Académique Documents

Professionnel Documents

Culture Documents

Kejriwal Geotech Pvt. LTD

Transféré par

Terapanth Yuvak Parishad VapiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kejriwal Geotech Pvt. LTD

Transféré par

Terapanth Yuvak Parishad VapiDroits d'auteur :

Formats disponibles

R.G.

SHAH MEMBER SECRETARY SEIAA (GUJARAT)

Government of Gujarat No. SEIAA/GUJ/EC/8(a)/

Sub:

STATE LEVEL ENVIRONMENT IMPACT ASSESSMENT AUTHORITY GUJARAT

/2012

Date:

Time Limit

Environment Clearance for setting up of the proposed Manmade Fibres manufacturing unit along with standby D.G. Sets [3 no. x 2 MW] at Plot No : 340, 341, 343, 344, Vill : Kareli, Tal : Palsana, Dist : Surat, proposed by M/s. Kejriwal Geotech Pvt. Ltd......................,... In Category 5(d) & 1(d) of Schedule annexed with EIA Notification dated 14/9/2006.

Dear Sir, This has reference to your application along with Form-I, dated 25/10/2010, EIA Report vide letter dated 17/10/2011, Additional information/documents vide letter dated 24/01/2012,Additional details vide letter dated 30/06/2012, submitted to the SEAC, seeking Environmental Clearance under Environment Impact Assessment Notification, 2006. The proposal is for Environmental Clearance for setting up of the proposed Manmade Fibres manufacturing unit along with standby D.G. Sets [3 no. x 2 MW] at Plot No : 340, 341, 343, 344, Vill : Kareli, Tal : Palsana, Dist : Surat, proposed by M/s. Kejriwal Geotech Pvt. Ltd. The unit has applied for manufacturing of Polyester Yarn (POY + st nd FDY) with total production capacity of 1,95,000 MT/annum (1 phase - 32,500 MT/annum & 2 phase-1,62,500 MT/annum). It is also proposed to install F.O. based D.G. Sets of 6 MW capacity [2 MW 3 nos.] as stand by arrangement. The proposed project falls under project / activity no. 5(d) & 1(d) in the Schedule of the EIA Notification, 2006. Total land area of the project is 69,922 m2. In first phase, Polyester Chips required will be procured from the market whereas in second phase Polyester Chips will be produced in the plant . The project activity is covered in 5(d) & 1(d) and is of B Category. Since the proposed project is in item no.5 & 1 of the EIA notification, 2006, it does need Public Consultation as per Para 7(i) III. Stage (3) (i) Public Consultation of EIA Notification, 2006. Public hearing for the project was organized by the Gujarat Pollution Control Board on 16/09/2011.

The SEAC, Gujarat had recommended to the SEIAA, Gujarat, to grant the Environment Clearance to this project for the above-mentioned mining project. The proposal was considered by SEIAA, Gujarat in its meeting held on 08.08.2012 at Gandhinagar. Since the public consultation is required for the project, the SEIAA hereby accords Environmental Clearance to above project under the provisions of EIA Notification dated 14th September, 2006 subject to the compliance of the following conditions. A. SPECIFIC CONDITIONS: 1.

st During the 1 phase, Polyester Chips required as a raw material for producing Polyester Yarn shall not be manufactured in the unit and it shall be procured from the market. 2. The project proponent shall obtain permission from the CGWA for ground water abstraction before commissioning of the 2nd phase of the project. 3. The project proponent shall install ETP, RO Plant and Effluent Evaporation Systems before commissioning of the 2nd phase of the project. A.1 WATER:

4.

5.

st Fresh water requirement for the project shall not exceed 1220.45 KL/day [i.e. 278.56 KL/day for 1 Phase and nd 941.89 KL/day for 2 Phase] and it shall be met through bore well water. Metering of daily ground water abstraction shall be done and its records shall be maintained. Industrial effluent generation during the 1st Phase shall not exceed 131.42 KL/day. DM Plant reject effluent after its neutralization, spin oil effluent after oil skimming and other industrial effluent streams shall be collected together in the Collection Tank and then completely reused in floor washing, flushing, dust suppression and green belt development within the premises.

Office : Gujarat Pollution Control Board, Paryavaran Bhavan Sector-10 A, Gandhinagar-382010 Phone No.:- (079) 232-32152,232-41514 Fax No.:-(079) 232-22784 E-mail : seiaaguj@yahoo.com, Website:- www.seiaa.gujarat.gov.in

Page 1 of 4

6.

Industrial effluent generation during the 2nd phase shall not exceed 1083.7 KL/day and it shall be treated in the ETP. Approx. 215 KL/day of treated effluent from the ETP shall be partly reused in dust suppression, green belt development & flushing whereas approx. 868 KL/day of balance treated effluent shall be passed through the RO system. RO permeate water to the tune of 781.2 KL/day shall be reused back in the process whereas RO reject effluent to the tune of 86.8 KL/day shall be completely evaporated in the Evaporator using flue gas from Thermic Fluid Heaters [Approx. 26 KL/day] and Four Effect Evaporator [60.8 KL/day]. 7. There shall be no industrial effluent discharge from the unit and the unit shall strictly adhere to zero discharge status in either of the Phase-1 and Phase-2. 8. The unit shall provide ETP having adequate primary and tertiary effluent treatment facilities, RO Plant and Effluent Evaporation Systems for treatment / disposal of effluent before commissioning of the Phase-2 of the project. The ETP shall be operated regularly and efficiently so as to achieve the GPCB norms at the outlet. RO Plant and Effluent Evaporation Systems shall be operated regularly and efficiently so as to maintain zero effluent discharge status all the time. 9. The unit shall provide flow meters / totalizers at the ETP outlet and on effluent reuse lines for measuring effluent generation, effluent reuse in floor washing, dust suppression, flushing and plantation / gardening etc. and maintain daily records of the same. 10. Proper logbooks of the ETP, RO Plant and MEE operation also showing effluent discharge quality and quantity, reused effluent quality and quantity, chemical & power consumption etc. shall be maintained and shall be furnished to the GPCB from time to time. 11. Domestic wastewater generation shall be 20 KL/day and it shall be disposed off through septic tank soak pit. 12. The unit shall join and participate financially and technically for any common environmental facility / infrastructure as and when the same is taken up by the Govt. / GPCB or any such authority created for this purpose by the Govt. / GIDC.

A.2 AIR: 13. There shall be no process emission from the unit. 14. FO / HSD to the tune of 28 MT/day shall be used as a fuel in standby D. G. Sets [3 no. x 2 MW each] and a stack of 50 m height shall be provided for flue gas emission from the D. G. Sets. The D.G. Sets shall be operated only in case of disruption of power supply. 15. Coal [119 MT/day] or FO [59.5 MT/day] shall be used as a fuel in the Thermic Fluid Heaters (HTM Heaters) [2 no.] and a stack of 55 m height shall be provided for flue gas emission from the Thermic Fluid Heaters. 16. Bag Filter and Ventury Water Scrubber shall be installed as air pollution control system for Thermic Fluid Heaters in case of use of coal as fuel and it shall be operated regularly and efficiently so as to achieve the GPCB norms at the stack outlet. 17. The flue gas emission from the Thermic Fluid Heaters and D. G. Sets shall conform to the standards prescribed by GPCB. At no time the emission levels shall go beyond the stipulated standards. 18. The fugitive emission in the work place environment and raw material storage area shall be monitored regularly. The emission shall strictly conform to the standards prescribed by the concerned authorities from time to time. A.3 HAZARDOUS/SOLID WASTES: 19. The company shall strictly comply with the rules and regulations with regards to handling and disposal of Hazardous waste in accordance with the Hazardous Waste (Management, Handing and Transboundary Movement) Rules 2008, as may be amended from time to time. Authorization from the GPCB shall be obtained for collection / treatment / storage / disposal of hazardous wastes. 20. ETP sludge shall be dried, packed and stored in separate designated hazardous waste storage facility with pucca bottom and leachate collection facility, before its disposal. 21. ETP sludge shall be disposed at the common TSDF. 22. Used oil shall be sent only to the registered recyclers. 23. Discarded containers / drums / bags / liners shall be either reused or returned back to suppliers or sold to the authorized vendors after decontamination. 24. Waste from polymerization process shall be sold off to actual consumers. A.4 SAFETY: 25. The company shall strictly comply with the rules and regulations under Manufacture, Storage and Import of Hazardous Chemicals Rules, 1989 as amended. 26. Proper ventilation shall be provided in the work area. 27. Personal Protective Equipment shall be provided to workers and its usage shall be ensured and supervised. 28. First Aid Boxes shall be made readily available in adequate quantity. 29. Personal Protective Equipments shall be provided to workers and its usage shall be ensured and supervised. 30. Tie up shall be done with nearby health care unit / doctor for seeking immediate medical attention in the case of emergency, regular medical check up of the workers and keeping its record etc.

Office : Gujarat Pollution Control Board, Paryavaran Bhavan Sector-10 A, Gandhinagar-382010 Phone No.:- (079) 232-32152,232-41514 Fax No.:-(079) 232-22784 E-mail : seiaaguj@yahoo.com, Website:- www.seiaa.gujarat.gov.in

Page 2 of 4

31. Training shall be imparted to all the workers on safety and health aspects. 32. Occupational health surveillance of the workers shall be done and its records shall be maintained. Preemployment and periodical medical examination for all the workers shall be undertaken on regular basis as per Factories Act & Rules. A.5 NOISE: 33. The overall noise level in and around the plant area shall be kept well within the prescribed standards by providing noise control measures including acoustic insulation, hoods, silencers, enclosures, vibration dampers etc. on all sources of noise generation. The ambient noise levels shall confirm to the standards prescribed under the Environment (Protection) Act and Rules. Workplace noise levels for workers shall be as per the Factories Act and Rules. A.6 GREEN BELT AND OTHER PLANTATION: 34. The unit shall develop green belt in at least 15,445 sq.m. area within premises by growing minimum 3000 trees along the periphery and road sides as proposed. Green belt shall comprise of rows of varying height trees of native species with thick foliage, along periphery of the premises. 35. Drip irrigation / low-volume, low-angle sprinkler system shall be used for the green belt development. 36. The unit shall also take up plantation on road sides and suitable open areas in the Textile Park / nearby village / school / any other open areas in consultation with the local body / GPCB and submit an action plan of plantation for next three years to the GPCB. B.OTHERS: 37. In the event of failure of any pollution control system adopted by the unit, the unit shall be safely closed down and shall not be restarted until the desired efficiency of the control equipment has been achieved. 38. A separate Environment Management Cell equipped with full fledged laboratory facilities and qualified personnel shall be set up to carry out the Environment Management and Monitoring functions and a separate budget shall be allocated for this purpose. 39. The funds earmarked for environment protection measures shall be maintained in a separate account and there shall not be any diversion of these funds for any other purpose. A year-wise expenditure on environmental safeguards shall be reported. 40. Pucca flooring / impervious layer shall be provided in the work areas. Leakages from the pipes, pumps, shall be minimal and if occurs, shall be arrested promptly. 41. All the issues raised in the public hearing shall be comprehensively addressed / complied with in a time bound manner. 42. The project proponent shall adhere to their commitments made during the public hearing held on 16/09/2011. 43. The company shall carry out other socio-economic developmental / community welfare activities in consultation with the District Development Officer / District Collector. 44. The project management shall effectively implement all the environment protection measures, risk mitigation measures and safeguards stated in the EIA report of the project. 45. The project proponent shall also comply with any additional condition that may be imposed by the SEAC or the SEIAA or any other competent authority for the purpose of the environmental protection and management. 46. No further expansion or modifications in the plant likely to cause environmental impacts shall be carried out without obtaining prior Environment Clearance from the competent authority. 47. The six monthly compliance reports on the conditions stipulated hereinabove shall be submitted to the SEIAA, GPCB and the Regional Office of the Ministry of Environment and Forests, Bhopal, without fail. 48. The project authorities shall earmark adequate funds to implement the conditions stipulated by SEIAA as well as GPCB along with the implementation schedule for all the conditions stipulated herein. The funds so provided shall not be diverted for any other purpose. 49. The applicant shall inform the public that the project has been accorded environmental clearance by the SEIAA and that the copies of the clearance letter are available with the GPCB and may also be seen at the Website of SEIAA/ SEAC/ GPCB. This shall be advertised within seven days from the date of the clearance letter, in at least two local newspapers that are widely circulated in the region, one of which shall be in the Gujarati language and the other in English. A copy each of the same shall be forwarded to the concerned Regional Office of the Ministry. 50. The project authorities shall also adhere to the stipulations made by the Gujarat Pollution Control Board. 51. The project authorities shall inform the GPCB, Regional Office of MoEF and SEIAA about the date of financial closure and final approval of the project by the concerned authorities and the date of start of the project. 52. The SEIAA may revoke or suspend the clearance, if implementation of any of the above conditions is not found satisfactory. 53. The company in a time bound manner shall implement these conditions. The SEIAA reserves the right to stipulate additional conditions, if the same is found necessary. The above conditions shall be enforced, inter-alia under the provisions of the Water (Prevention & Control of Pollution) Act,1974, Air (Prevention & Control of

Office : Gujarat Pollution Control Board, Paryavaran Bhavan Sector-10 A, Gandhinagar-382010 Phone No.:- (079) 232-32152,232-41514 Fax No.:-(079) 232-22784 E-mail : seiaaguj@yahoo.com, Website:- www.seiaa.gujarat.gov.in

Page 3 of 4

Pollution) Act, 1981, the Environment (Protection) Act, 1986 and the Public Liability Insurance Act, 1991 along with their amendments and rules. 54. This environmental clearance is valid for five years from the date of issue.

With regards, Yours sincerely, (R.G.SHAH) Member Secretary

Issued to: M/s. Kejriwal Geotech Pvt. Ltd Plot No : 340, 341, 343, 344, Vill : Kareli, Tal : Palsana, Dist : Surat.

Copy to:1. The Secretary, SEAC, C/O. G.P.C.B. Gandhinagar - 382010. 2. The Chairman, Central Pollution Control Board , Parivesh Bhavan, CBD -cum-Office Complex, East Arjun Nagar, New Delhi-110032 3. The Chief Conservator of Forests (Central), Ministry of Environment & Forests, Regional Office (WZ), E-5, Arera Colony, Link Road-3, Bhopal-462016, MP 4. Monitoring Cell, Ministry of Environment and Forests, Paryavaran Bhavan, CGO Complex, New Delhi-110003. 5. The Member Secretary, Gujarat Pollution Control Board, Paryavaran Bhavan, Sector-10 A, Gandhinagar-382010 6. Select File

(R.G.SHAH) Member Secretary

Office : Gujarat Pollution Control Board, Paryavaran Bhavan Sector-10 A, Gandhinagar-382010 Phone No.:- (079) 232-32152,232-41514 Fax No.:-(079) 232-22784 E-mail : seiaaguj@yahoo.com, Website:- www.seiaa.gujarat.gov.in

Page 4 of 4

Vous aimerez peut-être aussi

- Waste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesD'EverandWaste to Energy in the Age of the Circular Economy: Compendium of Case Studies and Emerging TechnologiesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Modeling, Control, and Optimization of Natural Gas Processing PlantsD'EverandModeling, Control, and Optimization of Natural Gas Processing PlantsÉvaluation : 5 sur 5 étoiles5/5 (1)

- BASF India LTDDocument6 pagesBASF India LTDmeetsarkarPas encore d'évaluation

- GIDC Education Society EC OrderDocument4 pagesGIDC Education Society EC Orderpulsarprakash26Pas encore d'évaluation

- EC For Induction Furnaces by East India Holdings PVTDocument4 pagesEC For Induction Furnaces by East India Holdings PVTChetan MaheshwariPas encore d'évaluation

- Gujarat Ambuja Exports EC OrderDocument5 pagesGujarat Ambuja Exports EC Ordershiva1720Pas encore d'évaluation

- A.A.Dolti Member Secretary Seiaa (Gujarat) : State Level Envir Onment Impact Assessment Auth Ority GujaratDocument6 pagesA.A.Dolti Member Secretary Seiaa (Gujarat) : State Level Envir Onment Impact Assessment Auth Ority GujaratHarish K V SPas encore d'évaluation

- AUTHORISATION No. 23HRZ49939995 Dated 25/05/2023 Proceeding No. JCEE-M/CHZ/TNPCB/F.0076SPR/HWA/OL/SPR/2023 Dated 25/05/2023Document5 pagesAUTHORISATION No. 23HRZ49939995 Dated 25/05/2023 Proceeding No. JCEE-M/CHZ/TNPCB/F.0076SPR/HWA/OL/SPR/2023 Dated 25/05/2023luckyloke RajendranPas encore d'évaluation

- Allegro Speciality Cfo OrderDocument5 pagesAllegro Speciality Cfo Orderap26n1389Pas encore d'évaluation

- Regional Office:: Guntur D.No:4-5-4/5C, 4/3 - Navabharath Nagar, Ring Road, Guntur - 522 006Document6 pagesRegional Office:: Guntur D.No:4-5-4/5C, 4/3 - Navabharath Nagar, Ring Road, Guntur - 522 006ROOPDIP MUKHOPADHYAYPas encore d'évaluation

- Mahalaxmi Castings Private LimitedDocument6 pagesMahalaxmi Castings Private LimitedSLngerPas encore d'évaluation

- PollDocument35 pagesPollmahfooz.salujasteelPas encore d'évaluation

- Indus Coffee - CFEDocument7 pagesIndus Coffee - CFEAPIIC EEPas encore d'évaluation

- EMP Raheja MindspaceDocument5 pagesEMP Raheja MindspaceJohn SharonPas encore d'évaluation

- BHEL Bhandara MPCB FileDocument9 pagesBHEL Bhandara MPCB FileVishvajit PatilPas encore d'évaluation

- Alkyl Amines KurkumbhDocument9 pagesAlkyl Amines KurkumbhVishvajit PatilPas encore d'évaluation

- GPCB STP GuideDocument7 pagesGPCB STP GuideyoyoPas encore d'évaluation

- Sri Balaji PackagingDocument3 pagesSri Balaji PackagingVijay SethupathiPas encore d'évaluation

- Iocl Eia Report For GuwahatiDocument12 pagesIocl Eia Report For GuwahatiNaruttam DasPas encore d'évaluation

- 02 Waste Management PlanDocument11 pages02 Waste Management Planihajar9Pas encore d'évaluation

- Cca & PWMDocument6 pagesCca & PWMishtiyaqchoudhary786Pas encore d'évaluation

- Amusement ParkDocument5 pagesAmusement Parksandip_exl100% (1)

- Sonar Bangla CementDocument6 pagesSonar Bangla CementSusobhon DasPas encore d'évaluation

- Online To: L,/efusite: P P (,Lil?I0ruDocument3 pagesOnline To: L,/efusite: P P (,Lil?I0rukrish659Pas encore d'évaluation

- Sample 1 - Details of ProjectDocument6 pagesSample 1 - Details of ProjectErwin Bernard NionesPas encore d'évaluation

- CertiFicate For Water - NEWDocument6 pagesCertiFicate For Water - NEWMohan RajPas encore d'évaluation

- Upd DSLDocument34 pagesUpd DSLViplove SinghPas encore d'évaluation

- GB 8978-1996 污水综合排放标准 (英文版)Document22 pagesGB 8978-1996 污水综合排放标准 (英文版)Yue YuPas encore d'évaluation

- Comprehensive Environmental ACTION PLAN REPORT OF GPCB - VAPI-2010Document95 pagesComprehensive Environmental ACTION PLAN REPORT OF GPCB - VAPI-2010neeraj sharmaPas encore d'évaluation

- PCB AknowledgmentDocument6 pagesPCB AknowledgmentDevaraj SubrmanayamPas encore d'évaluation

- EC Edible Oil Industrial Park ZaheerabadDocument4 pagesEC Edible Oil Industrial Park ZaheerabadKrishna PrasadPas encore d'évaluation

- A. Specific ConditionsDocument19 pagesA. Specific ConditionsPADMALOCHAN NANDAPas encore d'évaluation

- RKPPL Eia ReportDocument153 pagesRKPPL Eia ReportsachinsurawasePas encore d'évaluation

- R K CashewsDocument5 pagesR K CashewsVijay SethupathiPas encore d'évaluation

- SOPs Recycling Waste PDFDocument19 pagesSOPs Recycling Waste PDFBAlaPas encore d'évaluation

- Beva SiliconsDocument3 pagesBeva SiliconsvgvpplPas encore d'évaluation

- Chrome HardDocument23 pagesChrome Hardpallavan.kPas encore d'évaluation

- 02 Waste Management PlanDocument11 pages02 Waste Management Plansyafei mardiPas encore d'évaluation

- Eia Report Assessment Submitted To: Paryavarna Mitra Submitted By: Suman KumariDocument3 pagesEia Report Assessment Submitted To: Paryavarna Mitra Submitted By: Suman KumariSuman KumariPas encore d'évaluation

- Fatal Incident in Pipeline During Pigging Activity 1689382935Document4 pagesFatal Incident in Pipeline During Pigging Activity 1689382935harish14586100% (1)

- Environmental Clearance ProcedureDocument18 pagesEnvironmental Clearance ProcedureKhairul Hossain SaikatPas encore d'évaluation

- LPG Associated GasDocument53 pagesLPG Associated Gastaufany99Pas encore d'évaluation

- Mine Environmental ManagementDocument8 pagesMine Environmental ManagementWeeBooh Wit-aPas encore d'évaluation

- 10 Cum - DayDocument5 pages10 Cum - DayAbhijit MondalPas encore d'évaluation

- Authorisation Hazardous & Other Waste Rajdhani RecyclingDocument4 pagesAuthorisation Hazardous & Other Waste Rajdhani RecyclingRahul RPas encore d'évaluation

- 1384252949F.No. 198 ECDocument20 pages1384252949F.No. 198 ECPrintPas encore d'évaluation

- Incentives Schemes of Government of Gujarat For MSME: Gujarat Cleaner Production Centre 1Document23 pagesIncentives Schemes of Government of Gujarat For MSME: Gujarat Cleaner Production Centre 1Dhaval DudhatPas encore d'évaluation

- Environmental Infrastructure AT Vatva, AhmedabadDocument14 pagesEnvironmental Infrastructure AT Vatva, Ahmedabadpradips1Pas encore d'évaluation

- Compliance Report by Hariyana GovtDocument6 pagesCompliance Report by Hariyana GovtManoj NahakPas encore d'évaluation

- Grap-Ii (2022)Document10 pagesGrap-Ii (2022)harish14586Pas encore d'évaluation

- Project Report Battery Manufacturing PlantDocument14 pagesProject Report Battery Manufacturing PlantVasim Shaikh50% (4)

- Technical InstrumentationDocument209 pagesTechnical Instrumentationrenjithv_40% (1)

- Enviroment Conservation Rules 2023 - enDocument110 pagesEnviroment Conservation Rules 2023 - enabrar.060Pas encore d'évaluation

- Vineet Tex FabDocument7 pagesVineet Tex FabSharon SusmithaPas encore d'évaluation

- Environment Protection (Prescribed Waste) Regulations 1998: S.R. No. 95/1998Document32 pagesEnvironment Protection (Prescribed Waste) Regulations 1998: S.R. No. 95/1998Evan BuntoroPas encore d'évaluation

- Grap Order Dated 30.12.2022Document4 pagesGrap Order Dated 30.12.2022Rakesh JangraPas encore d'évaluation

- Malaysia EQA Scheduled Waste 2005Document31 pagesMalaysia EQA Scheduled Waste 2005Liong Shun Hsiang100% (1)

- Guidelines Textile Industry Draft PDFDocument36 pagesGuidelines Textile Industry Draft PDFRohan LadPas encore d'évaluation

- Optimization of Equipment Used in Wastewater Treatment PlantDocument3 pagesOptimization of Equipment Used in Wastewater Treatment PlantMatthew DelgadoPas encore d'évaluation

- State Pollution Control Board, Odisha: No. I), Cte - Office MemorandumDocument3 pagesState Pollution Control Board, Odisha: No. I), Cte - Office Memorandumkrish659Pas encore d'évaluation

- Diabetes: I. Separation As Experienced in The KoshasDocument3 pagesDiabetes: I. Separation As Experienced in The KoshasTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Diabetes: I. Separation As Experienced in The KoshasDocument3 pagesDiabetes: I. Separation As Experienced in The KoshasTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Board Branch: Merit NO. CAT Merit No Regno. Student Name THEORY (%) Mpec/ Non Mpec/ Seat No PHDocument6 pagesBoard Branch: Merit NO. CAT Merit No Regno. Student Name THEORY (%) Mpec/ Non Mpec/ Seat No PHTerapanth Yuvak Parishad VapiPas encore d'évaluation

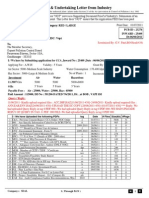

- K-Details of Raw Materials and ProductDocument1 pageK-Details of Raw Materials and ProductTerapanth Yuvak Parishad VapiPas encore d'évaluation

- J-Details of Air Pollution.19812Document1 pageJ-Details of Air Pollution.19812Terapanth Yuvak Parishad VapiPas encore d'évaluation

- Details of ETPDocument3 pagesDetails of ETPTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Land Possesion LatterDocument1 pageLand Possesion LatterTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Faslse EvedenceDocument8 pagesFaslse EvedenceDhruv DwivediPas encore d'évaluation

- 498a Frequently Asked Questions - Faq - Different Modes For Cracking 498a CaseDocument11 pages498a Frequently Asked Questions - Faq - Different Modes For Cracking 498a CaseTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Tag No F (PDF-WAT) : Water Consumption and Waste Water GenerationDocument1 pageTag No F (PDF-WAT) : Water Consumption and Waste Water GenerationTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Discahrge U - S 239 CRPC, Written ArgumentsDocument13 pagesDiscahrge U - S 239 CRPC, Written ArgumentsTerapanth Yuvak Parishad Vapi100% (3)

- HTTP GPCB - Guj.nic - in NOC ONL Forwarding Letter ParamDocument1 pageHTTP GPCB - Guj.nic - in NOC ONL Forwarding Letter ParamTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Monthly Report From Industry: 23366 Devam Plastic, - , - 396125 DIST: Valsad, TAL: Pardi, SIDC: Killa PardiDocument1 pageMonthly Report From Industry: 23366 Devam Plastic, - , - 396125 DIST: Valsad, TAL: Pardi, SIDC: Killa PardiTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Tag No. - : SR No 1 Water Stopper PVC Sheet 22500 Mtrs/monthDocument2 pagesTag No. - : SR No 1 Water Stopper PVC Sheet 22500 Mtrs/monthTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Machine A PDF Writer That Produces Quality PDF Files With Ease!Document2 pagesMachine A PDF Writer That Produces Quality PDF Files With Ease!Terapanth Yuvak Parishad VapiPas encore d'évaluation

- ONL Forwarding Letter ParamDocument2 pagesONL Forwarding Letter ParamTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Emission, Type, Source and Control Equipment's: Machine A PDF Writer That Produces Quality PDF Files With Ease!Document1 pageEmission, Type, Source and Control Equipment's: Machine A PDF Writer That Produces Quality PDF Files With Ease!Terapanth Yuvak Parishad VapiPas encore d'évaluation

- Machine Is A PDF Writer That Produces Quality PDF Files With Ease!Document6 pagesMachine Is A PDF Writer That Produces Quality PDF Files With Ease!Terapanth Yuvak Parishad VapiPas encore d'évaluation

- Form - 1 For Air ConsentDocument2 pagesForm - 1 For Air ConsentTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Quotation LetterDocument2 pagesQuotation LetterTerapanth Yuvak Parishad VapiPas encore d'évaluation

- Water PollutionDocument6 pagesWater PollutionNicholas WhitePas encore d'évaluation

- Pulp and PaperDocument62 pagesPulp and PaperGanga DharaPas encore d'évaluation

- The Emotional and Social Competency Inventory University EditionDocument4 pagesThe Emotional and Social Competency Inventory University EditionabayabayaPas encore d'évaluation

- Development and Quantification of Sustainability IndicatorsDocument95 pagesDevelopment and Quantification of Sustainability Indicatorsernesto.sanchez.castroPas encore d'évaluation

- Environmental Laws in The Philippines - ContextDocument3 pagesEnvironmental Laws in The Philippines - ContextJenifer Paglinawan0% (1)

- Kump.1 Leadership TheoriesDocument2 pagesKump.1 Leadership TheoriesYiisiengLingPas encore d'évaluation

- 5 Dried Fish ProcessingDocument3 pages5 Dried Fish ProcessingLgu BarraPas encore d'évaluation

- Unit 8 Saving The Earth': For 8 Grade Prepared by B. SelengeDocument12 pagesUnit 8 Saving The Earth': For 8 Grade Prepared by B. Selengeapi-346848444Pas encore d'évaluation

- Changing Nature of Managerial WorkDocument10 pagesChanging Nature of Managerial WorkakramPas encore d'évaluation

- Indus (Rough)Document43 pagesIndus (Rough)Dr. Dharmender PatialPas encore d'évaluation

- 9th Annual Indigenous and American Studies Storytellers Conference, Call For PapersDocument1 page9th Annual Indigenous and American Studies Storytellers Conference, Call For PapersHarvardNativePas encore d'évaluation

- Seattle Planning Commission 2020 Growth Strategy White PaperDocument18 pagesSeattle Planning Commission 2020 Growth Strategy White PaperThe Urbanist100% (1)

- Metro Vancouver Letter On Massey ProjectDocument3 pagesMetro Vancouver Letter On Massey ProjectJeff NagelPas encore d'évaluation

- MemorandumassignmentDocument2 pagesMemorandumassignmentapi-273594988Pas encore d'évaluation

- Rasuwagadhi Hydropower Company Limited: Rasuwagadhi Hydroelectric Project (111 MW)Document5 pagesRasuwagadhi Hydropower Company Limited: Rasuwagadhi Hydroelectric Project (111 MW)Sushmit SharmaPas encore d'évaluation

- Organizational Behavior & Development: Chapter 9 - Understanding Work TeamsDocument28 pagesOrganizational Behavior & Development: Chapter 9 - Understanding Work TeamsCharisse Aro YcongPas encore d'évaluation

- Brundtland Commission: Presented By-Shraddha Bahirat 2012MUD005Document12 pagesBrundtland Commission: Presented By-Shraddha Bahirat 2012MUD005Shraddha BahiratPas encore d'évaluation

- Split Ship Management LTDDocument6 pagesSplit Ship Management LTDNedjeljko PlazonićPas encore d'évaluation

- Case Study On Pasig River PhilippinesDocument19 pagesCase Study On Pasig River PhilippinesKatherine Ruth Miranda100% (1)

- Request To Write PHD Research Proposal On Climate ChangeDocument8 pagesRequest To Write PHD Research Proposal On Climate ChangeEconometrics FreelancerPas encore d'évaluation

- Eco AsgDocument7 pagesEco AsgAcePas encore d'évaluation

- Emergent or Prescriptive FormulationDocument10 pagesEmergent or Prescriptive FormulationDave Dearing100% (1)

- Community PsychologyDocument5 pagesCommunity PsychologyKilliam WettlerPas encore d'évaluation

- Oversight Implications of Sona 2017 On The Tourism Sector: DR Sibusiso Khuzwayo 17 February 2017Document24 pagesOversight Implications of Sona 2017 On The Tourism Sector: DR Sibusiso Khuzwayo 17 February 2017Mark Gil GuillermoPas encore d'évaluation

- State DayDocument7 pagesState DayShadang NauraPas encore d'évaluation

- Urban Design NotesDocument39 pagesUrban Design NotesSadhika S Farzana83% (6)

- Bank Written Question by BIBMDocument12 pagesBank Written Question by BIBMMasiur SajibPas encore d'évaluation

- Environmental Monitoring Officer (EMO) Activity ReportDocument4 pagesEnvironmental Monitoring Officer (EMO) Activity ReportMaricel RamiroPas encore d'évaluation

- Writing U56Document5 pagesWriting U56Như MiPas encore d'évaluation

- Rnc-Resolution-Exposing-United-Nations-Agenda21 1207112final-1Document2 pagesRnc-Resolution-Exposing-United-Nations-Agenda21 1207112final-1api-85286058Pas encore d'évaluation

- 3AE Hydro Politics BookDocument137 pages3AE Hydro Politics BookGielievrPas encore d'évaluation

- المؤسسات الريادية ومدى التزامها بالمسؤولية الاجتماعية للمؤسساتDocument20 pagesالمؤسسات الريادية ومدى التزامها بالمسؤولية الاجتماعية للمؤسساتFathiBastamiPas encore d'évaluation