Académique Documents

Professionnel Documents

Culture Documents

Roller Chain Transmission: I II ? 1.0 Input Sectinon Sprocket1 Sprocket2 Project Information Calculation Without Errors

Transféré par

Christian Fonseca RodriguezDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Roller Chain Transmission: I II ? 1.0 Input Sectinon Sprocket1 Sprocket2 Project Information Calculation Without Errors

Transféré par

Christian Fonseca RodriguezDroits d'auteur :

Formats disponibles

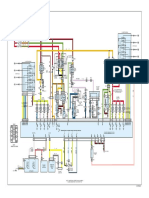

Roller chain transmission i ii ? 1.0 1.1 Calculation units 1.2 Transferred power 1.

3 Speed of the sprocket wheel (desired) 1.4 Speed of the sprocket wheel (actual) 1.5 The desired / actual transmission ratio 1.6 Torque 1.7 The type of driving machine (loading) 1.8 The type of driven machine (loading) 1.9 Type of lubrication 1.10 Number of links of the chain 1.11 Number of teeth of the sprocket wheel 2.0 2.2 Automatic design

DStandard roller chains (EU) / DIN 8187, ISO R-606, BS 228

Calculation without errors. Project information Informace o projektu Input sectinon The manner of loading, working parameters

Sprocket1

Sprocket2

SI Units (N, mm, kW)

P n n i Mk

9.60 116.5310732 116.5310732 3.884 787.02

CMedium duty ARequested failure free Even only Odd only

9.41 30 29.57 3.941 3039.75

[kW] [/min] [/min] [Nm]

AUniform loading or light shocks v5

Odd only

2.1 Chain type 2.3 Axis distance for Automatic design 2.4 Range of smaller sprocket teeth 2.5 Automatic design - press the button 2.6 Sort results according to parameter 2.7 Table of solutions 2.8 2.9

Type || z1 | z2 | n2 | i 3.94 | | A 683.6 || || Pp 17.04 | | v || SD | p | SP | Pp% | 92 | 110.2 m 20B - 2 || 17 | 67 | 29.6 | 1.05 || 12.88 | 15.95 | 1.06 | Transmission weight

700.00 17

Entered

[mm] 21

3.0

Design and calculation

20B - 2 (31.75)

3.1 Chain selection - Standard chain No. (Pitch) 3.2 Chain pitch / chains strands number 3.3 Sprocket - number of teeth / recomended 3.4 Pitch diameter 3.5 Desired axis distance / recomended 3.6 Actual axis distance / min.-max. 3.7 Number of chain links 3.8 Length of the chain 3.9 Speed of the chain / max 3.10 Design power / table power 3.11 Tensile force / Centrifugal force 3.12 Breaking force (table) / Force on the chain 3.13 Static coefficient of safety against breakage 3.14 Dynamic coefficient of safety against breakage 3.15 The calculated / permitted pressure in the chain joint 3.16 Level of safety of the chain joint 3.17 Total weight of the transmission / chain t z Dp C C X L v Pp Fu/Fc FB/Fr SB SD p SP m

31.750 17 172.790 683.60 683.56 88 2794 1.05 15.18 9108.9 170000 18.65 13.32 15.43 1.10 110.22

600 500 400 300 200 100 0

2 67 677.373 1270 595 - 5080 88 [mm] < 7.98 < 17.04 8.3 9117.3 > 10.58 > 12.83 < 16.91 > 1.00 20.96 [kg] [MPa] [m/s] [kW] [N] [N] 17 (min=15) [mm] [mm] [mm]

-200

-100 -200 -300 -400

200

400

600

800

1000

1200

? 4.0 Results, coeficients 4.1 Coefficients for power corrections 4.2 Coefficient of the number of teeth 4.3 Coefficient of the transmission ratio 4.4 Coefficient of shock (Service factor) 4.5 Coefficient of distances of axes 4.6 Coefficient of lubrication 4.7 Coefficient of temperature 4.8 Coefficient of service life 4.9 Calculation and setting of coefficients according to 4.10 Recommended type of lubrication 4.11 Type of lubrication (permissible) 4.12 Maximum slackness of the chain 4.13 Minimum / Maximum speed of sprocket 2 4.14 Coefficient of speed variation 5.0 Dimensions

Results section

K1 K2 K3 K4 K5 K6 K7

1.00 0.95 1.40 1.18 1.00 1.00 1.00

ISO 10823

1.10 0.95 1.40 1.18 1.00 1.00 1.00

Oil dip with splash ring Oil drops y 1.04 d1 d3 b1 b2 t g l e s1 s2 1.83 10.190 19.050 19.560 29.000 31.750 26.000 77.700 36.450 4.500 3.500 13.67 1.06 [mm] [m/s] [%] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

Da Dp Df R1 R2

187.871 172.790 153.367 9.711 57.455 124.706 18.191 2.381 15.285 22.225 128.340

692.454 677.373 657.950 434.645 128.657

[mm] [mm] [mm] [mm] [mm] [] [mm] [mm] [mm] [mm]

bf ba rx f Dg 6.0 Graphical output, CAD systems

632.923

[mm]

Vous aimerez peut-être aussi

- Spur Gearing, Helical Gearing (mm/ISO)Document6 pagesSpur Gearing, Helical Gearing (mm/ISO)oman1148Pas encore d'évaluation

- Motor Specifications and Ratings Mhma: 500W To 1.5kW High Inertia, Medium CapacityDocument6 pagesMotor Specifications and Ratings Mhma: 500W To 1.5kW High Inertia, Medium CapacitynvkjayanthPas encore d'évaluation

- Gear4 02Document101 pagesGear4 02pratapslairPas encore d'évaluation

- ENG - Lynx 300-300M - 140916 - SU - E4Document4 pagesENG - Lynx 300-300M - 140916 - SU - E4thyskiePas encore d'évaluation

- Duong Tien Luan - 20184997 - 124427Document18 pagesDuong Tien Luan - 20184997 - 124427Tien LuanPas encore d'évaluation

- ABB Servo Motors: 9C Series For ABB High Performance Machinery DrivesDocument8 pagesABB Servo Motors: 9C Series For ABB High Performance Machinery DriveseduantonioPas encore d'évaluation

- Bidi Flowtable With FT 1505 XLG 1955Document1 pageBidi Flowtable With FT 1505 XLG 1955ozmenPas encore d'évaluation

- Transmission and Differential SectionDocument245 pagesTransmission and Differential Sectionbillh@optonline.netPas encore d'évaluation

- Angrenaj 1 Tabel ProtocolDocument4 pagesAngrenaj 1 Tabel ProtocolFaur DanielPas encore d'évaluation

- Program PT AngrenajeDocument7 pagesProgram PT AngrenajeBalla AttilaPas encore d'évaluation

- Type of Calculation Date Customer Name Ref: Roller Chain Drives 29/08/2012 07:50:08 ModelDocument6 pagesType of Calculation Date Customer Name Ref: Roller Chain Drives 29/08/2012 07:50:08 Modelgrupa2904Pas encore d'évaluation

- Spur Gear PDFDocument8 pagesSpur Gear PDFLovely BalajiPas encore d'évaluation

- RE - Max 17 17 MM, Graphite Brushes, 4.5 Watt: Article NumbersDocument1 pageRE - Max 17 17 MM, Graphite Brushes, 4.5 Watt: Article NumbersJose CarlosPas encore d'évaluation

- 12H - Specs0Document5 pages12H - Specs0Marco OlivettoPas encore d'évaluation

- 160 H Grupo 1Document4 pages160 H Grupo 1Jose nildo lobato Mendes MendesPas encore d'évaluation

- Pittman GM9236S027Document0 pagePittman GM9236S027Nicola's SacPas encore d'évaluation

- Datasheet Do Shaker 394C06Document1 pageDatasheet Do Shaker 394C06dayanneromagnoliPas encore d'évaluation

- 160 H Grupo 2Document6 pages160 H Grupo 2Jose nildo lobato Mendes MendesPas encore d'évaluation

- 2004 Service Manual For Nissan 350zDocument7 pages2004 Service Manual For Nissan 350zHoward Ostfeld0% (1)

- Toyo Rubber CouplingDocument14 pagesToyo Rubber CouplingGreg SanjayaPas encore d'évaluation

- MINAS BLinfomationDocument7 pagesMINAS BLinfomationmashudi_fikriPas encore d'évaluation

- 17S78 BrushDC 71 v6 (1) .09Document1 page17S78 BrushDC 71 v6 (1) .09mgl_nkPas encore d'évaluation

- Pittman GM8724S023Document0 pagePittman GM8724S023Gustavo Gonzáles AlvitesPas encore d'évaluation

- Trochoidal TurningDocument6 pagesTrochoidal TurningHoang DHPas encore d'évaluation

- 1 143tecab5-Ie3Document1 page1 143tecab5-Ie3s bPas encore d'évaluation

- Motor Data Sheet: Motor Part Code: 1.143TECAB5-IE3 Frame Size: 90S-4Document1 pageMotor Data Sheet: Motor Part Code: 1.143TECAB5-IE3 Frame Size: 90S-4s bPas encore d'évaluation

- Metric (ISO) Fasteners: Torque SpecificationsDocument5 pagesMetric (ISO) Fasteners: Torque SpecificationsGolbert GolbiPas encore d'évaluation

- UnimogDocument19 pagesUnimogMichael KalbfleischPas encore d'évaluation

- Puente GruaDocument2 pagesPuente GruaAbel Valderrama PerezPas encore d'évaluation

- Training VibrasiDocument91 pagesTraining VibrasiArfahHamzah100% (5)

- Final Ppt-Auto LabDocument40 pagesFinal Ppt-Auto LabugtalkPas encore d'évaluation

- AMK DT ServomotorsDocument30 pagesAMK DT ServomotorsPaolo GiorgianniPas encore d'évaluation

- CHAIN CalculationDocument18 pagesCHAIN CalculationDmitrijs MuhinsPas encore d'évaluation

- Ball ScrewDocument10 pagesBall Screwfakihilham2705Pas encore d'évaluation

- Selection of Ball Screws 1Document4 pagesSelection of Ball Screws 1Minh Trí KnightPas encore d'évaluation

- 120h CV Spec1Document5 pages120h CV Spec1Yudi setiawanPas encore d'évaluation

- Design of Single Stage Reduction GearboxDocument6 pagesDesign of Single Stage Reduction GearboxJulien Reddi83% (6)

- Polaris Predator 500 Full Service ManualDocument193 pagesPolaris Predator 500 Full Service ManualDebbie Mattsen81% (16)

- Infinity m45 Quick ReferenceDocument6 pagesInfinity m45 Quick ReferenceakmicrodesignsPas encore d'évaluation

- Special Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitsDocument4 pagesSpecial Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitstutuionutPas encore d'évaluation

- Toughcarrier TCH10: Super High Load Capacity Single-Axis ActuatorDocument2 pagesToughcarrier TCH10: Super High Load Capacity Single-Axis ActuatornvkjayanthPas encore d'évaluation

- Chapter 7Document39 pagesChapter 7SayeedIshtiaquePas encore d'évaluation

- Datasheet For MotorDocument1 pageDatasheet For Motorsal_ssabriPas encore d'évaluation

- Molas e Slug Seletora 120HDocument5 pagesMolas e Slug Seletora 120HMarco OlivettoPas encore d'évaluation

- Maxon 144325Document1 pageMaxon 144325bleem41Pas encore d'évaluation

- Lec # 9 V-Belt DriveDocument46 pagesLec # 9 V-Belt DriveEl LordPas encore d'évaluation

- Project Report Manufacturing Process and Design of Machine Elements Gear BoxDocument23 pagesProject Report Manufacturing Process and Design of Machine Elements Gear BoxNisarg PatelPas encore d'évaluation

- DTS - Unit - 2 PDFDocument14 pagesDTS - Unit - 2 PDFmani100% (1)

- Misumi LMC GuideCalc PDFDocument1 pageMisumi LMC GuideCalc PDFSandeep JoglekarPas encore d'évaluation

- Presentation On Design of Transmission System For A GokartDocument21 pagesPresentation On Design of Transmission System For A GokartNikhil WarungasePas encore d'évaluation

- 2012 Subaru BRZ Service Shop ManualDocument172 pages2012 Subaru BRZ Service Shop ManualRahul JonesPas encore d'évaluation

- Volvo D12D EspecificacionDocument42 pagesVolvo D12D EspecificacionSilas F Pimenta92% (72)

- Esp. VirabrequimDocument4 pagesEsp. VirabrequimflavioPas encore d'évaluation

- TorqueDocument25 pagesTorquesami4330100% (3)

- DIN 3990 MDesign 2016 Esempio Spur Gear, Gear RackDocument17 pagesDIN 3990 MDesign 2016 Esempio Spur Gear, Gear RackmgualdiPas encore d'évaluation

- Technical Specification Tables For Construction Equipment VehicleDocument75 pagesTechnical Specification Tables For Construction Equipment VehicleHarley HariPas encore d'évaluation

- KGE1000Ti Service ManualDocument41 pagesKGE1000Ti Service Manualmarksmods100% (1)

- Dynamometer: Theory and Application to Engine TestingD'EverandDynamometer: Theory and Application to Engine TestingPas encore d'évaluation

- Machine Design Elements and AssembliesD'EverandMachine Design Elements and AssembliesÉvaluation : 3.5 sur 5 étoiles3.5/5 (2)

- Sudoku #1Document100 pagesSudoku #1Christian Fonseca RodriguezPas encore d'évaluation

- Hard SudoRETERTkuDocument125 pagesHard SudoRETERTkuJohn BaguioPas encore d'évaluation

- Han 2014Document20 pagesHan 2014Christian Fonseca RodriguezPas encore d'évaluation

- Matlab DSP ToolboxDocument800 pagesMatlab DSP ToolboxChristian Fonseca RodriguezPas encore d'évaluation

- Furier TransformDocument3 pagesFurier TransformChristian Fonseca RodriguezPas encore d'évaluation

- Automobile Component Design IDocument3 pagesAutomobile Component Design IRi ŚhiPas encore d'évaluation

- BVA300 Series Pneumatic Actuators For Use With Spirax Sarco Ball ValvesDocument11 pagesBVA300 Series Pneumatic Actuators For Use With Spirax Sarco Ball ValvesAdelio MercadejasPas encore d'évaluation

- VX WH VU GEN3 Series2 5e WiringDocument2 pagesVX WH VU GEN3 Series2 5e WiringDanniel PizattoPas encore d'évaluation

- Hydro Gear Parts List Manual For Model Number BDP 21L Service SchematicDocument12 pagesHydro Gear Parts List Manual For Model Number BDP 21L Service SchematicJoe AntPas encore d'évaluation

- Cummins NTC 400 SVC & Repair Vol 1Document280 pagesCummins NTC 400 SVC & Repair Vol 1FtFrancy95% (21)

- LG Rotary CompressorDocument2 pagesLG Rotary CompressorLuis C Sosa APas encore d'évaluation

- GR-1000XL-3: Self-Removable CounterweightDocument17 pagesGR-1000XL-3: Self-Removable Counterweightsrikanthc85Pas encore d'évaluation

- Manual de Partes LDW1003 (6B01E0)Document54 pagesManual de Partes LDW1003 (6B01E0)Enrique AssmannPas encore d'évaluation

- 4Document34 pages4juan carlos zavalaPas encore d'évaluation

- ZAE Operation Instructions Gearboxes Gearmotors EnglishDocument56 pagesZAE Operation Instructions Gearboxes Gearmotors EnglishhassanPas encore d'évaluation

- Shimano Biomaster 4000FBDocument1 pageShimano Biomaster 4000FBpikemanserbiaPas encore d'évaluation

- Docmine: Spare Parts CatalogDocument35 pagesDocmine: Spare Parts CatalogestebanPas encore d'évaluation

- Ivm Gate Valve 810 NPT A105nDocument1 pageIvm Gate Valve 810 NPT A105nASHIK TPas encore d'évaluation

- Table Equipment NumberDocument2 pagesTable Equipment NumberZaidy IrawannPas encore d'évaluation

- Jgekt PDFDocument2 pagesJgekt PDFDarmawan PutrantoPas encore d'évaluation

- Embrayage AmericaineDocument172 pagesEmbrayage Americainedenys92500Pas encore d'évaluation

- Parts - T 133 H x4 - enDocument101 pagesParts - T 133 H x4 - enАлексейPas encore d'évaluation

- Socket and Spigot JointDocument5 pagesSocket and Spigot Jointsarath.kumarnmk930Pas encore d'évaluation

- Volvo L90F: Parts CatalogDocument1 397 pagesVolvo L90F: Parts CatalogMepita Mecânica100% (2)

- El ABC de La ActitudDocument234 pagesEl ABC de La Actitudjuan castañedaPas encore d'évaluation

- Bomba Myers D35-20DVDocument12 pagesBomba Myers D35-20DVdiroperacionesPas encore d'évaluation

- Manual Birmingham FresadoraDocument49 pagesManual Birmingham FresadoraRichy SantoyoPas encore d'évaluation

- Schematic 1Document33 pagesSchematic 1chrisPas encore d'évaluation

- SM C400 OlderDocument64 pagesSM C400 OlderRemusPas encore d'évaluation

- Yale Mpe 2Document166 pagesYale Mpe 2Eldelson BaggetoPas encore d'évaluation

- NEC Requirements For Sizing Outlet BoxesDocument11 pagesNEC Requirements For Sizing Outlet BoxesJomari PecsonPas encore d'évaluation

- Manual Reparacion Mitsubishi Mirage 2000 PART 3Document53 pagesManual Reparacion Mitsubishi Mirage 2000 PART 3Jeffrey Morales MenaPas encore d'évaluation

- Liquid-Pump-75-HP-Series-Model-4B-S User ManualDocument26 pagesLiquid-Pump-75-HP-Series-Model-4B-S User ManualLuis Felipe Córdova RodríguezPas encore d'évaluation

- Otterbine Barebo Inc. Concept 3 50Hz ManualDocument23 pagesOtterbine Barebo Inc. Concept 3 50Hz ManualJaco RoetsPas encore d'évaluation

- Bobst Martin Catalog 2021 2Document24 pagesBobst Martin Catalog 2021 2belan_80Pas encore d'évaluation