Académique Documents

Professionnel Documents

Culture Documents

Mold 33

Transféré par

anisashraf90Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Mold 33

Transféré par

anisashraf90Droits d'auteur :

Formats disponibles

Material passing through the runner during mold filling forms a frozen wall layer as the mold steel

draws heat from the melt. This layer restricts the flow channel and increases the pressure drop through the runner. Round cross-section runners minimize contact with the mold surface and generate the smallest percentage of frozen layer cross-sectional area. As runner designs deviate from round, they become less efficient (see figure 7-20). Round runners require machining in both halves of the mold, increasing the potential for mismatch and flow restriction. A good alternative, the round-bottomed trapezoid, requires machining in just one mold half. Essentially a round cross section with sides tapered by five degrees for ejection, this design is nearly as efficient as the full-round design. The runner system often accounts for more than 40% of the pressure required to fill the mold. Because much of this pressure drop can be attributed to runner length, optimize the route to each gate to minimize runner length. For example, replace cornered paths with diagonals or reorient the cavity to shorten the runner. Runner thickness has a direct effect on filling pressure, cycle time, packing, and runner volume. The optimum runner diameter depends on a variety of factors including part volume, part thickness, filling speed and pressure, runner length, and material viscosity. For sufficient packing, make runners at least as thick as the Most of the design principles covered in this manual apply to all of these resins. When discussing guidelines or issues for a specific resin family, we reference these materials either by their Bayer trade names or by their generic polymer type. The material data scattered throughout the chapters is included by way of example only and may not reflect the most current testing. In addition, much of the data is generic and may differ from the properties of specific resin grades. For up-to-date performance data for specific Bayer resins, contact your Bayer sales representative or refer to the following information sources: Bayer Engineering Polymers Properties Guide: Contains common single-point

properties by resin family and grade. Bayer Plastics Product Information Bulletin: Lists information and properties for a specific material grade. In addition to design manuals, Bayer Corporation provides design assistance in other forms such as seminars and technical publications. Bayer also offers a range of design engineering services to its qualified customers. Contact your Bayer sales representative for more information on these other services. 2

Vous aimerez peut-être aussi

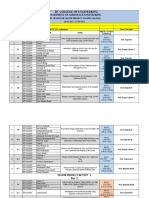

- Universiti Malaysia Perlis: Examination Result Semester 1 Academic Session 2011/2012Document1 pageUniversiti Malaysia Perlis: Examination Result Semester 1 Academic Session 2011/2012anisashraf90Pas encore d'évaluation

- DataDocument2 pagesDataanisashraf90Pas encore d'évaluation

- IDT2 Misconception2Document2 pagesIDT2 Misconception2anisashraf90Pas encore d'évaluation

- Compass Motor: ControllerDocument1 pageCompass Motor: Controlleranisashraf90Pas encore d'évaluation

- Bi Blog RafiDocument1 pageBi Blog Rafianisashraf90Pas encore d'évaluation

- Senarai Rajah: 4.4.1.1 Mesin Khn4 (Side Cut) 48Document1 pageSenarai Rajah: 4.4.1.1 Mesin Khn4 (Side Cut) 48anisashraf90Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 3 Carbohydrates' StructureDocument33 pages3 Carbohydrates' StructureDilan TeodoroPas encore d'évaluation

- g6 - AFA - Q1 - Module 6 - Week 6 FOR TEACHERDocument23 pagesg6 - AFA - Q1 - Module 6 - Week 6 FOR TEACHERPrincess Nicole LugtuPas encore d'évaluation

- SMR 13 Math 201 SyllabusDocument2 pagesSMR 13 Math 201 SyllabusFurkan ErisPas encore d'évaluation

- Environmental Economics Pollution Control: Mrinal Kanti DuttaDocument253 pagesEnvironmental Economics Pollution Control: Mrinal Kanti DuttashubhamPas encore d'évaluation

- Lecture 4 ENGR 243 DynamicsDocument45 pagesLecture 4 ENGR 243 DynamicsRobby RebolledoPas encore d'évaluation

- Classifications of AssessmentsDocument11 pagesClassifications of AssessmentsClaire CatapangPas encore d'évaluation

- Ricoh IM C2000 IM C2500: Full Colour Multi Function PrinterDocument4 pagesRicoh IM C2000 IM C2500: Full Colour Multi Function PrinterKothapalli ChiranjeeviPas encore d'évaluation

- FDA Approves First Gene Therapy, Betibeglogene Autotemcel (Zynteglo), For Beta-ThalassemiaDocument3 pagesFDA Approves First Gene Therapy, Betibeglogene Autotemcel (Zynteglo), For Beta-ThalassemiaGiorgi PopiashviliPas encore d'évaluation

- E Flight Journal Aero Special 2018 Small PDFDocument44 pagesE Flight Journal Aero Special 2018 Small PDFMalburg100% (1)

- Hole CapacityDocument2 pagesHole CapacityAbdul Hameed OmarPas encore d'évaluation

- Monergism Vs SynsergismDocument11 pagesMonergism Vs SynsergismPam AgtotoPas encore d'évaluation

- 2021-03 Trophy LagerDocument11 pages2021-03 Trophy LagerAderayo OnipedePas encore d'évaluation

- II 2022 06 Baena-Rojas CanoDocument11 pagesII 2022 06 Baena-Rojas CanoSebastian GaonaPas encore d'évaluation

- Android Developer PDFDocument2 pagesAndroid Developer PDFDarshan ChakrasaliPas encore d'évaluation

- The JHipster Mini Book 2Document129 pagesThe JHipster Mini Book 2tyulist100% (1)

- E MudhraDownload HardDocument17 pagesE MudhraDownload HardVivek RajanPas encore d'évaluation

- LEIA Home Lifts Guide FNLDocument5 pagesLEIA Home Lifts Guide FNLTejinder SinghPas encore d'évaluation

- Review1 ScheduleDocument3 pagesReview1 Schedulejayasuryam.ae18Pas encore d'évaluation

- Mark Garside Resume May 2014Document3 pagesMark Garside Resume May 2014api-199955558Pas encore d'évaluation

- MGMT Audit Report WritingDocument28 pagesMGMT Audit Report WritingAndrei IulianPas encore d'évaluation

- Harper Independent Distributor Tri FoldDocument2 pagesHarper Independent Distributor Tri FoldYipper ShnipperPas encore d'évaluation

- DN Cross Cutting IssuesDocument22 pagesDN Cross Cutting Issuesfatmama7031Pas encore d'évaluation

- Waterstop TechnologyDocument69 pagesWaterstop TechnologygertjaniPas encore d'évaluation

- Syllabus DresserDocument2 pagesSyllabus DresserVikash Aggarwal50% (2)

- Evaluation TemplateDocument3 pagesEvaluation Templateapi-308795752Pas encore d'évaluation

- Partes de La Fascia Opteva Y MODULOSDocument182 pagesPartes de La Fascia Opteva Y MODULOSJuan De la RivaPas encore d'évaluation

- 5c3f1a8b262ec7a Ek PDFDocument5 pages5c3f1a8b262ec7a Ek PDFIsmet HizyoluPas encore d'évaluation

- Role of Losses in Design of DC Cable For Solar PV ApplicationsDocument5 pagesRole of Losses in Design of DC Cable For Solar PV ApplicationsMaulidia HidayahPas encore d'évaluation

- Lesson PlanDocument2 pagesLesson Plannicole rigonPas encore d'évaluation

- Hey Friends B TBDocument152 pagesHey Friends B TBTizianoCiro CarrizoPas encore d'évaluation