Académique Documents

Professionnel Documents

Culture Documents

Compound Semi 2005 Mayo 15

Transféré par

barzanaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Compound Semi 2005 Mayo 15

Transféré par

barzanaDroits d'auteur :

Formats disponibles

LED modules make dirty water

potable

Two US teams working on a water-sterilization module that uses

AlGaN-based ultraviolet LEDs have demonstrated its ability to kill

harmful bacteria in flowing water.

One of the concepts developed is a module that does not require an

external energy source to power the LEDs, instead relying on the

flow of water to generate the required drive current.

Such purification modules, which would be far smaller and more

convenient than those that use mercury lamps to kill bacteria, could

become a high-volume market for UV-LEDs.

Although the concept of bacteria destruction with UV-LEDs has been

shown before with a static water sample, the purification of flowing

water is critical for the technology to become commercially viable.

In collaboration with microbiologist Anne Hanson at the University

of Maine Orono, Hydro-Photon, a Blue Hill, ME, company, developed

a bench-level prototype flowing water-treatment module that uses

10 AlGaN LEDs made by the South Carolina firm Sensor Electronic

Technology (SET).

The SET devices used in the module, which were developed in

collaboration with Asif Khan's group at the University of South

Carolina, emit at 280 nm, and the 4 cm 3 aluminum treatment

chamber is designed to maximize light reflection at this wavelength.

In tests using sterile tap water contaminated with a 10000

microbes/ml concentration of Ecoli, the UV-LEDs destroyed at least

95.5% of the bacteria. The best results were seen at lower flow

rates, where the germ destruction was close to 100%.

"The results put us anther step closer to demonstrating the basic

viability of the flow-through UV-LED water-purifier concept," said

Miles Maiden, CEO of Hydro-Photon. "At this point, the challenge is

to continue improving LED efficiency and power output.

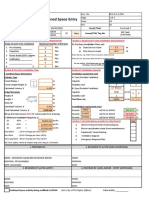

Water purifier: Hydro-Photon's 10-LED module has virtually

eliminated bacterial contamination in flowing water.

More power means faster flow and more purified water per minute."

Meanwhile, a second firm - Ohio-based start-up company Oh

Technology (OHT), which is also working with SET's LEDs -claims to

have reduced bacteria levels in flowing raw sewerage by 60%.

OHT's first battery of tests, which began in February this year,

looked at the effect of a prototype module containing 16 AlGaN

LEDs on raw fecal sewerage at a local wastewater-treatment facility.

According to the team, which included third-party testers at Tri

State Laboratory, the influent samples that contained fecal coliform

bacteria showed a 60% reduction in bacteria concentration after a

one-second flow-through. These bacteria are found in the digestive

tract, and include classes such as enter-obacter, citrobacter and E

coli, and concentrations of these bacteria are commonly used as an

indicator of sewerage contamination in water supplies.

"Our goal is to alleviate inadequate water situations that have

become a global epidemic," said OHT chief executive Damien Lieggi.

"The test results have provided proof of the basic viability and

instant kill efficiency of the LEDs." Lieggi added: "We want to turn

the worst possible conditions into drinking water. We feel that we

have achieved tremendous results at this level."

Lieggi describes OHT's technology as "self-sustaining", as it does

not rely on an external energy source: "[Our] patent-pending

technology uses the flow of water, which is converted into electrical

energy [to power] the LEDs, which in turn sterilize the water."

The LEDs in the current set-up emit about 1 mW at around 270 nm,

while OHT and SET are testing new, improved devices. Lieggi says

that a commercial product will be unveiled within a few months:

"What sets our product apart [is that] it eliminates the need for

batteries, solar panels and ballasts."

SET makes the short-wavelength LEDs used in the module using a

novel growth technique called migration-enhanced MOCVD

(Compound Semiconductor April p27). This approach, which differs

from conventional MOCVD in regard to the way gases are flowed

into the reaction chamber, improves the quality of A1N and AlGaN in

particular, while increasing the material-deposition rate.

Remis Gaska, SET's CEO, said of the Hydro-Photon work: "We

consider this to be a significant milestone in bringing our deep-UV

technology to such high-volume markets as water, air and surface

sterilization."

nLight claims diode-laser-output record

nLight, which is developing high-power, high-efficiency lasers based

on GaAs and InP material systems, says that it has set a new world

record for output power from a single 1 cm InP laser bar.

A water-cooled InP bar made by the Vancouver, WA, company

produced 88 W of continuous-wave power at 1470 nm. The

significance of the breakthrough, says nLight, is that diode bars

based on the technology could substantially improve high-power

diode-pumped solid-state (DPSS) lasers that emit in the so-called

"eye-safe" 1400-1600 nm range.

These large laser systems are usually pumped with high-power

GaAs diodes emitting around 800 nm. However, they require an

additional system, known as an optical parametric oscillator (OPO),

to shift the output wavelength into the eye-safe range.

Using InP-based diode bars, says nLight, means that an OPO is not

needed. That's because the 1470 nm output can be used to pump

an erbium-doped crystal, which emits directly in the eye-safe range.

And so the DPSS systems can be made smaller and more cheaply,

and could find more applications. The physics of the erbium-doped

crystal structure also means that less pumping power is required:

"The number of diode-laser bars required to reach a given pulse

energy [with an erbium-doped crystal] is reduced by at least an

order of magnitude," claimed the company.

Vous aimerez peut-être aussi

- Piccolo: Operating and Maintenance Instructions For The Deck OvenDocument44 pagesPiccolo: Operating and Maintenance Instructions For The Deck OvenAdam B100% (1)

- 3 To 8 Decoder in NGSPICEDocument14 pages3 To 8 Decoder in NGSPICEJaydip FadaduPas encore d'évaluation

- Problem set 1 covers energy, heat, gases, and thermodynamicsDocument15 pagesProblem set 1 covers energy, heat, gases, and thermodynamicsFikret BazPas encore d'évaluation

- International University: School of BiotechnologyDocument13 pagesInternational University: School of BiotechnologyHuong HuyenPas encore d'évaluation

- Optoelectronic Devices: - Text, Chapter 11 - Sze Is A Good ReferenceDocument71 pagesOptoelectronic Devices: - Text, Chapter 11 - Sze Is A Good ReferenceZiadelkPas encore d'évaluation

- Arduino Based Covid19 Sanitization and Water, Electricity SaviorDocument4 pagesArduino Based Covid19 Sanitization and Water, Electricity SaviorIJRASETPublicationsPas encore d'évaluation

- Uvsofiergroup NavarroDocument8 pagesUvsofiergroup NavarroChristian NavarroPas encore d'évaluation

- Water Purifier Using Ultra Violent RaysDocument42 pagesWater Purifier Using Ultra Violent RaysAshish KumarPas encore d'évaluation

- Purification of Brackish Water Using Hybrid CDI-EDI TechnologyDocument30 pagesPurification of Brackish Water Using Hybrid CDI-EDI TechnologyamtPas encore d'évaluation

- PerfectDocument71 pagesPerfectJose Virgilio Calambuhay JrPas encore d'évaluation

- SBIR Phase III-HighlightDocument9 pagesSBIR Phase III-HighlightAnthony D.Pas encore d'évaluation

- IoT Controlled Solar Panel CleanerDocument4 pagesIoT Controlled Solar Panel CleanerInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Uv-Ecoray en InetDocument3 pagesUv-Ecoray en InetfredguyPas encore d'évaluation

- Organic Led Research PaperDocument8 pagesOrganic Led Research Papergz46ktxr100% (1)

- Open Source Solar Powered UVC LED Water SteriliserDocument12 pagesOpen Source Solar Powered UVC LED Water SteriliserAston WalkerPas encore d'évaluation

- Research Paper On Led LightingDocument8 pagesResearch Paper On Led Lightingk0wyn0tykob3100% (1)

- Research Paper On LedDocument4 pagesResearch Paper On Ledgzrvpcvnd100% (1)

- Organic TransistorsDocument9 pagesOrganic TransistorsAnanth ShenoyPas encore d'évaluation

- Effectiveness of Electro Chemical Disinf-1 PDFDocument9 pagesEffectiveness of Electro Chemical Disinf-1 PDFsumit dekatePas encore d'évaluation

- Implementation of An Iot-Based Water Quality Monitoring System in Water Battery Electricity Generation PlantsDocument14 pagesImplementation of An Iot-Based Water Quality Monitoring System in Water Battery Electricity Generation PlantsJustine ReyesPas encore d'évaluation

- Original PhotonicsEurope2006 - PunkeDocument13 pagesOriginal PhotonicsEurope2006 - PunkeashikonlyPas encore d'évaluation

- Detect Water in Fuel with Innovative Electronics DeviceDocument11 pagesDetect Water in Fuel with Innovative Electronics Devicenachof1Pas encore d'évaluation

- Led Lights Research PaperDocument6 pagesLed Lights Research Papermqolulbkf100% (1)

- Dept of EceDocument38 pagesDept of EceBakiesaliyaPas encore d'évaluation

- Design and Development of Energy-Free Solar Street LED Light SystemDocument8 pagesDesign and Development of Energy-Free Solar Street LED Light SystemdseshireddyPas encore d'évaluation

- Bioinicia: Electrospinning SpecialistDocument4 pagesBioinicia: Electrospinning SpecialistOriana González HernándezPas encore d'évaluation

- Solar TreeDocument5 pagesSolar Treepraveentotager2000Pas encore d'évaluation

- GE-International Journal of Engineering Research: Automated Water Level ControllerDocument14 pagesGE-International Journal of Engineering Research: Automated Water Level ControllerSounds of PeacePas encore d'évaluation

- High-power Accelerator for Environmental ApplicationsDocument4 pagesHigh-power Accelerator for Environmental ApplicationsNhi LêPas encore d'évaluation

- Water Level Indicator: DescriptionDocument19 pagesWater Level Indicator: Descriptiontajju_121Pas encore d'évaluation

- Etm 2012 12 10 4Document1 pageEtm 2012 12 10 4npr68Pas encore d'évaluation

- Team09 PDFDocument23 pagesTeam09 PDFpleasename1Pas encore d'évaluation

- Ea 40Document6 pagesEa 40Harsh SharmaPas encore d'évaluation

- Performance Investigation of Visible Light Communication System Using Optisystem Simulation ToolDocument8 pagesPerformance Investigation of Visible Light Communication System Using Optisystem Simulation ToolLuisPas encore d'évaluation

- Smart Street Light Using Wind-Solar Hybrid Energy SystemDocument8 pagesSmart Street Light Using Wind-Solar Hybrid Energy SystemIJRASETPublicationsPas encore d'évaluation

- Iot Water Monitoring SystemDocument10 pagesIot Water Monitoring SystemPidot DotPas encore d'évaluation

- LIGHT TUBE: UV-A Decontamination Device 2017-MarDocument13 pagesLIGHT TUBE: UV-A Decontamination Device 2017-MarFrancesco Paolo TuccinardiPas encore d'évaluation

- PROMETE Light TubeDocument15 pagesPROMETE Light TuberobertogermanoPas encore d'évaluation

- Literature Review Water Level DetectorDocument8 pagesLiterature Review Water Level Detectorc5t9rejg100% (1)

- Pacific Gas and Electric Company: HID Electronic Ballast Overall Summary Report 3 Site AssessmentDocument22 pagesPacific Gas and Electric Company: HID Electronic Ballast Overall Summary Report 3 Site AssessmentatsoufienPas encore d'évaluation

- Cellulose/polyvinyl Alcohol Based Hydrogels For Reconfigurable LensDocument6 pagesCellulose/polyvinyl Alcohol Based Hydrogels For Reconfigurable LensVincent ShenPas encore d'évaluation

- Development of A Kit To Extract Water From Atmospheric Air 2017Document8 pagesDevelopment of A Kit To Extract Water From Atmospheric Air 2017pokygangPas encore d'évaluation

- Seoul Semiconductor Catalog 2013 Ver 5Document26 pagesSeoul Semiconductor Catalog 2013 Ver 5frankcandoPas encore d'évaluation

- Jurnal Pemurnian UVc 2Document9 pagesJurnal Pemurnian UVc 2Na JidPas encore d'évaluation

- Reshma SDocument30 pagesReshma SManjunath MaddyPas encore d'évaluation

- Paper - 2009 - Design and Optimization of A Collimating Optical System For High Divergence LED Light SourcesDocument11 pagesPaper - 2009 - Design and Optimization of A Collimating Optical System For High Divergence LED Light SourcesPaulPas encore d'évaluation

- Khadka 2020 IOP Conf. Ser. Earth Environ. Sci. 463 012121-1Document9 pagesKhadka 2020 IOP Conf. Ser. Earth Environ. Sci. 463 012121-1Mustafa GhoneimPas encore d'évaluation

- A Multifaceted GemDocument3 pagesA Multifaceted GemVivek PatelPas encore d'évaluation

- Annotated BibliographyDocument11 pagesAnnotated BibliographyRobert RobinsonPas encore d'évaluation

- Piezoelectric Energy Harvesting Device Optimization by Synchronous Charge ExtractionDocument14 pagesPiezoelectric Energy Harvesting Device Optimization by Synchronous Charge ExtractionNik NamePas encore d'évaluation

- OLED Seminar Report on Organic Light Emitting Diode TechnologyDocument18 pagesOLED Seminar Report on Organic Light Emitting Diode TechnologysyedbashaPas encore d'évaluation

- LED LightDocument22 pagesLED LightsultanprincePas encore d'évaluation

- Characterizing White Leds For General Illumination ApplicationsDocument6 pagesCharacterizing White Leds For General Illumination ApplicationsDishant GuptaPas encore d'évaluation

- LEDPhotocatalysis PDFDocument12 pagesLEDPhotocatalysis PDFninjaPas encore d'évaluation

- Miniaturisation For Chemistry, Physics, Biology and BioengineeringDocument16 pagesMiniaturisation For Chemistry, Physics, Biology and BioengineeringN28293Pas encore d'évaluation

- Organic Light Emitting Diode Research PaperDocument5 pagesOrganic Light Emitting Diode Research Paperukldyebkf100% (1)

- Battery That Extracts Energy From Water Salinity DifferenceDocument8 pagesBattery That Extracts Energy From Water Salinity DifferencejahidulPas encore d'évaluation

- Seminar Report On OLEDDocument26 pagesSeminar Report On OLEDsaicharan1990100% (2)

- Low Cost Water Purifier For Rural Areas PDFDocument3 pagesLow Cost Water Purifier For Rural Areas PDFOmunet NapthalPas encore d'évaluation

- Literature Review of Street Light ControlDocument6 pagesLiterature Review of Street Light Controlafduadaza100% (1)

- Solar-Powered Led Streetlamp With Microcontroller-Based Illumination SystemDocument16 pagesSolar-Powered Led Streetlamp With Microcontroller-Based Illumination SystemIJMSRTPas encore d'évaluation

- PHD ProposalDocument1 pagePHD ProposalMoaaz AhmedPas encore d'évaluation

- Heterogeneous Nanocomposite-Photocatalysis for Water PurificationD'EverandHeterogeneous Nanocomposite-Photocatalysis for Water PurificationPas encore d'évaluation

- IHE Nov09Document48 pagesIHE Nov09barzanaPas encore d'évaluation

- IHE Sept09Document28 pagesIHE Sept09barzanaPas encore d'évaluation

- Possible Effect of EMF On Human HealthDocument58 pagesPossible Effect of EMF On Human HealthAurora LightSkyPas encore d'évaluation

- IHE Oct09Document36 pagesIHE Oct09barzanaPas encore d'évaluation

- IHE June 09 LRDocument28 pagesIHE June 09 LRbarzanaPas encore d'évaluation

- IHE June 2010Document36 pagesIHE June 2010barzanaPas encore d'évaluation

- Ihe M-A 2011Document40 pagesIhe M-A 2011barzanaPas encore d'évaluation

- IHE Dec09Document36 pagesIHE Dec09barzanaPas encore d'évaluation

- IHE Nov10Document40 pagesIHE Nov10barzanaPas encore d'évaluation

- IHE April-May 2010Document36 pagesIHE April-May 2010barzanaPas encore d'évaluation

- IHE Sept Oct2010Document36 pagesIHE Sept Oct2010barzanaPas encore d'évaluation

- Managing Sepsis Monitoring Fluid Responsiveness Preventing VapDocument36 pagesManaging Sepsis Monitoring Fluid Responsiveness Preventing VapbarzanaPas encore d'évaluation

- IHE Feb-Mar 2010Document30 pagesIHE Feb-Mar 2010barzanaPas encore d'évaluation

- Medical Imaging Special: Imaging of Acute Stroke PatientsDocument36 pagesMedical Imaging Special: Imaging of Acute Stroke PatientsbarzanaPas encore d'évaluation

- The Continuing Challenge: Hospital HygieneDocument36 pagesThe Continuing Challenge: Hospital HygienebarzanaPas encore d'évaluation

- What The Future Holds For Mri: Medical Imaging SpecialDocument52 pagesWhat The Future Holds For Mri: Medical Imaging SpecialbarzanaPas encore d'évaluation

- Eunis 2009-Toum-The Official Electronic Notice Board of The University of Murcia-Presentation-Camera-ReadyDocument31 pagesEunis 2009-Toum-The Official Electronic Notice Board of The University of Murcia-Presentation-Camera-ReadybarzanaPas encore d'évaluation

- The Potential of The Semantic Web: Healthcare ItDocument40 pagesThe Potential of The Semantic Web: Healthcare ItbarzanaPas encore d'évaluation

- Oporto Egov ProjectDocument33 pagesOporto Egov ProjectbarzanaPas encore d'évaluation

- Trapped AntihydrogenDocument5 pagesTrapped AntihydrogenKing KusanakiPas encore d'évaluation

- Basic of Ubuntu LinuxDocument165 pagesBasic of Ubuntu Linuxmohammad reza ardian abdillahPas encore d'évaluation

- FMVSS 139 2022-10-01Document7 pagesFMVSS 139 2022-10-01skr_757Pas encore d'évaluation

- A Pilot's Guide To ILS PRM ApproachesDocument4 pagesA Pilot's Guide To ILS PRM ApproachesgregmPas encore d'évaluation

- E-Governance in KeralaDocument10 pagesE-Governance in KeralaRahmath SafeenaPas encore d'évaluation

- Homebuilding - Renovating-UltimateDesignBuildGuideDocument60 pagesHomebuilding - Renovating-UltimateDesignBuildGuideverivtudawPas encore d'évaluation

- Load of Pedstrain On FobDocument26 pagesLoad of Pedstrain On FobPOOJA VPas encore d'évaluation

- Practical Project Planning and Tracking Using Microsoft Project v2.7Document47 pagesPractical Project Planning and Tracking Using Microsoft Project v2.7Nelson Aguirre BravoPas encore d'évaluation

- Individual tone frequencies have hidden qualitiesDocument7 pagesIndividual tone frequencies have hidden qualitiesArnauPas encore d'évaluation

- Ventilation Plan For Confined Space EntryDocument9 pagesVentilation Plan For Confined Space EntryMohamad Nazmi Mohamad Rafian100% (1)

- Rosalind FranklinDocument1 pageRosalind FranklinMichael SmithPas encore d'évaluation

- No Curfew for College Dorm StudentsDocument2 pagesNo Curfew for College Dorm Students陳玟蓁Pas encore d'évaluation

- Vehicle and Driver Vibration - PPTDocument16 pagesVehicle and Driver Vibration - PPTAnirban MitraPas encore d'évaluation

- Matlab 8Document6 pagesMatlab 8Robert RoigPas encore d'évaluation

- Physics Chapter 2 Original TestDocument6 pagesPhysics Chapter 2 Original TestJanina OrmitaPas encore d'évaluation

- Comparisonofweldingeconomy Kehlnaht 12551752Document10 pagesComparisonofweldingeconomy Kehlnaht 12551752Asebaho BadrPas encore d'évaluation

- Dinosaur Bones - American Museum of Natural HistoryDocument7 pagesDinosaur Bones - American Museum of Natural HistoryNicholas FeatherstonPas encore d'évaluation

- BHCC Peri 5c Jyps - MK Classroom Toilet (Pending To Sign by Moe) - Removed - RemovedDocument8 pagesBHCC Peri 5c Jyps - MK Classroom Toilet (Pending To Sign by Moe) - Removed - RemovedrajavelPas encore d'évaluation

- Ake Products 001 2016Document171 pagesAke Products 001 2016davidPas encore d'évaluation

- 5054 s09 QP 1Document20 pages5054 s09 QP 1Hany ElGezawyPas encore d'évaluation

- Trade ReportDocument6 pagesTrade ReportIKEOKOLIE HOMEPCPas encore d'évaluation

- ION-CEDI-BR Ion PureDocument8 pagesION-CEDI-BR Ion PureAndri YantoPas encore d'évaluation

- Adjustment: - Electronic Modulated Air SuspensionDocument2 pagesAdjustment: - Electronic Modulated Air SuspensionThar KyiPas encore d'évaluation

- Shell Donax TA Transmission Fluid TDS PDFDocument1 pageShell Donax TA Transmission Fluid TDS PDFirwanbahrudin117134Pas encore d'évaluation

- Writing and Reporting For The Media Workbook 12Th Edition Full ChapterDocument32 pagesWriting and Reporting For The Media Workbook 12Th Edition Full Chapterdorothy.todd224100% (23)

- Microsoft Excel ExercisesDocument14 pagesMicrosoft Excel ExercisesJumaryse Marabut100% (2)

- Ethics UNAM IsakDocument74 pagesEthics UNAM IsakIsak Isak IsakPas encore d'évaluation

- FormatCARS KAAUH Alqahtani 106Document8 pagesFormatCARS KAAUH Alqahtani 106ZEYNOPas encore d'évaluation