Académique Documents

Professionnel Documents

Culture Documents

Study of Seat Assembly

Transféré par

AmolPagdalCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Study of Seat Assembly

Transféré par

AmolPagdalDroits d'auteur :

Formats disponibles

STUDY of

STUDY of

SEAT ASSEMBLY

SEAT ASSEMBLY

B/E is the world's largest

manufacturer of commercial and

general aviation aircraft seats.

Our global network of four seat

manufacturing plants and two

Dynamic Test Facilities gives B/E

the capacity and flexibility to

produce over 200,000 seats per

year, equaling more than 50% of

the world's total annual

requirements. With an installed

base of more than one million

seats currently in service, and

more manufacturing capacity in

place than the rest of the industry

combined.

14 AUG 2008

Index

000 Introduction

001 SEAT INSTALLATION AREAS BASELINE 1a

002 Ergonomics

a) Seat Utilization / Seat Mission

003 Design considerations

004 General Design Parameters

a) Static and Dynamic Strength

b) Fatigue / Abuse

c) Safety

d) Comfort

e) Durability

f) Maintainability

g) Styling

005 Family of Seats Catalog Options

006 Family of Seats

007 Seat Type Dimensions

a) Standard Triple

008 Seat Items and Location

009 SEAT DEFINITION

a) Seat Frame

b) Leg rest

c) Armrest

d) Headrest

010 Food Tray

011 Special Seat Features

012 EPML Installation

013 SEB Installation (One drawing for each IFE supplier)

014 AIRBUS INDUSTRY .

a) A 380 SUPPLIER STANDARD SEAT FEATURES

015 Center Console / Endbays

a) Center Console Armrest

b) Cocktail Trays

c) Endbays

016 Backrest

017 Placards

018 Seat Covers and Upholstery

a) Upholstery Styles

019 Safety Belts

020 IFE Equipment

a) Audio IFE

021 PC Power Port

a) PC Power and USB Ports

b) Under seat Electronics Box (UEB)

022 Mechanical Control

a) Seat Actuator Power Distribution

023 Trim and Finish

024 Composites Serve as Primary Structural Material

025 Premium Class Product DEFINITION

026 Minimum Catalog Qualification Requirements

027 WINSTON SALEM 14 DIGIT PART NUMBER

028 Main Cabin & Regional Existing Product Family

029 Premium Seating Lead Customers!

030 Premium Class Seating Solutions for All Pitches

031 Minipod Lie Flat Customers

032 Spectrum Installed Customer Base

033 THE END

1ntroduction

This Presentotion prooides Technicol definition of the B,E Aerospoce Business Closs seot.

The seot descrihed herein meets oll referenced specificotions. Prior to design of the seot, on extensioe

ergonomic studg uos done to moximize possenger comfort ond lioing spoce. Additionollg, on industriol

designer uos consulted to enhonce the oesthetics of the seot. A decreose in pox ueight uos occomplished hg

using light ueight moteriol throughout the seot. This decreose in ueight prooides o louer cost of ounership

for the customer.

SEAT INSTALLATION AREAS BASELINE 1a

UPPER DECK

MAIN DECK

B/E considers thoroughly the optimal comfort levels for seating and full flat positions for a long haul flight.

The seat shall be designed to fully accommodate an anthropometric range from the 50th percentile female to the

95th percentile male.

design with a thorough ergonomic study including both empirical and scientific evaluations in detail in order to

meet Air liners specific requirements.

Ergonomics

Seat Utilization / Seat Mission

All passengers enjoy greater privacy with a wrap-around shell and less exposed ottoman. The addition of an infinite

position, manually deploying aisle arm provides increased privacy in bed mode, or additional sleeping width if

desired by the passenger.

Aspects for design considerations

1. Privacy

Comfort is enhanced with the addition of several key features including: Premium Lounge position Greater bed length

Patented Crystal Flex back diaphragm system for optimum support and best-in-class thermal comfort.

Infinite-position arm height adjustment including a full-down position that significantly increases the bed width.

Proven ergonomics.

2. Comfort

Substantial improvements in personal stowage are a hallmark of the B/E proposal. Improvements include stowage

design space customizable. (e.g. amenities, literature, headsets, and water bottle).

3. Personal Stowage

A large (~11 x 20) meal table provides a rigid dining or work surface. The meal table adjusts fore and aft.

Meal table is machined with laminated inserts.

Seat width (hip width) has been increased to 22 for all pax. Seat width can be further increased to 28 by adjusting the

manually deployable armrest.

5.Seat Width

4. Meal Table

The Business Class seat will be certified for installation into the referenced aircraft. B/E will take responsibility to

have Boeing approve the interface loads report.

Static and Dynamic Strength

The Business Class seat meets or exceeds the following load requirements. In addition to aircraft in-flight loads and

regulatory requirements:

STATIC:

Forward (static) 9.0g

Down (static) 8.6g

Up (static) 5.4g

Side (static) 4.0g

Aft (static) 1.5g

250 lbs Impact (cart) load End-bay Bumper

300 lbs Fwd/Aft (in the extended position) Headrest

150 lbs Down (evenly distributed over upper surface) Tray Tables

300 lbs Down Armrests

200 lbs Aft Seat Backs

Ultimate Load Load direction Component

General Design Parameters

DYNAMIC:

All testing will be conducted in accordance with an approved Dynamic Test Plan and data acquisition as per SAE J2111.

All data presented in this report demonstrates compliance with the requirements of TSO-C127a.

14.0g Vertical (60 degree)

16.0g Horizontal

Inertial

Load

Inertial Load

Direction

IFE Functional Testing:

The finished seats will require function tests of

IFE using test equipment provided by the IFE

supplier.

50000 Extension Cycle Leg rest

50000@200lbs Down Bottom Supports

50000@100lbs Down/Side (45 degree angle) Armrests

300000@200lbs Down (uniformly distributed) Seat Bottom Cushions

50000@25lbs Mechanism Cycle

50000@150lbs Down In-Arm Tray Tables

50000@25lbs Mechanism Cycle

50000@150lbs Down Seat Back Tray Tables

100000@100lbs Aft Assist (top corners of back) Backs

Fatigue / Abuse:

The Business Class seat meets or exceeds the following cycle test requirements. All mechanisms, including recline

system and pneumatic lumber system, will be subject to cyclic testing and must pass pre-determined and agreed

number of cycles before failure to show that the MTBUR (Mean Time Between Unit Replacement ) is not less than

20,000 cycles. All parts will be subject to static abuse load testing to show compliance with existing certification

requirements at the time of the initial technical coordination meeting (ITCM).

Safety:

Seat Delethalization:

All components used in the seat assembly are fabricated and assembled to provide the ultimate in safety

characteristics. The seat design incorporates the strategic use of padding, and the absence of sharp edges or

unnecessary protrusions. The use of an approved belt mounted air bag is standard.

Fire, Smoke and Toxicity Protection:

The nonmetallic materials used in the construction of the Business Class seat meet the appropriate flammability

requirements of the subsection of the FAR/JAR 25.853 when tested in accordance with Appendix F of that document.

The toxicity requirements for B787 are not fully defined and no suitable materials are commercially available at the

time of this proposal that meet the total requirements. B/E requires a Standard Specification deviation on certain

flammability/smoke/toxicity requirements.

Seat Belt Attachment:

The seat belt attachment fitting allows sufficient, but limited freedom of swivel of the seat belt, for load alignment.

The seat belt fitting is located to allow the load applied by the seat belt to be consistent. An airbag belt is assumed.

Placards:

High quality, color coded, bilingual and placards shall be used and recessed into the surface to improve the

appearance of quality. Safety placards are to be installed in accordance with regulatory requirements, clearly visible

to the passenger seated behind. English language will be positioned with French language below.

Placards will be required restricting personal stowage during Taxi/Take-Off/Landing (TTOL).

Comfort:

The Business Class seat has been designed to provide optimum comfort with minimal cushioning in accordance with

approved orthopedic and independent ergonomic principles.

The cushions are both attractive and functional. The back and bottom cushions distribute the passengers body weight

and provide overall body support. The seat provides superior comfort with the seat in all positions. The seat will

transition into a flat, in-flight, bed surface of 80 inches.

The Business Class offering has several features designed to increase privacy while retaining a family seating capability.

Specifically:

Large privacy wings for all aisle pax. . Patented Diamond Layout

Patented CrystalFlex comfort system . Aisle access for all passengers

Self-contained suite for all passengers . Infinite position movable arms.

Partially shielded ottoman

Durability:

The Business Class seat is extremely rugged, built to provide extended long service life with low maintenance costs.

Materials and hardware utilized are of high strength aircraft quality.

A positive method of locking is provided for all hardware.

Maintainability:

All components which may require replacement or adjustment are readily accessible. Maintenance and/or removal can

be accomplished using standard hand tools.

High wear surfaces are protected from substantial abuse by utilizing durable injection molded materials and rub strips.

Easily removable backs and tables reduce replacement labor time.

The spring loaded shear pin is keyed in the up position, ensuring seat track engagement. Lock screw is flush with

track fitting body when engaged and provides evidence of positive engagement.

The minimum number of parts and efficient designs are utilized to lower inventory maintenance requirements.

Styling:

The seat creates an atmosphere of contemporary luxury and style. The arms, tables and cushions provide a balanced

blend of contour and mass and provide an attractive comfortable form. Care has been taken to provide a finished

appearance across the rear of the seat assembly. The crisp, clean side end bay design complements the styling

utilized in modern aircraft interiors. Light colors are used to enhance the visual space of the cabin.

Aesthetic that is welcoming and appears comfortable

Shapes that are simple and elegant

Cabin layout that appears spacious

Excellence in comfort in the lounge position

A relaxed Lounge Taxi Takeoff and Landing (TTL) position

A high quality restful sleep in the bed position

A great sense of individual space and privacy

To accommodate a customers desired styling and brand recognition, a pallet of selectable features will be

offered (Examples only) These features will largely be determined by the seat supplier, as approved by Boeing.

Optional head rest

Optional cup holder

Variable arm rest design

Choice of cushion shape,

Foam density

Choice of color and

dress cover material

Family of Seats Catalog Options

Optional head rest Articulation

Family of Seats

Tourist / Economy Seating

Using the Family of Seats

philosophy, a similar design and

certification approach would

permit the development a common

base structure or platform on

which all these seats are based.

A Matrix of installation Limitations

would accompany the seat family

defining where and how the seats

are approved to be installed in the

passenger cabin.

Premium Seating

(Business, First)

Premium Economy

Domestic Business

Enabling a family of

seats approach for

premium is a

challenge but

contains the same

benefits as economy.

Standard Seat Side View

Seat Type Dimensions

Standard Seat Front View

CG

16.97

35.89

BACK PIVOT

16.01

FOOTREST

IF

INSTALLED

CUSHION

18.50 MAX

SRP PER AS8049

16.91

18.64

.65

32.89

44.50

CRP

16.38

+.50

-.25

1.00

BACK PIVOT

18.35

28.50

+.00

-.25

PAN

13.29

24.00

+.00

-.25

24.50

MIN

3.00

2.5 10.00

1.55 (TYPE III EXIT ROWS ONLY)

1.30-2.20 (ALL PLACEMENTS EXCEPT TYPE III EXIT ROWS)

SRP PER AS8049

14.62

42.73

CRP

16.63

UNDERSEAT CLEARANCE

10.83

MAX

2.50

102

CG

11.88

18.50

.78

TABLE TRAVEL

3.00

8.75

2.99 MAX

HEADREST TRAVEL

(IF INSTALLED)

26.00

Standard Triple

Top View of Standard Seat, IAT and Exit Triple

(Top View of Double Seats Follow Same Pattern)

Key

T = Tip of Seat Belt

B = Buckle of Seat Belt

P = PCU

R = Recline Button

A = Ashtray

T B T B B T

P P P

R R R

A A

T B T B B T

P P

R R R

A A

P

Aisle

Outboard Outboard

Seat Items and Locations

SEAT DEFINITION

Seat Frame = Leg + Front Stud + Rear Fitting

The frame structure consists of machined aluminum fore and aft sections, which are fixed to aluminum lateral

tubes providing a rugged, rigid assembly to support the attachment points for the primary pax mechanism and

shell surround. All major structural components are attached using aircraft grade hardware. There are no blind

rivets or welding used on the primary structure..

All assemblies are equipped with standard load aligning seat belt brackets, which are designed to reduce the

possibility of failure by maintaining seat belt loads nearly constant regardless of the direction of loading.

Standard Features

Standard Airbus seat width 61.75-inches

Machined, anodized, aluminum system

Offset legs in all locations for consistency

One-piece front and rear leg

molded endbay/bumper and hostess step

CrystalFlex fabric bottom diaphragm suspension system

Quick release, anti-rattle rear track fitting

Rear Foot Block/Track Fitting Front Track Fitting

Seat Frame

+

=

Leg

+

Leg Assembly

Leg:

Machined aluminum leg system

One-piece unit

Floor distortion tolerant rear track fitting

Anti-rattle feature for the front fitting

Integral track cover & Anodized finish.

Front Stud and Anti-Rattle:

Machined stud (P/N 22303107) and

Anti-Rattle Nut (97123007)

Zinc nickel plated per AMS 2417 Type 2

Rear Fitting:

Machined Rear 3 stud track fitting

Single shear plunger

Studs and shear plunger Zinc Nickel plated

per AMS 2417 Type 2

Baggage Restraint

For Taxi/Take-Off/Landing, baggage is envisioned to be stored in the ottoman. Testing to allow ottoman stowage is

included in the B/E proposal.

Seat Backs

The seat back shall recline smoothly and effortlessly with a reliable recline system.

Backs are equipped with a 4-way electric lumbar. All structural members in the back of the seat are suitably recessed

or rounded, to enhance comfort and to reduce the possibility of passenger injury.

Seat back support assembly consists of a Crystal Flex supported diaphragm connected from the lateral composite

back tube. This arrangement, a standard in B/E seating provides a suspension comfort system with enhanced

thermal comfort for the passenger.

Recline and Control

The recline system shall be controlled by an infinitely variable electric actuation system. There should be individual

circuit-breaker under each seat to cut off the electrical power for seat actuation. Backup manual override systems

shall be required. Operation of manual overrides must be easy to use with minimal effort by one cabin crew.

The seats shall be designed to allow recline of the passenger at any position between upright position (take-off and

landing) and fully reclined position. Recline is powered up to 180. Bed shall be designed to accommodate aircraft

flight attitude. Manual override shall be provided as well.

Seat cradle directly linked with seat recline actuation with a range of positive inclination for upright, mid recline and

full bed position.

Seat translation is related and controlled by the recline button to full bed position. A visible means shall be provided

to show the take-off and landing. The Manual override will have a mechanical override integrated.

Leg rest

The leg rest structure will provide comfort by means of an individually deployable leg rest platform that is

infinitely adjustable and deploys to full horizontal position. In addition to this a fixed ottoman is also provided for

maximized passenger comfort.

The actuation system will have current sensing capability to avoid entrapment issues and the ottoman

cushion/support will hinge to prevent passenger foot entrapment. The leg rest will have a mechanical override

integrated into the bottom of the leg rest.

Independently-operated mechanical armrest is designed to comply with the handicap accessibility

requirements of 14 CFR 382.7. The armrest is infinitely adjustable through the entire travel from full upright

to bed height. The armrest mechanism has a damped motion and is counter-balanced to enhance a first

class experience.

Armrests

Headrest

A four-way manually adjustable headrest with side ears is included in this quote. Size and shape to be determined

by final styling of the back cushion. The headrest features a proven friction slide and pivot mechanism with 10

years of in-field reliability experience.

ARM REST/ ARMCAP/ ESCUTCHEON GAPS:

Interface gaps in between all these components shall not exceed .08 inches

Tray Tables deploy from the console. A food tray will span across to the opposite arm to provide a large rigid

meal surface. The tray will be 11 deep and approximately 20 wide. When deployed the tray retains a 9

clearance from the bottom cushion to allow adequate thigh clearance. Rotation is not necessary to allow

egress from the seat due to aisle access for all passengers and the deploying armrest

Food Trays

Food Tray Gaps:

Food Tray in stowed position-gap between the top surface of the tray and the

bottom edge of provision shall not exceed .125 inches.

Tray Tables

There are multiple stowage areas.

Personal stowage space shall be provided with easy access by the passenger.

Stowage area under the ottoman provides stowage for items such as:

Laptop

Blankets

Shoes

Handbag

A second stowage area above the console provides stowage for small items such

as:

Eye-glasses

Keys

Headsets

This area can be used for amenities as well as a convenient area to stow in-flight

menus.

A separate literature stowage area provides stowage for:

In-flight magazine(A4 size)

Safety Card (A8 size)

Sick bag

Reading materials

Stowage

Cocktail Table

It is a machined aluminum cocktail table with a recessed laminate

top for each passenger. Depending on location, this area may be

recessed specifically to hold a water bottle during flight.

Individual cocktail trays deploy in front of the console and the side

to improve egress

Ottoman Protection

Ottomans shall be protected from substantial impact damage from carts, trolleys and cabin luggage. The protection

shall act, firstly, as an impact absorber, and secondly as a sacrificial part. In this case multiple rub strips will protect

the ottoman and surrounding shell.

Seat Shell and Partition

The seat shell shall be designed in such a way to provide privacy to the

passenger in different seating positions. Overall styling and color and

trim to be determined by Air liner.

Material:

Composite Panel

Honeycomb Core

Special Seat Features

01 EPML Installation

02 SEB Installation (One drawing for each IFE supplier)

EPML Installation

The EPML can be mounted in the left hand seats in the lower end bay shroud.

SEB boxes are installed on the seat frame structure

and are designed to be light weight and rugged.

Ensures well positioned cabling and industry standard

fasteners.

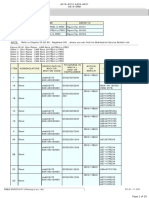

AIRBUS INDUSTRY . A 380 SUPPLIER STANDARD SEAT FEATURES

Note:

Front Row Seats & Seats with Furniture not-included.

B/C + and F/C as Full Sleeper (without environment)

** Standard Screen sizes

*** On customer request only

Seat Pitch Range as minimum guideline.

Noted standard features of the B/E offering include:

4 way adjustable headrest

4 way adjustable lumbar

Armrests provide maximum living space between

and under arms.

2 Actuator Design

Optimized seating positions from dining through

bed including a patented Z-bed position.

Standard Features

Center Console

9.5 inches wide

Amenities Recess

Leather wrapped padded armcap (leather CFE)

Passenger Control Unit (Optional)

PC Power Port (Optional)

Power Port Installation

KID 12v DC Power Port is mounted in the amenities recess

of the center console

Center Console / Endbays

End bays

Two inch wide handicap arm with discrete latch

Powder coated machined aluminum end bay

Injection molded rear trim cap and non-handedrubstrip

Passenger Control unit (Optional)

Powder coated machined aluminum front row module

Spring loaded injection molded armcap

Injection molded non-handed rubstrip

Mechanical Controls

PL Porter infinitely adjustable recline lock

Tamper proof adjustment mechanism

Six inch maximum recline availability

Aluminum control button

Console Inside

Backrest

01 Backrest Structure

02 Literature Pocket

Backrest Structure

Constructed of a light weight composite material

Slim line back shape with integral lumbar support

Body comfort suspension system

Back diaphragm made from a high strength

durable crystal flex fabric

Energy-absorbing features meeting FAR 25.562

and TSO-C127a HIC requirements

Literature Pocket

Cloth covered wire spring

Spring is attached directly to seat

structure

Velcro attachment to seat structure

Placards

01 Life Vest Placards

02 Safety Information Placards / Locations

03 Translation

01 Life Vest Placards

Integral life vest pouch and bottom

support

Snap closure

Red pull strap Placarding not required

02 Safety Information Placards / Locations

Safety information hot stamped on the backrest food

tray.

Location of safety information is available on the

upper right and left corners of the tray (Placarding

Optional)

The bottom cushion placard shows compliance with

FAR 25.853(c) and JAR 25.853 (C)

03 Translation

The safety information can be printed in any translation with customer furnished camera ready art work.

Artwork is needed 12 weeks prior to shipment of seats.

Other BFE (Buyer Furnished Equipment) Life Jacket

A life-jacket stowage container is to be located on each seat below the bottom cushion, so as to integrate with

the seat styling. A red strap retains and offers the lifejacket to the passenger when pulled open.

Seat Covers and Upholstery

01 Foam / Density

02 Fire Blocking Layer

03 Seat Cover Fabric / Leather

Bottom Cushion

Foam densities and profile shall provide lumbar and pelvic support, and an equal distribution of pressure on the

buttocks and thighs to minimize passenger discomfort in both upright and reclined position. Latest foam technology

shall be considered if it is proven to be able to enhance the passenger comfort.

The shape and size of the foam shall be standard where possible across the seat variants to reduce the variety of dress

covers. B/E will work to provide a back and bottom cushion to human shape and size specification. The width of the

bottom cushion is approximately 20. The length of the bottom cushion is approximately 19. The thickness of the

cushion varies from 3 thick to 4 thick. The cushions are not to be considered as flotation devices.

Each component used in the upholstery system must meet or exceed the requirements of the following:

14CFR 25.853(a), Amendment 25-83.

01 Foam / Density

Non-Flotation Molded Fire hard Foam

55 ILD Bottom Cushion & 35 ILD Headrest cushion

02 Fire Blocking Layer

Cushions are manufactured from Fire hard Foam and do not require a fire blocking layer unless leather is used.

03 Seat Cover Fabric / Leather

On dock date for fabric is 60 days prior to shipment of seats from B/E facility

10 linear yards of fabric required per color selection for flammability testing (if required)

Preferred Fabrics:

Fabric color is optional

Material composition 90% Wool/10% Nylon

Material density 12 OZ/SQ

2

CRP/SRP to be maintained within .50 inch of baseline certification

Style A : Simple roll-on dress covers, fitting the form and shape of the

ergonomically designed SPECTRUMseating.

Upholstery Styles

Style B: A modern design accentuating the seat height and contour creating

a look of enhanced space, while retaining the simple roll-on SPECTRUM

dress cover system.

Style C: Accentuating a plush seating environment, this style enhances the

look of seat width with the organic styled stitching giving added impression

that the SPECTRUM seat surrounds the passenger in comfort.

Style D: Vertical organic lines, continue to enhance the seat height, while

soft curves follow the natural shape of passengers...simple, comfortable and

stylish SPECTRUM compliments any cabin decor scheme.

Style E: Soft curves continue the organic appeal while additional stitching

accentuates the ergonomically designed SPECTRUM comfort system,

creating a look of enhanced lumbar support for the traveler.

Seatbelts

Standard Seatbelts

Amsafe P/N 2010-1-511-XXXX Series

TSO C22g, 30buckle, fabric label

Color is optional

Buckle (B) and Tip (T) locations

From inboard to outboard (standard triple) TB/BT/BT

All safety belts are CFE and must be received 60 days prior to

the first shipment of seats.

Optional Seatbelts

Amsafe P/N 2011-1-55-XXXX Series

TSO C22g, 90buckle, fabric label (CAA)

Color is optional

Safety Belts for 9g / 16g programs

Safety belts are CFE, installed by B/E Aerospace.

Standard belts are 3000 lbs nylon with 15 inch fixed, and 30 inch

buckle side lengths.

Color of safety belts is optional.

Safety belts have cloth name tag sewn on.

AmSafe P/N 502755-XXX-XXXX, Model 502758-1 (CAA)

AmSafe P/N 502745-XXX-XXXX, Model 502758 (FAA)

Other BFE (Buyer Furnished Equipment) seat belts

The airbag seat belts shall meet TSO C22g. The belt buckle will release

at 45 degrees. Length of seat belt should accommodate 5-95 percentile

passengers, and belt buckle should be within 1.5 inches of the centre

line of 50 percentile passenger with seat belt fastened.

IFE Equipment

01 Available PCU P/Ns

02 Available cable harness P/Ns

03 Available SEB P/Ns

01 Available PCU Part numbers

Matsushita Avionics RD-AX6737/6738-54

Matsushita Avionics RD-AX6737/6738-52

Matsushita Avionics RD-AX6737/6738-53

Matsushita Avionics RD-AX6739/6740-54

Matsushita Avionics RD-AX6739/6740-52

Matsushita Avionics RD-AX6739/6740-53

02 Available cable harness part numbers

Matsushita Avionics RD-AM6625-XX

03 Available SEB part numbers

Matsushita Avionics RD-AX4431-10

In-flight Entertainment and Communication

IFE equipment will be BFE. The mentioned IFE supplier is Thales or Panasonic. It is expected that the fitment of the

equipment will follow IFE Supplier installation guidelines. The IFE equipment shall be adequately protected from fluid

ingress. Either but not both IFE systems will be accommodated. The IFE system will be integrated into the seat design

to minimize LRU times.

Integrated Handset

The handset and cradle shall be installed to allow passengers easy access to the in-flight entertainment and services.

The handset is to be mounted vertically in the center console or horizontally under the privacy panel armrest (pending

industrial design). The position of the mounting shall be in such way that it will not cause any discomfort to the

passenger; should not take up seating space, and shall not be easily accidentally activated by the passengers whilst in

any seating position.

Remote Jack Module (RJM)

The seat will provision for an RJM and located with easy access.

The design will provision for up to a 15 widescreen format SVDU installed at a fixed

angle in the shell. The height of the monitor shall be determined to provide an

ergonomically correct view angle to suit the specified anthropometrics range of

occupant seated fully upright or in the reclined position.

Video Monitor (Smart video Display Unit)

In-seat Power Supply and Data Outlet(s) (ACOU)

An 110V A/C in-seat power and data outlet shall be provided for each passenger place. The outlets shall be mounted

within easy access by the passenger. The outlet sockets must be installed vertically to prevent fluid ingress.

The outlet housing design shall appear integral to the seat. However, the installation shall be modular. The in-seat

power supply outlet may also provision for up to two (2) data port outlets, and an external RCA jack for external video.

Seat Electrical Boxes (SEB)

All seat electrical boxes shall be mounted in order to allow adequate air for electronic cooling. If needed, a drip

shield is to be installed about these boxes to prevent fluid spillage. The access shall be maintenance -friendly, and

allow access to the seat electrical boxes without removing the seat from seat track.

Audio IFE

Standard Audio IFE

N/A (not required if no IFE chosen)

Audio IFE Option

Top mounting option

Installation with remote

transducer

Inboard arms only

Angled towards passenger

Side mounting option

Integral transducer

Inboard arms only

SPECTRUM Approved Systems

MASC

Rockwell

Thales

KID

General Dynamics

See Table 01 for Approved IFE

Components

Note:

All cable lengths are pre-determined

Side Mounted Option

Top Mounted Option

P/N DESCRIPTION

P/N DESCRIPTION 700-2326-004 RH Side Mount PCU

RD-AX6739-XX Side Mounted PCU (LH) 700-2326-003 LH Side Mount PCU

RD-AX6740-XX Side Mounted PCU (RH) 700-2327-001 Top Mount PCU

RD-AX6733-XX Top Mounted PCU 700-2205-002 RJU

RD-AX6421-18 Dual Pin RJU 700-2323-002 SEB

RD-AX6426-05 Single Pin RJU 749-0548-XXX In Seat Harness

RD-AX4431-10 SEB (Airbus)

RD-AM7902-XX In Seat Harness TPL

RD-AM7929-XX In Seat Harness DBL P/N DESCRIPTION

Z280H3030000 110V Oulet unit

Z280H1030013 110V Oulet Front Plate

P/N DESCRIPTION Z285H0121110 ISPC (Double)

177806-X01 PCU (Top & Side) Z280H1500XXX ISPS - PPUI Harness

170777-25 RJU TBD DSEB - ISPC Harness

177745-101 SEB Z270H3101XXX ISPC - ACOU Harness

177925-101 SEB Terminator Z280H3105XXX ISPC - PPUI Harness

177824-101 ISPC ATB01-12/XXX Bonding Cable

177829-101 110V AC Outlet Unit

177822-101 USB Incl Harness

177180-000 PED In Use Light P/N DESCRIPTION

177179-XXX ISPS - PPUI Harness 1171-1 110V Oulet Unit

178208-00X SEB - PCU/RJU Harness 1170-1 ISPS

177585-0XX Multi Power Harness 750-5150-402 In Use Light

177178-XX ISPS - ACOU Harness 1170805 Cable Assy ISPS - OU

177590-XXX Grounding Harness 1170801 Cable Assy In Use Light

1170803 Cable Assy Seat to Seat

GENERAL DYNAMICS (110V)

MASC

THALES

ROCKWELL

KID (110V)

SPECTRUM Approved Components

Table 01

PC Power and USB Ports

Standard PC Power and USB Ports

N/A (not required if no IFE chosen)

PC Power and USB Port Options

2 outlets per triple, 1 per double

Mounted on front beam, beneath cushion

Accommodates the following systems:

KID

Thales

General Dynamics

110V AC or 15V DC Systems

PC power in-use indicator light location on

end bays

See Table 25.21.016.01 for Approved IFE

Components

Power Port Example

Escape Path Lighting

PC Power In-Use

Indicator Light

Location

Underseat Electronics Box (UEB)

Standard UEB

N/A (not required if no IFE chosen)

UEB Options

Lightweight, rugged and mounted to a universal UEB

bracket on seat frame

Accommodates MACS, Rockwell, KID and General

Dynamics systems

Thales systems require a mounted UEB to the baggage

bar (not shown)

Well-positioned for cabling and industry standard fasteners

Seat Actuator Power Distribution

Legrest actuator and

Housipart comparison

Leg rest Housing Stress analysis @

16g & Envelope comparison.

Recline (Rotary) actuator and

Housing analysis

Recline rest Housing Stress analysis

@ 16g & Envelope comparison.

Seat Pan actuator and Housing

analysis

Seat pan Housing Envelope

comparison.

Foot rest actuator and

Housing analysis

Foot rest Housing & Envelope

comparison

Actuator major components

and its function are as shown:

Trim and Finish

Available color scheme:

- LT Grey (BAC7801)/Dark Grey (BAC7722)

- LT Grey (BAC7734)/Dark Grey (NEO 0823)

- LT Grey (57-1-8084)/Blue (7445)

Standard Options

Trim and Finish Components

Armcaps

Escutcheons

Tray tables

Powder coated surfaces

Choice of 4 color combinations*

Option AC

Blue-Black 7923 and Pepperdust 7801

Option AD

Blue-Black 7923 and Light Gray 7734

Option BC

Dark Gray 7800 and Pepperdust 7801

Option BD

Dark Gray 7800 and Light Gray 7734

* Color swatches available upon request

Option AC Option AD

Option BC Option BD

Cross Reference:

- BAC7801...... Pantone 4C

-BAC7722...... Pantone 412C

- BAC7734...... Pantone 429C

- NEO 0823..... Pantone 432C

- 57-1-8084..... Pantone 434C

- 7745............. Pantone 2955U

NOTE: Pantone numbers provide closest available approximation to the actual color.

Color chips available upon request.

Composites Serve as Primary Structural Material

Carbon laminate

Carbon sandwich

Other composites

Aluminum

Titanium

Composites

50%

Aluminum

20%

Titanium

15%

Steel

10%

Other

5%

Minimum Catalog Qualification Requirements

An Airplane Passenger Seat That:

Is Previously TSOd

Meets the Target Weight Criteria (+ or (x)%)

Can Be Manufactured/Assembled, Shipped by the

Supplier and received by Boeing in Less Than 4

Months

Fits Through the Airplane Door

Or, is received in Component Modules Capable

of Fitting Through the Airplane Door

Can Be Installed in the Airplane Within specified

time.

Or, Modules Can Be Reassembled and Installed

Within specified time

Has Boeing-Defined Standard Structural and

Electrical Interfaces

Meets RM&T Requirements for:

(x) Number of Cycle Tests

(y) Dollars per Flight Hour Maintenance Cost

Supplier data has been received and approved by

Boeing for the seat model.

The seat model has successfully passed the FAI.

1 0 0 3 0 2 0 0 1 B 0

WINSTON SALEM 14 DIGIT PART NUMBER

FIRST (7) DIGITS IS THE

PART BASE NUMBER

NEXT (3) DIGITS

IS THE PART DASH

NUMBER

EVEN NUMBERS = 002

RIGHT HANDED

ODD NUMBER = 001

LEFT HANDED

NEXT (2) DIGITS

IS THE PART TRIM AND FINISH

NEXT (2) DIGITS

IS THE CUSTOMER COAD

1 1 A

CENTER CONSOL 1003021001-AB01a

Main Cabin & Regional

Existing Product Family

Premium Seating Lead Customers!

42 Pitch 50 Pitch 55 Pitch

Millennium E

Mini POD

Millennium

Concept Side

Sleep Seating

80 Pitch

Voyager Lie Flat

Super First Class

POD

Premium Class Seating Solutions for All Pitches

MinipodLie Flat Customers

Spectrum Installed Customer Base

I1/)) O+

Prepared & Compiled

A.GOPI KRISHNA A.GOPI KRISHNA A.GOPI KRISHNA A.GOPI KRISHNA

REFERENCES

ov.c o{ vvv : ,1 +in.on vcn _ /)(11(1 ov.c o{ vvv : ,1 +in.on vcn _ /)(11(1 ov.c o{ vvv : ,1 +in.on vcn _ /)(11(1 ov.c o{ vvv : ,1 +in.on vcn _ /)(11(1

WWW.WIKEPEDIA.COM WWW.WIKEPEDIA.COM WWW.WIKEPEDIA.COM WWW.WIKEPEDIA.COM

Vous aimerez peut-être aussi

- NSRM A320 V2500Document163 pagesNSRM A320 V2500bielmao80% (5)

- SRM CFM56-5B - A318 - 319 - 320 - 321 (RDN 307) R65Document1 396 pagesSRM CFM56-5B - A318 - 319 - 320 - 321 (RDN 307) R65Andres Mendez50% (2)

- The God Code by Gregg BradenDocument1 pageThe God Code by Gregg BradenAmolPagdal57% (7)

- Seat Classifications - 9g/16g/16g "Compatible": 1.9G Seats A. What Is A 9G Seat?Document4 pagesSeat Classifications - 9g/16g/16g "Compatible": 1.9G Seats A. What Is A 9G Seat?sravantiPas encore d'évaluation

- Flight Instructor Guide Whiteboard LayoutsDocument32 pagesFlight Instructor Guide Whiteboard LayoutsJosh Haslemore100% (26)

- CNW A320Document83 pagesCNW A320ollieknightPas encore d'évaluation

- How Fighter Pilots Use MathDocument33 pagesHow Fighter Pilots Use Mathrmpilot2012100% (5)

- Rivets PatchDocument100 pagesRivets PatchOmar SalazarPas encore d'évaluation

- Airbus A320 FamilyDocument103 pagesAirbus A320 FamilyRoni OliveiraPas encore d'évaluation

- Aircraft SeatsDocument19 pagesAircraft SeatsMakrem CherifPas encore d'évaluation

- 2520 M1F00 01 00 Iss 11Document1 page2520 M1F00 01 00 Iss 11Christina GrayPas encore d'évaluation

- Task 53-00-14-300-002Document5 pagesTask 53-00-14-300-002mashobih hussururPas encore d'évaluation

- Ata 11 Placards and MarkingDocument8 pagesAta 11 Placards and MarkingAvtechPas encore d'évaluation

- A318/A319/A320/A321: Service BulletinDocument129 pagesA318/A319/A320/A321: Service BulletinPradeep K sPas encore d'évaluation

- A320 Family EASA Required Placards and Markings: EIAS Ref PR1413152 Iss2Document48 pagesA320 Family EASA Required Placards and Markings: EIAS Ref PR1413152 Iss2Roman KytsaniukPas encore d'évaluation

- Mmel A320Document105 pagesMmel A320Levan KhupeniaPas encore d'évaluation

- A320 AMM ch11Document636 pagesA320 AMM ch11Larry Bogues0% (1)

- A330 AMM ch09Document111 pagesA330 AMM ch09Larry BoguesPas encore d'évaluation

- A320 - SRM - 01-Feb-2020 - TASK 53-00-11-283-005 - Allowable Damage Limits For Dents - GenericDocument6 pagesA320 - SRM - 01-Feb-2020 - TASK 53-00-11-283-005 - Allowable Damage Limits For Dents - GenericJivendra KumarPas encore d'évaluation

- ATA 2200 SpecificationDocument17 pagesATA 2200 SpecificationhjhjhhPas encore d'évaluation

- Creating Affluence The A-to-Z Steps... by Deepak Chopra Download Now PDFDocument7 750 pagesCreating Affluence The A-to-Z Steps... by Deepak Chopra Download Now PDFAmolPagdal10% (10)

- BASF Snap Fit Design GuideDocument24 pagesBASF Snap Fit Design GuidewantamanualPas encore d'évaluation

- Aerospace MaterialsDocument126 pagesAerospace MaterialsseenuPas encore d'évaluation

- Reggiane Re.2005 Basic DataDocument5 pagesReggiane Re.2005 Basic Datapurn prakashPas encore d'évaluation

- Design and Fabrication of Ultra Light AircraftDocument111 pagesDesign and Fabrication of Ultra Light AircraftVarphi16100% (2)

- BCH1900 PTMV2 R 201Document400 pagesBCH1900 PTMV2 R 201jleal73100% (8)

- Seat Track FittingsDocument29 pagesSeat Track FittingsAmolPagdalPas encore d'évaluation

- Aircraft Seat RegulationDocument2 pagesAircraft Seat RegulationaerendiliPas encore d'évaluation

- Aircraft Passenger SeatDocument16 pagesAircraft Passenger SeatkabangiPas encore d'évaluation

- Kink Seal FlapDocument9 pagesKink Seal FlapJivendra KumarPas encore d'évaluation

- Airbus A320 Structural Repair Manual Perfect PointDocument1 pageAirbus A320 Structural Repair Manual Perfect PointAli KashiPas encore d'évaluation

- A318/A319/A320/A321: Service BulletinDocument56 pagesA318/A319/A320/A321: Service BulletinPradeep K sPas encore d'évaluation

- Airbus A318 A319 A320 A321Document24 pagesAirbus A318 A319 A320 A321HelloWorldPas encore d'évaluation

- Arp 5632Document11 pagesArp 5632batmanbittuPas encore d'évaluation

- A380 WING RIB Feet CrackingDocument9 pagesA380 WING RIB Feet CrackinggygjhkjnlPas encore d'évaluation

- A318/A319/A320/A321: Service BulletinDocument128 pagesA318/A319/A320/A321: Service BulletinPradeep K sPas encore d'évaluation

- Introduction ManualDocument26 pagesIntroduction ManualTURBOJATOPas encore d'évaluation

- 93M VVC 10570 Aircraft Inspection ReportDocument140 pages93M VVC 10570 Aircraft Inspection ReportMaria Fernanda Peñates VargasPas encore d'évaluation

- 32-41-00 - WHEELS: 32-41-00 PB 001 Conf 00 - Wheels - Description and OperationDocument51 pages32-41-00 - WHEELS: 32-41-00 PB 001 Conf 00 - Wheels - Description and OperationashufriendluckyPas encore d'évaluation

- Risk of Injury in Side Facing Aircraft Seats 200713 CAMI SFSDocument32 pagesRisk of Injury in Side Facing Aircraft Seats 200713 CAMI SFStjgPas encore d'évaluation

- Aero Stock ListDocument1 543 pagesAero Stock ListGaynor Morgan67% (3)

- Certificado Tipo B-737 PDFDocument99 pagesCertificado Tipo B-737 PDFCardenitasForfyTathyPas encore d'évaluation

- Zone and ATA Chapter PDFDocument25 pagesZone and ATA Chapter PDFdnes9999Pas encore d'évaluation

- CFM 56 Compressor Surge PresentationDocument14 pagesCFM 56 Compressor Surge PresentationKamal Mh100% (1)

- Aerospace Seat TracksDocument7 pagesAerospace Seat TracksSergey FedorinovPas encore d'évaluation

- A320Document2 908 pagesA320ranjit100% (1)

- b-767 - Rev 38 PDFDocument334 pagesb-767 - Rev 38 PDFJohn PelsPas encore d'évaluation

- TP14308E - Transport Canada Civil Aviation Guidelines - Maintenance Policy ManualsDocument40 pagesTP14308E - Transport Canada Civil Aviation Guidelines - Maintenance Policy ManualsAruna WijesinghePas encore d'évaluation

- SB76Document11 pagesSB76HenryPas encore d'évaluation

- A318/A319/A320/A321: Service BulletinDocument53 pagesA318/A319/A320/A321: Service BulletinGuy Ulrich DouoguiPas encore d'évaluation

- GeneralDocument48 pagesGeneralParag Alamyan100% (1)

- A320 ComputerDocument12 pagesA320 ComputerAlbert O'clockPas encore d'évaluation

- A318-A319-A320-A321 - (A319-SRM) (53-21-11 Pageblock 001 SKIN PLATES - SKIN PLATES)Document29 pagesA318-A319-A320-A321 - (A319-SRM) (53-21-11 Pageblock 001 SKIN PLATES - SKIN PLATES)Violet Paris100% (1)

- 200-32-325 R01 Dt. 14.07.21Document18 pages200-32-325 R01 Dt. 14.07.21Pradeep K sPas encore d'évaluation

- ATA Chapter NumbersDocument22 pagesATA Chapter NumbersBurhanudheen Kodiyathoor100% (2)

- All Tool ListsDocument367 pagesAll Tool ListsArabyAbdel Hamed Sadek0% (1)

- Avionics Component Repairs Capabilities 2016Document70 pagesAvionics Component Repairs Capabilities 2016Adel KhelifiPas encore d'évaluation

- Pinnacle 1022022 SERIES Passenger Seats For Lan Airlines A319 / A320 AircraftDocument360 pagesPinnacle 1022022 SERIES Passenger Seats For Lan Airlines A319 / A320 Aircraftlibrolibro1Pas encore d'évaluation

- A318/A319/A320/A321: Service BulletinDocument23 pagesA318/A319/A320/A321: Service BulletinPradeep K sPas encore d'évaluation

- Engine Variant: V2527-A5Document12 pagesEngine Variant: V2527-A5Kartika Ningtyas100% (1)

- Aerospace Products BrochureDocument15 pagesAerospace Products BrochurejesszeusPas encore d'évaluation

- @A318/A319/A320/A321: Chapter 49 - Airborne Auxiliary PowerDocument31 pages@A318/A319/A320/A321: Chapter 49 - Airborne Auxiliary PowerFabian Andres Soto Lineros (LATAM)Pas encore d'évaluation

- Human Factors Case Study Aircraft Seats: Michelle Hirlam April 2002Document19 pagesHuman Factors Case Study Aircraft Seats: Michelle Hirlam April 2002pvssrhPas encore d'évaluation

- ZW100-G 1.1-1.6 Cum PDFDocument5 pagesZW100-G 1.1-1.6 Cum PDFSriram NambiPas encore d'évaluation

- AerocityDocument20 pagesAerocityapi-199203074Pas encore d'évaluation

- Super Aero CityDocument19 pagesSuper Aero CityPhilippine Bus Enthusiasts SocietyPas encore d'évaluation

- Brochure Hyundai AeroDocument10 pagesBrochure Hyundai Aerokangminsok100% (3)

- Galon Industry SeatsDocument34 pagesGalon Industry Seatsmaverick_13Pas encore d'évaluation

- 25-27-048 BE 87269 Cradle B747Document516 pages25-27-048 BE 87269 Cradle B747Stanko PetrovicPas encore d'évaluation

- Catia SymbolsDocument9 pagesCatia SymbolsAmolPagdalPas encore d'évaluation

- BIW Design PDFDocument17 pagesBIW Design PDFAmolPagdalPas encore d'évaluation

- Volvo ApqpDocument30 pagesVolvo ApqpAmolPagdalPas encore d'évaluation

- Automotive Interior Solutions Optimised Performance and Surface AestheticsDocument16 pagesAutomotive Interior Solutions Optimised Performance and Surface AestheticsAmolPagdal100% (1)

- Eaton ApqpDocument142 pagesEaton ApqpAmolPagdalPas encore d'évaluation

- K EjectionDocument21 pagesK EjectionAmolPagdalPas encore d'évaluation

- Green Planet Store ManagementDocument2 pagesGreen Planet Store ManagementAmolPagdalPas encore d'évaluation

- Basic Hole System or Hole Basi1Document2 pagesBasic Hole System or Hole Basi1AmolPagdalPas encore d'évaluation

- Natural Brilliance, Move From Feeling Stuck To Achieving Success (1997) 0925480517Document106 pagesNatural Brilliance, Move From Feeling Stuck To Achieving Success (1997) 0925480517AmolPagdalPas encore d'évaluation

- PlasticProductdesign 3 PDFDocument116 pagesPlasticProductdesign 3 PDFAmolPagdalPas encore d'évaluation

- Concept Generation & Concept Selection PDFDocument20 pagesConcept Generation & Concept Selection PDFcadcam01Pas encore d'évaluation

- Electrical Presentation & General TopicsDocument77 pagesElectrical Presentation & General TopicsAmolPagdalPas encore d'évaluation

- Total Quality Management (TQM) 1Document21 pagesTotal Quality Management (TQM) 1AmolPagdalPas encore d'évaluation

- PlasticProductdesign 2 PDFDocument115 pagesPlasticProductdesign 2 PDFAmolPagdalPas encore d'évaluation

- Chapter 9 Towing and TaxiingDocument3 pagesChapter 9 Towing and TaxiingHrishikesh NarasimhanPas encore d'évaluation

- Federal Aviation Administration, DOT 135.351: 135.349 Flight Attendants: Initial and Transition Ground TrainingDocument2 pagesFederal Aviation Administration, DOT 135.351: 135.349 Flight Attendants: Initial and Transition Ground TrainingmollyPas encore d'évaluation

- PMDG 747 Type Course Lesson 1Document26 pagesPMDG 747 Type Course Lesson 1Eusebiu Pungaru100% (3)

- Jet Fuel Is KeroseneDocument6 pagesJet Fuel Is KeroseneGuy Razer50% (2)

- Vintage Airplane - Oct 2011Document44 pagesVintage Airplane - Oct 2011Aviation/Space History Library100% (2)

- Cessna 182S 1997on MM 182SMMDocument1 127 pagesCessna 182S 1997on MM 182SMMmlcaem100% (2)

- 1WIPL-D Antenna Placement On Airbus A320Document2 pages1WIPL-D Antenna Placement On Airbus A320rammahPas encore d'évaluation

- Vintage Airplane - Jan 1985Document28 pagesVintage Airplane - Jan 1985Aviation/Space History Library100% (2)

- 525mm 77Document40 pages525mm 77francklin1912Pas encore d'évaluation

- Prof Badge Syllabus2020 EDITED 28122021Document103 pagesProf Badge Syllabus2020 EDITED 28122021piranap piranapPas encore d'évaluation

- Optimum Altitude: Headwind Rules of ThumbDocument5 pagesOptimum Altitude: Headwind Rules of ThumbDarshan452Pas encore d'évaluation

- Mbeab Amt 412 Prelim Module No.3 ContinuationDocument9 pagesMbeab Amt 412 Prelim Module No.3 ContinuationJames Russell S. SanchoPas encore d'évaluation

- NTSB Aviation Accident Factual ReportDocument8 pagesNTSB Aviation Accident Factual ReportHonolulu Star-AdvertiserPas encore d'évaluation

- Master Airscrew PDFDocument3 pagesMaster Airscrew PDFJoseAlfredoCarneiroDosSantosPas encore d'évaluation

- Kampfflieger Sack As-6 V1 1x48Document3 pagesKampfflieger Sack As-6 V1 1x48Attila DienesPas encore d'évaluation

- Endless Return of The Nazi SaucersDocument19 pagesEndless Return of The Nazi Saucerslaerciofilho100% (3)

- Monoplane Vs BiplaneDocument9 pagesMonoplane Vs BiplaneElías Ruiz MorenoPas encore d'évaluation

- Jet Propulsion Research PaperDocument6 pagesJet Propulsion Research Paperskpcijbkf100% (1)

- Grade 6 - Science: Flight Mini UnitDocument33 pagesGrade 6 - Science: Flight Mini Unitapi-378557749Pas encore d'évaluation

- Airplane Isometric ViewDocument3 pagesAirplane Isometric ViewMar Jerome TomasPas encore d'évaluation

- Lesson C: The Passive 2: Grammar ActivitiesDocument1 pageLesson C: The Passive 2: Grammar ActivitiesKarinaPas encore d'évaluation

- Wing Load Calculation: (Example Document For LSA Applicants - v1 of 08.03.16)Document16 pagesWing Load Calculation: (Example Document For LSA Applicants - v1 of 08.03.16)Leonardo VasconcelosPas encore d'évaluation

- DA20-C1 Airplane Flight Manual (Rev 25)Document268 pagesDA20-C1 Airplane Flight Manual (Rev 25)Jeff Arrington100% (1)