Académique Documents

Professionnel Documents

Culture Documents

OSBl Considerations For Refinery Expansion Projects

Transféré par

ReaderRRGHT0 évaluation0% ont trouvé ce document utile (0 vote)

535 vues10 pagesOSBl Considerations for Refinery Expansion Projects

Titre original

OSBl Considerations for Refinery Expansion Projects

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentOSBl Considerations for Refinery Expansion Projects

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

535 vues10 pagesOSBl Considerations For Refinery Expansion Projects

Transféré par

ReaderRRGHTOSBl Considerations for Refinery Expansion Projects

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 10

Page 1 of 10

Title: OSBL Considerations for Refinery Expansion Projects

Authors: Mr. Dominic M. Varraveto, Manager, Burns & McDonnell

Date: March 18-20, 2007

Presented at: National Petrochemical & Refiners Association Annual Meeting

ABSTRACT

As demand for transportation fuel has remained strong despite rising prices and as refinery utilization hovers near

maximum sustainability interest in refinery expansion projects has increased. Refinery expansion projects can be

divided into two major parts distinguished by the industry as ISBL, Inside Battery Limit and OSBL, Outside Battery

Limit. The ISBL portion of an expansion project typically focuses on the addition of new or additional process units

to the existing refinery configuration.

The OSBL portion of that same project generally consists of all the other necessary supporting elements including

utility systems, interconnecting process and utility piping, feed and product handling and storage etc. In some cases

OSBL may also include an entire unit for production of a key process reactant such as hydrogen and for safe

handling and disposal of waste streams and byproducts like sour water and sulfur. Many projects include revamp of

existing process units as part of OSBL.

This paper will focus on the OSBL portion of three example refinery expansion projects consisting of 1) replacing

an existing vacuum distillation unit, 2) adding a new vacuumdistillation unit and a new delayed coker and 3) adding

and integrating a new crude distillation unit, a new delayed coker and a new hydrocracker to a typical FCC based

gasoline refinery. The intent will be to identify and compare the various OSBL requirements for each example

expansion project and to discuss guidelines for improving the accuracy of the OSBL definition early in project

development.

INTRODUCTION

A meaningful discourse about OSBL considerations for a refinery project and more specifically, an expansion project

relies on a clear definition of what is and what is not meant by outside battery limits or OSBL. This term does not

have a universally accepted definition. For different entities in the same organization the OSBL portion of a project

often varies, especially during initial project conception and often, even further into project development. The same

lack of a common definition can be said to be true between organizations, for example, between owner and

engineering/construction contractor. The first section of this paper discusses how the entire scope of a refinery project

can be split between ISBL and OSBL and how the OSBL portion can be divided further into subcategories according to

the nature of the work.

The second section of this paper discusses recent refinery projects and how the nature of these projects is affected by

several factors including return on investment in the refining industry, growth in demand for refined products, access to

crude supplies and impact of environmental compliance. Recently, solid operating margins and continued

profitability has allowed refinery owners to come out of the latest round of environmental spending for Low Sulfur

Gasoline, LSG, and Ultra Low Sulfur Diesel, ULSD, with an increased appetite for additional refinery investment

changing the fundamental nature of the typical refinery expansion project.

The third part of this paper looks at the OSBL portion of three recent refinery expansion projects: 1) VacuumUnit,

VAC replacement, 2) Addition of a VacuumUnit coupled with a new Delayed Coker Unit, VAC/DCU, and 3)

Page 2 of 10

Addition of new Crude Distillation Unit, new Delayed Coker and new Hydrocracker, CDU/DCU/HDC. These

examples will describe increased OSBL scope corresponding to the recent and larger refinery expansion projects

currently underway in the refining industry.

The final section of this paper suggests guidelines and practices for improving the accuracy of the OSBL definition

earlier in the project development effort. An accurate and reliable OSBL definition has become essential since the

OSBL portion of an expansion project is no longer insignificant relative to ISBL and because the size of todays

expansion project is now truly deserving of the title Major Project.

DEFINITION OF OSBL

A somewhat overly simplistic definition of OSBL relative to refinery expansion projects is all aspects that are not

included in the ISBL portion of the project. In other words OSBL is everything else including scope that was

unexpected and unplanned for during initial project development. By this definition OSBL will be incompletely

defined until it presumably can be defined in latter stages of the development process. A more specific way to define

OSBL is to initially attempt to identify what everything else includes as early in the project as possible and practical.

OSBL will include more than interconnecting piping and pipe racks. Also included is infrastructure, secondary process

units, revamps to existing process units and financial costs like interest and taxes etc. Infrastructure includes not only

utility system equipment but also roads, rail spurs, docks, loading and unloading equipment, buildings (warehouse,

power house, control room, office buildings etc).1 Table No. 1 below lists classifications which can be used to

differentiate OSBL scope and summarizes the items included in each category.

Table No. 1: OSBL Classifications

Classification Description

Interconnecting Systems Pipe/Pipe Rack, Power, Controls

Infrastructure Utility System Equipment, Roads, Tanks,

Truck and/or Rail Feed and Product

Unloading/Loading, Buildings

Secondary Process Units WWTP (Waste Water Treatment Plant),

ARU (Amine Regen Unit), SWS (Sour

Water Stripper), SRU (Sulfur Recovery

Unit), TGTU (Tail Gas Treating Unit),

SMR (Hydrogen), Air Separation

Revamp of Existing Units Increase Throughput and/or Conversion

Financial Owners Cost, Start Up, Working Capital,

Interest, Taxes

Other Land, Permits, Fees

Infrastructure is very general and can be further categorized by considering process equipment to supply typical utilities

like steam, water (boiler feed, cooling) air (instrument and plant), fuel (natural gas, and refinery fuel gas) power

(electric) etc. Table No. 2 lists the equipment frequently associated with some of the more common OSBL

infrastructure.

Page 3 of 10

Table No. 2: Examples of OSBL Equipment for Utility Infrastructure

Utility System Equipment

Steam Boiler Deaerator, Boiler, Circulation Pumps

Water Boiler Feed Filters, Ion Exchange, Chemical Treatment, RO

Membrane, Preheat Exchangers, Pumps, Tanks

Water Cooling Cooling Tower, Circulation Pumps, Chemical

Treatment

Air Instrument/Plant Compressor, Intercooler, Drier

Fuel Fuel Gas Conditioning Mix Drum, Condenser, Liquid KO drum,

Filter/Coalescer, Preheater, Strainer(s)

Power Electric Transformers, power distribution

Additional utility systems, not shown in Table No. 2 above, which may require equipment for reliable supply may

include nitrogen, potable water, utility water, fire water etc.

Infrastructure also includes systems and associated equipment to handle return streams and wastes. For refinery

units these systems include steam condensate collection/return flares, sewers etc. Table No. 3 lists equipment

associated with these systems.

Table No. 3: Examples of OSBL Equipment for Waste Streams

Utility System Equipment

Excess Vapor/Overpressure

Protection

Flare Flare Header, KO Drum/Pump, Flare,

Flare Gas Recovery Compressor

Sewer Process Sump, CPI (Corrugated Plate

Interceptor for Oil Removal),

Pump(s), Slop Oil Tank

Sewer Storm Sump Pump(s), Tank or Pond

Condensate Steam Collection Drum, Pump(s), Tank

Some utility systems like sewers will require waste water treatment which should be considered in the OSBL

classification of secondary or supporting process units. Essential secondary process units in todays refinery for treating

waste include a Waste Water Treatment Plant, WWTP and Sulfur Recovery Facilities usually comprised of Sour Water

Stripper, SWS, Amine Regeneration Unit, ARU, Sulfur Recovery Unit, SRU and Tail Gas Treating Unit, TGTU. The

SWS and ARU process liquid streams, removing hydrogen sulfide, H

2

S, and ammonia, NH3, so the liquid streams can

be re-used (i.e. lean amine) or processed further and discharged (i.e. stripped sour water).

The SRU/TGTU processes the concentrated sour gases fromthe SWS and ARU producing molten sulfur byproduct

and dischargeable vent gas. Other process units that might be included in OSBL secondary process units include

facilities to produce a key reactant for a primary process unit. Examples are a Steam/Methane Reformer, SMR,

producing hydrogen for a Hydrotreater or Hydrocracker and an Air Separation plant producing Oxygen for Sulfur Plant

Oxygen Enrichment or for petroleumcoke gasification.

Factors Affecting Refinery Expansion Projects Until very recently it has been difficult for refiners to attract investment

capital both from internal as well as external sources. Some reasons for this have been low return on investment due to

poor margins, surplus capacity and environmental regulation. In that kind of economic environment, limited capital

was primarily appropriated for environmental compliance to remain viable. Investment for economic benefit i.e.

profitability, was limited or non-existent. However, through creative and clever improvement of existing facilities

some refiners conceived and executed low cost projects that had significant bottomline impact. These projects were

Page 4 of 10

usually characterized by step wise debottlenecking over several years that resulted in overall increase in refinery

throughput and/or conversion. These types of projects were typically completed in conjunction with regularly

scheduled maintenance turnarounds and did not involve addition of new process units or improvement to existing

infrastructure. The OSBL portion of these projects was small or nearly insignificant.

For a time this approach was adequate to keep pace with growing demand. However, during this same time period

many refineries, especially smaller less complex facilities were forced to close. Closings have been accelerated by the

cost of environmental compliance both to manufacture LSG and ULSD and to reduce air and water pollution

originating in refineries. Over the same period, growth in demand for transportation fuel increased steadily as the

number of passenger vehicles as a percent of the US fleet has declined and the number of light trucks and sport utility

vehicles as percent of the US fleet has increased.

Eventually the combination of growing demand and loss of capacity fromrefinery closings has exceeded increased

output fromincremental debottlenecking and created a much more balanced, or, some would say, precarious market for

refined transportation fuel. Margins and profitability have improved dramatically especially for refiners capable of

processing heavier, higher sulfur crude oil. With the bulk of the large environmental expenditures already made, at least

for the near to mid term (3 to 5 years), there is an increasing appetite for relatively large expansion projects. These

larger expansion projects are now characterized by significant capacity increases of 50 to 100%. In some instances this

involves a second parallel processing train with new infrastructure and secondary process units. The OSBL portion for

these projects is a significant percentage of the overall project cost.

The three example projects in the next section will illustrate how the OSBL content has increased as refinery expansion

projects have evolved fromincremental de-bottlenecking to significant capacity growth.

EXAMPLES OF RECENT REFINERY EXPANSION PROJECTS

Example No. 1: VacuumUnit, VAC, replacement

This project involved replacing the existing vacuumunit furnace, vacuumfractionation tower, overhead ejector system,

Heavy Vacuum Gas Oil, HVGO, pumps and Wash Oil pumps, addition of new HVGO vs. Crude heat exchangers as

well as modifications to the existing Crude preheat system, HVGO heat removal system, vacuumunit charge pumps

and crude and vacuumsection heat integration. The project positioned the refinery for greater flexibility in crude feed

selection allowing heavier crudes with higher percentages of gas oil to be processed. The increased gas oil filled excess

FCC capacity. The scope and other details of the project can be found in reference 2.

Figure No. 1: VAC Replacement

The OSBL for this project was limited and was not identified separately from the ISBL as described. By definition

VAC replacement excluded revamp work to existing process units. Spare FCC capacity already existed and the

design basis defined the heavier crude such that the gas oil content increased but the residual content (i.e. DCU feed)

would not increase as a result of the project. Replacement of portions of the HVGO product line to and around the

Gas Oil Hydrotreater processing FCC feed was the only significant OSBL work. The HVGO piping replacement

was less than 5% of the overall project and all the OSBL work was less than about 10% of the overall project.

Example No. 2: New Vacuum Unit and New Delayed Coker, VAC/DCU

Reconfiguring an existing refinery to process heavier crude and meet Clean Fuel requirements was achieved in this

project by adding a new Vacuum unit and a new Delayed Coker. Revamp of at least 11 existing process units was

part of the OSBL scope including converting an existing residual oil desulfurizer to a gas oil hydrotreater, a shift in

FCC conversion to higher gasoline yield, upgrade of the light ends fractionation and treating areas and modification

of two distillate hydrotreaters for ULSD production. In addition, the OSBL scope included upgrade and expansion

of the refinery Amine Circulation and Treating, Sour Water collection and Hydrogen distribution. A new Hydrogen

plant was also included in the OSBL scope.

Page 5 of 10

By far the largest parts of the OSBL scope were 2 miles of pipe rack, the corresponding interconnecting process and

utility piping and over 500 tie-ins needed to install and support the pipe. There were many project specific

requirements including extensive application of heat tracing, both steam and electrical, to new and existing

interconnecting pipe. The introduction of new intermediate process streams from the DCU required a significant

modification to existing tankage. These modifications vary for each stream but included new gas blanketing, a new

floating roof, recommissioning of an existing tank heater, new insulation, new heat tracing, and addition of water

draw collection, piping manifolds and pumps.

Overall, the OSBL was slightly above 30% of the total project cost. The revamps comprised about one third or 10%

and the interconnecting piping and tankage modifications were about two thirds or 20% of the total project cost.

Other than tankage, the OSBL for this example project did not have a very significant infrastructure component.

This is somewhat unexpected considering the size and impact on the configuration of the refinery. Some possible

reasons for this relatively small infrastructure requirement were some of the typical OSBL infrastructure like the

coke handling facilities was included in the DCU ISBL and the expansion project was based on a shift to lower

cost crude and increased conversion rather than an increase in throughput.

Figure No. 2: New VAC/DCU

Page 6 of 10

Example No. 3 - New Crude Distillation Unit, New Delayed Coker and New Hydrocracker, CDU/DCU/HDC.

This example involves the most extensive project of the three presented in that it combines a greater than 50% increase

in throughput with an increase in conversion for processing a significantly heavier and higher sulfur crude. In fact the

sulfur recovered fromthe refinery will increase by nearly an order magnitude as a result of this project.

Like the previous example this project involves a new VAC unit and a new DCU. In this example the new VAC is part

of an entirely new Crude Distillation Unit, CDU. The differences end there since this project also includes a Gas Oil

Hydrocracker which removes a significant amount of sulfur and converts a significant portion of gas oil producing

distillate that meets ultra low Clean Fuels requirements and also produces a hydrotreated FCC feed stream. Applying

the definition of established earlier, the OSBL will include interconnecting pipe, pipe racks, electric power supply and

distribution, infrastructure, secondary process units, and revamps. The flow sketch in Figure No. 3 shows the major

aspects of the ISBL portion for this example. Not shown in this figure are all the new secondary process units. These

new facilities are part of the OSBL and include Hydrogen Production, Sour Water Collection and Processing, Amine

Circulation and Regeneration, Sulfur Recovery, Tail Gas Treating and Waste Water Treatment.

Figure No. 3

There are also a significant number of revamps associated with this example that will be part of the OSBL portion of

the project. They include upgrading the existing crude unit to process heavier crude, modifying the FCC for higher rate

and shift in yield, expanding the existing DHT for increased throughput and higher feed sulfur, increasing throughput

Page 7 of 10

Page 8 of 10

and adding the capability to process DCU Naphtha in the Naphtha Hydrotreater, NHT, and Reformer and expanding

the light ends treating, fractionation and processing in the Alkylation and Polymerization, ALKY/POLY area. A

detailed listing of the OSBL scope for this project in comparison to the other examples is shown in Table No. 4.

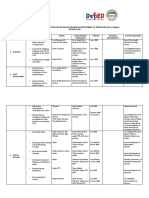

Table No. 4: OSBL Content Comparison of Example Projects

OSBL

Classification

Example No.1

VAC

Example No. 2

VAC/DCU

Example No.3

VAC/DCU/HDC

Interconnecting

Systems

HVGO Piping Process and utility

Piping/Racks

Pipe/Pipe Racks, Power,

Controls

Infrastructure None Utility System

Equipment

(Insignificant)

Utility System

Equipment,

Roads, Tanks, Truck

and Rail Product

Loading, Buildings

Secondary Process Units None SMR (Hydrogen)

ARU and SWS

WWTP, ARU/SWS,

SRU/TGTU, SMR

(Hydrogen)

Revamp of

Existing Units

None Resid HDS to Gas Oil

Feed HDT, 2 DHTs, 2

FCCs, LPG treating &

Fractionation, Amine,

SWS

NHDS, DHDS, LPG

fractionation

Financial Owners Cost, Start Up,

Working Capital,

Interest, Taxes

Same items as VAC Same items as VAC

Other Demolition, Permits,

Fees

Same items as VAC Same items as VAC

MEETING OSBL EXPECTATIONS DURING PROJECT DEVELOPMENT

This section will discuss possible reasons Why the OSBL costs of Refinery Expansion projects consistently exceed

expectations by large margins and provide recommendations for improving OSBL definition quality.

There are many possible reasons that can cause the OSBL part of a refinery expansion project to exceed expectations.

Taken in combination the difference between expectations and actual outcome will be significant. Some of these

reasons are listed below in Table No. 5. They include factors that affect both definition and pricing of the OSBL scope.

Page 9 of 10

Table No. 5: Why Expansion OSBL Does Not Meet Expectations

No. Reason Impacts

Definition Pricing

1. Unfamiliarity with size and complexity of evolving expansion

projects.

X

2. Inadequacy of time and resources allocated for OSBL

development.

X X

3. Overly optimistic about extra capacity in existing infrastructure for

expansion needs.

X

4. Failure to properly account for site specific issues like soil, climate,

plant layout etc.

X

5. Use of factors instead of current pricing to predict costs. X

6. Unrealistic allowance for escalation, contingency etc. X

The three examples discussed in the previous section illustrate why many may be unfamiliar with the size and

complexity of evolving refinery expansion projects. Until recently expansion project scope was limited to revamp of a

single existing unit with very limited OSBL/Infrastructure content like Example No. 1. The goal for this type of project

was primarily to reduce raw material cost and improve operating margin with less emphasis on large increases in

throughput and product volume. The more recent, larger projects combine very large increases in through put coupled

with a significant shift in crude feed gravity and sulfur content. These projects are relatively recent and present a steep

learning curve to the inexperienced. Assembling an experienced project team and planning and organizing a disciplined

project development effort are essential first steps for better meeting project expectations.

Some might say it is somewhat foolhardy to estimate OSBL/Infrastructure cost too early in project development1.

On the other hand more time is required to successfully define a large, complex project. Much of the early activity will

not require cost estimating. Early activity should focus on gaining a realistic understanding of the capacity of existing

infrastructure to support additional load and what must be included in the scope to meet site specific needs. If

necessary, elements of the existing infrastructure should be inspected and tested while in service to prove suitability

and capacity. Determining availability of open space, the extent of demolition and site clearing and relative location of

ISBL, OSBL and Infrastructure is crucial.

OSBL development should be started early even while ISBL is still being developed. Initial site specific OSBL and

Infrastructure scope can be developed early using similar or go by ISBL designs. Utilities and infrastructure needs

can also be determined fromthe go by designs using scaling factors. The scaling factors can be validated later in the

development when a firmISBL definition emerges. Develop site specific OSBL and Infrastructure Scope taking into

account relative location of

ISBL and Infrastructure.

Conceptual cost estimating for refineries and chemical plants is typically done by applying installation cost factors to

sized equipment.

3

While this technique has proven successful for the ISBL portion of projects, it is less than

satisfactory for OSBL, especially projects containing a relatively large interconnecting pipe and pipe rack component.

For this type of OSBL scope, using technical deliverables like preliminary layouts, pipe/rack routing, electrical one

lines etc to produce material take offs is a much more reliable method for costing the non-equipment component of

OSBL. Where significant equipment based infrastructure is needed installation cost factors can be used.

The scope definition should be checked by comparison against other similar projects. Adjustments for differences

related to variation between projects due to site and project specific characteristics should be taken into account when

making the comparison. In addition, the use of project development checklists specific to each project phase and rating

tools to quantitatively assess the completeness of the scope definition should be included near the end of each project

phase in the development process. Finally, given the evolution of refinery expansion projects fromsmall to large and

Page 10 of 10

simple to complex, time and funding should be included in the project development budget near the completion of the

OSBL development effort for An independent assessment of the costs outside project influence.

4

Table No. 6 summarizes the recommendations made above for improving the OSBL development and achieving

congruence between expectations and actual results.

Table No. 6: Recommendations for Meeting OSBL Expectations

No. Reason OSBL Fails Expectation Recommendation to Meet Expectation

1. Unfamiliarity with size and complexity of

evolving expansion projects.

Assemble experienced team and follow

disciplined development plan.

2. Inadequacy of time and resources allocated for

OSBL development.

Start OSBL development effort early and gain

site specific knowledge.

3. Overly optimistic about extra capacity in

existing infrastructure for expansion needs.

Inspect and analyze existing infrastructure and

estimate preliminary cost to expand capacity

as needed.

4. Failure to properly account for site specific

issues like soil, climate, plant layout etc.

Use check lists and rating tools to guide and

assess development.

5. Use of factors instead of current pricing to

predict costs.

Use layouts, routings, one lines to develop

material take offs for costing OSBL.

6. Unrealistic allowance for escalation,

contingency etc.

Engage independent outside review.

References

1. Smith, R. S. Factored Estimating Guidelines Refinery/Petrochemical Projects, Cost Engineering Vol. 39 No. 4

(April 1997): 36-41

2. Spangler, R. et al Flexibility in Design of Crude Unit Revamp AM-06- 14 NPRA Annual Meeting. Salt Lake City,

Utah: March 2006

3. Page, John S. Conceptual Cost Estimating Manual, 2nd Edition Section 18 Elsivier, 1996

4. McIntire, P. Cost Estimating Challenges Face Frontier Projects, Oil & Gas Journal, Vol. 99 No. 33 (August 2001)

Vous aimerez peut-être aussi

- Anthony Robbins - Time of Your Life - Summary CardsDocument23 pagesAnthony Robbins - Time of Your Life - Summary CardsWineZen97% (58)

- As-Built Commercial BLDG.1Document11 pagesAs-Built Commercial BLDG.1John Rom CabadonggaPas encore d'évaluation

- Kerala Government Calendar 2013Document12 pagesKerala Government Calendar 2013Afsal MohmedPas encore d'évaluation

- EATCO - Suez Petrochemicals Complex - Gas To PolyolefinsDocument136 pagesEATCO - Suez Petrochemicals Complex - Gas To PolyolefinsAndrzej SzymańskiPas encore d'évaluation

- Parker HPD Product Bulletin (HY28-2673-01)Document162 pagesParker HPD Product Bulletin (HY28-2673-01)helden50229881Pas encore d'évaluation

- MS Blending DDS Rev-B1Document56 pagesMS Blending DDS Rev-B1SaMona ThakerPas encore d'évaluation

- Caesar II TrainingDocument61 pagesCaesar II TrainingReaderRRGHT86% (7)

- Process Industry Practices Insulation: PIP INEG2000 Guidelines For Use of Insulation PracticesDocument15 pagesProcess Industry Practices Insulation: PIP INEG2000 Guidelines For Use of Insulation PracticesZubair RaoofPas encore d'évaluation

- Parts Manual: Generator SetDocument118 pagesParts Manual: Generator SetAhmed Kamal100% (2)

- Business PlanDocument74 pagesBusiness PlanandysupaPas encore d'évaluation

- Haldia Refinery Project Appraisal ReportDocument43 pagesHaldia Refinery Project Appraisal Reportaravind_k104Pas encore d'évaluation

- Cost EstimationDocument29 pagesCost Estimationgeorgiadisg100% (4)

- Uh 60 ManualDocument241 pagesUh 60 ManualAnonymous ddjwf1dqpPas encore d'évaluation

- Control ValvesDocument50 pagesControl ValvesReaderRRGHT93% (15)

- Pricing Strategy RefineryDocument13 pagesPricing Strategy RefineryAnuj GuptaPas encore d'évaluation

- SXV RXV ChassisDocument239 pagesSXV RXV Chassischili_s16Pas encore d'évaluation

- Vintage Airplane - May 1982Document24 pagesVintage Airplane - May 1982Aviation/Space History LibraryPas encore d'évaluation

- Unit 042 CCR Presentation Very GoodDocument29 pagesUnit 042 CCR Presentation Very GoodNguyễn Ngọc Tưởng100% (1)

- Capture Plan Aramco & SABIC - Crude Oil To Chemicals Project - COTCDocument9 pagesCapture Plan Aramco & SABIC - Crude Oil To Chemicals Project - COTCAri BinukoPas encore d'évaluation

- Hydrocracking StrategyDocument5 pagesHydrocracking StrategyDhanny MiharjaPas encore d'évaluation

- Reliance Petcoke Maitra-RelianceDocument20 pagesReliance Petcoke Maitra-Reliancestavros7Pas encore d'évaluation

- Dutch Refinery Model PDFDocument23 pagesDutch Refinery Model PDFgenergiaPas encore d'évaluation

- ENQDocument257 pagesENQAkash Verma100% (1)

- Feasibility Study of Liquefied Natural Gas ProjectDocument13 pagesFeasibility Study of Liquefied Natural Gas Projectkeshermech100% (1)

- 100 Yer Pe PDB 0003Document21 pages100 Yer Pe PDB 0003Janakiraman MalligaPas encore d'évaluation

- Process Propane DehydrogenationDocument4 pagesProcess Propane DehydrogenationRodrigo MazzarellaPas encore d'évaluation

- 138 Download Value Addition Through Refinery PetrochemicalDocument54 pages138 Download Value Addition Through Refinery PetrochemicaloptisearchPas encore d'évaluation

- Refinery Design PDFDocument108 pagesRefinery Design PDFGabriel ManavellaPas encore d'évaluation

- NTPC PresentationDocument222 pagesNTPC PresentationReaderRRGHT100% (2)

- Essar Oil LTD PresentationDocument15 pagesEssar Oil LTD PresentationNikhil GargPas encore d'évaluation

- Virtual Refinery ManualDocument14 pagesVirtual Refinery Manualpeng88ap100% (1)

- Modernizacion de Refineria Talara PeruDocument4 pagesModernizacion de Refineria Talara PeruAngelo HurtadoPas encore d'évaluation

- Economic Bottom of The Barrel Processing To Minimize Fuel Oil ProductionDocument5 pagesEconomic Bottom of The Barrel Processing To Minimize Fuel Oil Productionfisco4rilPas encore d'évaluation

- TAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1Document69 pagesTAC42055 - HO01 Edition I2.0: Section 1 Module 1 Page 1matheus santosPas encore d'évaluation

- Evaluation of A Small RefineryDocument364 pagesEvaluation of A Small RefineryAdamu Musa100% (4)

- Dahej Liquefied Natural Gas Terminal ProjectDocument45 pagesDahej Liquefied Natural Gas Terminal ProjectIndependent Evaluation at Asian Development BankPas encore d'évaluation

- Nozzle Loads Piping Stresses and The Effect of Piping On EquipmentDocument40 pagesNozzle Loads Piping Stresses and The Effect of Piping On Equipmentcaesar00100% (6)

- 11 - Refining and Petrochemical Integration Case Study Proceedings PDFDocument22 pages11 - Refining and Petrochemical Integration Case Study Proceedings PDFmujeebtalib100% (1)

- Mini Oil Refinery PlantsDocument3 pagesMini Oil Refinery Plantsdndudc100% (4)

- Refinery Configuration (With Figures)Document9 pagesRefinery Configuration (With Figures)phantanthanhPas encore d'évaluation

- Guidelines For The Establishment of A REFINERYDocument12 pagesGuidelines For The Establishment of A REFINERYbonostore100% (1)

- Hyundai Shell Revamp Paper PDFDocument2 pagesHyundai Shell Revamp Paper PDFProcess EngineerPas encore d'évaluation

- Profitability CKMDocument46 pagesProfitability CKMmujeebmehar100% (2)

- 112 Refinery Overview ChevronDocument2 pages112 Refinery Overview Chevronupender345Pas encore d'évaluation

- Refinery Operations Planning Final ReportDocument31 pagesRefinery Operations Planning Final ReportMohamed AlaaPas encore d'évaluation

- Introduction To Piping Engineering PDFDocument0 pageIntroduction To Piping Engineering PDFReaderRRGHTPas encore d'évaluation

- Uniflex Eliminate Fuel OilDocument20 pagesUniflex Eliminate Fuel Oilsantoso hadiPas encore d'évaluation

- JamnagarDocument3 pagesJamnagarkallurisuryaPas encore d'évaluation

- Hydro Cracking Tech For Middle DistDocument34 pagesHydro Cracking Tech For Middle Distapi-3709413100% (1)

- Asian Refining GrowningDocument40 pagesAsian Refining GrowninggustavoemirPas encore d'évaluation

- Pressure Reducing and Desuperheating ValveDocument8 pagesPressure Reducing and Desuperheating ValveReaderRRGHTPas encore d'évaluation

- Em FlexicokingDocument8 pagesEm FlexicokingHenry Saenz0% (1)

- 2012 Ethylene Plant For ItbDocument8 pages2012 Ethylene Plant For ItbKhumaedi Muharom Al-AzisPas encore d'évaluation

- Refinery - Petrochemicals Master Plan Article - KBRDocument7 pagesRefinery - Petrochemicals Master Plan Article - KBRstavros7Pas encore d'évaluation

- Oo004-Brochure Ethelyne-Brochure Web PDFDocument16 pagesOo004-Brochure Ethelyne-Brochure Web PDFrob.careyPas encore d'évaluation

- Gas Train Project PQDocument50 pagesGas Train Project PQvrajakisoriDasiPas encore d'évaluation

- Design Basis of Aromatics Complex PDFDocument14 pagesDesign Basis of Aromatics Complex PDFminh nguyen100% (1)

- Naphtha Catalytic Cracking For Propylene ProudctionDocument5 pagesNaphtha Catalytic Cracking For Propylene ProudctionWong Yee SunPas encore d'évaluation

- 5 - Duqm RefineryDocument17 pages5 - Duqm RefineryLien Nguyen100% (3)

- Iso Dewaxing PDFDocument32 pagesIso Dewaxing PDFMohamed Adel100% (2)

- Oil Refining Process Units For Sale and Relocation - All ClientsDocument1 pageOil Refining Process Units For Sale and Relocation - All ClientsRahim1850Pas encore d'évaluation

- Towards A Zero Gasoline Refinery PTQ Parts 1 2Document15 pagesTowards A Zero Gasoline Refinery PTQ Parts 1 2Anil UpadhyaPas encore d'évaluation

- Gas To Liquids Technology (GTL)Document30 pagesGas To Liquids Technology (GTL)Muhammad TeaimaPas encore d'évaluation

- Guidelines For National Gas Expansion Programme FinalDocument11 pagesGuidelines For National Gas Expansion Programme FinalEguono OmonighoPas encore d'évaluation

- Revamping For ULSD ProductionDocument8 pagesRevamping For ULSD Productionsam josephPas encore d'évaluation

- Unit 02 Karbala Refinery Project - Oct 3 17Document37 pagesUnit 02 Karbala Refinery Project - Oct 3 17noor taha100% (2)

- Integration of Petrochemical and Refinery Plants As An Approach To Compete in Hydrocarbon MarketDocument31 pagesIntegration of Petrochemical and Refinery Plants As An Approach To Compete in Hydrocarbon MarketHuiJooHweePas encore d'évaluation

- Refining-Petrochemical Integration-FCC Gasoline To PetrochemicalsDocument4 pagesRefining-Petrochemical Integration-FCC Gasoline To PetrochemicalsKwangsjungPas encore d'évaluation

- Review of Small Stationary Reformers For Hydrogen ProductionDocument52 pagesReview of Small Stationary Reformers For Hydrogen ProductionSoineth GuzmánPas encore d'évaluation

- TCM 701Document20 pagesTCM 701OYINLOLA ADESOKANPas encore d'évaluation

- Nit 1005 Mab Amd 1Document95 pagesNit 1005 Mab Amd 1Pradeep KumarPas encore d'évaluation

- MPR January 2019Document23 pagesMPR January 2019Anonymous MKT2rZVkNPas encore d'évaluation

- Poly Olefin HandbookDocument90 pagesPoly Olefin HandbookKenneth HowesPas encore d'évaluation

- Retrofit: Increasing The Efficiency of Pumps: Wayne Jones Ajit KumarDocument4 pagesRetrofit: Increasing The Efficiency of Pumps: Wayne Jones Ajit KumarDon LorimerPas encore d'évaluation

- Literature Review On Oil and GasDocument7 pagesLiterature Review On Oil and Gasafdtakoea100% (1)

- Pipeline Hazards. PresentationDocument20 pagesPipeline Hazards. PresentationReaderRRGHT100% (1)

- Ödéw ∞Dcg 30 º¡Jéñzq Gƒdóy Ómƒÿg ∫Ƒñ≤Dg Ωé¶F »'ADocument1 pageÖdéw ∞Dcg 30 º¡Jéñzq Gƒdóy Ómƒÿg ∫Ƒñ≤Dg Ωé¶F »'AReaderRRGHTPas encore d'évaluation

- Australia Brochure PDFDocument14 pagesAustralia Brochure PDFReaderRRGHTPas encore d'évaluation

- Italian Business Culture ReportDocument9 pagesItalian Business Culture ReportReaderRRGHTPas encore d'évaluation

- KSR Vol IDocument230 pagesKSR Vol IneenarajeshPas encore d'évaluation

- Auto Turn-Off For Water Pump With Four Different Time SlotsDocument3 pagesAuto Turn-Off For Water Pump With Four Different Time SlotsKethavath Sakrunaik K100% (1)

- Tourbier Renewal NoticeDocument5 pagesTourbier Renewal NoticeCristina Marie DongalloPas encore d'évaluation

- RESEARCH 10 Module 1 Lesson 1 (WEEK 1-2)Document5 pagesRESEARCH 10 Module 1 Lesson 1 (WEEK 1-2)DennisPas encore d'évaluation

- Report-Smaw Group 12,13,14Document115 pagesReport-Smaw Group 12,13,14Yingying MimayPas encore d'évaluation

- Pontevedra 1 Ok Action PlanDocument5 pagesPontevedra 1 Ok Action PlanGemma Carnecer Mongcal50% (2)

- Ice 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisDocument15 pagesIce 3101: Modern Control THEORY (3 1 0 4) : State Space AnalysisBipin KrishnaPas encore d'évaluation

- Controlador DanfossDocument2 pagesControlador Danfossfrank.marcondes2416Pas encore d'évaluation

- MSC ACFN2 RD4 ClassDocument25 pagesMSC ACFN2 RD4 Classmengistu jiloPas encore d'évaluation

- Bin Adam Group of CompaniesDocument8 pagesBin Adam Group of CompaniesSheema AhmadPas encore d'évaluation

- Coco Mavdi Esl5Document6 pagesCoco Mavdi Esl5gaurav222980Pas encore d'évaluation

- Needle BasicsDocument31 pagesNeedle BasicsARYAN RATHOREPas encore d'évaluation

- Assignment-For-Final of-Supply-Chain - Management of Courses PSC 545 & 565 PDFDocument18 pagesAssignment-For-Final of-Supply-Chain - Management of Courses PSC 545 & 565 PDFRAKIB HOWLADERPas encore d'évaluation

- CH 15Document58 pagesCH 15Chala1989Pas encore d'évaluation

- Annex To ED Decision 2013-015-RDocument18 pagesAnnex To ED Decision 2013-015-RBurse LeePas encore d'évaluation

- Reference by John BatchelorDocument1 pageReference by John Batchelorapi-276994844Pas encore d'évaluation

- Ged 102 Mathematics in The Modern WorldDocument84 pagesGed 102 Mathematics in The Modern WorldKier FormelozaPas encore d'évaluation

- DLI Watchman®: Vibration Screening Tool BenefitsDocument2 pagesDLI Watchman®: Vibration Screening Tool Benefitssinner86Pas encore d'évaluation

- List of HTML TagsDocument5 pagesList of HTML TagsdorinadidPas encore d'évaluation

- Process Description of Function For Every Unit OperationDocument3 pagesProcess Description of Function For Every Unit OperationMauliduni M. AuniPas encore d'évaluation

- What Are Some of The Best Books On Computer ScienceDocument9 pagesWhat Are Some of The Best Books On Computer ScienceSarthak ShahPas encore d'évaluation

- FKTDocument32 pagesFKTNeeraj SharmaPas encore d'évaluation