Académique Documents

Professionnel Documents

Culture Documents

Automatic LPG As Booking System

Transféré par

Suresh SsbnTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Automatic LPG As Booking System

Transféré par

Suresh SsbnDroits d'auteur :

Formats disponibles

AUTOMATIC LPG REFILL BOOKING ABSTARCT Booking for a LPG Cylinder Refill and getting it delivered in time is getting

easier. The new system is an Indian Oil initiative to introduce simpler ways for customers to book for their Indane gas LPG refill. The system is provided and maintained by Cellular Ltd. SMS (Short Message Service): This too is a 24 x 7 facility where Indane customers can send an SMS from their mobile phone to register for the service and subsequently book for refills. If the customer is using SMS facility for the first time, then SMS IOC < STD Code + Distributor's T e l . N u m b e r > <Consumer Number> to the unique Idea number for your city. For example, in case the distributor's telephone number in Delhi is 26024289 and consumer number is QX00827C, SMS shall be sent as follows: IOC 01126024289 QX00287C. For subsequent bookings, send SMS IOC to the same number. With a view to provide better services to the customers and to reduce the scope for irregularities, we have introduced the facility of refill booking through Short Messaging Service (SMS).and also if an gas leakage is detected automatically main supply will OFF in order to avoid fire accident.

1. INTRODUCTION

Pervasive computing (also known as ubiquitous computing) brings to light a new genre of computing where in the comput-er completely pervades the life of the user. Pervasive compu-ting applications promise seamless integration of digital infra-structure with their interconnected devices and services into our everyday lives . In India the supply of LPG through pipelines is not possible due to shortage of LPG production . As technology being improved many gas agencies or distributors have implemented IVRS these days although due to daily busy schedules, cus-tomer finds very difficult to book new cylinder, and also it is very dangerous when a LPG gas leakage occurs in any domes-tic usage, chemical industry or in any other applications. This paper provides automatic booking of LPG cylinder and to overcome the problem of LPG leakage. IVRS system was borne from general complaints of consum-ers that landline phones of their distributors were either busy or no one answered the call promptly. With this system, a con-sumer can approach the gas agency by dialing a toll-free (or non-free) number and later will have to follow the interactive directions. Finally, the system will announce the customer number and confirms the customer number and also confirms the refill of cylinder by pressing 1. Here with most people who are illiterate find it difficult in handling call or unable to use the higher end technology . So our proposal is to complete-ly automate the process of refill booking without human inter-vention that accordingly will help consumer against foul play. Our system is also intended to help consumers to upgrade their safety standards, act in accordance with statutory requirements on environmental commitments and most impor-tantly the basic function being prevented by accidents and protect life

and property from disasters. The primary objective of our paper is to measure the gas present in the cylinder when weight of the cylinder reached below the fixed load, using the pervasive sensors . The gas retailer gets the order for a new cylinder and the house owner (consumer) receives the message about the same and the details about the booking proceedings. And the sec-ondary objective is to provide any malfunction in gas system in order to prevent damage or explosion of LPG. 1.1 EMBEDDED SYSTEM Embedded systems are controllers with on chip control which consist of microcontrollers, input and output devices, memories etc. and it can be used for a specific application. A small computer designed in a single chip is called single chip microcomputer. A single chip microcomputer typically includes a microprocessor, RAM, ROM, timer, interrupt and peripheral controller in a single chip. This single chip microcomputer is also called as a microcontroller. These microcontrollers are used for variety of applications where it replaced the computer. The usage of this microcomputer for specific applications, in which the microcontroller a part of application is called, embedded systems. Computing systems are everywhere. Its probably no surprise that millions of computing systems are built every year destined for desktop computers (Personal Computers, or PCs), workstations, mainframes and servers. Thus an embedded system is nearly any computing system other than a desktop, laptop, or mainframe computer.

1.2 CHARACTERISTICS OF AN EMBEDDED SYSTEM 1.2.1 SINGLE-FUNCTIONED An embedded system usually executes only one program, repeatedly. For example, a pager is always a pager. In contrast, a desktop system executes a variety of programs, like spreadsheets, word processors, and video games, with new programs added frequently. 1.2.2 TIGHTLY CONSTRAINED All computing systems have constraints on design metrics, but those on embedded systems can be especially tight. A design metric is a measure of an implementations features, such as cost, size, performance, and power. Embedded systems often must cost just a few dollars, must be sized to fit on a single chip, must perform fast enough to process data in real-time, and must consume minimum power to extend battery life or prevent the necessity of a cooling fan. 1.2.3 REACTIVE AND REAL-TIME Many embedded systems must continually react to changes in the systems environment, and must compute certain results in real time without delay. For example, a car's cruise controller continually monitors and reacts to speed and brake sensors. It must compute acceleration or decelerations amounts repeatedly within a limited time; a delayed computation result could result in a failure to maintain control of the car.

1.3. EMBEDDED PROCESSOR TECHNOLOGY 1.3.1 STANDARD GENERAL PURPOSE PROCESSORS (SGPP) Standard general purpose processors (SGPP) are carefully designed and offer a maximum of flexibility to the designer. Programming SGPPs can be done in nearly every high-level language or assembly language and requires very little knowledge of the system architecture. As SGPPs are manufactured to high numbers, NRE is spread upon many units. Nevertheless SGPPs are more expensive than other solutions like FPGAs or single purpose processors, when used in products with a large number of selling units. These devices are produced to work in a broad range of environments since those are not designed to be energy efficient nor high-performance for specific applications. Examples for standard general purpose processors are: Motorola ARM Atmel AVR Microchip PIC Intel Pentium-(I/II/III/IV)-Series 1.3.2. STANDARD SINGLE PURPOSE PROCESSORS (SSPP) Standard single purpose processors, sometimes called peripherals, are off the-shelf pre-designed processors, optimized for a single task, such as digital signal processing, analog to digital conversion, timing, etc. SSPPs are manufactured in high quantities, so NRE is spread upon many units. The total costs per SSPP unit are lower than for custom single purpose processors.

1.3.3. CUSTOM SINGLE PURPOSE PROCESSORS (CSPP) Custom single purpose processors are designed for a very specific task. This implies less flexibility, longer time-to-market and high costs. On the other hand CSPP can be designed to be very small, fast and power-efficient. Examples for such CSPP are FPGAs or more general PLDs. 1.3.4. APPLICATION SPECIFIC INSTRUCTION-SET PROCESSORS (ASIP) ASIPs are basically standard general purpose processors which are extended by domain-specific instructions. This allows domain-relevant tasks to be performed highly optimized, while keeping the flexibility of general purpose processors. 1.3.5. SPECIFIC DESIGN OF EMBEDDED SYSTEM PROCESSOR When designing an embedded system, usually, the first step is to specify the intended or required functionality. This is mostly done using natural language, after the functionality is specified it is formalized in some sort of definition language such as VHDL or Verilog. Subsequently the resulting design is converted into hardware or software components which are then implemented. 1.4 IMPORTANCE Radiation level measurement and monitoring of parameters like temperature, gas etc., in nuclear power plants is a very important problem that imposes the implementation of distributed surveillance systems. Usually these type of systems use networks of sensors for detection. Besides the quality and sensibility of the sensors, the connections to the monitoring system of large number of sensor raise some difficulties when wires are used. The advantage of using these radio

technologies are the flexibility in topology implementation and reorganization of the measurement systems as well as the possibility of realization of portable devices connected to a measuring and monitoring system with in an area. Security and accuracy are major concerns. So to overcome these issues the data should be encrypted to provide security for secret data. In this paper we implement Tiny Encryption Algorithm (TEA) at the either nodes. 1.5 CONCERNS OF SYSTEM Three of the major concerns regarding the implementation of wireless technologies in nuclear power and nuclear reactors include electromagnetic and radio frequency interference (EMI/RFI), cyber security, and installation issues such as the coverage of the wireless signal and integration with existing data networks. Because of the continued evolution of wireless technology and the efforts of the U.S. Nuclear Regulatory Commission (NRC) and similar governing entities to maintain up-to-date requirements, the steps performed today to install a wireless system into a plant may be inadequate five years from now.In nuclear power plants, redundancy is an important aspect of defense against mishaps. Wireless sensors provide an easy, cost-effective path to redundancy without compromising safety. For example, a process parameter may be measured with both wired and wireless sensors. The wired sensors can be designated as the primary element and used all the time, and the wireless sensors can be designated as the back-up element and used only when the wired sensor is unavailable. This has a number of advantages.

BLOCK DIAGRAM TRANSMITTER

RECEIVER

HARDWARE DESCRIPTION 5.1 POWER SUPPLY 5.1.1 CIRCUIT DIAGRAM

Fig 5.1.2Circuit Diagram of Power Supply 5.1.2 WORKING PRINCIPLE The AC voltage, typically 220 rms, is connected to a transformer, which steps that ac voltage down to the level of the desired DC output. A diode rectifier then provides a full-wave rectified voltage that is initially filtered by a simple capacitor filter to produce a dc voltage. This resulting dc voltage usually has some ripple or ac voltage variation. A regulator circuit removes the ripples and also remains the same dc value even if the input dc voltage varies, or the load connected to the output dc voltage changes.

5.1.3 BLOCK DIAGRAM

TRANSFORMER

RECTIFIER

FILTER

IC

LOAD

Fig 5.1.3 Block Diagram of power supply 5.1.4 TRANSFORMER The potential transformer will step down the power supply voltage (0-230V) to (0-6V) level. Then the secondary of the potential transformer will be connected to the precision rectifier, which is constructed with the help of op-amp. The advantages of using precision rectifier are it will give peak voltage output as DC; rest of the circuits will give only RMS output. 5.1.5 RECTIFIER A rectifier is an electrical device that converts alternating current to direct current or at least to current with only positive value, a process known as rectification. Rectifiers are used as components of power supplies and as detectors of radio signals. 5.1.6 BRIDGE RECTIFIER When four diodes are connected as shown in the power supply circuit diagram, is called Bridge rectifier. The input to the circuit is applied to the diagonally opposite corners of the network, and the output is taken from the remaining two corners.

5.1.7 VOLTAGE REGULATORS Voltage regulators comprise a class of widely used ICs. Regulator IC units contain the circuitry for reference source, comparator amplifier, and overload protection all in a single IC. IC units provide regulation of either a fixed positive voltage, a fixed negative voltage, or an adjustably set voltage. The regulators can be selected for operation with load currents from hundreds of milli amperes to tens of amperes, corresponding to power ratings form milli watts to ten watt. A fixed three-terminal voltage regulator has an unregulated dc input voltage, Vi, applied to one input terminal, a regulated dc output voltage, Vo , from a second terminal, with the third terminal connected to ground.

5.1 ATMEGA 8 5.1.1 CONCEPTS OF MICROCONTROLLER : Microcontroller is a general purpose device, which integrates a number of the components of a microprocessor system on to single chip. It has inbuilt CPU, memory and peripherals to make it as a mini computer. A microcontroller combines on to the same microchip: The CPU core Memory(both ROM and RAM) Some parallel digital i/o

Micro controllers will combine other devices such as:

A timer module to allow the micro controller to perform tasks for certain time periods. A serial i/o port to allow data to flow between the controller and other devices such as a PIC or another Microcontroller. An ADC to allow the Micro controller to accept analogue input data for processing. Micro controllers are : Smaller in size Consumes less power Inexpensive Micro controller is a stand alone unit ,which can perform functions on its own without any requirement for additional hardware like i/o ports and external memory. The heart of the microcontroller is the CPU core. In the past, this has traditionally been based on a 8-bit microprocessor unit. For example Motorola uses a basic 6800 microprocessor core in their 6805/6808 microcontroller devices. In the recent years, microcontrollers have been developed around specifically designed CPU cores, for example the microchip PIC range of microcontrollers.

5.1.2 MICROCONTROLLER ATmega8: PIN DIAGRAM:

5.1.2.1 FEATURES: High-performance, Low-power AtmelAVR 8-bit Microcontroller Advanced RISC Architecture 130 Powerful Instructions Most Single-clock Cycle Execution 32 8 General Purpose Working Registers Fully Static Operation Up to 16MIPS Throughput at 16MHz On-chip 2-cycle Multiplier

High Endurance Non-volatile Memory segments 8Kbytes of In-System Self-programmable Flash program memory 512Bytes EEPROM

1Kbyte Internal SRAM Write/Erase Cycles: 10,000 Flash/100,000 EEPROM Data retention: 20 years at 85C/100 years at 25C(1) Optional Boot Code Section with Independent Lock Bits In-System Programming by On-chip Boot Program Peripheral Features Two 8-bit Timer/Counters with Separate Prescaler, one Compare Mode One 16-bit Timer/Counter with Separate Prescaler, Compare Mode, and Capture Mode Real Time Counter with Separate Oscillator Three PWM Channels 8-channel ADC in TQFP and QFN/MLF package Eight Channels 10-bit Accuracy 6-channel ADC in PDIP package Six Channels 10-bit Accuracy Byte-oriented Two-wire Serial Interface Programmable Serial USART Master/Slave SPI Serial Interface Programmable Watchdog Timer with Separate On-chip Oscillator On-chip Analog Comparator

Special Microcontroller Features Power-on Reset and Programmable Brown-out Detection Internal Calibrated RC Oscillator External and Internal Interrupt Sources

Five Sleep Modes: Idle, ADC Noise Reduction, Power-save, Power-down, and Standby I/O and Packages 23 Programmable I/O Lines 28-lead PDIP, 32-lead TQFP, and 32-pad QFN/MLF Operating Voltages 2.7V - 5.5V (ATmega8L) 4.5V - 5.5V (ATmega8) Speed Grades 0 - 8MHz (ATmega8L) 0 - 16MHz (ATmega8)

5.1.2.2 PIN DESCRIPTIONS: 1.VCC Digital supply voltage.

2.GND Ground.

3. XTAL1/XTAL2/TOSC1/TOSC2

Port B (PB7..PB0) Port B is an 8-bit bi-directional I/O port with internal pull-up resistors (selected for each bit). The Port B output buffers have symmetrical drive characteristics with both high sink and source capability. As inputs, Port B pins that are externally pulled low will source current if the pull-up resistors are activated. The Port B pins are tri-stated when a reset condition becomes

active,even if the clock is not running. Depending on the clock selection fuse settings, PB6 can be used as input to the inverting Oscillator amplifier and input to the internal clock operating circuit.Depending on the clock selection fuse settings, PB7 can be used as output from the inverting Oscillator amplifier.If the Internal Calibrated RC Oscillator is used as chip clock source, PB7..6 is used as TOSC2..1input for the Asynchronous Timer/Counter2 if the AS2 bit in ASSR is set. Port C (PC5..PC0) Port C is an 7-bit bi-directional I/O port with internal pull-up resistors (selected for each bit). The Port C output buffers have symmetrical drive characteristics with both high sink and source capability. As inputs, Port C pins that are externally pulled low will source current if the pull-up resistors. PC6/RESET If the RSTDISBL Fuse is programmed, PC6 is used as an I/O pin. Note that the electrical characteristics of PC6 differ from those of the other pins of Port C.If the RSTDISBL Fuse is unprogrammed, PC6 is used as a Reset input. A low level on this pin for longer than the minimum pulse length will generate a Reset, even if the clock is not running. Shorter pulses are not guaranteed to generate a Reset. Port D (PD7..PD0) Port D is an 8-bit bi-directional I/O port with internal pull-up resistors (selected for each bit). The Port D output buffers have symmetrical drive characteristics with both high sink and source capability. As inputs, Port D pins that are externally pulled low will source current if the pull-up resistors are activated. The Port D pins are tri-stated when a reset condition becomes active,even if the clock is not running.

RESET Reset input. A low level on this pin for longer than the minimum pulse length will generate a reset, even if the clock is not running. Shorter pulses are not guaranteed to generate a reset. 5.1.2.3 ATmega8(L) AVCC AVCC is the supply voltage pin for the A/D Converter, Port C (3..0), and ADC (7..6). It should be externally connected to VCC, even if the ADC is not used. If the ADC is used, it should be connected to VCC through a low-pass filter. Note that Port C (5..4) use digital supply voltage, VCC.AREF AREF is the analog reference pin for the A/D Converter. 5.1.2.4 ARCHITECTURAL OVER VIEW

5.3 LCD DISPLAY: An LCD is a small low cost display. it is easy to interface with a microcontroller because of an embedded controller (the black blob on the back of the

board). This controller is standard across many displays (hd 44780), which means many micro-controllers have libraries that make displaying messages as easy as a single line of code.

Fig 5.3 Schematic view of 16 x 2 LCD display 5.3.1 FEATURES: 5 x 8 dots with cursor built-in controller (ks 0066 or equivalent) + 5v power supply (also available for + 3v) 1/16 duty cycle b/l to be driven by pin 1, pin 2 or pin 15, pin 16 or a.k (led) n.v. optional for + 3v power supply

5.3.2 ADDRESS CODE:

Fig 5.3.2 Address code for 16 x 2 LCD display 5.3.3 DETAILS OF 16 X 2 LCD DISPLAY:

Fig 5.3.3Pin details for 16 x 2 LCD display 5.4 KEY PAD (4X1 MATRIX) This note describes an method of interfacing a matrix keyboard to EZ328 using minimum number of I/O ports. We use a 4x1 matrix keypad as an example. It requires only five I/O ports. (In general, it takes n+1 ports to interface a nxn matrix keyboard). It is a low cost solution. No TTL logic ICs are used. The components mainly used in the interfacing circuitry include only diodes and resistors which can greatly reduce the system cost and size of the product.

Fig.5.4., schematic view of 4x1 Keypad Figure 5.4 shows a functional block diagram of the keyboard interface. As seen in this diagram, there are two major parts. Interrupt & interfacing Circuity - generates interrupt to EZ328 when there is a key pressed and provides connection to EZ328s I/O ports Keyboard matrix - a 4x1 matrix keypad The interrupt and interfacing circuit includes some diodes, resistors, pull-up resistors and a NPN transistor.The transistor part is designed as an inverter for generating interrupt signal to EZ328 when there is a key pressed. There are two groups of diodes mainly for restricting signal flow in single direction so as to enable this circuitry to identify the pressed key uniquely. One of these two groups of diodes have been wired together to provide a OR function which in turn allows any key pressed on each column of the keypad to signal the transistor part for generating interrupt. This solution demonstrates a simple mechanism to build a keyboard with minimum I/O port used. In this application, we use a 4x4 matrix keypad as an example. It requires only five I/O ports for interfacing. One of them is used for generating the interrupt signal in the beginning and used as an I/O port for key

scanning operation afterwards. Detail of the method in scanning and identifying the pressed key will be discussed in the section SCAN KEYOperation. It should also be noted that in this design, EZ328 uses five ports for interfacing but only one of them requires interrupt capability. 5.4.1 SCAN KEY OPERATION Five ports are used for key scanning function in this system. One of them (PD7) is used as the interrupt pin before a key is pressed. Before the key scanning process starts, all of the I/O ports except the one with interrupt capability is configured as output high. Then, when there is a key pressed, one of the columns on the keypad changes state from low to high. As all the columns on the keypad are wired together to form a OR logic to the base of the NPN transistor, it will generate an active low interrupt signal to EZ328 and initiates the interrupt handler to scan the pressed key.When the key scanning process begins, one of the five I/O ports will be configured to output high while the other ports are configured to input.

The states on all ports are then read and compared with the pattern recorded in a predefined lookup table in order to locate which key is pressed. If the key is not found, another port will be configured to output high instead and read the states again. This process is repeated until all ports have been configured once to output high or a key is found.Since the circuitry provides feedback paths, one of the input port will change state from low to high by the output high port and the states obtained can identify uniquely which key is being pressed. 5.5 ZIGBEE

5.5.1 UART A universal asynchronous receiver/transmitter, abbreviated UART, is a type of "asynchronous receiver/transmitter", a piece of computer hardware that translates data between parallel and serial forms. UARTs are commonly used in conjunction with communication standards such as EIA RS-232, RS-422 or RS485. The universal designation indicates that the data format and transmission speeds are configurable and that the actual electric signaling levels and methods (such as differential signaling etc.) typically are handled by a special driver circuit external to the UART. 5.5.2 ZIGBEE MIWI is a specification for a suite of high level communication protocols using small, low-power digital radios based on the IEEE 802.15.4-2003 standard for Low-Rate Wireless Personal Area Networks (LR-WPANs), such as wireless light switches with lamps, electrical meters with in-home-displays, consumer electronics equipment via short-range radio needing low rates of data transfer. The technology defined by the MIWI specification is intended to be simpler and less expensive than other WPANs, such as Bluetooth. MIWI is targeted at radiofrequency (RF) applications that require a low data rate, long battery life, and secure networking.

Fig.5.5.2 Schematic view of Zigbee

MIWI is a low-cost, low-power, wireless mesh networking standard. First, the low cost allows the technology to be widely deployed in wireless control and monitoring applications. Second, the low power-usage allows longer life with smaller batteries. Third, the mesh networking provides high reliability and more extensive range. It is not capable of powerline networking though other elements of the OpenHAN standards suite promoted by openAMI and UtilityAMI deal with communications co-extant with AC power outlets. In other words, MIWI is intended not to support powerline networking but to interface with it at least for smart metering and smart appliance purposes. Utilities, e.g. Penn Energy, have declared the intent to require them to interoperate again via the openHAN standards.

Typical application areas include

Home Entertainment and Control Smart lighting, advanced temperature control, safety and security, movies and music Wireless Sensor Networks Starting with individual sensors like Telosb/Tmote and Iris from Memsic. 5.5.3 DEVICE TYPES There are three different types of MIWI devices: MIWI coordinator (ZC): The most capable device, the coordinator forms the root of the network tree and might bridge to other networks. There is exactly one MIWI coordinator in each network since it is the device that started the network originally. It is able to store information about the network, including acting as the Trust Center & repository for security keys. MIWI End Device (ZED): Contains just enough functionality to talk to the parent node (either the coordinator or a router); it cannot relay data from other devices. This relationship allows the node to be asleep a significant amount of the time thereby giving long battery life. A ZED requires the least amount of memory, and therefore can be less expensive to manufacture than a ZR or ZC. 5.5.3 SOFTWARE AND HARDWARE The software is designed to be easy to develop on small, inexpensive microprocessors. The radio design used by MIWI has been carefully optimized for low cost in large scale production. It has few analog stages and uses digital circuits wherever possible.Even though the radios themselves are inexpensive, the MIWI Qualification Process involves a full validation of the requirements of the physical

layer. This amount of concern about the Physical Layer has multiple benefits, since all radios derived from that semiconductor mask set would enjoy the same RF characteristics. On the other hand, an uncertified physical layer that malfunctions could cripple the battery lifespan of other devices on a MIWI network. Where other protocols can mask poor sensitivity or other esoteric problems in a fade compensation response, MIWI radios have very tight engineering constraints: they are both power and bandwidth constrained. Thus, radios are tested to the ISO 17025 standard with guidance given by Clause 6 of the 802.15.4-2006 Standard. Most vendors plan to integrate the radio and microcontroller onto a single chip getting smaller devices.

Fig.5.5.3 Pin connection of Zigbee 5.5.4 ELECTRICAL CHARACTERSTICS:

Fig.5.5.4 Electrical characteristics of Zigbee 5.5.5 DEVICE OVERVIEW The MRF24J40MA is a 2.4 GHz IEEE Std. 802.15.4 compliant, surface mount module with integrated crystal, internal voltage regulator, matching circuitry and PCB antenna. The MRF24J40MA module operates in the nonlicensed 2.4 GHz frequency band and is FCC, IC and ETSI compliant. The integrated module design frees the integrator from extensive RF and antenna design, and regulatory compliance testing, allowing quicker time to market.

5.6 CIRCUIT DIAGRAM OF ZIGBEE

Fig 5.5.6 MRF24J40MA Block Diagram

Fig 5.5.7 Circuit Diagram 5.5.7 FEATURES: 2.4 GHz IEEE Std. 802.15.4 RF Transceiver Module : IEEE Std. 802.15.4 Compliant RF Transceiver . Supports MIWI, MIWI, MIWI P2P and Proprietary Wireless Networking Protocols Small Size: 0.7 x 1.1 (17.8 mm x 27.9 mm), Surface Mountable Integrated Crystal, Internal Voltage Regulator, Matching Circuitry and PCB Antenna Easy Integration into Final Product Minimize Product Development, Quicker Time to Market Radio Regulation Certification for United States (FCC), Canada (IC) and Europe (ETSI) Compatible with Microchip Microcontroller Families (PIC16F, PIC18F, PIC24F/H, dsPIC33 and PIC32) Up to 400 ft. Range Operating Voltage: 2.4-3.6V (3.3V typical) Temperature Range: -40C to +85C Industrial Simple, Four-Wire SPI Interface Low-Current Consumption: -RX mode: 19 mA (typical) -TX mode: 23 mA (typical)

-Sleep: 2 A (typical) RF/Analog Features: ISM Band 2.405-2.48 GHz Operation Data Rate: 250 kbps -94 dBm Typical Sensitivity with +5 dBm Maximum Input Level +0 dBm Typical Output Power with 36 dB TX Power Control Range Integrated Low Phase Noise VCO, Frequency Synthesizer and PLL Loop Filter . Digital VCO and Filter Calibration . Integrated RSSI ADC and I/Q DACs Integrated LDO . High Receiver and RSSI Dynamic Range . MAC/Baseband Features:

Hardware CSMA-CA Mechanism, Automatic ACK Response and FCS Check Independent Beacon, Transmit and GTS FIFO Supports all CCA modes and RSS/LQI Automatic Packet Retransmit Capable Hardware Security Engine (AES-128) with CTR, CCM and CBC-MAC modes . Supports Encryption and Decryption for MAC Sublayer and Upper Layer .

5.5.8 Applications 2.4-GHz IEEE 802.15.4 systems RF4CE remote control systems (64-KB flash and higher) MIWI systems (256-KB flash) Home/Building automation Lighting systems Industrial control and monitoring Low-Power wireless sensor networks Consumer electronics Health care

GSM MODEM:

Model of gsm modem Sim300 - gsm/gprs engine. Works on frequencies egsm 900 mhz, dcs 1800 mhz and pcs 1900 mhz. Sim300 features gprs multi-slot class 10/ class 8 (optional) and supports the gprs coding schemes.

Feautures of gsm kit: This gsm modem is a highly flexible plug and play quad band gsm modem for direct and as integration to rs232. Supports features like voice, data/fax, sms, gprs and integrated tcp/ip stack. Control via at commands. Use ac dc power adaptor with following ratings dc voltage : 12v /1a. Current consumption in normal operation 250ma, can rise up to 1amp while transmission.

Introduction:

This document describes the hardware interface of the simcom sim300 module that connects to the specific application and the air interface. As sim300 can be integrated with a wide range of applications, all functional components of sim300 are described in great detail. This document can help you quickly understand sim300 interface specifications, electrical and mechanical details. With the help of this document and other sim300 application notes, user guide, you can use sim300 module to design and set-up mobile applications quickly

Product concept :

Designed for global market, sim300 is a tri-band gsm/gprs engine that works on frequencies egsm 900 mhz, dcs 1800 mhz and pcs1900 mhz. Sim300 provides gprs multi-slot class 10 capability and support the gprs coding schemes cs-1, cs-2, cs-3 and cs-4.

With a tiny configuration of 40mm x 33mm x 2.85 mm , sim300 can fit almost all the space requirement in your application, such as smart phone, pda phone and other mobile device. The physical interface to the mobile application is made through a 60 pins board-to-board connector, which provides all hardware interfaces between the module and customers boards except the rf antenna interface. The keypad and spi lcd interface will give you the flexibility to develop customized applications. Two serial ports can help you easily develop your applications.

Two audio channels include two microphones inputs and two speaker outputs. This can be easily configured by at command.

Sim300 provide rf antenna interface with two alternatives: antenna connector and antenna pad. The antenna connector is murata mm9329-2700. And customers antenna can be soldered to the antenna pad. The sim300 is designed with power saving technique, the current consumption to as low as 2.5ma in sleep mode. The sim300 is integrated with the tcp/ip protocolextended tcp/ip at commands are developed for customers to use the tcp/ip protocol easily, which is very useful for those data transfer applications.

Sim300 key features at a glance:

Application interface: All hardware interfaces except rf interface that connects sim300 to the customers cellular application platform is through a 60-pin 0.5mm pitch board-to-board connector. Sub-interfaces included in this board-to-board connector are described in detail in following chapters:

Power supply Dual serial interface Two analog audio interfaces Sim interface

Electrical and mechanical characteristics of the board-to-board connector are specified. There we also order information for mating connectors. Power supply:

The power supply of sim300 is from a single voltage source of vbat= 3.4v...4.5v. In some case, the ripple in a transmit burst may cause voltage drops when current consumption rises to typical peaks of 2a, so the power supply must be able to provide sufficient current up to 2a. For the vbat input, a local bypass capacitor is recommended. A capacitor (about 100f, low esr) is recommended. Multi-layer ceramic chip (mlcc) capacitors can provide the best combination of low esr and small size but may not be cost effective. A lower cost choice may be a 100 f tantalum capacitor (low esr) with a small (1 f to 10f) ceramic in parallel, which is illustrated as following figure. And the capacitors should put as closer as possible to the sim300 vbat pins. The following figure is the recommended circuit.

The following figure is the vbat voltage ripple wave at the maximum power transmit phase, the test condition is vbat=4.0v, vbat maximum output current =2a, ca=100 f tantalum capacitor (esr=0.7) and cb=4.7f

Power supply pins on the board-to-board connector:

Eight vbat pins of the board-to-board connector are dedicated to connect the supply voltage; four gnd pins are recommended for grounding. Backup can be used to back up the rtc. Minimizing power losses:

Please pay special attention to the supply power when you are designing your applications. Please make sure that the input voltage will never drops below 3.4v even in a transmit burst during which the current consumption may rise up to 2a. If the power voltage drops below 3.4v, the module may be switched off. Using the board-to-board connector will be the best way to reduce the voltage drops. You should also take the resistance of the power supply lines on the host board or of battery pack into account.

Monitoring power supply: To monitor the supply voltage, you can use the at+cbc command which include three parameters: voltage percent and voltage value (in mv). It returns the battery voltage 1-100 percent of capacity and actual value measured at vbat and gnd. The voltage is continuously measured at intervals depending on the operating mode. The displayed voltage (in mv) is averaged over the last measuring period before the at+cbc command was executed.

Power up and power down scenarios Turn on sim300:

Sim300 can be turned on by various ways, which are described in following

Via pwrkey pin: starts normal operating mode Via rtc interrupt: starts alarm modes

Turn on sim300 using the pwrkey pin (power on):

You can turn on the sim300 by driving the pwrkey to a low level voltage For period time. The power on scenarios illustrate as following figure.

Turn on sim300 using the rtc (alarm mode):

Alarm mode is a power-on approach by using the rtc. The alert function of rtc makes the sim300 wake up while the module is power off. In alarm mode, sim300 will not register to gsm network and the software protocol stack is close. Thus the parts of at commands related with sim card and protocol stack will not accessible, and the others can be used as well as in normal mode. Use the at+calarm command to set the alarm time. The rtc remains the alarm time if sim300 was power down by at+cpowd=1 or by pwrkey pin. Once the alarm time expires and executed, sim300 goes into the alarm mode. In this case, sim300 will send out an unsolicited result code (urc):

Rdy alarm mode:

During alarm mode, using at+cfun command to query the status of software protocol stack; it will return 0 which indicates that the protocol stack is closed. Then after 90s, sim300 will power down automatically. However, during alarm mode, if the software protocol is started

by at+cfun=1, 1 command, the process of automatic power down will not available. In alarm mode, driving the pwrkey to a low level voltage for a period will cause sim300 to power down

Turn off sim300:

Following procedure can be used to turn off the sim300:

Normal power down procedure: turn off sim300 using the pwrkey pin Normal power down procedure: turn off sim300 using at command Under-voltage automatic shutdown: takes effect if under-voltage is detected Over-temperature automatic shutdown: takes effect if over-temperature is detected

Turn off sim300 using the pwrkey pin (power down) :

You can turn off the sim300 by driving the pwrkey to a low level voltage for period time. The power down scenarios illustrate as following figure. This procedure will let the module to log off from the network and allow the software to enter into a secure state and save data before completely disconnect the power supply. Before the completion of the switching off procedure the module will send out result code:

Power down:

After this moment, no any at commands can be executed. Module enters the power down mode, only the rtc is still active. Power down can also be indicated by vdd_ext pin, which is a low level voltage in this mode.

Turn off sim300 using at command : You can use an at command at+cpowd=1 to turn off the module. This command will let the module to log off from the network and allow the software to enter into a secure state and safe data before completely disconnect the power supply.

Power down:

After this moment, no any at commands can be executed. Module enters the power down mode, only the rtc is still active. Power down can also be indicated by vdd_ext pin, which is a low level voltage in this mode

Under-voltage automatic shutdown:

Software will constantly monitors the voltage applied on the vbat, if the measured battery voltage is no more than 3.5v, the following urc will be presented:

Power low warning:

If the measured battery voltage is no more than 3.4v, the following urc will be presented:

Power low down:

After this moment, no further more at commands can be executed. The module will log off from network and enters power down mode, only the rtc is still active. Pow Restart sim300 using the pwrkey pin :

You can restart sim300 by driving the pwrkey to a low level voltage for period time, same as turn on sim300 using the pwrkey pin. Before restart the sim300, you need delay at least 500ms from detecting the vdd_ext low level on. The restart scenarios illustrate as the following figure.

Power saving : There are two methods to achieve sim300 module extreme low power. at+cfun is used to set module into minimum functionality mode and /dtr hardware interface signal can be used to set system to be sleep mode (or slow clocking mode).

Minimum functionality mode :

Minimum functionality mode reduces the functionality of the module to a minimum and, thus, minimizes the current consumption to the lowest level. This mode is set with the at+cfun command which provides the choice of the functionality levels <fun>=014

0: minimum functionality;

1: full functionality (default);

4: disable phone both transmit and receive rf circuits; If sim300 has been set to minimum functionality by at+cfun=0, then the rf function and sim card function will be closed, in this case, the serial ports is still accessible, but all at commands need rf function or sim card function will not accessible. If sim300 has disable all rf function by at+cfun=4, then rf function will be closed, the serial ports is still active in this case but all at commands need rf function will not accessible. When sim300 is in minimum functionality or has been disable all rf functionality by at+cfun=4, it can return to full functionality by at+cfun=1.

Sleep mode (slow clocking mode) :

Through dtr signal control sim300 module to enter or exit the sleep mode in customer applications. When dtr is in high level, at the same time there is no on air or audio activity is required and no hardware interrupt (such as gpio interrupt or data on serial port), sim300 will enter sleep mode automatically. In this mode, sim300 can still receive paging or sms from network. In sleep mode, the serial port is not accessible.

Wake up sim300 from sleep mode :

When sim300 is sleep mode, the following method can wake up the module. Enable dtr pin to wake up sim300; If dtr pin is pull down to a low level this signal will wake up sim300 from power saving mode. The serial port will be active after dtr change to low level about 20m

Receive a voice or data call from network to wake up sim300; Receive a sms from network to wake up sim300 Rtc alarm expired to wake up sim300;

Max232: Pin diagram:

Pin diagram of max232

Features: Meets or exceeds tia/eia-232-f and itu recommendation v.28 Operates from a single 5-v power supply with 1.0-_f charge-pump capacitors Operates up to 120 kbit/s Two drivers and two receivers.

30-v input levels Low supply current ( 8 ma typical) Esd protection exceeds jesd 22 2000-v human-body model (a114-a)

Upgrade with improved esd (15-kv hbm) and 0.1-_f charge-pump capacitors is available with the max202.

Description: The max232 is a dual driver/receiver that includes a capacitive voltage generator to supply tia/eia-232-f voltage levels from a single 5-v supply. Each receiver converts tia/eia-232-f inputs to 5-v ttl/cmos levels. These receivers have a typical threshold of 1.3 v, a typical hysteresis of 0.5 v, and can accept 30-v inputs. Each driver converts ttl/cmos input levels into tia/eia-232-f levels. The driver, receiver, and Voltage-generator functions are available as cells. Logic circuit diagram:

Schematic diagram of max232 chip:

Figure 6 : Schematic diagram of max232

Test circuit:

Waveforms:

CHAPTER 6 SOFTWARE ANALYSIS 6.1 INTRODUCTION TO CODE VISION AVR CodeVisionAVR is a C cross-compiler, Integrated Development

Environment and Automatic Program Generator designed for the Atmel AVR family of microcontrollers. The program is a native 32bit application that runs under the Windows 95, 98, NT 4, 2000 and XP operating systems. The C crosscompiler implements nearly all the elements of the ANSI C language, as allowed by the AVR architecture, with some features added to take advantage of specificity of the AVR architecture and the embedded system needs. The compiled COFF object files can be C source level debugged, with variable watching, using the Atmel AVR Studio debugger. The Integrated Development Environment (IDE) has built-in AVR Chip InSystem Programmer software that enables the automatical transfer of the program to the microcontroller chip after successful compilation/assembly. The In-System Programmer software is designed to work in conjunction with the Atmel STK500, Kanda Systems STK200+/300, Dontronics DT006, Vogel Elektronik VTEC-ISP, Futurlec JRAVR and MicroTronics' ATCPU/Mega2000 development boards. For debugging embedded systems, which employ serial communication, the IDE has a built-in Terminal. Besides the standard C libraries, the CodeVisionAVR C compiler has dedicated libraries for: Alphanumeric LCD modules Philips I2C bus National Semiconductor LM75 Temperature Sensor

Philips PCF8563, PCF8583, Dallas Semiconductor DS1302 and DS1307 Real Time Clocks Dallas Semiconductor 1 Wire protocol Dallas Semiconductor DS1820/DS18S20 Temperature Sensors Dallas Semiconductor DS1621 Thermometer/Thermostat Dallas Semiconductor DS2430 and DS2433 EEPROMs SPI Power management Delays Gray code conversion.

CodeVisionAVR also contains the CodeWizardAVR Automatic Program Generator, that allows you to write, in a matter of minutes, all the code needed for implementing the following functions: External memory access setup Chip reset source identification Input/Output Port initialization External Interrupts initialization Timers/Counters initialization Watchdog Timer initialization UART initialization and interrupt driven buffered serial communication Analog Comparator initialization ADC initialization SPI Interface initialization I2C Bus, LM75 Temperature Sensor, DS1621 Thermometer/Thermostat and PCF8563, PCF8583,

DS1302, DS1307 Real Time Clocks initialization 1 Wire Bus and DS1820/DS18S20 Temperature Sensors initialization LCD module initialization

CONCLUSION: The product design prototype is constructed and when a Small amount of LPG is brought near the system, the system sensor detects the leakage and sends the SMS to housemates and activates the alarm and switches on the exhaust fan. Also system prototype continuously monitors the LPG level of the cylinder and books the cylinder automatically through SMS using GSM modem.

Vous aimerez peut-être aussi

- Fabrication of Three Axis CraneDocument43 pagesFabrication of Three Axis CraneSuresh SsbnPas encore d'évaluation

- A Low Cost Flyback CCM Inverter For ACDocument2 pagesA Low Cost Flyback CCM Inverter For ACSuresh SsbnPas encore d'évaluation

- Speed Control of PMSM MotorDocument38 pagesSpeed Control of PMSM MotorSuresh SsbnPas encore d'évaluation

- CCM Invert ErDocument5 pagesCCM Invert ErSuresh SsbnPas encore d'évaluation

- DS HM2007Document21 pagesDS HM2007Ankitha ReddyPas encore d'évaluation

- Transformer Indication SystemDocument67 pagesTransformer Indication SystemSuresh SsbnPas encore d'évaluation

- Dip TitleDocument8 pagesDip TitleSuresh SsbnPas encore d'évaluation

- Environment Monitoring PICDocument80 pagesEnvironment Monitoring PICSuresh SsbnPas encore d'évaluation

- BLDC Sepic Motor Torque ControlDocument60 pagesBLDC Sepic Motor Torque ControlSuresh SsbnPas encore d'évaluation

- Ieee Robot ProjectDocument5 pagesIeee Robot ProjectSuresh SsbnPas encore d'évaluation

- Transmission BROKEN CONDUTOR DetectionDocument48 pagesTransmission BROKEN CONDUTOR DetectionSuresh SsbnPas encore d'évaluation

- Hope This Is Very Useful Info To All.......... : Breathing TherapyDocument4 pagesHope This Is Very Useful Info To All.......... : Breathing TherapySuresh SsbnPas encore d'évaluation

- RF Based Spying Robot Using Wireless CameraDocument4 pagesRF Based Spying Robot Using Wireless CameraSuresh SsbnPas encore d'évaluation

- Health Monitoring Using Xbee and GSMDocument81 pagesHealth Monitoring Using Xbee and GSMSuresh SsbnPas encore d'évaluation

- Old World Light Bulb LoadDocument8 pagesOld World Light Bulb LoadSuresh SsbnPas encore d'évaluation

- A DC-DC Converter Based On The Three-State Switching Cell For High Current and Voltage Step-Down ApplicationsDocument10 pagesA DC-DC Converter Based On The Three-State Switching Cell For High Current and Voltage Step-Down Applicationsssbtech2013Pas encore d'évaluation

- Induction Motor Based Energy HarvestingDocument3 pagesInduction Motor Based Energy HarvestingSuresh SsbnPas encore d'évaluation

- SensorsDocument38 pagesSensorsSuresh SsbnPas encore d'évaluation

- Electrical LoadDocument2 pagesElectrical LoadSuresh SsbnPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- ETO Entrance Exam Syllabus PDFDocument3 pagesETO Entrance Exam Syllabus PDFMadhavananda MadhuPas encore d'évaluation

- Instrument Transformers CatalogueDocument12 pagesInstrument Transformers CatalogueGanesh DuraisamyPas encore d'évaluation

- SSSC (Static Synchronous Series Compensator) : DonsiónDocument9 pagesSSSC (Static Synchronous Series Compensator) : DonsióntamsidePas encore d'évaluation

- Electrostatic 15: Part No. Topic & Lecture Name DurationsDocument2 pagesElectrostatic 15: Part No. Topic & Lecture Name DurationsGourab RoyPas encore d'évaluation

- 300B Parallel SET AmplifierDocument8 pages300B Parallel SET Amplifierandree wPas encore d'évaluation

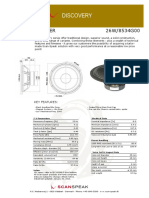

- Scanspeak Woofer 26w-8534g00Document2 pagesScanspeak Woofer 26w-8534g00Aldo DolcePas encore d'évaluation

- ConductivityDocument4 pagesConductivityAyeshaPas encore d'évaluation

- Wiring Diagram of Modular Switch Panel (MSF)Document5 pagesWiring Diagram of Modular Switch Panel (MSF)Rendy MechanicPas encore d'évaluation

- 4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualDocument24 pages4 To 20 Ma Remote Indicator: Instructions, Operation Maintenance ManualsancakemrePas encore d'évaluation

- Manual Topworx D Series Discrete Valve Controllers Topworx en 82606 PDFDocument67 pagesManual Topworx D Series Discrete Valve Controllers Topworx en 82606 PDFWanderson PessoaPas encore d'évaluation

- MSE310-2016 Lecture Notes 3.0-3.1.5 (Student) PDFDocument63 pagesMSE310-2016 Lecture Notes 3.0-3.1.5 (Student) PDFRanaPas encore d'évaluation

- Ieee 80 Tiuch and Step Volt - Full CalcDocument22 pagesIeee 80 Tiuch and Step Volt - Full CalcVasu Iyer100% (1)

- Cyg PRS-7367Document235 pagesCyg PRS-7367MarkusKunPas encore d'évaluation

- Dual-Band Omnidirectional Antenna Vertical Polarization: Vvpol Omni 870-960/1920-2170 360°/360° 9/10dbiDocument2 pagesDual-Band Omnidirectional Antenna Vertical Polarization: Vvpol Omni 870-960/1920-2170 360°/360° 9/10dbiGabi GabrielPas encore d'évaluation

- 1.characteristics of SCRDocument6 pages1.characteristics of SCRVenkat Sai ChowdaryPas encore d'évaluation

- AX8 Owners Manual PDFDocument111 pagesAX8 Owners Manual PDFSoe SirawitPas encore d'évaluation

- Digital Key Coded LockDocument11 pagesDigital Key Coded LockEngr. Zeeshan mohsin100% (1)

- WESM WESMMNM 033 - Revision34Document55 pagesWESM WESMMNM 033 - Revision34Romel Cabrera IIPas encore d'évaluation

- Boss rv6 Manual PDFDocument1 pageBoss rv6 Manual PDFwplaisPas encore d'évaluation

- Engineering Physics Laboratory: Course ObjectivesDocument3 pagesEngineering Physics Laboratory: Course ObjectivesNaveenraj NPas encore d'évaluation

- L&T Price ListDocument40 pagesL&T Price ListAshish Marotkar80% (5)

- PD-Diagnosis Physical Basic Practical Experience With OWTS: April 2006Document41 pagesPD-Diagnosis Physical Basic Practical Experience With OWTS: April 2006dio39saiPas encore d'évaluation

- Datasheet PDFDocument11 pagesDatasheet PDFAbel Pereira de OliveiraPas encore d'évaluation

- 2 - SCH 401 - Electrochemical Cells and Nernst Equation (Compatibility Mode)Document35 pages2 - SCH 401 - Electrochemical Cells and Nernst Equation (Compatibility Mode)Samson OdhiamboPas encore d'évaluation

- Excel Load CalculatorDocument5 pagesExcel Load CalculatorArideepPas encore d'évaluation

- CHAPTER 2 - Transducer - 2Document73 pagesCHAPTER 2 - Transducer - 2RafaelTituzPas encore d'évaluation

- Kw-Xg56tu Xr411xx Xr414ui Xr416xx Xr417ee Xr418j (SCH)Document31 pagesKw-Xg56tu Xr411xx Xr414ui Xr416xx Xr417ee Xr418j (SCH)Jory2005Pas encore d'évaluation

- Lecture Schedule Subject: Linear Integrated Circuits Subject Code: L503 Name of Staff: Assini.HDocument3 pagesLecture Schedule Subject: Linear Integrated Circuits Subject Code: L503 Name of Staff: Assini.HAssini HussainPas encore d'évaluation

- Manual Pre KS45Document21 pagesManual Pre KS45alcom100% (1)

- User's ManualDocument24 pagesUser's ManualMARKO021Pas encore d'évaluation