Académique Documents

Professionnel Documents

Culture Documents

Double Deck

Transféré par

Jose CarlosDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Double Deck

Transféré par

Jose CarlosDroits d'auteur :

Formats disponibles

A. Zhazylbekova, B.K.

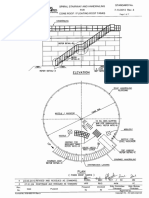

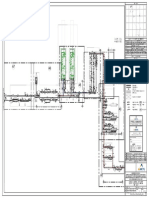

Kumar CALCULATION AND DESIGN OF THE LARGE VOLUME TANKS EXPOSED TO SEISMIC LOADS In the recent times a clear tendency to build large volume tanks of 50,000 to 100,000 m3 with double-deck floating roofs has been traced. Most frequently the construction areas of such tanks are critical both from climatic (snow, wind, ice storm) and seismic point of view. During the design stage of the double-deck floating roof two alternative engineering, fabrication and installation concepts are implemented [1]: 1. Standard solution using plate-by-plate method when the greater part of the roof assembly and welding works is performed on site. The roof consists of two decks: upper and lower decks interconnected by a number of concentric rings that form ring cells. The external cell is separated by radial partition walls to form leak-proof boxes (see Fig.1); 2. New solution using installation method of the factory-assembled rectangular boxes. The boxes are radially oriented towards the centre of the tank. The spaces between the boxes are covered with plate-by-plate panels on the upper and lower decks during the installation (see Fig.2). Thus the main difference between these design layouts of the roofs is the division principle into ring or radial cells. In accordance with the design rules the tank roof shall be stable, floating and robust when at least two Fig.1. Structural layout of floating roof adjacent cells are no more leak-proof and the outside load equally or non-equally distributed acts on the upper deck (see Fig.3). Distinguishing design characteristic of the vertical cylindrical tanks of the large volume is that as the diameter of the structure increases curvature of the cylindrical wall and hence its rigidity significantly decrease [2]. When such tanks are constructed in the seismic regions and in the high wind/snow areas reliability of the structural design and engineering is of great importance [3]. Development and testing of the tank calculation methods that meet the latest global requirements of the engineering science are also essential.

Fig.2.

Fig.3. Design combinations of the effects on the floating roof Experience with various software products has shown that application of ANSYS computer system is the most effective for the calculation of the tank structures. Basic software package for calculation of the tank wall, fixed and floating roofs, individual assemblies such as tie-ins, etc was launched in the last several years within ANSYS computer system. This software is provided with the strength and stability control units. Software programs have coded representation, that is to say letters, which do not require reprogramming and ensure fully automatic calculations when initial data are measured. This reduces design period significantly. The example and calculation results of the floating roof are shown below. Finite element calculation pattern of the floating roof is illustrated in Fig. 4.

Fig.4. Model engineering of the floating roof using finite element method: ) calculation pattern; b) segment

Two consecutive tasks shall be solved for structural calculations: floatability control, in other words determination of the roof equilibrium position in the liquid under the snow load with the account of possible leakage in several cells; strength control of the roof structural elements at the equilibrium position obtained.

Fig.5. Determination of the roof static equilibrium position: ) static equilibrium position; b) calculation pattern for determination of the roof static equilibrium position using deflection method

Task solving gets complicated since there are no external bracings in the floating roof, and such structure is considered unstable from the structural mechanics point of view. It is commonly known that application of the computer systems is no longer possible in this case [4]. Universal special technique has been developed which allows for application of this calculation method. It is based on the iterative approach and enables determination of the roof depth rate , roof swing (Fig 5) and all components of the stress and strain state for any design variant for the roof or pontoon. Widely recognized deflection method forms the basis of this technique. Two additional bracings are introduced into the calculation pattern, one of the bracing prevents from vertical movement, and the other bracing does not allow the roof to turn (see Fig. 6).

Fig.6. Calculation results of the floating roof ) travel of the lower deck b) equivalent stresses of the lower deck elements

The bracings introduced make the system stable and allow for various calculation methods, including finite element method. Based on the software developed the calculations have been made for the double-deck floating roofs of different geometrical dimensions under the wide range of snow loads. Researches demonstrate that when the tank diameter increases the advantage of the floating roofs versus fixed roofs becomes undeniable even if snow bags occur. Large diameter fixed roofs require additional supports to be installed inside the tank which reduce snow load on the tank wall during static loading, however are ineffective under horizontal seismic loads. Increase of the floating roof diameter up to 70 m is a favourable factor since it enhances roof floatability and load-carrying ability; when diameter is greater than 75 m these parameters remain unchanged. Application of the corrected calculation patterns throughout the design stages of the tanks allows for detailed research and true and reliable evaluation of the structural stability and strength. The calculations performed have confirmed the possibility to install steel cylindrical tanks of 100 000 m3 in the seismic areas with high snow and wind loads.

BIBLIOGRAPHY 1. Kucherenko V.A. Recommendations on the snow load determination for the certain surfaces, M.L.; 1983 2. Yelenitskiy E.Ya. Best calculation of the strength for the vertical cylindrical steel tank walls, Structural theory and structural analysis. 2009 - 1 3. Yelenitskiy E.Ya. Seismic protection of the vertical cylindrical steel tanks, Antiseismic construction. Safety of constructions, 2006 No. 5 4. Goldenblat I.I., Nikolaenko N.A. Structural analysis of the seismic and impulsive forces. - : State publication for construction, 1961. . , , , . . Summary In this article questions of calculation and design of tanks of large volumes in the conditions of seismic influences are considered. The complex of actions for improvement of calculations of a wall of the tank, the stationary and floating roofs, separate knots, tank check on natural loadings is considered. Increase of system of automation of the program of calculation is considered. . .. 10.11.12 .

Vous aimerez peut-être aussi

- Engineering Drawing ManualDocument128 pagesEngineering Drawing Manualadnan100% (6)

- A-1-10-Specification For FRP Vessels and TanksDocument17 pagesA-1-10-Specification For FRP Vessels and TanksbecemPas encore d'évaluation

- 650-1001 Rev 0 - Shell Manhole Cover Flange ThicknessDocument3 pages650-1001 Rev 0 - Shell Manhole Cover Flange ThicknessShayan Hasan KhanPas encore d'évaluation

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7Pas encore d'évaluation

- General Specification For Wire Mesh Demisters: Fgeir FmfgitgDocument6 pagesGeneral Specification For Wire Mesh Demisters: Fgeir Fmfgitgpriti kumariPas encore d'évaluation

- Storage Tank: Standard Drawing FORDocument25 pagesStorage Tank: Standard Drawing FORHamid Mansouri100% (1)

- B ABK 5000 1 API 650 Calculation ReportDocument50 pagesB ABK 5000 1 API 650 Calculation ReportZackPas encore d'évaluation

- Design Calculation R1 PDFDocument14 pagesDesign Calculation R1 PDFJagankumarPas encore d'évaluation

- Compressor Drive Engine Power CalculatorDocument2 pagesCompressor Drive Engine Power CalculatorJoshi DhvanitPas encore d'évaluation

- Single Col - Tank-2013Document35 pagesSingle Col - Tank-2013Hgagselim SelimPas encore d'évaluation

- Pull Out TestDocument4 pagesPull Out TestjmiguelmenaPas encore d'évaluation

- Steel Structures Design and Drawing PDFDocument38 pagesSteel Structures Design and Drawing PDFShri100% (5)

- 121205Document25 pages121205wdavid81Pas encore d'évaluation

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraPas encore d'évaluation

- Sample Resume For Civil Engineer - ConnectCVDocument2 pagesSample Resume For Civil Engineer - ConnectCVRo AnPas encore d'évaluation

- Cooper B Line Pipe HangersDocument332 pagesCooper B Line Pipe HangersAhmed EmadPas encore d'évaluation

- PVV Cal Sheet LabixDocument45 pagesPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- APQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareDocument2 pagesAPQP or Advanced Product Quality Planning Standard, APQP Training, APQP Consulting, APQP SoftwareselvamPas encore d'évaluation

- Curb AngleDocument1 pageCurb Angle940623015859Pas encore d'évaluation

- Inigneers India Lltvilteid: ElevationDocument7 pagesInigneers India Lltvilteid: ElevationSandip SurPas encore d'évaluation

- Floating Roof DesinDocument5 pagesFloating Roof Desindimdaliak_985662241Pas encore d'évaluation

- Floating Roof Design (Liquid Hight)Document4 pagesFloating Roof Design (Liquid Hight)Hamid MansouriPas encore d'évaluation

- Pipe Support SpansDocument4 pagesPipe Support SpansMitchellgranyPas encore d'évaluation

- API 650 Datasheet 1Document16 pagesAPI 650 Datasheet 1alwacsPas encore d'évaluation

- Autoplant Projectshowcase DLDocument90 pagesAutoplant Projectshowcase DLJose CarlosPas encore d'évaluation

- AST - Tank Shell DesignDocument17 pagesAST - Tank Shell DesignAntony Bruno GenewinPas encore d'évaluation

- GIS 18 012 31 October 2007Document11 pagesGIS 18 012 31 October 2007Jose Carlos100% (1)

- Pressure Vessel PlateDocument4 pagesPressure Vessel PlateYetkin ErdoğanPas encore d'évaluation

- Ammonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesDocument16 pagesAmmonia Gas Spherical Storage Tank SS-101: Technological Institute of The PhilippinesVaanPas encore d'évaluation

- PRG - GG - GEN - 0001 - R00 - e - Design Pressure N TempeDocument19 pagesPRG - GG - GEN - 0001 - R00 - e - Design Pressure N TempeKorcan ÜnalPas encore d'évaluation

- Basic Pipe Stress TutorialDocument24 pagesBasic Pipe Stress TutorialoanzarPas encore d'évaluation

- Mechanical Design Calculation: DocumentDocument146 pagesMechanical Design Calculation: DocumentvikramPas encore d'évaluation

- ch26 PDFDocument70 pagesch26 PDFbookppPas encore d'évaluation

- Internal Floating Roof VesselDocument2 pagesInternal Floating Roof Vesselumair saeed100% (1)

- Design Documentation GuidelinesDocument7 pagesDesign Documentation Guidelinesmelsime001Pas encore d'évaluation

- OSEA ASCE7-10 Most Common Errors in Seismic Design-04!14!15Document59 pagesOSEA ASCE7-10 Most Common Errors in Seismic Design-04!14!15Aie BantuganPas encore d'évaluation

- 00000-UDS-001 (Chemical Injection Unit) Rev 0Document2 pages00000-UDS-001 (Chemical Injection Unit) Rev 0sithulibraPas encore d'évaluation

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuPas encore d'évaluation

- Limpet With Jacket Nozzle OrientationDocument1 pageLimpet With Jacket Nozzle OrientationArunkumar MyakalaPas encore d'évaluation

- ETHANOL (6.0D X 8.825 H), Rev. 0Document26 pagesETHANOL (6.0D X 8.825 H), Rev. 0Sangramkeshari BejaPas encore d'évaluation

- Docslide. Limpet Coil CalculationDocument1 pageDocslide. Limpet Coil CalculationAdrian StoicescuPas encore d'évaluation

- Storage Tank Design Calculation - Api 650Document21 pagesStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Casting of ConcreteDocument3 pagesCasting of ConcreteoliverPas encore d'évaluation

- Floating Roofs Single DeckDocument8 pagesFloating Roofs Single DeckRajaram100% (1)

- API 650 Tank Data SheetDocument30 pagesAPI 650 Tank Data Sheetnarongsak_371005440Pas encore d'évaluation

- D-01 NocDocument29 pagesD-01 NocRochdi Sahli100% (1)

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1robertantoreni100% (9)

- Venting CalculationDocument14 pagesVenting CalculationValen MaselaPas encore d'évaluation

- Cladding SystemDocument44 pagesCladding SystemMugunthan KannanPas encore d'évaluation

- Pressure - Vacuum Relief Valve - Part 1Document10 pagesPressure - Vacuum Relief Valve - Part 1winarnobPas encore d'évaluation

- Materials SelectionDocument35 pagesMaterials SelectionAlok KumarPas encore d'évaluation

- DJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDocument3 pagesDJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDIANTOROPas encore d'évaluation

- 3191-CS-01 Rev A-009-011Document3 pages3191-CS-01 Rev A-009-011Syed Zain AliPas encore d'évaluation

- Tank DesignDocument2 pagesTank DesignkamleshyadavmoneyPas encore d'évaluation

- ITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpDocument20 pagesITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpHamid MansouriPas encore d'évaluation

- 03 Metal Packing Support PlatesDocument3 pages03 Metal Packing Support PlatesypatelsPas encore d'évaluation

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohPas encore d'évaluation

- Spherical Tank PDFDocument1 pageSpherical Tank PDFevrim77Pas encore d'évaluation

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1Pas encore d'évaluation

- Api 571-1Document11 pagesApi 571-1Raghavan100% (1)

- 7-12-0007 Rev6 (Pipe Leg Support)Document1 page7-12-0007 Rev6 (Pipe Leg Support)sumit kumar100% (1)

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocument127 pagesPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresPas encore d'évaluation

- Derakane Momentum 470 300 Epoxy Vinyl Ester ResinDocument14 pagesDerakane Momentum 470 300 Epoxy Vinyl Ester ResinKaren Elias Villegas50% (2)

- THK Design CalculationDocument3 pagesTHK Design CalculationalexnomitaPas encore d'évaluation

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaPas encore d'évaluation

- Ball Valve SpecDocument35 pagesBall Valve SpecsandystaysPas encore d'évaluation

- WRC Check List CriteriaDocument1 pageWRC Check List CriteriaAlvin Smith100% (1)

- MecaStack MatindokDocument59 pagesMecaStack MatindokmedyPas encore d'évaluation

- ASME Formula DerivationDocument1 pageASME Formula Derivationvm153748763Pas encore d'évaluation

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Document23 pagesES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsPas encore d'évaluation

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsPas encore d'évaluation

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutPas encore d'évaluation

- Mistakes and Misconceptions in Valve Leak TestingDocument5 pagesMistakes and Misconceptions in Valve Leak TestingNadi Jothidan KLPas encore d'évaluation

- KIRK KWM Mist EliminatorsDocument3 pagesKIRK KWM Mist EliminatorsperrychemPas encore d'évaluation

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988D'EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockPas encore d'évaluation

- 05 2 Chicago 09-61 0091Document16 pages05 2 Chicago 09-61 0091Jose CarlosPas encore d'évaluation

- Acad Camp - ChahuayDocument1 pageAcad Camp - ChahuayJose CarlosPas encore d'évaluation

- WPSDocument1 pageWPSJose CarlosPas encore d'évaluation

- Analsis Sismico Tk-44Document15 pagesAnalsis Sismico Tk-44Jose CarlosPas encore d'évaluation

- 4.2 Investigating Causes of Large Scale Fire Whirls Using Numerical SimulationDocument8 pages4.2 Investigating Causes of Large Scale Fire Whirls Using Numerical SimulationJose CarlosPas encore d'évaluation

- International Journal of EngineeringDocument9 pagesInternational Journal of EngineeringJose CarlosPas encore d'évaluation

- Tanque Eten 90 MBDocument49 pagesTanque Eten 90 MBJose CarlosPas encore d'évaluation

- 1.1 Simple Span Beams: CHAPTER 1: Analysis of BeamsDocument11 pages1.1 Simple Span Beams: CHAPTER 1: Analysis of BeamsRaza AidanPas encore d'évaluation

- Modeling Approach: MED FileDocument4 pagesModeling Approach: MED Filefepamplona81Pas encore d'évaluation

- 3510 Off White Gylon Data SheetDocument1 page3510 Off White Gylon Data SheetJose CarlosPas encore d'évaluation

- LCC LCC LCC LCCDocument1 pageLCC LCC LCC LCCJose CarlosPas encore d'évaluation

- BVD9040gb DensPhase Pump Data Sheet Aug13Document4 pagesBVD9040gb DensPhase Pump Data Sheet Aug13Jose CarlosPas encore d'évaluation

- 23 1 A 6 - 108 09Document8 pages23 1 A 6 - 108 09Jose CarlosPas encore d'évaluation

- CVT Vertically Suspended Sump PumpDocument6 pagesCVT Vertically Suspended Sump PumpJose CarlosPas encore d'évaluation

- Liters PDFDocument1 pageLiters PDFJose CarlosPas encore d'évaluation

- ASCE710WDocument20 pagesASCE710WCamilo GarcíaPas encore d'évaluation

- 05 2 Chicago 09-61 0091Document16 pages05 2 Chicago 09-61 0091Jose CarlosPas encore d'évaluation

- 1015Document141 pages1015Jose CarlosPas encore d'évaluation

- 02 Cosmosmotion OverviewDocument2 pages02 Cosmosmotion OverviewalanitotkdPas encore d'évaluation

- Ul IndiceDocument2 pagesUl IndiceJose CarlosPas encore d'évaluation

- PhotoWorks 05 000Document2 pagesPhotoWorks 05 000Jose CarlosPas encore d'évaluation

- API 650 Tank Nozzle Stand OutDocument8 pagesAPI 650 Tank Nozzle Stand OutmadodandembePas encore d'évaluation

- Date Tested: Performance Check of Sieves With Designation Larger Than 4.75mm/no. 4 (ASTM E11)Document64 pagesDate Tested: Performance Check of Sieves With Designation Larger Than 4.75mm/no. 4 (ASTM E11)Hamza MukhtarPas encore d'évaluation

- Better Diesel Yield.: High Performance Dewaxing With MIDW Catalyst Technology and ServicesDocument2 pagesBetter Diesel Yield.: High Performance Dewaxing With MIDW Catalyst Technology and ServicesAnonymous Sy7yVvPas encore d'évaluation

- Errors, Defects and Safety Control at Construction Stage Errors, Defects and Safety Control at Construction StageDocument7 pagesErrors, Defects and Safety Control at Construction Stage Errors, Defects and Safety Control at Construction StageDeepak AttardePas encore d'évaluation

- Aisi 9254 - Spring SteelDocument2 pagesAisi 9254 - Spring SteelSergio100% (1)

- Developing An Android Application For College Management SystemDocument6 pagesDeveloping An Android Application For College Management SystemHackerPas encore d'évaluation

- CMP IECEx ATEX 01Document10 pagesCMP IECEx ATEX 01rocket-vtPas encore d'évaluation

- CV Kak IwanDocument5 pagesCV Kak IwanRisma OnOffPas encore d'évaluation

- Bendable ConcreteDocument7 pagesBendable ConcreteNelly PadriquePas encore d'évaluation

- Elcb, RCCB, ElboDocument5 pagesElcb, RCCB, ElboNisitha Tharushan DarmarathnaPas encore d'évaluation

- Psoc 2015 NewDocument20 pagesPsoc 2015 Newvenki249Pas encore d'évaluation

- 0 6 Lec6 EE418 Steady - State - ErrorDocument18 pages0 6 Lec6 EE418 Steady - State - Erroryoussef hossamPas encore d'évaluation

- Endorsed Mini Project Oct21 Feb22 Student Ver (With Rubric)Document5 pagesEndorsed Mini Project Oct21 Feb22 Student Ver (With Rubric)Faiz JaafarPas encore d'évaluation

- AA V1 I2 Small Turbojet EnginesDocument2 pagesAA V1 I2 Small Turbojet Enginesgagagogo89Pas encore d'évaluation

- Final ISAET, IAAST and IA-E Conference Program April 28-29, 2016 Pattaya (Thailand)Document26 pagesFinal ISAET, IAAST and IA-E Conference Program April 28-29, 2016 Pattaya (Thailand)Deanvi Fahira WisnuputriPas encore d'évaluation

- Product and Manufacturing Information PMIDocument3 pagesProduct and Manufacturing Information PMIlaboratorioPas encore d'évaluation

- Sar EcDocument363 pagesSar EcdhananjayslambPas encore d'évaluation

- 202109061606473596205Document37 pages202109061606473596205ashenafiiPas encore d'évaluation

- Caixa Gbox - DocDocument15 pagesCaixa Gbox - Docsimao.bolaPas encore d'évaluation

- Sophomore Electrical - Group (1) : Specialized Programs - Spring 2022Document14 pagesSophomore Electrical - Group (1) : Specialized Programs - Spring 2022Tasneem YounesPas encore d'évaluation

- Contemporary ArchitectureDocument25 pagesContemporary ArchitectureJazper NuñezPas encore d'évaluation