Académique Documents

Professionnel Documents

Culture Documents

API Piping Plans

Transféré par

Mohit MundraTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

API Piping Plans

Transféré par

Mohit MundraDroits d'auteur :

Formats disponibles

PIPING PLAN PLAN 01

WHAT

WHY

WHERE Custom seal chamber, most likely an ANSI/ASME pump. Clean, moderate temperature fluids. Used with single seals, rarely with dual seals.

Internal seal chamber Seal chamber heat removal. flush from pump Seal chamber venting on discharge horizontal pumps. Reduce risk of freezing/polymerizing fluid in exposed Plan 11 piping

PLAN 02

Dead-ended seal No fluid recirculation needed. chamber with no flush.

Cooling jacket seal chambers in high temperature services. Clean fluids. Top-entry mixers/agitators with dry seals. Heating jacket seal chambers in fluids that solidify at low temperatures.

PLAN 03

Circulation created by No external fluid recirculation Large bore/open throat seal the design of the seal needed. Solids removal from chambers. Dirty or chamber. seal chamber. contaminated fluids.

PLAN 11

Seal flush from pump discharge through orifice. Default single seal flush plan.

Seal chamber heat removal. General applications with Seal chamber venting on clean fluids. Clean, nonhorizontal pumps. Increase polymerizing fluids. seal chamber pressure and fluid vapor margin.

PLAN 13

Recirculation from seal Continuous seal chamber chamber to pump venting on vertical pumps. suction through orifice. Seal chamber heat removal Standard flush plan on vertical pumps

Vertical pumps. Seal chamber pressure is greater than suction pressure. Moderate temperature fluids with moderate solids.

PLAN 14

Seal flush from pump discharge and recirculation to pump suction with orifices. Combination of Plan 11 and Plan 13.

Continuous seal chamber Vertical pumps. Clean, nonventing on vertical pumps. polymerizing fluids at Seal chamber heat removal. moderate temperatures. Increase seal chamber pressure and fluid vapor margin.

PLAN 21

Seal flush from pump Seal cooling. Reduce fluid discharge through temperature to increase fluid orifice and cooler. vapor margin. Reduce coking. Cooler added to Plan 11 flush increases heat removal.

High temperature service, typically less than 177C (350F). Hot water over 80C (180F). Clean, nonpolymerizing fluids.

PLAN 23

Seal flush from internal pumping device through cooler. Standard flush plan in hot water services.

Efficient seal cooling with low cooler duty. Increase fluid vapor margin. Improve water lubricity.

High temperature service, hot hydrocarbons. Boiler feed water and hot water over 80C (180F). Clean, non-polymerizing fluids.

PLAN 31

Seal flush from pump Seal chamber heat removal. discharge through Solids removal from flush and cyclone separator. seal chamber. Centrifuged solids are returned to pump suction

Dirty or contaminated fluids, water with sand or pipe slag. Non-polymerizing fluids.

PLAN 32

Seal flush from an Seal chamber heat removal. external clean source. Process and solids removal from seal chamber. Increase seal chamber pressure and fluid vapor margin.

Dirty or contaminated fluids, paper pulp. High temperature service. Polymerizing and/or oxidizing fluids.

PLAN 41

Seal flush from pump Seal cooling. Solids removal discharge through from flush and seal chamber. cyclone separator and cooler. Combination of Plan 21 and Plan 31.

High temperature service, typically less than 177C (350F). Dirty or contaminated fluids, water with sand or pipe slag. Nonpolymerizing fluids.

PLAN 52

Unpressurized buffer fluid circulation through reservoir. Fluid is circulated by a pumping ring in the dual seal assembly.

Outboard seal acts as a safety backup to the primary seal. Zero to very low process emissions. No process contamination is allowed.

Used with dual unpressurized seals. High vapor pressure fluids, light hydrocarbons. Hazardous/toxic fluids. Heat transfer fluids.

PLAN 53 A

Pressurized barrier fluid Isolate process fluid. circulation through Zero process emissions reservoir. Fluid is circulated by a pumping ring in the dual seal assembly.

Used with dual pressurized seals. High vapor pressure fluids, light hydrocarbons. Hazardous/toxic fluids. Heat transfer fluids. Dirty/abrasive or polymerizing fluids. Mixers/agitators and vacuum service.

PLAN 53 B

Pressurized barrier fluid circulation with bladder accumulator. Fluid is circulated by a pumping ring in the dual seal assembly.

Isolate process fluid. Used with dual pressurized Zero process emissions. seals. High vapor pressure Higher pressure than Plan fluids, light hydrocarbons. 53A. Hazardous/toxic fluids. Heat transfer fluids. Dirty/abrasive or polymerizing fluids.

PLAN 53 C

Pressurized barrier fluid circulation with piston accumulator. Fluid is circulated by a pumping ring in the dual seal assembly.

Isolate process fluid. Zero process emissions. Higher pressure than Plan 53A. Dynamic tracking of system pressure.

Used with dual pressurized seals. High vapor pressure fluids, light hydrocarbons. Hazardous/toxic fluids. Heat transfer fluids.

PLAN 54

Pressurized barrier fluid Isolate process fluid. Zero Used with pressurized dual circulation by external process emissions. Seal seals. High vapor pressure system. cannot induce circulation fluids, light hydrocarbons. Hazardous/toxic fluids. Heat transfer fluids. Dirty/abrasive or polymerizing fluids. Mixers/agitators.

PLAN 55

Unpressurized buffer Outboard seal acts as a safety fluid circulation by backup to the primary seal. external system. Zero to very low process emissions. No process contamination is allowed. Additional heat removal from the inner seal. Seal cannot induce circulation.

Used with unpressurized dual seals. Hazardous/toxic fluids. Fluids that may solidify in contact with atmosphere.

PLAN 62

External quench on Prevent solids buildup on Used with single seals. atmospheric side of seal. atmospheric side of seal. Oxidizing fluids or fluids Quench fluids typically Prevent icing. that coke, hot hydrocarbons. steam, nitrogen, or Crystallizing fluids or fluids water. that salt out. Caustic. Cold fluids less than 0C (32F).

PLAN 65 A

External drain with Safety indicator for primary May be used alone or with leakage detection on seal detects failure. Plan 62 quench. Used with atmospheric side of seal. close clearance throttle bushing. Useful with single seals in remote locations and critical services.

PLAN 65 B

External drain with Leakage collection to detect leakage detection on for process leakage. atmospheric side of seal Safety indicator to detect seal failure. Continuous monitoring of leakage rates to atmosphere

Use with close clearance throttle bushing. Use with non-flashing, condensing fluids. Useful with seals in remote locations and critical services

PLAN 66 A

Leakage detection on atmospheric side of seal utilizing two throttle bushings in series

Safety indicator for primary seal to detect failure. Minimize leakage from seal gland in case of seal failure.

May be used alone or with Plan 65A or Plan 65B. Used with flashing or nonflashing fluids. Useful with single seals in remote locations and critical services. Used with close clearance throttle bushings.

PLAN 66 B

Leakage detection on Safety indicator for primary May be used alone or with atmospheric side of seal seal detects failure. Plan 65A or Plan 65B. utilizing a throttle Used with close clearance bushing and orifice throttle bushing. plug. Used with flashing or nonflashing fluids. Useful when adding atmospheric side leakage detection to an existing seal. Useful with single seals in remote locations and critical services. Unpressurized buffer Zero to very low process gas control system. emissions. Safety backup to Containment seal primary seal. support typically with nitrogen buffer gas Used with dual unpressurized containment seals. High vapor pressure fluids, light hydrocarbons. Hazardous/toxic fluids. Clean, non-polymerizing, non-oxidizing fluids. Used in combination with Plan 75 and/or Plan 76.

PLAN 72

PLAN 74

Pressurized barrier gas Isolate process fluid. Zero Used with dual pressurized control system. Gas seal process emissions gas seals. High vapor support typically with pressure fluids, light nitrogen barrier gas. hydrocarbons. Hazardous/toxic fluids. Services that do not tolerate liquid barrier seals. Clean, non-polymerizing fluids Moderate temperature fluids.

PLAN 75

Drain from containment seal cavity to liquid collector and vapor recovery

Leakage collection for zero to very low process emissions. Safety indicator for primary seal.

May be used alone or with Plan 72 on containment seals. Fluids that condense at ambient temperature. High vapor pressure fluids, light hydrocarbons. Hazardous/toxic fluids. Clean, non-polymerizing, non-oxidizing fluids.

PLAN 76

Vent from containment Leakage collection for zero to seal cavity to vapor very low process emissions. recovery. Safety indicator for primary seal.

May be used alone or with Plan 72 on containment seals. Fluids that do not condense at ambient temperature. High vapor pressure fluids, light hydrocarbons. Hazardous/toxic fluids. Clean, non-polymerizing, non-oxidizing fluids.

Vous aimerez peut-être aussi

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsD'EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahPas encore d'évaluation

- CRP Sampling Literature PDFDocument8 pagesCRP Sampling Literature PDFgullenariPas encore d'évaluation

- Ipea PRVDocument51 pagesIpea PRVAnonymous qhVGVpPas encore d'évaluation

- P RefStd - 4043 - 004 - v091130 - EN - LOPADocument9 pagesP RefStd - 4043 - 004 - v091130 - EN - LOPAlucianduPas encore d'évaluation

- Standard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticeDocument9 pagesStandard Operating Procedure - Liquid Nitrogen - Storage, Use & Transportation Guidance & Code of PracticejrodPas encore d'évaluation

- The New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsDocument3 pagesThe New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsvheshaghianPas encore d'évaluation

- (TP0A004) Accuracy of Metering Versus Tank Gauging of Vessel Delivered Petroleum LiquidsDocument4 pages(TP0A004) Accuracy of Metering Versus Tank Gauging of Vessel Delivered Petroleum LiquidsRoberto Carlos TeixeiraPas encore d'évaluation

- CMPAPPP Separator Vessel and Filter Design GuideDocument18 pagesCMPAPPP Separator Vessel and Filter Design GuideJWilson73Pas encore d'évaluation

- Procedure Natural Gas Piping Purging HazardsDocument4 pagesProcedure Natural Gas Piping Purging HazardsEko KurniawanPas encore d'évaluation

- Materials Selection in Oil and Gas-An OverviewDocument15 pagesMaterials Selection in Oil and Gas-An OverviewAli AliPas encore d'évaluation

- 1.1. Process Measurement and Industrial InstrumrntationDocument34 pages1.1. Process Measurement and Industrial InstrumrntationKemal GetisoPas encore d'évaluation

- Installation Procedure - 1200ADocument18 pagesInstallation Procedure - 1200AHarshkumar PatelPas encore d'évaluation

- Magnetic Flow Meter 1 - 6f9aDocument16 pagesMagnetic Flow Meter 1 - 6f9aSilvaACAPas encore d'évaluation

- DistillationColumnDrawingAutoCAD PDFDocument3 pagesDistillationColumnDrawingAutoCAD PDFAbhijeet SahuPas encore d'évaluation

- Applications Guideline-Flashing (Water)Document2 pagesApplications Guideline-Flashing (Water)strahor7492Pas encore d'évaluation

- BakerHughes BN ReciprocatingCompressorsMonitoring Brochure-Web-NA-1112...Document9 pagesBakerHughes BN ReciprocatingCompressorsMonitoring Brochure-Web-NA-1112...Abbas AlnajjarPas encore d'évaluation

- PSV Test Risk AssessmentDocument44 pagesPSV Test Risk AssessmentAlabandi DodshPas encore d'évaluation

- Acoustic Induced Vibration - Flare Systems PDFDocument2 pagesAcoustic Induced Vibration - Flare Systems PDFsri9987Pas encore d'évaluation

- Abilene, Inc.: An Introduction To Boiler MaintenanceDocument19 pagesAbilene, Inc.: An Introduction To Boiler MaintenanceSubbarayan SaravanakumarPas encore d'évaluation

- Instrumentations of Chemical ProcessDocument27 pagesInstrumentations of Chemical ProcessNor Hamizah Hassan100% (1)

- Bench Testing of Relief ValvesDocument1 pageBench Testing of Relief ValvesSARATH KRISHNAKUMARPas encore d'évaluation

- API Stands ListDocument6 pagesAPI Stands ListudaybhatkandePas encore d'évaluation

- Leakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Document5 pagesLeakage Acceptance Rates Comparison Metal & Soft Seated Valves Api 598/api 6D/Mss Sp-61/Fci 70-2Ashfaq AnwerPas encore d'évaluation

- MC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1Document18 pagesMC20005-WHP-WI-P-0118 Corrosion PR & Erosion PR Datasheet WI - Rev.D1nguyenmainamPas encore d'évaluation

- Flare Line Failure CaseDocument20 pagesFlare Line Failure CaseHitesh PanchalPas encore d'évaluation

- Saes J 002Document25 pagesSaes J 002Dinesh BoopalanPas encore d'évaluation

- Area 200 PFD. in Proforma v2Document2 pagesArea 200 PFD. in Proforma v2Derek DennisPas encore d'évaluation

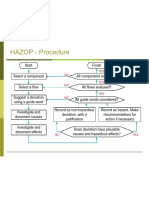

- Hazard and Operability Studies (HAZOP) 2Document15 pagesHazard and Operability Studies (HAZOP) 2jeevanantham 5846Pas encore d'évaluation

- PVC - Explosion Caused by Flashing Liquid in A Process VesselDocument8 pagesPVC - Explosion Caused by Flashing Liquid in A Process Vesselwiboonwi100% (1)

- PSV and PRV PDFDocument5 pagesPSV and PRV PDFMetoo ChyPas encore d'évaluation

- HGU ManualDocument15 pagesHGU ManualGarvit ChopraPas encore d'évaluation

- Process Op GAS PROCESSINGDocument3 pagesProcess Op GAS PROCESSINGjohn MPas encore d'évaluation

- Surge Relief Valve PDFDocument2 pagesSurge Relief Valve PDFMuhammadImaduddienSalamPas encore d'évaluation

- Unit Control Concepts PDFDocument7 pagesUnit Control Concepts PDFasotozuazuaPas encore d'évaluation

- Aaharya Technologies Aspen Hysys Training ProgramDocument2 pagesAaharya Technologies Aspen Hysys Training Programpavanchem61Pas encore d'évaluation

- 10 Steps To Pump ReliabilityDocument15 pages10 Steps To Pump ReliabilityaqhammamPas encore d'évaluation

- Liquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Document70 pagesLiquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Achmadda FebiyonoPas encore d'évaluation

- A 01 Pumps, Valves & CoolersDocument24 pagesA 01 Pumps, Valves & CoolersСергей КороткийPas encore d'évaluation

- 4 - Operation Manual M&W Head Control - 00 - ENDocument5 pages4 - Operation Manual M&W Head Control - 00 - ENTaco PinhoPas encore d'évaluation

- Crude Oil Pipeline Calculation PDFDocument104 pagesCrude Oil Pipeline Calculation PDFYaserPas encore d'évaluation

- 1 What Is Functional Safety, SIF, SISDocument17 pages1 What Is Functional Safety, SIF, SISAlice LinPas encore d'évaluation

- General Use SOP For Cryogenic LiquidsDocument2 pagesGeneral Use SOP For Cryogenic LiquidsSandeep ShettyPas encore d'évaluation

- Using A Car Seal To Lock A Ball ValveDocument30 pagesUsing A Car Seal To Lock A Ball ValvesnamprogPas encore d'évaluation

- CCC White Paper Control Challenges of SMR Compressors Nov 2016Document6 pagesCCC White Paper Control Challenges of SMR Compressors Nov 2016ejzuppelli8036Pas encore d'évaluation

- 2012-11-43 Anti-Surge Valves For Dynamic CompressorsDocument5 pages2012-11-43 Anti-Surge Valves For Dynamic Compressorssourcemenu100% (2)

- IGC Document 154 09 EDocument47 pagesIGC Document 154 09 Elutfirashid87Pas encore d'évaluation

- Simulators For Risk AssessmentDocument20 pagesSimulators For Risk Assessmentajrojas1359100% (1)

- SMPV ProformasNewDocument20 pagesSMPV ProformasNewSanjeet Kumar SinghPas encore d'évaluation

- Gas Blowby CaseDocument2 pagesGas Blowby Casejainrakeshj4987Pas encore d'évaluation

- Air Fin Cooler Discharge Temperature Control OptionsDocument13 pagesAir Fin Cooler Discharge Temperature Control OptionsMuhammad ImranPas encore d'évaluation

- NGL Extraction TechnologiesDocument10 pagesNGL Extraction Technologieswylie010% (1)

- Compressor CharacteristicDocument6 pagesCompressor CharacteristicSyedMeherAliPas encore d'évaluation

- Pump Troubleshooting GuideDocument15 pagesPump Troubleshooting GuidevenkeekuPas encore d'évaluation

- Compression and Condensation of Carbon DioxideDocument11 pagesCompression and Condensation of Carbon DioxideNguyen Dang Hanh100% (3)

- Habonim SIL CertificationDocument7 pagesHabonim SIL Certificationjamil vora0% (1)

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979D'EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonPas encore d'évaluation

- Structured What If Technique A Complete Guide - 2020 EditionD'EverandStructured What If Technique A Complete Guide - 2020 EditionPas encore d'évaluation

- Chesterton API Piping PlansDocument11 pagesChesterton API Piping PlansDelfinshPas encore d'évaluation

- Plano de Selagem Api 610 PDFDocument1 pagePlano de Selagem Api 610 PDFAnonymous 1XHScfCIPas encore d'évaluation

- Catalogue GX CompressorDocument6 pagesCatalogue GX CompressorMohit MundraPas encore d'évaluation

- Energy RecoveryDocument21 pagesEnergy RecoveryMohit MundraPas encore d'évaluation

- Muffler TheoryDocument2 pagesMuffler TheoryMohit Mundra100% (1)

- Condenser Design ProcedureDocument3 pagesCondenser Design ProcedureMohit Mundra0% (2)

- Exhaust and Muffler Design of A Formula SAE CarDocument14 pagesExhaust and Muffler Design of A Formula SAE CarMohit Mundra67% (3)

- Production Planning and ControlDocument51 pagesProduction Planning and ControlMohit MundraPas encore d'évaluation

- Fluid Mechanics Lab Assignment S. No. Name of ExperimentDocument1 pageFluid Mechanics Lab Assignment S. No. Name of Experimentविश्वेश सिंहPas encore d'évaluation

- Deltaflux Bypass FlowmeterDocument2 pagesDeltaflux Bypass Flowmeternieav280Pas encore d'évaluation

- API Standard 520 - Sizing, Selection, & Installation of Pressure Relieving Devices Part I, Sizing & SelectionDocument5 pagesAPI Standard 520 - Sizing, Selection, & Installation of Pressure Relieving Devices Part I, Sizing & SelectionD K SPas encore d'évaluation

- Fluid Mechanics and Heat Transfer April May 2008 Question PaperDocument8 pagesFluid Mechanics and Heat Transfer April May 2008 Question PaperelimelekPas encore d'évaluation

- ReviewDocument31 pagesReviewkarlobrondialPas encore d'évaluation

- CVNG 1001 Orifice Lab 2015Document3 pagesCVNG 1001 Orifice Lab 2015Harrington HaynesPas encore d'évaluation

- Process Engineering Toolkit SolutionsDocument71 pagesProcess Engineering Toolkit SolutionsTeymur RegenmaisterPas encore d'évaluation

- PSV Report BlockedDocument5 pagesPSV Report BlockedElias EliasPas encore d'évaluation

- THERMOFLUIDS EXIT TERMS COMPILATION Updated PDFDocument1 659 pagesTHERMOFLUIDS EXIT TERMS COMPILATION Updated PDFAlteaAlPas encore d'évaluation

- Heat Load Resistance of Cryogenic Storage TanksDocument70 pagesHeat Load Resistance of Cryogenic Storage Tanksakur3003Pas encore d'évaluation

- General Instruments SpecificationsDocument44 pagesGeneral Instruments Specificationsavinash1109Pas encore d'évaluation

- High DP Orifice FlowDocument2 pagesHigh DP Orifice FlowtibitomicPas encore d'évaluation

- Gas Lifted Dual Completions Using Venturi Orifice Valves Schlumberger Shell Valvula NovaDocument20 pagesGas Lifted Dual Completions Using Venturi Orifice Valves Schlumberger Shell Valvula NovaIván Velázquez0% (1)

- Fluid Flow MeasurementDocument27 pagesFluid Flow MeasurementPercival ArcherPas encore d'évaluation

- Fluid Dynamic Effects On Apollo Engine Pressure SpikesDocument5 pagesFluid Dynamic Effects On Apollo Engine Pressure SpikesKanishka LankatillakePas encore d'évaluation

- 4me4 22 Fluid Mechanics LabDocument92 pages4me4 22 Fluid Mechanics LabSri E.Maheswar Reddy Assistant ProfessorPas encore d'évaluation

- CH 06 MCQSDocument1 pageCH 06 MCQSasif nawazPas encore d'évaluation

- Attachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1Document1 pageAttachment-3: Relief Valve Sizing Calculation (Blocked Outlet Case-Two Phase Relief) Page 1 of 1rohitkushPas encore d'évaluation

- IntakesDocument20 pagesIntakesKamal KatwalPas encore d'évaluation

- AT - OM - EN Vaccum Pump at 3006Document38 pagesAT - OM - EN Vaccum Pump at 3006Anh Vo100% (3)

- Lab Manual PDFDocument67 pagesLab Manual PDFGupteswara PadhyPas encore d'évaluation

- 16 Marks Quesrtion Bank Without Unit 1Document8 pages16 Marks Quesrtion Bank Without Unit 1mohanPas encore d'évaluation

- CMTD Excel PDFDocument3 pagesCMTD Excel PDFJesús Alejandro González CañasPas encore d'évaluation

- Interview Questions InstrumentDocument53 pagesInterview Questions InstrumentQamar Hassan IqbalPas encore d'évaluation

- Senior Dual-Chamber Orifice Fitting - DanielsDocument30 pagesSenior Dual-Chamber Orifice Fitting - DanielsJoseVillanuevaPas encore d'évaluation

- Servo Valve Operation PrincipleDocument14 pagesServo Valve Operation Principlehosein30Pas encore d'évaluation

- Laboratory Manual: MEC259 Unified Mechanical Engineering IIDocument35 pagesLaboratory Manual: MEC259 Unified Mechanical Engineering IIHimanshu Kumar Raut100% (2)

- Orifice CalculationsDocument23 pagesOrifice CalculationsYatish Kumar Jain0% (1)

- De Super HeatersDocument10 pagesDe Super Heaterssandeep kumarPas encore d'évaluation

- Single Phase Flow Vjan2020 - MyAbdn PDFDocument53 pagesSingle Phase Flow Vjan2020 - MyAbdn PDFUsman MuhammadPas encore d'évaluation