Académique Documents

Professionnel Documents

Culture Documents

Kumar

Transféré par

Comsip400Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Kumar

Transféré par

Comsip400Droits d'auteur :

Formats disponibles

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 1

TEC Division

ADSS Cables

Installation Guide

This document presents Synergy Cables recommendations for installation of its ADSS cables.

Issues related to installing cables in the proximity of high voltage power cables are not discussed

in this document.

The content of this document is intended as a service to Synergy Cable Ltd. customers. Synergy

Cables Ltd. disclaims any responsibility for any result or consequence of using the information

contained in this document. In no event shall Synergy Cables Ltd. or its employees, agents or

affiliates, be liable for any direct, indirect, actual, special or consequential damages resulting from

following the instructions in this document or from the information contained herein.

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 2

TEC Division

1. General

This procedure provides general information for installing

Synergy Cables ADS Series ADSS (All-Dielectric Self-

Supporting) fiber optic cables. Each installation will be

influenced by local conditions.

The reader should be experienced in aerial fiber optic cable

placement.

This procedure contains references to specific tools and

materials in order to illustrate a particular method. Such

references are not intended as product endorsements.

Detailed instructions are marked by a grey background.

2. Safety Precautions

This section discusses some basic safety considerations

applicable to aerial cable installations.

Warning

Cable installation in general and ADSS cable installation

in particular requires skill and know-how. Never attempt

to install ADSS cables with unskilled personnel.

Use protective leather gloves and, if necessary, rubber

gloves. Use the leather gloves when climbing or

descending a pole, and when working with sharp

instruments or materials. Wear rubber gloves when

working near exposed electrical circuits.

Use a safety harness on all bucket trucks and aerial lifts.

A body belt and safety strap for the bucket or platform

must be used when the equipment is in operation to

minimize the chance of injury.

Before climbing a pole, inspect it for significant

deterioration and safety hazards splintering, insect nests,

sharp protrusions, etc.).

Position all motorized equipment so that exhausts are

directed away from the location where most work will be

done.

Under extreme conditions a cable under tension may

snap free and cause injury. Therefore, unless absolutely

necessary, personnel should not remain in an area

where a cable is being pulled around a piece of

hardware under tension. If needed, the installer can

remain in such an area if he or she stays clear of the

hardware under tension and has a clear path to safety.

Keep hands free of tools or materials when climbing or

descending a pole or ladder. Do not step on cables,

cable enclosures, or suspended equipment which might

provide unsafe footholds.

Read the entire procedure before starting a cable

installation. Thoroughly understand the procedure, its

precautions, and the tools and equipment required

before starting work.

3. Cable Handling

Caution

Care must be taken to avoid cable damage during placement

and handling. Fiber optic cables are sensitive to excessive

pulling, bending, twisting and crushing and impact forces.

Any such damage may alter the cable's characteristics to the

extent that the cable section may have to be replaced. To

ensure all specifications are met, consult the cable

specification sheet for the cable you are installing.

3.1 Installation Tension

There are two different tensions to keep in mind during

installation of ADSS cables. One is the maximum pulling

tension during installation; the other is the span tension.

The maximum tension during installation depends on the

cable construction and design. Values for standard Synergy

Cables ADSS cables are given in the table at the end of this

document.

After the cable is pulled in, it is placed in the pole hardware

under tension. This tension, referred to as the span tension,

is calculated for each cable to achieve a 1% installation sag

at different environmental conditions. Such conditions are

defined as Light, Medium and Heavy, reflecting different wind

velocity and ice buildup on the cable. The span tensions for

Light, Medium and Heavy conditions are given in the table at

the end of this document.

3.2 Minimum Bend Radius

Excessively sharp bends can damage the fibers in fiber optic

cables. The minimum bend radii for both tensioned and no-

tension conditions are found on the cable specification sheet.

As a general rule, the minimum bend radius for a non-

armored cable is as follows:

Cable under load - 20 times the nominal outside

diameter of the cable

Cable under no load -10 times the nominal outside

diameter of the cable.

3.3. Installation Methods

Two basic installation methods are commonly used:

Moving Drum Method: When a cable is pulled directly

from the cable drum mounted on a moving vehicle as it

drives along the pole line. The cable drum must be mounted

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 3

TEC Division

on a proper support to allow easy cable pay off. This method

is described in Section 6 below.

Stationary Drum Method: In the stationary drum method

of aerial cable installation, the cable is pulled along the cable

route through temporary support hardware installed for this

purpose. This method is described in Section 5 below. The

Stationary Drum installation method is more time consuming

than the Moving Drum Method.

A complimentary installation technique is often used where

the cable is coiled on the ground in figure-eight

configuration. This technique is often used in order to pull

the cable in both directions from a central location.

Alternatively it is used when switching from the moving drum

installation method to the stationary drum installation

method.

The figure-eight configuration is shown in Figure 1. The

Figure-Eight coil should measure at least 10 m by 5 m and

be protected from passersby.

Figure 1: Laying down a cable in figure eight

configuration

When long lengths of cable need to be unreeled, there is a

danger that the weight of the coils may damage the cable at

the bottom. This can be prevented by spreading the cable

out into several figure-eight coils as shown in Figure 1.

In order to pull from a figure-eight coil, it is sometimes

necessary to turn it over to expose the cable end. This task

usually requires three persons, one at the center and one at

each end.

3.4 Cable Drum Care and Inspection

Leave the protective covering on the drum intact until it

arrives at the installation site. Upon removal of the

protective covering, inspect the cable jacket for signs of

damage.

If the covering has been previously removed, secure the

cable end(s) during transit to prevent damage. Cable

drums should be stored vertically on their flanges and

chocked to prevent rolling.

Synergy Cables recommends measuring the fiber

attenuation in the cable just prior to installation using an

Optical Time Domain Reflectometer (OTDR).

Make sure to have on hand the data sheet for the

specific cable to be installed in order to have first hand

information about its mechanical properties.

During installation, periodically inspect the reel to ensure

that the through-bolts do not loosen. Tightening them

will ensure that the cable pays off the drum correctly.

4. Planning and Preparation

Prior to beginning an aerial cable installation, careful

planning and preparation are necessary. Representatives of

each organization potentially affected by the installation

(utilities, street department, police, etc.) should be present

during the route survey. Approval by all necessary parties

should be secured before detailed planning begins. A few of

the issues to be considered are listed in the following

paragraphs. Planning should be undertaken jointly by

construction and engineering personnel. Hardware

requirements should also be considered at the planning stage.

4.1 Route Planning, Pole Selection and

Authorization

Determine the ability of existing pole lines and guys to

support the new cable, as well as any restrictions

imposed by the pole owner. The anchoring and guying

of the cable is crucial for its safe operation. Ideally, the

guying should remove all of the lateral stress on each

pole so that the pole simply supports the weight of the

cables, hardware and equipment attached to it. Your

companys normal specifications concerning anchoring

and guying of poles should be followed.

Set new poles only when there is no existing utility and

when a reasonable alternate route does not exist.

Written permission must be obtained from the proper

authorities before placing new poles, and all other

utilities having underground plant in the area must be

contacted so they can locate and mark their facilities

prior to new pole placement.

Examine the ability of existing dead-end poles to

withstand the temporary stresses of installation. Because

it is impractical to tension each of the spans along the

route simultaneously, a dead-end pole will be subjected

to an unbalanced load as the cable is tensioned on one

end of the cable run before the other. This temporary

unbalanced loading can be relieved by placing temporary

guy wires on tangent poles where there is no down guy.

Determine whether temporary guying is needed

according to your companys standard route engineering

guidelines.

Ensure proper clearance from electric power lines and

other cables that may sag near the fiber optic cable.

Determine the clearances between the proposed fiber

optic cable plant and existing facilities on a case-by-case

basis by referring to local safety codes, and your

companys standard operating procedures.

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 4

TEC Division

4.2 Installation Planning

Planning the actual installation should take place only after a

thorough route survey. The installation method to be used

(Moving Drum or Stationary Drum) will be largely dictated by

the cable route. On occasion, it may be necessary to use

both methods. With the proper installation hardware, any of

these methods can be used to install Solo ADSS cable.

4.3 Splice Locations and Cable Slack

Requirements

Select splice locations during the route survey and make

plans for slack and splice closure storage. Splice

locations should be placed to allow for the longest

possible continuous cable spans and a minimum number

of splices.

The splice points should be chosen to facilitate the later

splicing operation and should be easily and conveniently

accessible to a splicing vehicle.

The amount of slack cable left at each splice point must

be sufficient to reach from the poles height to the

planned splicing vehicle location on the ground. An

additional 5 meters should be added onto this length to

allow for closure requirements (Figure 3). This slack

should be allowed for when planning the route and

ordering cable. Leave sufficient slack at each future drop

point to allow for splicing.

4.4 Pole Hardware

ADSS cable installations require a special tangent assembly

or a mechanical dead-end at each pole. Use the following

guidelines to identify the hardware needs of each pole:

Line offset of 0 to 20 (horizontal or vertical) require

fiber optic tangent assembly (Figure 2)

Line offset >20 (horizontal or vertical) or at the ends of

the cable require fiber optic dead-end (see Figure 3).

The cable must be properly tensioned as described in Section

7 before it is permanently secured into the tangent

assemblies and dead-end fixtures. Section 8, ADSS Cable

Hardware, provides guidance on installation of pole hardware.

Figure 2: Fiberoptic Tangent Assembly

Figure 3: Dead-ends are needed for line offsets more than 20

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 5

TEC Division

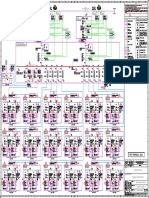

Figure 4: Stationary Drum Installation Method

5. Stationary Drum Installation Method

In the stationary drum method of aerial cable installation, the

cable is pulled along the cable route through temporary

support hardware installed for this purpose (Figure 4). When

the cable is in place between splice points, the cable is

tensioned and terminated at each dead-end pole along the

route. The cable spans are then lifted out of the temporary

support hardware and placed in tangent clamps at each

intermediate pole.

The stationary drum method is generally slower and more

costly than the moving drum method, but can be used

anywhere since it does not require an unobstructed right of

way or vehicular access to the pole line. Higher costs are

imposed by the difficulty of coordinating the pulling operation

over the length of the route.

5.1 General Considerations

Determine the cable drum and pull locations, each of

which can be at any point along the route. The location

of the cable drum and any subsequent intermediate pull

points must be determined during the route survey.

Some of the factors to consider are:

o Where significant elevation change occurs along the

route, it is usually best to pull downhill.

o The cable drum location should be accessible by the

drum carrying truck, but removed from vehicle and

pedestrian traffic.

By using the figure-eight coiling procedure, cable from

one drum can be pulled in both directions from a central

point. The route can be subdivided into shorter pulls to:

o Keep the pulling tension below the cables rated

strength.

o Avoid pulling across sharp turns.

o Provide cable slack at designated points to allow for

future drops.

o Compensate for insufficient temporary support

hardware or personnel to cover the entire route.

o Installation time will be minimized if drums can be

set up for continuous pulls in both directions from a

splice point.

o To prevent damage to the cable during payoff:

Keep the cable drum leveled to avoid cable rubbing

against the drum flanges.

o Orient the cable drum so that the natural payoff

direction is directly towards the first pole.

o Pay out the cable from the top of the drum as

shown in Figure 4 to eliminate possible cable

contact with the ground.

5.2 Temporary Support Hardware

Temporary support hardware must be selected and

placed so as to maintain the cables minimum bend

radius throughout the route and to prevent the cables

entanglement on obstructions in the right-of-way.

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 6

TEC Division

5.3 Stringing Block Placement

Hang the proper stringing block on each pole or support

structure. 50 cm (or greater) blocks should be used for

any offset poles 10 and 20 cm blocks utilized for

straight line poles (Figure 5).

On poles with an offset greater than 10, elevate the

block by securing a rope to the shackle to ensure proper

retention of the cable in the block. Attach the rope to

one bottom pin of the shackle, bring the rope above the

attachment point and back down to the opposite shackle

pin (Figure 6).

Figure 5. Stringing Blocks

5.4 Pulling Operation

The pull can be accomplished by using a cable pulling

winch. Care must be taken not to exceed the cables

rated pulling strength. Use a tension monitoring or

limiting winch or install a break-away swivel properly

rated for the cable between the pulling line and the

cable (Figure 7).

Figure 7. Swivel and pulling grip

During the pull, sufficient personnel should be on hand

to monitor the entire pull route. Two-way

communication should be established between the pull

point, the cable drum location, and each of the route

observers.

Start the pull very slowly as the cable is drawn from the

drum at ground level up through the temporary support

hardware located atop the first pole. Once the cable end

is past the first pole, the pulling speed can be gradually

and steadily increased. If sufficient support hardware is

in place, pulling speeds on the order of 50 m per minute

are typical.

Observers at the pull point drum location and along the

pull route must be alert for any condition which might

cause cable damage and be able to stop the pull

immediately if any damaging conditions are observed:

o Avoid exceeding the cables rated pulling strength

and bending the cable beyond its minimum bend

radius.

o Control the unreeling of the cable either by hand or

with a cable drum brake in order to prevent free-

running or jerking of the cable.

o At the pull point, winch the cable so as to prevent

either free-running or jerking of the cable. If either

is observed, the pull must be halted until the cause

is eliminated.

Excessive oscillation or surging of the cable can be

damaging. Reduce the pulling speed or add additional

temporary support hardware to minimize these

conditions.

When the cable reaches the pull point, do not allow it to

engage the winch unless the winch maintains the cables

minimum bend radius.

Pull the amount of cable specified in the route plan and

pull plan. This amount should include all slack

requirements as outlined above.

When the cable has been pulled into place as specified

by the route plan:

o Install a dead-end on one end of the cable span at

the cable drum end as outlined in Section 8.

o Complete any pole modifications or additional

temporary / permanent guying, as well as the

installation of the dead-end and tangent clamp pole

fixtures (see Section 8).

o Proceed to Section 7 for instructions on tensioning

and terminating the cable.

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 7

TEC Division

Figure 8: J -hook

6. Moving Drum Installation Method

In the moving drum method, the cable is paid off of a

moving vehicle as it drives along the pole line. As the vehicle

passes each pole, the cable is raised into place and into a J-

hook (Figure 8) or block fitting for temporary support. This

procedure progresses down the

pole line until a dead-end pole is

reached.

At this point the cable is

tensioned and terminated into

dead-end fittings. The cable

between dead-ends is then lifted

out of the temporary fittings at

each of the inter-mediate poles

and placed in permanent tangent

assemblies.

Note: Some tangent assemblies

are designed to allow a cable to

be placed in them during the

moving drum method. After the

cable is span tensioned, an insert is placed in the assembly to

secure it. (Figure 9)

Figure 9. Tangent assembly

In most cases, the Moving Drum method is the fastest and

least expensive method of installing aerial cable. Pole-

mounted hooks are the only temporary support devices

required and fewer personnel are required than by other

methods. However, this method requires vehicular access to

the placement side of the pole line and a right-of-way clear

of tree limbs, guy wires, and other obstructions.

Begin the installation with the drum-carrying vehicle

about 15 meters from the pole and facing away from it

down the pole line (Figure 10). The cable must pay off

the top of the drum towards the rear of the vehicle.

Pull off the necessary amount of slack as specified above.

Prepare the cable and install the dead-end as specified

in Section 8.

Lift the dead-end to the top of the pole and mount on

the pole fixture. It may also be necessary to pay out

additional length as the cable is lifted.

Figure 10. Moving drum installation set up

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 8

TEC Division

Slowly drive the drum-carrying vehicle down the

placement side of the pole line, paying out cable off

the back of the truck. Once the drum is

approximately 15 meters past each pole, lift the

cable up the pole and place it in a J-hook or block

fitting (Figure 11).

Once the cable drum reaches the end of the span, lift

the cable to its assigned position on the dead-end

pole.

Complete any pole modifications or additional

temporary / permanent guying.

Proceed to Section 7 for instructions on tensioning

and terminating the cable. The sequence in which

the cable sections are tensioned and dead-ended is

unimportant as long as a central pole is not

converged upon from both directions.

After the cable sections are properly tensioned and

secured into dead-ends at both ends of the cable

span:

o Lift the cable out of the J-hooks / blocks at each

intermediate pole.

o Secure the cable in a tangent assembly on each

pole as described in Section 8.

Figure 11. Moving drum installation

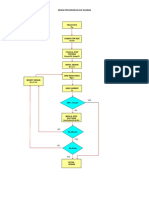

7. Cable Tensioning

Caution

Proper measuring of tension is critical for a safe

installation of aerial plant. Please read and understand all

of Section 7 before attempting to apply tension to the

cable.

7.1 General

After the proper amount of cable has been placed in

temporary support hardware between the dead-end poles,

the cable must be properly tensioned before it is

permanently secured into tangent assemblies.

With a dead-end fitting already in place on one end of the

span, the cable is tensioned by pulling on its opposite

free end with a chain hoist, using the set up shown in

Figure 12.

Once the cable sections are under the required tension,

the free end of the cable is terminated into a dead-end

described in Section 8.

7.2 Tensioning Operation

Note: Before beginning this stage of the installation, any

pole modifications or additional temporary / permanent

guying must be completed.

Proceed to the end of the cable section which does

not have a dead-end fitting already in place from the

cable installation procedure. Pull out all cable slack

between the dead-end poles.

Install a temporary dead-end (as described in Section

8) approximately 3 to 4 meters away from the pole.

Set up the temporary dead-end, a chain hoist, an in-

line dynamometer, and other hardware as shown in

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 9

TEC Division

Figure 12. Typically, the chain hoist is strapped to

the dead-end pole. Specific operation of the chain

hoist should follow manufacturers recommendations.

Apply tension to the cable with the chain hoist.

During the tensioning operation, do not exceed the

limits of maximum allowed pulling tension for the

cable and the strength of the poles themselves. For

long spans under high tension, it may be necessary

to use two chain hoist temporary dead-end set-ups in

succession to take out the slack and achieve the

necessary tension.

The tension can be initially monitored at the dead-

end pole with the dynamometer shown in Figure 12.

When tensioning several straight spans (with few

offsets), it may be necessary to use false dead-ends

even though the pole offset is less than 20 (Figure

13). This may be necessary to ensure that a 1%

installation sag is maintained for all spans. Friction

built up on some of the blocks or J-hooks on the far

end of the tensioning operation may cause greater

than 1% sag in those spans.

The number of spans between false dead-ends will

vary, depending on the route and span lengths, but

up to 20 straight pole spans are typical before false

dead-ends should be used.

Once the cable section is under the required tension,

terminate the cable into a dead-end as described in

Section 8. The dead-end should be placed on the

cable where it reaches the pole fixture, unless

allowances are being made for grade changes or

turns.

Figure 12. Tensioning equipment

7.3 Tensioning Across Turns and Grade

Changes

Caution

As the cable is placed under tension, weaknesses in the

cable plant can cause failure of pole fittings, support

hardware or even the poles themselves.

The risk of death or injury due to such failures is best

minimized by keeping all but essential personnel clear of

the tensioning operation. Nobody should be allowed to

climb intermediate poles as the span they support is

being placed under tension. If possible, passersby on the

ground should be kept away from the poles during this

operation.

Within the cable bend radius and limitations discussed in

Section 3, the cable section may extend across turns and

grade changes in the pole line. Since an ADSS cable is

normally placed in the permanent support hardware after

tensioning, any change in pole line direction complicates

the process. Two possible cases are discussed below.

a) Cable on inside of turn:

As the cable in this situation is tensioned, the cable will

naturally tend to pull inside of the corner pole. A

horizontally mounted stringing block (per Figure 6) will

keep separation to a minimum.

Tension the cable in stages:

Tension the cable to the degree planned from the

dead-end pole.

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 10

TEC Division

While monitoring the tension, move the cable from

the temporary support hardware at the inside turn to

the cables permanent support hardware on the pole.

As the cable is pulled out to the pole, tension will

increase. Take care not to exceed the maximum

pulling tension of the cable or the capacity of the

poles and hardware. It may be necessary to relieve

tension by backing off with the chain hoist at the

dead-end pole. Continue this process until the cable

is in place on the pole at the inside turn.

b) Cable on the pole at a grade change:

The procedure used to tension the cable across a

change of grade is similar to that used on an inside

turn. The cable will pull up or down, depending on

the direction of the grade change, rather than

horizontally as in the case of an inside turn.

Temporary support hardware must be mounted

accordingly.

Caution

Temporary support hardware used to restrain a cable

being tensioned will be subjected to a significant portion

of the cables tensile loading and must be mounted

accordingly.

Do not allow personnel on the inside turn pole while

tension is being increased at the dead-end pole. If

personnel are sent up the inside turn pole, they must stay

on the pole side opposite the cable.

8. Vibration Damping

Vibration dampers must be installed at the same time the

cable is clipped in to suppress Aeolian vibration which can

be induced by local environmental conditions. Experts in

the field state damage caused by Aeolian vibration is at its

peak in the first 24 to 48 hours after sagging and dead

ending than at any other period in the life of the cable

Spiral vibration dampers are recommended to be used on

all ADSS installations where voltages are below 230 kV.

These type dampers are very effective in damping. They

do not cause damage to the ADSS cable sheath. Since they

don't require patch rods they are easy to install and are

very economical.

9. Hardware

Synergy Cables does not recommend a specific hardware

manufacturer. It is important, though, to use high quality

hardware from reputable manufacturers in order to

assure a long term reliable and safe ADSS cable

installation.

In order to select the proper product the installer must

know the following:

nominal outside diameter of the cable

degree of offset from one pole to the next

maximum cable tension under fully loaded conditions

When ordering dead-ends, it is important to ensure

that all other necessary pole hardware is ordered.

(see Figure 13) These items include:

o thimble clevis

o eye nuts

o extension links (to maintain cable minimum bend

radius)

Determine the proper attachment location of the

cable on the poles. Mark the location of the

attachment point on the cable with a wrap of tape.

Drill the appropriate holes in wooden poles or apply

band attachments to concrete or metal poles and

mount supporting hardware accordingly.

Refer to the manufacturers recommended

procedures for installation.

Use vibration dampers to minimize wind effects.

Figure 13. False dead-end

Website: www.Synergy-Cables.com E-Mail: export@synergy-cables.com Synergy Cables Ltd.

Page 11

TEC Division

Mechanical Parameters of Synergy Cables ADSS Cables

Wi nd Condi ti ons

( 3 )

Light Medium Heavy

Number

of

Elements

Cable

Weight

(kg/ km)

Cable

Diameter

(mm)

SPAN

(m)

I nstallation

Tension

(N)

(2)

ADS Series

Sag

(m)

Span

Tension (N)

Sag

(m)

Span

Tension (N)

Sag

(m)

Span

Tension

(N)

105 11.5 30 400 0.16 1230 0.48 1600 0.66 2370

40 525 0.22 1540 0.69 1970 0.95 2940

60 800 0.37 2100 1.16 2650 1.6 3900

70 860 0.46 2300 1.42 2930 2.27 4320

80 985 0.54 2560 1.68 3240 2.33 4755

100 1255 0.71 3040 2.25 3820

120 1520 0.89 3500 2.80 4380

135 1785 1.01 3870 3.23 4810

2-30

ADSB, 5

Elements

150 1920 1.16 4170 3.70 5180

120 12.7 30 425 0.16 1310 0.49 1650 0.67 2430

40 570 0.23 1630 0.71 2030 0.96 3000

50 715 0.30 1940 0.94 2400 1.28 3530

60 845 0.38 2220 1.17 2750 1.62 4020

70 990 0.45 2520 1.43 3080 1.97 4500

80 1120 0.54 2780 1.69 3390 2.35 4990

100 1500 0.70 3340 2.22 4050

120 1780 0.88 3840 2.79 4628

135 1936 1.02 4150 3.26 5020

32-60

ADSC, 5

Elements

150 2200 1.16 4530

125 12.7 30 443 0.16 1320 0.50 1640 0.67 2.44

40 580 0.24 1640 0.71 2040 0.97 3000

50 795 0.30 2000 0.92 2470 1.26 3590

60 950 0.38 2300 1.16 2800 1.60 4080

70 1085 0.46 2570 1.42 3130 1.96 4540

80 1240 0.54 2850 1.68 3450 2.32 5000

100 1530 0.72 3350 2.22 4070

120 180 0.90 3830 2.80 4650

135 2080 1.04 4220 3.23 5100

62-72

ADSC, 6

Elements

150 2340 1.18 4600

180 14.2 30 580 0.17 1500 0.5 1800 0.67 2590

40 820 0.24 1890 0.7 2260 0.96 3220

50 1000 0.32 2220 0.94 2630 1.28 3770

60 1220 0.4 2600 1.17 3060 1.61 4330

70 1400 0.49 2890 1.42 3415 1.97 4820

80 1640 0.57 3240 1.67 3800

100 1960 0.76 3790 2.23 4450

120 2360 0.94 4390

74-96

ADSC, 8

Elements

135 2640 1.09 4800

220 16 30 834 0.19 1730 0.49 2015 0.66 2810

40 1100 0.27 2150 0.70 2500 0.94 3500

50 1290 0.35 2500 0.93 2920 1.27 4070

60 1590 0.44 2910 1.17 3360 1.61 4660

70 1860 0.53 3290 1.40 3800 1.94 5220

80 2150 0.62 3680 1.66 4215

100 2690 0.81 4400 2.17 5030

98-126

ADSC ,10

Elements

120 3250 1.00 5114

280 17.2 30 1030 0.21 1910 0.49 2200 0.66 3030

40 1340 0.29 2380 0.71 2710 0.95 3720

50 1720 0.37 2900 0.91 3280 1.25 4400

60 2030 0.47 3300 1.15 3740 1.58 5030

70 2440 0.56 3800 1.38 4270

80 2750 0.65 4215 1.62 4725

122-144

ADSC, 12

Elements

100 3470 0.85 5070

1. Values shown are for KP jacket design. Other cables available upon request,

2. 1% Sag at installation

3. NESC Light Medium Heavy

Ice (mm) 0 6.5 12.5

Wind (km/hr) 94.4 62.8 62.8

Extra (N/m) 0.7 2.5 4.4

Vous aimerez peut-être aussi

- Request For Information Log V1Document2 pagesRequest For Information Log V1Comsip400Pas encore d'évaluation

- Molecular Basis of Inheritance: DNA and RNA Structure, Packaging and FunctionDocument22 pagesMolecular Basis of Inheritance: DNA and RNA Structure, Packaging and FunctionComsip400Pas encore d'évaluation

- The Indian School Kingdom of Bahrain Department of Physics Practice Paper On Objective Type (One Marke Each) Questions Class Xii PhysicsDocument7 pagesThe Indian School Kingdom of Bahrain Department of Physics Practice Paper On Objective Type (One Marke Each) Questions Class Xii PhysicsComsip400Pas encore d'évaluation

- Notes: International Power SaDocument1 pageNotes: International Power SaComsip400Pas encore d'évaluation

- KumarDocument27 pagesKumarComsip400Pas encore d'évaluation

- KumarDocument29 pagesKumarComsip400Pas encore d'évaluation

- KumarDocument20 pagesKumarComsip400Pas encore d'évaluation

- Ipp Limit: Reference DrawingsDocument1 pageIpp Limit: Reference DrawingsComsip400Pas encore d'évaluation

- KumarDocument20 pagesKumarComsip400Pas encore d'évaluation

- Document Title TP Document No. Revision Project Title Contract Number Contractor Doc No. Con. Doc. RevisionDocument15 pagesDocument Title TP Document No. Revision Project Title Contract Number Contractor Doc No. Con. Doc. RevisionComsip400Pas encore d'évaluation

- CIDC Model EPC Agreement 22032018Document342 pagesCIDC Model EPC Agreement 22032018Chetan Kumar jainPas encore d'évaluation

- 33Kv Main Gis MV Panel Loc: Switchgear Room (MCR) : To Amin 132Kv Switchyard (Pdo) To Amin 132Kv Switchyard (Pdo)Document1 page33Kv Main Gis MV Panel Loc: Switchgear Room (MCR) : To Amin 132Kv Switchyard (Pdo) To Amin 132Kv Switchyard (Pdo)Comsip400Pas encore d'évaluation

- Guide To Fuse SelectionDocument20 pagesGuide To Fuse SelectionBrenda Naranjo MorenoPas encore d'évaluation

- KumarDocument36 pagesKumarComsip400Pas encore d'évaluation

- Draft: Installation & Maintenance Manual Neutral Earthing ResistorsDocument6 pagesDraft: Installation & Maintenance Manual Neutral Earthing ResistorsComsip400Pas encore d'évaluation

- 9.3 UMB-Config-Tool - Manual - en PDFDocument27 pages9.3 UMB-Config-Tool - Manual - en PDFComsip400Pas encore d'évaluation

- Fidic Letters by ContractorDocument77 pagesFidic Letters by ContractorMajid Hassen83% (54)

- HLL Container Specification Engl PDFDocument54 pagesHLL Container Specification Engl PDFSzilárd SzabóPas encore d'évaluation

- KumarDocument10 pagesKumarComsip400Pas encore d'évaluation

- KumarDocument16 pagesKumarComsip400100% (1)

- KumarDocument60 pagesKumarComsip400Pas encore d'évaluation

- KumarDocument49 pagesKumarComsip400Pas encore d'évaluation

- KumarDocument60 pagesKumarComsip400Pas encore d'évaluation

- KumarDocument2 pagesKumarComsip400Pas encore d'évaluation

- KumarDocument9 pagesKumarComsip400Pas encore d'évaluation

- Lightning Strike Counter: Lightning Protection Equipment CatalogDocument1 pageLightning Strike Counter: Lightning Protection Equipment CatalogComsip400Pas encore d'évaluation

- Cooper - Intrinsic Safety GuideDocument20 pagesCooper - Intrinsic Safety Guidetkdrt2166100% (2)

- Models: Terrastreamer Early Streamer Emission (Ese) TerminalsDocument1 pageModels: Terrastreamer Early Streamer Emission (Ese) TerminalsComsip400Pas encore d'évaluation

- V2i12 Ijertv2is120210Document7 pagesV2i12 Ijertv2is120210KarthikeyanKarthikPas encore d'évaluation

- Protection Radius: The ESE PrincipleDocument1 pageProtection Radius: The ESE PrincipleComsip400Pas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Section 3000 Fiber OpticsDocument16 pagesSection 3000 Fiber Opticstouchme cityPas encore d'évaluation

- Opx-Box: Platform Highlights Software SupportDocument5 pagesOpx-Box: Platform Highlights Software SupporthoainamcomitPas encore d'évaluation

- OTU-8000 Optical Test Unit: Rack-Mounted Fiber Test For Backbone, Metro, and Access NetworksDocument2 pagesOTU-8000 Optical Test Unit: Rack-Mounted Fiber Test For Backbone, Metro, and Access Networksvijay_786Pas encore d'évaluation

- Tier-2 Optical Time Domain Reflectometer For Multimode and Single-Mode Fibre CablingDocument6 pagesTier-2 Optical Time Domain Reflectometer For Multimode and Single-Mode Fibre Cablingsorangel_123Pas encore d'évaluation

- OLTS and OTDRDocument5 pagesOLTS and OTDRCandyPas encore d'évaluation

- Longitudinal Ship's Hull Strength Monitoring With Optical Fiber SensorsDocument4 pagesLongitudinal Ship's Hull Strength Monitoring With Optical Fiber SensorsMahdiPas encore d'évaluation

- Automation Design Instructions For Substation Communication SystemsDocument36 pagesAutomation Design Instructions For Substation Communication SystemssabeerPas encore d'évaluation

- FOCLaying ProceduresDocument10 pagesFOCLaying ProceduresjahanzaibPas encore d'évaluation

- Digitronf-Srt004-Rev02 Test ManualDocument10 pagesDigitronf-Srt004-Rev02 Test Manualzym3344Pas encore d'évaluation

- Qualifications Pack - Occupational Standards For Telecom IndustryDocument36 pagesQualifications Pack - Occupational Standards For Telecom Industrysergio sabPas encore d'évaluation

- Cable Route Survey DictionaryDocument18 pagesCable Route Survey DictionaryginziroPas encore d'évaluation

- FOC Test MCB To SBDocument42 pagesFOC Test MCB To SBMuhammad Ashraf KadabaPas encore d'évaluation

- Tia TSB 140 2004Document28 pagesTia TSB 140 2004k1gabitzu9789Pas encore d'évaluation

- Optical - Time Domain Reflectometry PDFDocument0 pageOptical - Time Domain Reflectometry PDFmentongPas encore d'évaluation

- 1finity C200 Series Communications Integrators: Data SheetDocument3 pages1finity C200 Series Communications Integrators: Data SheetNguyen Vu Hoang ThachPas encore d'évaluation

- FLU OPTIFIBER ManualDocument116 pagesFLU OPTIFIBER ManualKojiro HadatePas encore d'évaluation

- How To Do OTDR Testing For FOC - V2Document39 pagesHow To Do OTDR Testing For FOC - V2Aung Thein OoPas encore d'évaluation

- OFO Installation Guidelines For ADSS Cables V6 PDFDocument27 pagesOFO Installation Guidelines For ADSS Cables V6 PDFUdriste DanielPas encore d'évaluation

- Otdr TrainingDocument31 pagesOtdr TrainingKenneth GarciaPas encore d'évaluation

- OTDR Application Trace Fiber Losses LengthDocument4 pagesOTDR Application Trace Fiber Losses LengthHarrish GunaPas encore d'évaluation

- Fiber Optic CableDocument182 pagesFiber Optic CableNik Mohd Hasani100% (3)

- Optical Time Domain Reflectometer SimulatorDocument3 pagesOptical Time Domain Reflectometer SimulatorSteven YoungPas encore d'évaluation

- Fiber Optic System Testing Tutorial: AEN 135, Revision 2Document11 pagesFiber Optic System Testing Tutorial: AEN 135, Revision 2Jose Luis ZimicPas encore d'évaluation

- Fiber OWL 4 ORL Optical Return Loss Meter: Operations GuideDocument49 pagesFiber OWL 4 ORL Optical Return Loss Meter: Operations GuideaustintanPas encore d'évaluation

- Fiber ITPDocument17 pagesFiber ITPDennis DahlPas encore d'évaluation

- Anritsu Understanding OtdrsDocument60 pagesAnritsu Understanding OtdrsMathieu Bolle100% (3)

- Optical Fibers - Optical Attenuation Variation - Method of TestDocument8 pagesOptical Fibers - Optical Attenuation Variation - Method of Test张骏Pas encore d'évaluation

- Optical Fiber Fusion Splicer Product ManualDocument22 pagesOptical Fiber Fusion Splicer Product ManualDemian HessePas encore d'évaluation

- Etisalat Design Guide-Jan 2013 PDFDocument26 pagesEtisalat Design Guide-Jan 2013 PDFamylyPas encore d'évaluation

- Final Varia OFC IDH-BayanaDocument22 pagesFinal Varia OFC IDH-BayanasrdsoseePas encore d'évaluation