Académique Documents

Professionnel Documents

Culture Documents

Design Control Room

Transféré par

wq22030202Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design Control Room

Transféré par

wq22030202Droits d'auteur :

Formats disponibles

D De es si ig gn ni in ng g C Co on nt tr ro ol l R Ro oo om ms s f fo or r H Hu um ma an ns s

Page: 1

This article was originally published in www.contrglobal.com Issue Date: July 2004, Posted 7/10/2004

By Ian Nimmo and John Moscatelli

Todays work environment has been revolutionized by PCs and PC workstations. The most dramatic

changes have taken place in industrial control centers and control rooms. Control rooms, traditionally

used for sharing instrumentation information, have evolved from large panels with support

instrumentation in adjacent rooms, to modern control buildings that support people interfacing with

computers. This change has impacted the way these buildings are designed and has introduced a new

discipline called Human Factor Engineering (HFE).

In the past, the only human factor influencing control room design was the grouping of instruments to

support pattern recognition. This scheme allowed operators and engineers to maintain the big picture of

the process under control. Sometimes the designers followed another simple human factors guideline that

dictated a minimum and maximum height for instrument mounting, somewhere between 4070 in. from

the floor, so the typical operator could read all the instruments without having to stoop or stretch.

Unfortunately for processors, the vast majority of the control panels were not designed by human factors

engineers, but by instrumentation engineers, unfamiliar with the finer points of ergonomics.

Instrument engineer-designed panels do have some redeeming featuresmany of which readers should

be familiar with, including the ability to recognize patterns and quickly identify process changes.

Similarly well-known to veteran processors was the ability to identify trends by pen marks in the folds of

plotter paper, and the enforcement of a low number of alarms due to cost and space limitations.

Unfortunately, most did not recognize these positive aspects of traditional control interfaces during the

transition from analog instrument-based control to digital (computer) control. Much of this was lost

during the transition to first and second-generation Distributed Control System (DCS) control room

designs. During that period, some processors also lost the ability to effectively share control and process

information among operators (both field and control room), supervisors, engineers and managers.

The House Instruments Built

The building that housed the control room was designed with the instrumentation in mind, and then, later,

DCS equipment. The primary and secondary users of the building were often an afterthought and had to

live within the constraints of the design. Often kitchens, and even restrooms, were not originally planned,

so space for operator comfort was adapted where available.

First generation DCS-based control room plans were adapted from buildings designed to accommodate

the 50-year old control panel. The result? Long, thin, crowded control rooms with poor console

adjacencies and poor traffic patterns. Typically, these control rooms were located in the field, with the

redundant instrument panel in the background (Figure 1).

D De es si ig gn ni in ng g C Co on nt tr ro ol l R Ro oo om ms s f fo or r H Hu um ma an ns s

Page: 2

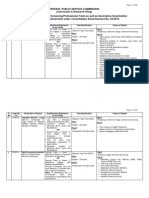

Figure 1: First Generation Control Room

(Left) Long, narrow control rooms with bad lighting, (Below) The typical industrial control panel:

complicated, busy, but mostly understandable.

Second-generation control rooms were often characterized by their

independence from field instrumentation; as witnessed by the

appearance of the first consolidated control rooms. The advent of

electronics permitted greater distances between the field instruments

and the previous-generation control rooms, but the instrument

engineer still dominated their design.

Operating consoles were usually off-the-shelf designs supplied by the

same instrumentation vendors who produced DCS equipment. This

technology was big, bulky, noisy, and did not adhere to modern ergonomic design considerations. Hence,

support equipment such as hardwired alarms, phones, public address systems, and PCs were difficult to

incorporate into the layout of the room. All of these things were just bad add-on accessories.

It was during this stage of control room design evolution that industry trade associations and regulators

began to realize that the layout of the room, the control interfaces it encompasses and the building its

housed in, have a great impact on an operators performance.

When we look at human reliability we discover that even on a good day, seemingly innocuous elements

of the work environment can stress the operator. Common maladies such as headaches, eye strain and

sleep-related problems often have root causes traceable to such factors as glare from poorly designed

lighting systems; poor temperature and humidity control; bad air quality; and poorly maintained

buildings.

Adding to the woes of the operator are poor workspace design, an environment aggravated by

uncomfortable consoles, keyboards, chairs and noise. Often excessive, noise generated by console fans,

panel alarms, radio/PA speaker interference and constant radio communications all contribute to poor

ambient conditions.

These environmental factors are exacerbated by a poorly implemented DCSs. Many systems are plagued

with issues that make it very difficult for an operator to detect, diagnose and respond to in an abnormal

situation. These issues commonly include excessive and undisciplined use of alarms that obscure more

critical alarms; poor user interfaces that make it difficult to recognize changes and perceive important

D De es si ig gn ni in ng g C Co on nt tr ro ol l R Ro oo om ms s f fo or r H Hu um ma an ns s

Page: 3

deviations; and poor navigation, forcing operators to spend precious time flipping through displays to find

critical data.

One-Trick Pony

The workstation is often designed for one specific taskinterfacing with the DCSand thus has no

capacity for other duties such as report writing or training. Similarly, there are often few, or inadequate

facilities for using and storing manuals and communication equipment. Other ergonomic problems

include broken or patched chairs, furniture never designed for 24-hour operations and no rest/recovery

strategies incorporated into control room design. Resourceful operators often find ways of taking a break

or getting some exercise, but few control room environments take into account operator downtime or well

being into the design (Figure 4).

Distractions are myriad and create one of the most common environmental problems for operators.

Distractions can come from anywhere: poor traffic flow through the building, non-essential personnel

congregating in the control room; undisciplined telephone traffic; auxiliary equipment noise; doors

opening; alarms sounding; other operators talking on the radio, etc. The list is endless but the point is

distractions in the control room are not conducive to trouble-free operations.

To Err is Human

Human errors, such as those that led to the Texaco Pembroke incident, have forced the processing

industry to respond by changing the way they design and build control rooms. Standards organizations

have also started to produce guidance and best practices for building design. The industry has recognized

that many of the systems used within the control room need to be addressed ergonomically using a

human, or a user-centered design approach (Figure 2). ISO 11064 part 1 Ergonomic Design Principles for

the Design of the Control Center reads in part:

The combination of human and machines, in its organizational and environmental context, is considered

as an overall system to be optimized. The optimization is achieved by developing solutions that

emphasize and maximize the strengths, features and capabilities of both humans and machines in a

complimentary fashion. The human component, the machine (hardware and software), the work

environment, and the control (operation and management) shall be harmonized integrated during all

phases of the design process, conceptual and detailed design, assembly and construction, commissioning,

user training and operations.

Figure 2: User-Centered Design Approach

Future control rooms, like the one shown here by Galen Cranz, Dept. of Architecture, University of

Calif., follow ISO 11064 design guidance on workstation groupings, spacing requirements and visual

display locations.

Worldwide industrial practice has evolved to build new control buildings that will withstand a worst-case-

scenario incident and still protect the inhabitants of the building. However, with the growth in

centralization and the flexibility to move the building anywhere, industry has responded by moving non-

critical people outside the battery limits and into a safe area. The API Guidelines Management of

D De es si ig gn ni in ng g C Co on nt tr ro ol l R Ro oo om ms s f fo or r H Hu um ma an ns s

Page: 4

HAZARDS Associated with Location of Process Plant Buildings, Recommended Practice 752 provides

advice on building structures and locating personnel, but this is not a legal requirement, and is often not

implemented in a new building project due to economic constraints.

Steps to Good Design

To generate a Functional Design Specification, ISO 11064 identifies a front-end loading methodology,

but the organization also acknowledges that many of the other work design systems required to ensure

human safety, such as health and well-being, are not fully identified or addressed by the standard.

The standards do, however, help the designer understand the use of space, considerations for workstation

layout and design, and the use of other systems such as off-workstations. The methodology is a

participatory process and uses an iterative design approach.

Regardless, important questions must be addressed before the design process is started. During the

process the designer often has to deal with additional complexity, such as changes to the number of

console operators; changes in DCS system and technology; a change in software and user interface design

capability; or correcting previous design deficiencies or incorporating recent advances in control, process

technology, operations and improved management systems.

Step 1-Identify Primary Users

Accurately defining the number of operators depends on new approaches to determining staffing levels.

Most previous control room schemes have had more operators than required, or created an unevenly

distributed work load. Operator roles and responsibilities must also be defined, and that dictates the

console operators span of control (how many operating units). The number of console operators is also

influenced by organizational and management system constraints such as training.

Step 2Identify HCI Design

Once the number of console operators has been determined, the next step in design a truly ergonomic

system is to specify the Human Computer Interface (HCI) System.

Although it is difficult at this stage of a typical project to design the HCI, it is possible to generate a

vendor independent specification which includes a graphics navigation strategy, a keyboard design and

the number of screens per console. This HCI system guidance is specified in the EEMUA 201 Human

Computer Interface Guidance document.

At this point a graphics style guide can also be developed , but will require good human factors

engineering involvement to specify foundation requirements that are needed to guide important decisions.

These decisions are based on questions such as: Will the background color for screens be a lighter gray,

or will a more traditional color such as black be used? This is important for lighting design to ensure

glare is not an issue. The last decision to make at this stage is to determine if the design will incorporate

large off-workstations, safety systems, communication systems, hardwired panels, etc.

Step 3Specify Console Requirements

With personnel and equipment requirements known, designers can determine console requirements. This

is one of the main systems requiring ergonomic design considerations. Companies commissioning new

control building and control room facilities must decide on how much investment they want to put into

the console. The choices are to continue to use one of the instrument vendors off-the-shelf consoles, use

off-the-shelf office furniture or use off-the-shelf console furniture that is designed for the control room.

Only one of these solutions will meet the international ergonomic requirements and encompass the

physical, anatomical, anthropometric, physiological, behavioral and biomechanical capabilities ins such a

D De es si ig gn ni in ng g C Co on nt tr ro ol l R Ro oo om ms s f fo or r H Hu um ma an ns s

Page: 5

way as to provide good workplace layout and design, e.g., working postures, materials handling, line of

sight and repetitive movement. Currently the U.S. regulators do not insist on human factor compliance,

however, they have tried to pass, and will continue to promote legislation in this area as the current

annual cost for shift worker fatigue exceeds $77 billion.

Step 4Specify Console Layout

Once the numbers of consoles are known, and the size and equipment requirements are specified, the

layout of the consoles in the control room needs to be specified based on communication and

collaboration requirements. This is determined by studying the process interactions and identifying

common utilities that will cause domino effects. Locating the console operators in close proximity will

promote, but not guarantee, improved communication and collaboration.

The ISO 11064 standard Part 3, Control Room Layout, provides guidance on workstation groupings,

spacing requirements and location of visual displays for best line of sight.

This is an undeveloped topic for industrial control rooms. Recent research has suggested that trying to

provide a traditional chair and table solution is doomed to failure due to the wide variation in operating

styles, and how people handle stress and fatigue. It is becoming apparent that flexibility is the main

requirement. Being able to vary posture by perching, lounging or standing are good options to supplement

the more traditional right-angle seating . With the introduction of power napping who knows were

console design may go?

The most important factor in console design is not only to meet the ergonomic standards, but to provide a

practical work environment that looks good, reduces stress and fatigue, and helps operators perform their

tasks efficiently.

The simple, low-cost solution for control room users is to specify an instrumentation vendors off-the-

shelf solution. But a few years down the road, legislation might check this common-sense tactic, forcing

users to upgrade to a more ergonomic solution, something that could be expensive, difficult and

disruptive to implement. Any savings realized by going for the low-cost solution will be lost in the

upgrade. The user company should also consider the yearly costs related to shift-worker fatigue and the

impact of human error on profitability. What looks initially like a cost effective solution is really a poor

investment.

Step 5Secondary Requirements

The next step is to identify the secondary users of the control building. They may include engineers,

supervisors and others who support activities such as training. Questions, such as whether or not issuing

work permits is to be done in this building or at some alternative facility must be addressed. Once these

issues have been identified and resolved the rooms specifications can be determined.

Figure 3: A

Practical Plan

Step 6Specifying Room Adjacency and Space

Step 6, as required by the ISO 11064 standards, is to work with users

to determine the control rooms parameters, such as space required, its

intended use, and its adjacency requirements identified as either

preferred, neutral or negative adjacency. During this phase designers

should determine the ergonomic requirements of each of the individual

rooms in the building. Lighting, noise and traffic flow should be

specified as well, and include addressing reverberation issues and

specifying windows, walls and ceilings (Figure

3).

D De es si ig gn ni in ng g C Co on nt tr ro ol l R Ro oo om ms s f fo or r H Hu um ma an ns s

Page: 6

ISO standards require designers to work with users to determine control room parameters. Lighting,

noise and traffic control are among the many elements that must be factored into a cohesive room plan so

that operators and other personnel can do their jobs accurately and safely.

Step 7Functional Requirements

This is where a knowledgeable control room architect needs to be involved in understanding and

extracting details for heating and ventilation, air circulation, specific lighting levels, and electrical/piping

and communications equipment requirements.

The International Ergonomics Association says ergonomics (or human factors) is the scientific discipline

concerned with the understanding of interactions among humans and other elements of a system, and the

profession that applies theory, principles, data and methods to design in order to optimize human well-

being and overall system performance. This is exactly what the standards are calling for; hence, industry

has to respond by re-training instrument engineers or employing trained professionals with HFE

experience to design a control room. Its not just an instrument panel anymore.

The IEA continues, Ergonomists contribute to the design and evaluation of tasks, jobs, products,

environments and systems in order to make them compatible with the needs, abilities and limitations of

people.

This is the motivation. Control rooms are about the people in them, not the equipment. Domains of

specialization within the discipline of ergonomics are broadly the following; says the IEA website

(www.iea.cc/ergonomics). Physical ergonomics is concerned with human anatomical, anthropometric,

physiological and biomechanical characteristics as they relate to physical activity. (Relevant topics

include working postures, materials handling, repetitive movements, work related musculoskeletal

disorders, workplace layout, safety and health).

These are the required skills needed to design a console. It is not a task to be left to an instrument

engineer or an architect. Cognitive ergonomics is concerned with mental processes, such as perception,

memory, reasoning, and motor response, as they affect interactions among humans and other elements of

a system. (Relevant topics include mental workload, decision-making, skilled performance, human-

computer interaction, human reliability, work stress and training as these may relate to human-system

design), the website continues.

During a control room design relevant systems such as alarm management, Human Computer Interface

Design, Staffing Assessments and dealing with training and stress management would require new skills

never before used in previous control room projects, but will provide new benefits and opportunities that

will allow a new culture and new ways of doing business.

Organizational ergonomics is concerned with the optimization of sociotechnical systems, including their

organizational structures, policies, and processes, according to IEA.

As we change the culture, the organization, staffing, technology, policies and many management systems,

the sponsors can clearly see that this is really a paradigm shift. The old way of building control rooms is

in the past and a new set of rules exist. Changing to the new paradigm is a wise decision.

D De es si ig gn ni in ng g C Co on nt tr ro ol l R Ro oo om ms s f fo or r H Hu um ma an ns s

Page: 7

Ian Nimmo is president and a founder of User Centered Design Services, an ASM Consortium affiliate

member and service provider. John Moscatelli is managing partner of User Centered Design Services.

Mr. Nimmo can be reached at inimmo@mycontrolroom.com.

For free subscription to the digital edition of Control Global magazine, delivered each month to your

email inbox go to http://www.omeda.com/cont/.

Vous aimerez peut-être aussi

- Factors For Control Room DesignDocument4 pagesFactors For Control Room DesignNeeraj Sharma100% (2)

- The Future of Control Room DesignDocument11 pagesThe Future of Control Room DesignS.KAMBANPas encore d'évaluation

- Control Centre Layout Location DesignDocument10 pagesControl Centre Layout Location Designwq22030202Pas encore d'évaluation

- Control Room Design PDFDocument6 pagesControl Room Design PDFTomas JeffersonPas encore d'évaluation

- Control Room Design ConsiderationsDocument8 pagesControl Room Design ConsiderationssuhartoPas encore d'évaluation

- Power Control Room (PCR) Guide Specification v6Document5 pagesPower Control Room (PCR) Guide Specification v6solvoltraPas encore d'évaluation

- Control Room DesignDocument2 pagesControl Room DesignChi PhamPas encore d'évaluation

- Bip 2124-2013Document221 pagesBip 2124-2013ali rabieePas encore d'évaluation

- Design and Check Certificate (El & Elv) : Drawing ID Drawing Title Rev. NoDocument2 pagesDesign and Check Certificate (El & Elv) : Drawing ID Drawing Title Rev. NomuhammadPas encore d'évaluation

- Speaker Application Guide 1Document68 pagesSpeaker Application Guide 1Ravinder Gu100% (1)

- Iesna Advanced Roadway Lighting WorkshopDocument37 pagesIesna Advanced Roadway Lighting WorkshopJose QuiroaPas encore d'évaluation

- Stadium Technical RequirementsDocument22 pagesStadium Technical RequirementsDaniel BenyPas encore d'évaluation

- Installation Manual For NVRDocument91 pagesInstallation Manual For NVRDaniel CharlesPas encore d'évaluation

- BOSCH EN54 Certification BookletDocument60 pagesBOSCH EN54 Certification BookletdsfargegPas encore d'évaluation

- PA System DesignDocument14 pagesPA System DesignajeeshsivanPas encore d'évaluation

- EST EST3 v3.0 Programming ManualDocument176 pagesEST EST3 v3.0 Programming ManualAhmed Sweet100% (2)

- Data Center Tier ClassificationDocument7 pagesData Center Tier ClassificationTajudeen IbrahimPas encore d'évaluation

- GEN031 - Design Installation Guide Inners - Gent SRDocument46 pagesGEN031 - Design Installation Guide Inners - Gent SRmohamedkhalifehPas encore d'évaluation

- Audiovisual Systems Design and Coordination Components Performance Standard DS1 Public ReviewDocument29 pagesAudiovisual Systems Design and Coordination Components Performance Standard DS1 Public Reviewdimlou1100% (1)

- Drone Surveying Explained - From GCPs To PPK EbookDocument16 pagesDrone Surveying Explained - From GCPs To PPK Ebookcarlos alvarezPas encore d'évaluation

- PA System Design GuideDocument68 pagesPA System Design GuideBob Pierce100% (1)

- Security Expert Security Purpose Controller SP C April 2018 PDFDocument4 pagesSecurity Expert Security Purpose Controller SP C April 2018 PDFFernando RibeiroPas encore d'évaluation

- IESNA Lighting LevelsDocument36 pagesIESNA Lighting LevelsBruna Quintanilla0% (1)

- BS en 62676 Series - Guidance For Customers About Grading and Other Important MattersDocument3 pagesBS en 62676 Series - Guidance For Customers About Grading and Other Important MattersnpfhPas encore d'évaluation

- IEE EMC Guidance Doc PDFDocument60 pagesIEE EMC Guidance Doc PDFped376Pas encore d'évaluation

- Tuvit Whitepaper Data Center Tsi En50600Document12 pagesTuvit Whitepaper Data Center Tsi En50600saba0707Pas encore d'évaluation

- PRAESENSA Introduction 2018Document39 pagesPRAESENSA Introduction 2018Trần Văn BắcPas encore d'évaluation

- The Uptime Institute Tier Classification System: Comparisons With TIA-942Document2 pagesThe Uptime Institute Tier Classification System: Comparisons With TIA-942Doruk BakırPas encore d'évaluation

- 48kwh - Construction Work 3Document22 pages48kwh - Construction Work 3nguyenvanmyk410kxPas encore d'évaluation

- Good Control Room Design BAWarchitectureDocument10 pagesGood Control Room Design BAWarchitectureAle SanzPas encore d'évaluation

- T6-CCTV-Main and Spare Equipment Bill of Quantity (Rev.00.02)Document9 pagesT6-CCTV-Main and Spare Equipment Bill of Quantity (Rev.00.02)ressariPas encore d'évaluation

- En ISO 11064-4 - ErgonomicDocument4 pagesEn ISO 11064-4 - ErgonomicAibruob OmegaPas encore d'évaluation

- DP Data Center Checklist 1Document2 pagesDP Data Center Checklist 1Damy van de MerbelPas encore d'évaluation

- Icao An14 Vol 2 Heliports 3d Edition 2009Document0 pageIcao An14 Vol 2 Heliports 3d Edition 2009kkpartnerPas encore d'évaluation

- Constructability Metrics PDFDocument21 pagesConstructability Metrics PDFHenry R. RealonPas encore d'évaluation

- FIre and Life Safety Ebook PDFDocument69 pagesFIre and Life Safety Ebook PDFAmritraj CharlesPas encore d'évaluation

- Ibms Design Based ReportDocument67 pagesIbms Design Based ReportShameel PtPas encore d'évaluation

- BS 5839 Fire Detection and Alarm Systems 2002 PDFDocument10 pagesBS 5839 Fire Detection and Alarm Systems 2002 PDFpepeillo123Pas encore d'évaluation

- Rtu FDSDocument30 pagesRtu FDSroopchandanPas encore d'évaluation

- Swindon LV Switchboard and Generator Specification EHS (ME) 012013Document46 pagesSwindon LV Switchboard and Generator Specification EHS (ME) 012013Tukaram PawarPas encore d'évaluation

- ultimate comfort ةحارلا ةــمق: The expression of نع رــيبعتلا يــفDocument2 pagesultimate comfort ةحارلا ةــمق: The expression of نع رــيبعتلا يــفdonia wanita0% (1)

- Matv Smatv ProjectDocument44 pagesMatv Smatv ProjectartmehrPas encore d'évaluation

- Breeam Offices 2008Document315 pagesBreeam Offices 2008Ana RuxandraPas encore d'évaluation

- EST4 Overview Data Sheet Final 8819Document6 pagesEST4 Overview Data Sheet Final 8819RaviPas encore d'évaluation

- IP CCTV System Design GuideDocument50 pagesIP CCTV System Design Guidemujeeb.alam4100% (6)

- Integrated Control SystemsDocument8 pagesIntegrated Control SystemsAnonymous FFMmIJyPas encore d'évaluation

- Aircraft Hangar MaintenanceDocument71 pagesAircraft Hangar MaintenanceromysagunPas encore d'évaluation

- ABB-412-WPO Higher Efficiency in OperationsDocument16 pagesABB-412-WPO Higher Efficiency in OperationsSergio Alexander Fonseca CorredorPas encore d'évaluation

- Control Room Design - Guidance Document EEMUA 201 3rd Edition Updated 2018Document8 pagesControl Room Design - Guidance Document EEMUA 201 3rd Edition Updated 2018LeandroPas encore d'évaluation

- 294-RU MemoriaDocument7 pages294-RU MemoriaquynhthomPas encore d'évaluation

- Emewrgency Accident MGMTDocument10 pagesEmewrgency Accident MGMTNinad SamelPas encore d'évaluation

- Operations: A Control Room Is Only A Component in A Complex SystemDocument22 pagesOperations: A Control Room Is Only A Component in A Complex SystemSalih Doğruer-butik ŞahsiyetPas encore d'évaluation

- H Man/Compu Rin: Te TerfaceDocument9 pagesH Man/Compu Rin: Te TerfaceFernando RomeroPas encore d'évaluation

- System EngineeringDocument11 pagesSystem Engineeringapi-26349602100% (2)

- Computer System MaintenanceDocument13 pagesComputer System MaintenanceQummiel CerezaPas encore d'évaluation

- Aaa1.facilities Midterm ReviewerDocument21 pagesAaa1.facilities Midterm ReviewerEunice VargasPas encore d'évaluation

- Human Factors Engineering and Flight Decl Design: Kathy H. AbbottDocument15 pagesHuman Factors Engineering and Flight Decl Design: Kathy H. AbbottKalimiPas encore d'évaluation

- Meaningful Ways To Interpret Building Data: FeatureDocument5 pagesMeaningful Ways To Interpret Building Data: Featurejdietz4Pas encore d'évaluation

- Osnovni Elektronski Zahtjevi ZIS-aDocument12 pagesOsnovni Elektronski Zahtjevi ZIS-aBajro TursunovicPas encore d'évaluation

- Programmable Electronic System (PES) Requirements PDFDocument16 pagesProgrammable Electronic System (PES) Requirements PDFwq22030202Pas encore d'évaluation

- Fieldbustutorialpart2 Justifyingfiledbus 101110165259 Phpapp02Document31 pagesFieldbustutorialpart2 Justifyingfiledbus 101110165259 Phpapp02Nurdeny Hidayanto PribadiPas encore d'évaluation

- Programmable Logic Controller PDFDocument5 pagesProgrammable Logic Controller PDFwq22030202Pas encore d'évaluation

- Integrated Analyzer Systems and Shelters PDFDocument7 pagesIntegrated Analyzer Systems and Shelters PDFwq22030202Pas encore d'évaluation

- Gas Chromatographs PDFDocument10 pagesGas Chromatographs PDFwq22030202Pas encore d'évaluation

- Machinery Vibration and Monitoring Systems PDFDocument2 pagesMachinery Vibration and Monitoring Systems PDFwq22030202Pas encore d'évaluation

- Electrical and Instrumentation Requirements For Simple Packa PDFDocument4 pagesElectrical and Instrumentation Requirements For Simple Packa PDFwq22030202Pas encore d'évaluation

- Export Protection and Packaging, Class MJ Pumps and Compress PDFDocument11 pagesExport Protection and Packaging, Class MJ Pumps and Compress PDFwq22030202Pas encore d'évaluation

- Human FactorDocument17 pagesHuman Factorwq22030202Pas encore d'évaluation

- Electrical and Instrumentation Requirements For Packaged Equ PDFDocument23 pagesElectrical and Instrumentation Requirements For Packaged Equ PDFwq22030202Pas encore d'évaluation

- Export Protection and Packaging, Class MC - ExchangersDocument7 pagesExport Protection and Packaging, Class MC - Exchangerswq22030202Pas encore d'évaluation

- Air Operated Control Valves PDFDocument7 pagesAir Operated Control Valves PDFwq22030202Pas encore d'évaluation

- Basic Process Control Systems Requirements PDFDocument32 pagesBasic Process Control Systems Requirements PDFwq22030202100% (1)

- DCS HandbookDocument25 pagesDCS Handbookwq22030202Pas encore d'évaluation

- Preparation For Domestic Shipment of Rotating (Non-API), Spe PDFDocument4 pagesPreparation For Domestic Shipment of Rotating (Non-API), Spe PDFwq22030202Pas encore d'évaluation

- Human Factor in Plant SafetyDocument9 pagesHuman Factor in Plant Safetywq22030202Pas encore d'évaluation

- PART 2-A SIS Applications in BoilersDocument29 pagesPART 2-A SIS Applications in BoilersAdila AnbreenPas encore d'évaluation

- Human Factor in Alarm ManagementDocument7 pagesHuman Factor in Alarm Managementwq22030202Pas encore d'évaluation

- Human Factor in PlantDocument22 pagesHuman Factor in Plantwq22030202Pas encore d'évaluation

- Controller WorkloadDocument6 pagesController Workloadwq22030202Pas encore d'évaluation

- Human Factor in BPCSDocument11 pagesHuman Factor in BPCSwq22030202Pas encore d'évaluation

- Human Factor Engineering in Control RoomDocument9 pagesHuman Factor Engineering in Control Roomwq22030202Pas encore d'évaluation

- Control Loop Foundation OverviewDocument163 pagesControl Loop Foundation Overviewsubhu1981Pas encore d'évaluation

- Control Loop CalculationDocument5 pagesControl Loop Calculationwq22030202Pas encore d'évaluation

- BPCS Operator WorkloadDocument13 pagesBPCS Operator Workload王强Pas encore d'évaluation

- Controlengrasia0803 FoundationDocument4 pagesControlengrasia0803 Foundationwq22030202Pas encore d'évaluation

- Control Operator OverloadDocument7 pagesControl Operator Overloadwq22030202Pas encore d'évaluation

- Abs Catalogo 2021 ENGDocument26 pagesAbs Catalogo 2021 ENGMo ZeidPas encore d'évaluation

- Engineering Optimization: Theory and Practice Third EditionDocument27 pagesEngineering Optimization: Theory and Practice Third EditionMohit Natu100% (1)

- Chapter 6 ControlDocument148 pagesChapter 6 Control.ılı.Govíиð ЯäJ.ılı.Pas encore d'évaluation

- Composite Element DurabilityDocument6 pagesComposite Element Durabilityjklo12Pas encore d'évaluation

- Do 254 Explained WPDocument6 pagesDo 254 Explained WPPrabakaran EllaiyappanPas encore d'évaluation

- PMT Product Manager Technical Role GuidelineDocument14 pagesPMT Product Manager Technical Role GuidelineKishore Kumar100% (2)

- Asphalt Plant (PDL)Document9 pagesAsphalt Plant (PDL)Mojammel HaquePas encore d'évaluation

- HVDC Cables 2Document32 pagesHVDC Cables 2elsaordunaPas encore d'évaluation

- Resume For Broadcasting InternshipDocument7 pagesResume For Broadcasting Internshipbcrqs9hr100% (2)

- ML-P1-6009-CO-1-060-T-CAL-00006 - Big Arch - Rev01 Span 60mDocument115 pagesML-P1-6009-CO-1-060-T-CAL-00006 - Big Arch - Rev01 Span 60mRavi Teja PolisettiPas encore d'évaluation

- BU EA Designbook 96p v092018 EN Web PDFDocument96 pagesBU EA Designbook 96p v092018 EN Web PDFsohil patelPas encore d'évaluation

- 3 ISO26262 AssessmentDocument19 pages3 ISO26262 AssessmentOscar Alfonso Iñigo GéneraPas encore d'évaluation

- ABB Robotic Arc WeldingDocument12 pagesABB Robotic Arc Weldinganidarius301100% (1)

- Combined Ad No 4Document66 pagesCombined Ad No 4HassanPas encore d'évaluation

- Ge6075 - Professional Ethics in Engineering: 2 Marks Questions and AnswersDocument16 pagesGe6075 - Professional Ethics in Engineering: 2 Marks Questions and Answerseee2014.rvsPas encore d'évaluation

- General MOS For CW Pump Rev.2Document23 pagesGeneral MOS For CW Pump Rev.2Adithira BimasalakaPas encore d'évaluation

- Computer, ScienceDocument16 pagesComputer, ScienceAnonymous Cw1DGmRfPas encore d'évaluation

- SF AERO Skills Map Aircraft Maintenance Track PDFDocument50 pagesSF AERO Skills Map Aircraft Maintenance Track PDFrehannstPas encore d'évaluation

- HVDS BasicDocument67 pagesHVDS Basicjothipriyad100% (1)

- Aws D1-4 - 1998 PDFDocument55 pagesAws D1-4 - 1998 PDFJJ Saab100% (1)

- Road Map EPCDocument33 pagesRoad Map EPCBehnaz MotamedPas encore d'évaluation

- Filtration Handbook: Awareness of FluidsDocument22 pagesFiltration Handbook: Awareness of Fluidsmatteo_1234Pas encore d'évaluation

- Prequalified Consultants-Firm - 1-10-22Document39 pagesPrequalified Consultants-Firm - 1-10-22Timothy CrusePas encore d'évaluation

- Top University in Gurugram for B Tech in AI and ML CoursesDocument16 pagesTop University in Gurugram for B Tech in AI and ML CoursesKR MangalamPas encore d'évaluation

- Methods Tools Design Methodology and Design PractiDocument9 pagesMethods Tools Design Methodology and Design PractiAde SurPas encore d'évaluation

- Undergraduate Software Engineering Students in Startup BusinessesDocument8 pagesUndergraduate Software Engineering Students in Startup BusinessesMahardika Agil Bima IIPas encore d'évaluation

- S3 Course HandoutDocument109 pagesS3 Course HandoutRanjan DhungelPas encore d'évaluation

- Structural Engineering 1 Assignment: Timber TestsDocument12 pagesStructural Engineering 1 Assignment: Timber Testsbrkn8Pas encore d'évaluation

- Cyclonic Area Manual: For Design and Installation ProfessionalsDocument32 pagesCyclonic Area Manual: For Design and Installation ProfessionalsVenkata RajuPas encore d'évaluation

- Yokogawa CVP - Old.Document11 pagesYokogawa CVP - Old.Karthikeya Rao KPas encore d'évaluation