis dimensions of cross section of truss bridge

3. Dimensions of members in main truss

4. Dimensions of members in floor beam system

5. Geometric properties of section

II FLOOR BEAM DESIGN

1. Stringer design

2. Check stringer following strength limit state I

3. Cross beam design design

4. Check cross beam following strength limit state I

III MAIN TRUSS DESIGN

1. Determine dead loads acting on main truss

2. Internal force in truss members due to dead load

3. Distribution factor of main truss

4. Unfactored internal forces in truss member due to live load

5. Load combination for live load

6. Load combination for main truss

7. Geometric properties of members

8. Check member in main truss

IV BRACING SYSTEM DESIGN

1. Content of checking

2. Lateral force acting on structure

3. Internal forces in bracing member following strength limit state II

4. Checking tensile member

5. Checking compressive member

VI TRUSS JOINT DESIGN

1. General principle

2. Design procedure

3. Design chord conection at joints

VII DRAWING.

I INPUT DATA AND BASIC DIMENSIONS OF SUPER STRUCTURE

1. Input data

- Span length : 80m

- Bridge width : 3 lanes

- Live load : HL 93 and pedestrian 3x10

3

kPa

- Material of truss : Steel M270, grade 345

- Concrete grade of slab : 35 Mpa

- Connection : high strength bolt

- Thickness of slab: 20 cm

- Unit weight of concrete: 25 KN/m

3

- Thickness of wearing surface: fine grained asphalt layer: 7cm

2. Basic dimensions of cross section of truss bridge

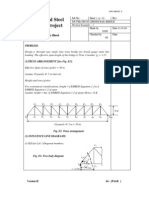

- Chosen span structure as in the below figure :

GENERAL CROSS-SECTION OF BRIDGE

Bridge cross-section

Bridge longitudinal section

2% 2%

1

1 bottomchord

2

diagonal , vertical 2

topchord 3

3

4

crossbeam 4

5

longitudinal girder 5

6

bracket 6

deck 7

7

8

pedestrian 8

9

topconnectionframesystem 9

11

bottomlongitudinal connectionframesystem 11

12

toplongitudinal connectionframesystem 12

10

clearance 10

Do

D1

T1

D2

T2

D3

T3

D4

T4

D5

T5

D6

T6

D7

T7

D8

T8

I I

T9

D9 D10

- Main truss height : H

- The main truss height is chosen following the requirements :

+ Small main truss self weight

+ Insurance of navigational clearance level

+ Small architecture height for deck truss bridge

+ Insurance of vertical stiffness of span structure

+ Aesthetics purpose

In experience, for simple span bridge, the height of main truss is normally

chosen as below :

H = (

)

Where L is the span length of the bridge. L = 80 m. Hence :

H = 8 11.43 m.

However, the height of main truss should satisfy the vertical clearance

specified in TCN 2.3.3.2, i.e. 5300 mm.

We choose H = 10.0 m.

- Distance between 2 main trusses : B

- B depends on the clearance. This distance should be large enough to

prevent bridge from overturning under the action of lateral forces such as

wind forces, laterally fluctuating forcesIt is also wide enough for

rational torsion rigidity of bridge.

4

1

3

c r o s s - s ec t io n i - i t o p l o ng it udinal c o nnec t io n f r ame s y s t em

c r o s s - s ec t io n ii - ii bo t t o m l o ng it udinal c o nnec t io n f r ame s y s t em

- The number of lane is 3 lanes. Basing on the Specification for Highway

Design TCVN 4054, the width of one lane depends on the class of road.

It ranges from 2.75m to 3.75m. Here we choose it as 3.5m (3500 mm).

- Furthermore, the distance of one curb to separate carriageway and main

truss is 0.25 m(also for curb to separate carriageway lanes), the width of

main truss member is chosen as 500mm, so that the distance from center

to center of 2 main trusses is :

B = 3x3.5 + 2x0.25+2x0.25 + 0.5 = 12 m.

- Total bridge width : B = B

1

+ 2b

2

+ 2b

3

+ 2b

4

+ 2b

5

+ 2b

6

.

Where :

+ B

1

: carriageway width. B

1

= 3x3.5m.

+ b

2

: railing between main trusses and carriageway. b

2

= 0.25 m.

+ b

3

: main truss width. b

3

= 0.5 m.

+ b

4

: railing between side walk and main trusses. b

4

is taken as 0.25

m.

+ b

5

: side walk width. We chose b

5

= 2 m.

+ b

6

: the outside railing. Normally b

6

= 0.2 0.5 m. We choose b

6

=

0.5 m.

- Total bridge width : B = B

1

+ 2b

2

+ 2b

3

+ 2b

4

+ 2b

5

+ 2b

6

.

B = 17 m.

- Length of panel : d.

- d is the distance between 2 adjacent cross-beam. In experience, d is

normally chosen as below :

d = (0.6 0.8)H

d = 6 8 m.

We choose d = 8 m.

3. Dimensions of members in main truss.

- Box section is applied for chords and end post.

- I section is applied for hip vertical and diagonals.

- Dimensions of sections of members are shown in the below figure :

4. Dimensions of members in floor beam system.

- Floor beam system includes cross beams and stringers. It bears the load

of deck slab as well as live load, then transfers it to the main trusses.

Stringers lay on cross beams and are connected to them by high

strength bolts.

- Dimensions of section of cross beam and stringer are chosen as below :

- Cross beams : the effective length used in calculating cross beam is

equal to distance from 2 gussets of main trusses. We denotes by L

1

= B

1

+ 2b

2

= 11 m

+ The height h of section is chosen as simple beams, i.e. :

h = (1/7-1/12)L

1

h = 733 440 mm.

We choose h = 800 mm.

+ The top and bottom flange width b

t

are the same and ranges from

(1/3 2/3)h = 266 533 mm. We choose b

t

= 350 mm.

+ The thickness t

w

web is:

According to the standard ASTM, the minimum thickness of web is

12mm.

I choose t

w

= 22 mm.

+ The thickness flange: 25 mm

- Stringer : the effective length of stringer is distance between 2 adjacent

cross beam or the length of panel d, where d = 8.0 m. Hence, the height

of section h :

H=(1/10-1/15)d

h = 533 800 mm.

I choose h = 500 m.

The thickness of flange and web are taken as 20 mm for all.

The flange width is chosen to be 250 mm.

hip ver t ical and diagonal sect ion end post and chor d sect ion

These dimensions are shown in the figure below.

5.Geometric properties of section

Section Sectional area

A(m

2

)

Moment of

inertia

I(m

4

)

Section

modulus

S(m

3

)

Cross beam 0.034 0.0034 0.0068

Stringer 0.0192 0.0007 0.0033

II. FLOOR BEAM DESIGN

1. Stringer Design.

a. Determination of load distribution factors for stringer.

For moment

- For interior girder : using tabular method ( TCN 4.6.2.2.2 )

+ For one lane loaded :

g

mg1

=

0.1

0.4 0.3

3

0.06

4300 .

g

s

K

S S

L Lt

| |

| | | |

+

| | |

\ . \ .

\ .

+ For two or more lanes loaded :

g

mg2

=

0.1

0.6 0.2

3

0.075

2900 .

g

s

K

S S

L Lt

| |

| | | |

+

| | |

\ . \ .

\ .

Where:

E

slab

= 0.043xxf

s

0.5

= 3.18 x 10

4

MPa

E

g

= 2 x 10

5

MPa

n = E

s

/E

g

= 6.3

e

g

= (H y

e

)-h

f

/2 = 0.15 m

K

g

= n(I

d

+Ae

g

2

) = 7.13 x 10

-2

m

4

= 7.13x10

9

mm

4

g

mg1

= 0.38

g

mg2

= 0.46

Check the range of applicability : 1100 mm S = 1500 mm 4900 mm.

110 mm t

s

= 200 mm 300 mm

6000mm L = 8000 mm 73000 mm

N

b

= 7 > 4

OK. Choose the maximum value to be the load distribution factor for interior

girder :

g

mg

= max (g

mg1

, g

mg2

)

g

mg

= 0.46

- The level rule method is used for exterior girder.

+ Basing on the influence line of reaction of each girder ( from 1 to 4 ), we can

calculate the load distribution factors for moment and shear for each girder

due to live load ( truck load and lane load ).

+ For truck load : g

HL

= 0.5y

i

, where y

i

is the ordinate of the i

th

axle on the

influence line.

+ For lane load : g

Lan

=

i

, where

i

is the area of corresponding influence line.

+ These factors should be factored with the multiple presence factor m.

- For exterior girder :

+ For one lane loaded : m = 1.2

- For design truck load :

g

HL1

=

g

HL1

= 0.678

- For lane load :

g

Lan1

=

g

Lan1

= 0.98

+ For two or more lanes loaded : m = 1.

g

mb2

= 0.77

2800

e

mg

d

g

| |

+

|

\ .

d

e

= 400 mm.

Range of applicability : 300 mm d

e

1700 mm.

out of range of applicability, g

mb2

= 0.666. Hence :

g

HL

= max(g

HL1

,g

mb2

) g

HL1

= 0.678

g

Lan

= max(g

Lan1

,g

mb2

) g

Lan

= 0.98

For shear

- For interior girder

+ For one lane loaded :

g

vg1

= 0.36

7600

S

+

g

vg1

= 0.56

+ For two or more lanes loaded :

g

vg2

=

2.0

0.2

3600 10700

S S | |

+

|

\ .

g

vg2

= 0.62

check the range of application : 1100 mm S = 2200 mm 4900 mm.

110 mm t

s

= 200 mm 300 mm

6000mm L = 8000 mm 73000 mm

N

b

= 7 > 4

Choose the maximum value as the distribution factor for shear for interior

girder :

g

vg

= max(g

vg1

; g

vg2

)

g

vg

= 0.62

- For exterior girder .

+ For one lane loaded : using level rule method.

As calculated above : g

HL1

= 0.678

g

Lan1

= 98

+ For two or more lane loaded :

g

vb2

= 0.6

3000

e

vg

d

g

| |

+

|

\ .

d

e

= 400 mm inside the range of application (300 mm d

e

1700 mm )

g

vb2

= 0.45

Therefore : g

vbHL

= 0.678

g

vblan

= 0.98

I establish the following table :

Girder no. For moment For shear

Truck

load

Lane

load

Design

vehicle

Lane

load

Exterior

gider

0.678 0.98 0.678 0.98

Interior

girder

0.46 0.46 0.62 0.62

b. Determine dead loads.

- Dead load stage I

+ Stringer self weight : DC

dc

=

s

.A

A : cross sectional area. A = 0.0192 m

2

.

s

: Steel unit weight.

s

= 78.5 kN/m

3

.

DC

dc

= 1.51 kN/m.

+ dead load of deck slab : for both interior and exterior girders :

DC

bm

= S.t

s

.

c

S : distance between 2 adjacent girder. S = 1500 mm

t

s

: slab thickness. t

s

= 200 mm.

c

: concrete unit weight.

c

= 25 kN/m

3

.

DC

bm

= 7.5 kN/m

Total dead load stage I : DC = 9.01 kN/m.

- Dead load stage II

-

+ Dead load of concrete element : 1 kN/m

+ Dead load of steel element : 0.15 kN/m

Assume that, dead load of railing is borne by only exterior girder (

girder 1 ).

Girder 1 : DC

lc

= 1.15 kN/m

Girder 2 : DC

lc

= 0 kN/m

+ Dead load of wearing surface on one girder :

water proofing layer : t

1

= 0.4 cm ,

1

= 18 kN/m

3

asphalt concrete layer : t

2

= 7 cm.

2

= 22 kN/m

3

.

+ Dead load of utility: DW

uti

= 5 KN/m

DW

as

+ DW

uti

= 36.5 KN/m

For interior girder : DC

sur

= (0.04x18 + 0.07x22)x1.5= 3.39 kN/m

For exterior girder : DC

sur

= (0.04x18 + 0.08x22)x2.0 = 4.52 kN/m

Total dead load stage II : For exterior girder : DW = 3.39 kN/m

For interior girder : DW = 5.67 kN/m.

I establish the following table :

Load type Interior girder Exterior girder Unit

DC 9.01 9.01 kN/m

DW 3.39 5.67 kN/m

Sum 12.4 14.68 kN/m

c. Internal forces due to live load determination.

The influence line of moment and shear for stringer:

For strength limit state I, the most critical section for moment is

midspan section and the most critical one for shear is girder end

section.

Internal forces due to design truck will be taken as the maximum value of

two cases above.

Bending moment

+ Moment due to design truck : M

truck1

= 145.y

M1

+ 145.y

M3

+ 35.y

M4

M

truck2

= 145.y

M1

+ 145.y

M3

+ 35.y

M5

M

truck

= max(M

truck1

; M

truck2

).

+ Moment due to design tandem : M

tandem1

= 110.y

M1

+ 110. y

M2

.

35kN 145kN 145kN

110kN 110kN

2

Influence line at L/2

35kN 145kN 145kN

110kN 110kN

tandem

truck

1.2m

4.3m 4.3m

1.2m

4.3m 4.3m

tandem

truck

Case 2

Case 1

0

0

1

.

400

lane load

lane load

1

.

7

1

.

7

2

Influence line at L/2

tandem

truck

lane load

4.3m 4.3m

1.2m

0

.

8

5

0

.

4

6

2

5

0

Influence line at bearing shoe

1

,

0

0

35kN 145kN 145kN

110kN 110kN

M

tandem2

= 110. y

M2

+ 110. y

M4

.

M

tandem

= max(M

tandem1

; M

tandem2

).

+ Moment due to design vehicle : M

xetk

= max(M

truck

; M

tandem

).

+ Moment due to lane load : q

lan

= 9.3 kN/m

M

lan

= 9.3.

M

Where

M

is the area of corresponding moment influence line.

Shear force

+ Shear force due to design truck : V

truck

= 145.y

M1

+ 145.y

M3

+

35.y

M4

.

+ Shear force due to tandem : V

tandem

= 145.y

M1

+ 145.y

M2

.

+ Shear force due to lane load : V

lan

= 9.3.

V(+)

.

Where

V(+)

is the positive area of corresponding shear influence line.

Internal

forces

Type of load Unit

Design vehicle Lane load

M

1

374 74.4 kN.m

V

0

212.06 37.2 kN.

- Load combination due to live load HL 93

+ Moment combination (factored with distribution factor g

m

).

IM = 25 %

For interior girder :

M

LLg

= g

mg

( 1 + IM ).M

xetk

+ g

mg

.M

lan

.

M

LLg

= 249.274 kN.m

For exterior girder :

M

LLb

= g

HL

(1 + IM).M

xetk

+ g

lan

.M

lan

.

M

LLb

= 389.88 kN.m

+ Shear force combination (factored with distribution factor g

v

)

IM = 25 %

For interior girder :

V

LLg

= g

vg

(1 + IM).V

xetk

+ g

vg

.V

lan

.

V

LLg

= 187.41 kN.

For exterior girder :

V

LLb

= g

HL

(1 + IM).V

xetk

+ g

lan

.V

lan

.

V

LLb

= 216.18kN.

d. Internal forces due to dead load.

- Dead load stage I .

Internal

forces

DC Influence line

area

Interior

girder

Exterior

girder

Unit

M

1DC

9.01 8 72.8 72.8 kN.m

V

0DC

9.01 4 36.4 36.4 kN

- Dead load stage II.

Internal

forces

DW Influence line

area

Interior

girder

Exterior

girder

Unit

Gider 2 Girder 1

M

1DW

3.39 5.67 8 27.12 45.36 kN.m

V

0DW

3.39 5.67 4 13.56 22.68 kN

e. Internal force combination at sections of exterior girder

- Strength limit state I :

-

+ Moment : M

uCD1g

= .(1.75M

LLg

+ 1.25.M

DCg

+ 1.5.M

DWg

).

Where : load modifier. = 1.0 for normal bridge.

M

uCD1g

= 841.33 kN.m

+ Shear : V

uCD1g

= .(1.75V

LLg

+ 1.25.V

DCg

+ 1.5.V

DWg

).

V

uCD1g

= 457.835 kN

f. Internal force combination at sections of interior girder

- Strength limit state

+ Moment : M

uCD1b

= .(1.75M

LLb

+ 1.25.M

DCb

+ 1.5.M

DWb

).

M

uCD1b

= 567.91 kN.m

+ Shear : V

uCD1b

= .(1.75V

LLb

+ 1.25.V

DCb

+ 1.5.V

DWb

).

V

uCD1b

= 393.81 kN

+Establish the following table.

LOAD COMBINATION RESULTS

Internal forces Strength limit state I Unit

Girder 2 Girder 1

M

1

841.33 567.91 kN.m

V

0

457.835 393.81 kN

On comparing, the internal forces in the exterior girders are greater than

that in interior girder so that, the exterior will be chosen to check.

Vous aimerez peut-être aussi

- Truss DesignDocument10 pagesTruss DesignselvakumarPas encore d'évaluation

- Bridge TrussDocument15 pagesBridge TrussArjunRK100% (1)

- Steel Truss BridgeDocument27 pagesSteel Truss BridgeNoman ShakirPas encore d'évaluation

- Bridge Design Report - Final-SadaDocument294 pagesBridge Design Report - Final-SadaSadatcharaMoorthi NPas encore d'évaluation

- Steel Truss Bridge Design ExampleDocument63 pagesSteel Truss Bridge Design ExampleCarlos Silva Castillo75% (4)

- Design of A Composite Bridge DeckDocument121 pagesDesign of A Composite Bridge DeckAnonymous JLaQiSPas encore d'évaluation

- Truss BridgesDocument21 pagesTruss BridgesAzaz Ahmed50% (2)

- ST5015-Design of BridgesDocument14 pagesST5015-Design of BridgesNarayanan MoorthyPas encore d'évaluation

- 3bow-String Girder - Design Construction Aspects PDFDocument12 pages3bow-String Girder - Design Construction Aspects PDFankur mundraPas encore d'évaluation

- Design A Truss BridgeDocument37 pagesDesign A Truss BridgeFrederico DonagemmaPas encore d'évaluation

- Concrete T-Beam Bridge DesignDocument3 pagesConcrete T-Beam Bridge Designjclou021167% (12)

- 25m Single Lane Bridge Design Calculations Latest PDFDocument16 pages25m Single Lane Bridge Design Calculations Latest PDFshafiullahPas encore d'évaluation

- Analysis of Deck Slab and Tee Beam of A BridgeDocument59 pagesAnalysis of Deck Slab and Tee Beam of A Bridgenvnrev86% (66)

- Grillage AnalysisDocument9 pagesGrillage Analysismonika chauhanPas encore d'évaluation

- 25m Single Lane Bridge Design Calculations LatestDocument16 pages25m Single Lane Bridge Design Calculations Latestntah84100% (4)

- Design and Analysis of Truss Bridge-1 PDFDocument16 pagesDesign and Analysis of Truss Bridge-1 PDFsiddharth singhPas encore d'évaluation

- Analysis of Bridge Substructure Using IRC SP:114... by Aakash ModiDocument147 pagesAnalysis of Bridge Substructure Using IRC SP:114... by Aakash ModiAAKASHPas encore d'évaluation

- Design of PSC Cross Girder As Per IRC 112Document2 pagesDesign of PSC Cross Girder As Per IRC 112rrajdeep54100% (4)

- R. C. C. Bridge DesignDocument65 pagesR. C. C. Bridge DesignZuzar100% (3)

- Bridge Loading Idealisation For Grillage AnalysisDocument8 pagesBridge Loading Idealisation For Grillage AnalysisHarold Jackson MtyanaPas encore d'évaluation

- Steel Truss Bridge 85 MT Bowarch Pedestrian BridgeDocument19 pagesSteel Truss Bridge 85 MT Bowarch Pedestrian Bridgeakshay kothiyalPas encore d'évaluation

- Single Span Steel Composite Plate Girder Bridge PDFDocument42 pagesSingle Span Steel Composite Plate Girder Bridge PDFNeeta RautelaPas encore d'évaluation

- Truss Bridge ProjectDocument16 pagesTruss Bridge ProjectChrisYap100% (1)

- Lecture5 - Girder Design 1Document54 pagesLecture5 - Girder Design 1Anubhav ChaudharyPas encore d'évaluation

- Positioning of Irc Live LoadsDocument3 pagesPositioning of Irc Live Loadsvasu7900100% (1)

- A Report On Truss BridgesDocument16 pagesA Report On Truss BridgesAzaz Ahmed89% (9)

- Tubular Truss ExampleDocument12 pagesTubular Truss ExampleMock Khang Hi100% (1)

- Slab DesignDocument163 pagesSlab DesignRonnie1478Pas encore d'évaluation

- Reinforced Concrete Bridge Deck Design PDFDocument6 pagesReinforced Concrete Bridge Deck Design PDFFrancisco FaggioniPas encore d'évaluation

- T Girder Bridge Deck Diaphragm-20 MDocument14 pagesT Girder Bridge Deck Diaphragm-20 MAmitabha DebPas encore d'évaluation

- T-Roff Girder DesignDocument41 pagesT-Roff Girder Designlinda100% (1)

- Design of Bridges1Document30 pagesDesign of Bridges1rahatul bashirPas encore d'évaluation

- 25m Span Superstructure of Bridge DesignDocument45 pages25m Span Superstructure of Bridge Designshekhar Nath chapagain75% (4)

- Chapter 9 Pump SelectionDocument40 pagesChapter 9 Pump SelectionDuke ThibbotuwawaPas encore d'évaluation

- Structural Bridge Design Example Manual - New Zealand & AustraliaDocument388 pagesStructural Bridge Design Example Manual - New Zealand & AustraliaEric Villenas0% (1)

- Design of Truss BridgeDocument18 pagesDesign of Truss BridgeBCE 2074 B Teacher100% (3)

- Pedestrian Bridge DesignDocument188 pagesPedestrian Bridge DesignMuzamil Maqbool RatherPas encore d'évaluation

- 2-Span PSC Composite Girder FinalDocument51 pages2-Span PSC Composite Girder FinalSuman DharaPas encore d'évaluation

- Pile Cap Design For All New PilesDocument30 pagesPile Cap Design For All New PilesPartha Gangopadhyay100% (2)

- Bridge Deck Slab Design ProcedureDocument12 pagesBridge Deck Slab Design ProcedurePravin Awalkonde100% (1)

- Design of BridgesDocument37 pagesDesign of Bridgespatel urvesh100% (1)

- Analysis of Deck Slab and Tee Beam of A BridgeDocument59 pagesAnalysis of Deck Slab and Tee Beam of A Bridgenidhisasidharan100% (2)

- Design of Steel TrussDocument20 pagesDesign of Steel Trussvarinder47100% (1)

- Design of Pedestrian Steel Foot Over Bridge A Project ReportDocument46 pagesDesign of Pedestrian Steel Foot Over Bridge A Project ReportInternational Journal of Innovative Science and Research Technology86% (7)

- MainBridge - Design ReportDocument18 pagesMainBridge - Design ReportWan100% (1)

- Tut 1 - Import From SPCDocument16 pagesTut 1 - Import From SPCmanoj_structurePas encore d'évaluation

- Steel Truss DesignDocument10 pagesSteel Truss DesignRichard Teves100% (3)

- Design of RCC T - Girder Deck Using Morice & Little MethodDocument33 pagesDesign of RCC T - Girder Deck Using Morice & Little Methodvasu7900100% (4)

- Bridge Design Using STAADDocument38 pagesBridge Design Using STAADpheron200390% (10)

- Design of A Modern High Rise Building in Abu-Dhabi (United Arab Emirates University) Graduation Project II Fall 2010Document50 pagesDesign of A Modern High Rise Building in Abu-Dhabi (United Arab Emirates University) Graduation Project II Fall 2010April Ingram100% (1)

- Prestressed Beam Girder Floor Made of High Strength ConcreteDocument18 pagesPrestressed Beam Girder Floor Made of High Strength ConcreteSebastian GusetuPas encore d'évaluation

- One Way Solid SlabDocument26 pagesOne Way Solid SlabalaajabbarPas encore d'évaluation

- One Way Solid Slab DesignDocument26 pagesOne Way Solid Slab DesignJohn Mejia50% (4)

- Appendix GBDocument28 pagesAppendix GBHundeejireenyaPas encore d'évaluation

- Design Verification CalculationsDocument15 pagesDesign Verification CalculationsKarthik KrPas encore d'évaluation

- REPORTDocument29 pagesREPORTabdelbasset.mnasriaPas encore d'évaluation

- Detailed Calculation For Box Girder DesignDocument109 pagesDetailed Calculation For Box Girder Designleodegarioporral100% (8)

- Analysis and Design of Multi Storey BuildingDocument36 pagesAnalysis and Design of Multi Storey Buildingdev6483% (12)

- Joist SlabDocument13 pagesJoist SlabAhmed Nabil80% (5)

- Britain's Urban Future, HJDocument31 pagesBritain's Urban Future, HJVũ Trí MinhPas encore d'évaluation

- HPC Structural Designers GuideDocument128 pagesHPC Structural Designers Guideapi-3698973100% (4)

- Howards City PlanningDocument17 pagesHowards City PlanningVũ Trí MinhPas encore d'évaluation

- Britain's Urban Future, HJDocument31 pagesBritain's Urban Future, HJVũ Trí MinhPas encore d'évaluation

- HPC Structural Designers GuideDocument128 pagesHPC Structural Designers Guideapi-3698973100% (4)

- Geo TechnicsDocument36 pagesGeo TechnicsVũ Trí MinhPas encore d'évaluation

- IELTS Visuals Writing About Graphs, Tables and Diagrams PDFDocument68 pagesIELTS Visuals Writing About Graphs, Tables and Diagrams PDFSaleh KhalidPas encore d'évaluation

- Guide4appusehighperfconcrete enDocument30 pagesGuide4appusehighperfconcrete enVũ Trí MinhPas encore d'évaluation

- Tech. Paper 1 OkDocument8 pagesTech. Paper 1 OkVũ Trí MinhPas encore d'évaluation

- Application of High Perfomance Concrete On A 85-Story High Rise Building in TaiwanDocument8 pagesApplication of High Perfomance Concrete On A 85-Story High Rise Building in TaiwanVũ Trí MinhPas encore d'évaluation

- BIFRHJMJBYDocument48 pagesBIFRHJMJBYVũ Trí MinhPas encore d'évaluation

- Etd Tamu 2003A 2003032815 Cuad 1Document297 pagesEtd Tamu 2003A 2003032815 Cuad 1Vũ Trí MinhPas encore d'évaluation

- Guide4appusehighperfconcrete enDocument30 pagesGuide4appusehighperfconcrete enVũ Trí MinhPas encore d'évaluation

- HPC Structural Designers GuideDocument128 pagesHPC Structural Designers Guideapi-3698973100% (4)

- SuganoDocument8 pagesSuganoVũ Trí MinhPas encore d'évaluation

- Pavement Construction EquipmentDocument56 pagesPavement Construction EquipmentVũ Trí MinhPas encore d'évaluation

- Chap 17 HPCDocument16 pagesChap 17 HPCLeen LeeanPas encore d'évaluation

- Soil A MaterialDocument40 pagesSoil A MaterialVũ Trí MinhPas encore d'évaluation

- 930 373Document377 pages930 373Vũ Trí MinhPas encore d'évaluation

- Introduction of PavementDocument14 pagesIntroduction of PavementVũ Trí MinhPas encore d'évaluation

- Gmail 2013 Network Lottery Promotional: USD$2,000, 000, 00 (Two Million United State Dollars Only)Document1 pageGmail 2013 Network Lottery Promotional: USD$2,000, 000, 00 (Two Million United State Dollars Only)Vũ Trí MinhPas encore d'évaluation

- Aggregates For Concrete and Road Construction MaterialsDocument19 pagesAggregates For Concrete and Road Construction MaterialsVũ Trí MinhPas encore d'évaluation

- SB2Document18 pagesSB2Vũ Trí MinhPas encore d'évaluation

- LRFD 3 5 2Document62 pagesLRFD 3 5 2Vũ Trí MinhPas encore d'évaluation

- 09 Factor of Safety and Probability of FailureDocument14 pages09 Factor of Safety and Probability of FailurerPas encore d'évaluation

- Stress and Pore Pressure Changes in Clay During and After The Expansion of A Cylindrical CavityDocument18 pagesStress and Pore Pressure Changes in Clay During and After The Expansion of A Cylindrical CavityVũ Trí MinhPas encore d'évaluation

- 2007 Minnesota State Buidling Code PDFDocument416 pages2007 Minnesota State Buidling Code PDFRyan KuntzPas encore d'évaluation

- Central Building of Kočevski Rog, Base 20Document4 pagesCentral Building of Kočevski Rog, Base 20Una GalePas encore d'évaluation

- Groyne Material: Rock Groynes Cost Advantages DisadvantagesDocument1 pageGroyne Material: Rock Groynes Cost Advantages DisadvantagesMahdi FekiPas encore d'évaluation

- Industrial Standards Pipe FittingsDocument27 pagesIndustrial Standards Pipe FittingsYaneYang100% (1)

- Construction Terms (Mste)Document3 pagesConstruction Terms (Mste)seyer intPas encore d'évaluation

- 27,30 - The Saudi Building Code (SBC) - PDF - 124-124Document1 page27,30 - The Saudi Building Code (SBC) - PDF - 124-124heshamPas encore d'évaluation

- Schedule of Rates Amravati-Nagpur Region YEAR 2018-2019: MaterialDocument17 pagesSchedule of Rates Amravati-Nagpur Region YEAR 2018-2019: MaterialSathish KumarPas encore d'évaluation

- Compilation Edited Table Final Na TlgaDocument5 pagesCompilation Edited Table Final Na TlgaMichaela Villavicencio100% (1)

- Geoweb Channel OverviewDocument8 pagesGeoweb Channel OverviewJonathan CanturinPas encore d'évaluation

- IT Application Final AssignmentDocument15 pagesIT Application Final AssignmentWanPas encore d'évaluation

- Condition Inspection Form (Cif) B01818LZDocument18 pagesCondition Inspection Form (Cif) B01818LZMars TinPas encore d'évaluation

- Steel DesignDocument21 pagesSteel DesignShaikh Muhammad AteeqPas encore d'évaluation

- Energy EfficientDocument89 pagesEnergy EfficientHIMA MiniPas encore d'évaluation

- Civil Work QuantitiesDocument6 pagesCivil Work QuantitiesRenvil PedernalPas encore d'évaluation

- Rate AnalysisDocument190 pagesRate AnalysisKeshava Murthy89% (27)

- Natural Stone Fixing SystemsDocument42 pagesNatural Stone Fixing SystemsBara' alsayedPas encore d'évaluation

- Low-Cosf Wood Homes For Rural AmericaConstruction ManualDocument117 pagesLow-Cosf Wood Homes For Rural AmericaConstruction ManualRenata Braga100% (1)

- 2nd Summative Test TLE 10Document2 pages2nd Summative Test TLE 10MaCel VM100% (2)

- Ireps Tender 3Document22 pagesIreps Tender 3Project DS EnterprisePas encore d'évaluation

- Hilti Firestop Catalogue FinalisedDocument76 pagesHilti Firestop Catalogue FinalisedInayath HussainPas encore d'évaluation

- Mix Design Guide: ACI NEDUET Students ChapterDocument10 pagesMix Design Guide: ACI NEDUET Students ChapterAsad AshfaqPas encore d'évaluation

- Capslon ProjectDocument8 pagesCapslon ProjectAnkush LilharePas encore d'évaluation

- Dayworks ScheduleDocument4 pagesDayworks ScheduleRyan De Vera Pagal100% (2)

- Improvement in Properties of Porous Concrete Using FiberDocument5 pagesImprovement in Properties of Porous Concrete Using FiberPawan Patidar0% (1)

- Single and Double Floor ConstructionDocument51 pagesSingle and Double Floor ConstructionDhruv DidolkarPas encore d'évaluation

- Irfan CVDocument3 pagesIrfan CVMohd.irfanPas encore d'évaluation

- Bridge Components and ElementsDocument59 pagesBridge Components and ElementsHaris khanPas encore d'évaluation

- Liquid Granite Tech Sheet 2 PDFDocument2 pagesLiquid Granite Tech Sheet 2 PDFEsha Kapoor100% (2)

- NGCP Laspinas AccomplishmentDocument12 pagesNGCP Laspinas AccomplishmentNAIRASECPas encore d'évaluation

- Catalog Shear ConnectorDocument16 pagesCatalog Shear ConnectordedePas encore d'évaluation