Académique Documents

Professionnel Documents

Culture Documents

Teaching & Learning Resource (TLR) (Safety)

Transféré par

obaidur_rehman_3Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Teaching & Learning Resource (TLR) (Safety)

Transféré par

obaidur_rehman_3Droits d'auteur :

Formats disponibles

Teaching & Learning Resource (TLR) (Safety)

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 2/27

Contents

1.1.1. Safety Introduction: ..................................................................................... 5 General Requirements for a Safe Practice: ............................................... 5 1.1.2. Human and Environmental Factors That May Lead To an Accident:........... 7 1.1.3. Identification and Use of Materials: ............................................................ 9 Dangers associated with some materials: ................................................ 9 1. Compressed Gases ................................................................................ 9 2. Cryogenic Materials: ............................................................................. 9 3. Explosives: ........................................................................................... 10 4. Salt Bath: ............................................................................................. 10 1.1.4. Need for Eye Protection:............................................................................ 11 1. How can we control eye hazards at the source .................................. 11 1.1.5. Hazardous substances: .............................................................................. 12 1.1.6. Types of fire: .............................................................................................. 13 1. Class A ................................................................................................. 13 2. Class B ................................................................................................. 13 3. Class C ................................................................................................. 13 4. Class D ................................................................................................. 13 1.1.7. Types of Fire Extinguisher: ......................................................................... 15 1. Water Extinguishers: ........................................................................... 15 2. Foam: .................................................................................................. 15 3. Carbon dioxide: ................................................................................... 15 4. Dry chemical (powder):....................................................................... 15 5. First Aid: .............................................................................................. 16 1.1.8. Electrical Safety: ......................................................................................... 17 1. Methods of protection from electrical danger: .................................. 17 Insulation: ............................................................................................... 17 Grounding: .............................................................................................. 18 Circuit Protection Devices: ...................................................................... 18

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 3/27

Residual current device: ......................................................................... 19 2. First aid procedures: ........................................................................... 19 Mouth To Mouth Resuscitation: ............................................................. 19 Dealing with Electric Shock: .................................................................... 20 Dealing with eye and other types of physical injury ............................... 20 1.1.9. Safety Procedures: ..................................................................................... 21 1. Proper Lifting Procedures: .................................................................. 21 2. Manual Lifting: .................................................................................... 21 3. Use of Lifting Equipment: ................................................................... 23 4. Procedures for the safe handling and storage of materials: .............. 26 1.1.10. WORKSHEET: ............................................................................................ 27

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 4/27

Learning Outcomes

After completing this learning unit trainee will be able to: 1. Identify hazards and safety facilities in aworkshop.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 5/27

1.1.1. Safety Introduction:

Accidents do not happen, they are caused. We cant think of a single accident that could not have been prevented by care and forethought on somebodys parts. Accident can and must be prevented. Prevention of accident is known as Safety. As a general guidance to safety, No person employed in a factory or workshop should willfully and without reasonable cause does anything likely to cause endanger him or others. Not only must an employer ensure that he, his premises and plant constitute a safe place to work, but every employee, trainee and experienced worker must ensure that he is a fit and capable person to carry out his or her assigned tasks. Safety in the Workshop is very crucial both in terms of human as well as profitability of an industry because poor safety procedures lead to lot of accidents. The primary aim of safety in the workshop is to foster a safe work environment for people engaged in work or employment. As a secondary effect, it may also protect co-workers, employers, customers, suppliers, nearby communities and other members of the public who are impacted by the workplace environment. General safety principles applicable to all types of workplace are fire precautions, correct use of personal protective equipment, hygiene standards, toxic processes, workplace noise and correct manual handling techniques. A hazard is something that can cause harm if not controlled. Anyone who is working in a workshop should have a thorough understanding about safety facilities, potential hazards related to workshop and machinery and first aid procedures.

General Requirements for a Safe Practice:

Alertness to danger Maintaining personal hygiene General tidiness Protecting self and others Knowledge of emergency Hazard reporting procedures To use safe working methods within the workshop To use of protective clothing where applicable To do work which worker trained and learn to do To do work with attention and thought Obey all the company/workshop health and safety rules/orders

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 6/27

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 7/27

1.1.2. Human and Environmental Factors That May Lead To an Accident:

tiredness carelessness improper behavior Behavior in workshop should be proper and dress code should be followed strictly

unsuitable clothing

Playing around in the workshop and running should be avoided

lack of training

While training the worker must listen or read the instructions and must understand the symbols used in industry to represent the things that are placed in the surrounding and signs of danger.

unguarded or faulty tools and machinery lack of adequate ventilation

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 8/27

Faulty machines and tools might cause accident when using them by the workers

Unguarded machine and tool might cause accident when using them by the workers Inadequate ventilation might produce uncomfortable temperature and humidity which will increase the fatigue of the worker Keep work areas clean

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 9/27

1.1.3. Identification and Use of Materials:

Dangers associated with some materials: 1. Compressed Gases There are two types of hazards associated with the use, storage and handling of compressed gas cylinders: the chemical hazard associated with the cylinder contents (corrosive, toxic, flammable, etc.) and the physical hazards represented by the presence of a high pressure vessel in the work place. All compressed gases are hazardous because of the high pressures inside the cylinders. Gas can be released deliberately by opening the cylinder valve, or accidentally from a broken or leaking valve or from a safety device. There have been many cases in which damaged cylinders have become uncontrolled rockets or pinwheels and have caused severe injury and damage.

2. Cryogenic Materials: Cryogenic materials are commonly used in the workplace for a variety of purposes, such as refrigeration and medical applications. Due to their extremely cold temperatures, cryogenic materials can be hazardous if handled and stored incorrectly. Any employees handling cryogenic materials must wear personal protective equipment. If employees are exposed to the extreme cold of cryogenic materials they should receive treatment immediately to prevent permanent injury. In the event that an individual inhales cryogenic materials, he should seek immediate attention to prevent serious injury or death.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 10/27

3. Explosives:

Explosives can be set off by heat, friction (rubbing), shock (for example due to an item containing explosives being dropped) or static electricity. Explosives can become easier to set off accidentally as they get older and deteriorate or if they are contaminated with rust, grit or other materials. Some explosives become more dangerous if they are wet. So do not apply water to suspect items. 4. Salt Bath: Salt bath is a heating device used in some work places. Common dangers associated with salt baths include: Explosive generation of steam due to water or moisture being inadvertently introduced into the molten salt. Fires caused through the hot molten salts coming into contact with combustible materials. Burns resulting from contact with the molten salt. These are especially hazardous when caused by molten cyanides since absorption via body tissues can lead to fatal poisoning. Accidental ingestion of cyanide salts. Overheating and eventual explosive decomposition of nitrate salts at temperatures above 600 0C. Explosive reactions between molten nitrates and aluminum or magnesium alloys under certain conditions. Molten nitrates and cyanides may decompose explosively if mixed together

Salt bath furnace

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 11/27

1.1.4. Need for Eye Protection:

Eye protection is important to protect against dust particles sparks or even liquid splashes. Particular attention should be made to selecting the right type of protection. The most common hazards to the eyes are:

dust and dirt blown around by the wind; flying particles from drilling, cutting, digging and other similar operations; ultraviolet radiation from welding and electrical work; splashes; fibers from insulating materials, such as fiberglass; and Irritants and corrosives.

1. How can we control eye hazards at the source?

Use protective screens and wire mesh grids to protect yourself from flying particles. Install safety glass guards on machines to prevent injuries caused by flying chips or splashing liquids. Place moveable shields around grinders, lathes and other similar machines to protect other workers. Enclose sources of fine dusts, mists or vapors. Control dust and fumes using general or local ventilation systems. Isolate hazardous operations in separate areas. For outdoor work, damp down work areas and seal dusty surfaces.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 12/27

1.1.5. Hazardous substances:

All people working in the area should be familiar with the hazards of the experiment and the appropriate emergency response procedures. It is must to wash face, hands, neck and arms after using the toxic materials. Very Toxic materials are substances that may cause serious harm to an individual if it enters the body. Whenever possible, it is always best to avoid using a very toxic material either by eliminating its use (by changing the method or process for example) or by substituting the very toxic material with a less hazardous material. To prevent exposure to a very toxic material, strict control measures are required. Ventilation is a very important control measure for very toxic materials. Well-designed and wellmaintained ventilation systems remove the very toxic vapors, fumes, mists or airborne dusts from the workplace before workers are exposed. For the storage of very toxic materials, ensure that the storage area is clearly identified with warning signs, is clear of obstructions and is accessible only to trained and authorized personnel.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 13/27

1.1.6. Types of fire:

Fire is an exothermic reaction between fuel and oxygen. Fire is a process that requires that a combustible material subjected to sufficient heat and has access to oxygen.

Fire is a process that requires that a combustible material subjected to sufficient heat and has access to oxygen. To illustrate how these three elements are dependent on one another, we can put them together in a triangle, which we call the fire triangle. The fuel must be heated to its ignition temperature for combustion to occur. The reaction will keep going as long as there is enough heat, fuel and oxygen. This is known as the fire triangle.

1. Class A Fires involve solid materials of an organic nature such as wood, paper, cloth, rubber and plastics that do not melt. 2. Class B Fires involve liquids. They include petrol, diesel, thinners, oils, paints, wax, cooking fat and plastics that melt. 3. Class C Fires involve electricity. 4. Class D Fires involve flammable metals such as magnesium, aluminum, titanium, sodium and potassium.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1 Task:

Date: [24-1-13] Rev: 0 Page 14/27

Each type of fire poses its own particular risk. Try and answer these questions, explaining your answer. 1. Would you use water on a type C fire? 2. Would you use water on a chip pan fire? 3. Copy and complete the table:

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 15/27

1.1.7. Types of Fire Extinguisher:

There are four main types of fire extinguishers used for fighting fire: Water Foam Carbon dioxide Powder

Fire extinguisher used to be different colors but now, in a workplace, they must be all red. To tell them they all have different flash on them. 1. Water Extinguishers: Suitable for most Class A fires, caused by the combustion of materials such as wood, straw, textiles, paper, coal etc. 2. Foam: Ordinary solid combustibles, Flammable liquids and gases (Petrol, grease and oil fires are included in this class.) 3. Carbon dioxide: Flammable liquids and gases (Petrol, grease and oil fires are included in this class.), fires involve combustible metals and fires involving electrical appliances. 4. Dry chemical (powder): Ordinary solid combustibles, flammable liquids and gases, energized electrical equipment.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 16/27

5. First Aid: First-aid is the assessment and interventions that can be performed by a first aider during an emergency with minimal equipment until appropriate medical personnel arrive. The life of an injured or ill worker or member of the public within the vicinity of the workplace may depend on proper first-aid being given within the first few minutes of an accident or an illness. Besides saving lives, first-aid treatment is important in preventing further complications from injury and pain and in promoting recovery. It is also important for minor injuries such as burns, sprains, cuts, etc. While it is important to understand that first aid has its limitations and does not take the place of professional medical treatment, if a person is sick or injured, then they need help immediately. Sometimes people worry about doing the wrong thing, so dont act at all or act too slowly. However it is also important that the first aider is not panicking. Careful and deliberate action undertaken without too much delay is most beneficial to the casualty. Try to remain calm and think your actions through. A calm and controlled first aider will give everyone confidence that the event is being handled efficiently and effectively.Each emergency is different, so it is impossible to provide you with a precise list of things you need to do for every situation. However if you follow the principles of first aid, you should deliver appropriate care, even if you are not sure of what the underlying problem is.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1 1.1.8. Electrical Safety:

Date: [24-1-13] Rev: 0 Page 17/27

Exposure to electrical hazard will be minimal unless the operator becomes involved with machine repair. The machine operator is mostly concerned with the on and off switch on the machine tool. However, if adjustments or repairs must be made, the power source should be disconnected. If the machine tool is wired permanently, the circuit breaker should be switched off and tagged with an appropriate warning statement. Most often the power source will not be disconnected for routine adjustment such as changing machine speeds. However, if a speed change involves a belt change, make sure that no other person is likely to turn on the machine while the operators hands are in contact with belts and pulleys. An electrical shock is received when electrical Current passes through the body. You will get an electrical shock if a part of your Body completes an electrical circuit by touching a live wire and an electrical ground, or touching a live wire and another wire at a different voltage.

1. Methods of protection from electrical danger:

Insulation Earthing circuit breakers fuses residual current devices (RCD)

Insulation: All electrical cords should have sufficient insulation to prevent direct contact with wires. It is particularly important to check all cords before each use, since corrosive chemicals or solvent vapors may erode the insulation.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 18/27

Damaged cords should be repaired or taken out of service immediately, especially in wet environments such as cold rooms and near water baths.

Grounding: Only equipment with three-prong plugs should be used. The third prong provides a path to ground that helps prevent the buildup of voltages that may result in an electrical shock or spark. This does not guarantee that no one will receive a shock, be injured, or be killed. It will, however, substantially reduce the possibility of such accidents, especially when used in combination with other safety measures.

Circuit Protection Devices: Circuit protection devices are designed to automatically limit or shut off the flow of electricity in the event of a ground-fault, overload, or short circuit in the wiring system. Fuses, circuit breakers, and ground-fault circuit interrupters are three wellknown examples of such devices. Fuses and circuit breakers prevent over-heating of wires and components that might otherwise create hazards for operators. They disconnect the circuit when it becomes overloaded. This overload protection is very useful for equipment that is left on for

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 19/27

extended periods of time, such as stirrers, vacuum pumps, drying ovens and other electrical equipment. Residual current device: A residual current device is a safety device that switches off electrically automatically if there is a fault. RCDs are far more sensitive than a normal fuse or circuit breaker and provide additional protection against electric shock. Additional protection by means of an RCD can be a lifesaver. An RCD constantly monitors the electric current flowing along a circuit. If it detects electric current flowing down the unintended path, such as through a person who has touched the live part, it will switch the circuit off very quickly, thereby significantly reducing the risk of death and serious injury. Using electrical appliances, while wet, significantly increases the risk of electric shock. RCD can protect you from electrical shocks.

2. First aid procedures:

Mouth To Mouth Resuscitation:

Make sure the person is lying on a hard, flat surface. Look into the mouth and throat to ensure that the airway is clear .If an object is present, try to sweep it out with your fingers (wear disposable surgical gloves if they are available). Tilt the person's head back by placing your hand on his forehead and lifting his chin with the first two fingers of your other hand. Look, listen, and feel for air coming out of the victim's mouth by bending your own ear down to his mouth. Tilt your head towards the victims feet, so you can also look to see if his chest is rising and falling. Continue to tilt the head back with both hands as you look, listen and feel for air. Take a deep breath, pinch the victim's nose closed with the hand that is holding the forehead, seal your lips around the victim's mouth and give him several deep breaths. Pause in between each one to inhale shortly. Look, listen and feel for breathing from your victim. Continue to give him mouthto-mouth at steady, regular intervals,

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1 pausing only to take breathe. Always look to see if the chest is rising and falling, to ensure your breaths are getting through. Dealing with Electric Shock:

Date: [24-1-13] Rev: 0 Page 20/27

If someone in your presence receives an electric shock and is still in contact with its source, turn off the current at once either by pulling out the plug or switching off at the socket or consumer unit. If this is not possible, do not take hold of the person or the current may pass through you too. Pull the victim free with a scarf or dry towel or something like that, or knock their hand free of the electrical equipment with a piece of wood. As a last resort, free the victim by taking hold of their loose clothing but without touching the body. Do not attempt to move anyone who has fallen as a result of electric shock except to place them in a recovery position as they may have sustained other injuries. Wrap them in a blanket or coat to keep them warm until they can move themselves. Once the person can move and is no longer in connect with the electrical equipment, treat their electric burns by reducing the heat of the injury under slowly running cold water. Then apply a dry dressing and seek medical advice.

Dealing with eye and other types of physical injury

Blows to the Eye

Apply a cold compress without putting pressure on the eye. Crushed ice in a plastic bag can be taped to the forehead to rest gently on the injured eye. In cases of pain, reduced vision, or discoloration (black eye), seek emergency medical care. Any of these symptoms could mean internal eye damage. Foreign Objects

If a foreign object becomes stuck in the eye, let the eye tear in an effort to naturally flush it out. The alternative is to flush the eye with clean, drinkable water.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 21/27

1.1.9. Safety Procedures:

1. Proper Lifting Procedures:

Using improper lifting procedures may result in a permanent back injury. Back injury can be avoided if the correct lifting procedures are followed. When lifting heavy or large objects, get some assistance or use a hoist or forklift. Objects within your ability can be lifted safely as long as the following procedures are followed: Aware the safe working load of the equipment and use loads up to that limit Use equipment with test certificate Do periodic testing and inspection on the machine Maintain the equipment in good condition Always check the safety and secure of lifting points of the equipment Get awareness on handling and slinging methods on the machine and use them appropriately Get awareness on crane signaling and use them at appropriate time Follow given safety procedures when using the equipment Use protective equipment including helmet, footwear and gloves

2. Manual Lifting:

When lifting a load manually: Keep the feet apart and knees bend position Grasp the load firmly and Keep the arms close to the body Lift the weight by straightening the bent knees without bending the back Twisting of the body while lifting should be avoided Use the leg muscles to do the work and lift slowly. Do not bend over the load as this will put excessive strain on your spine.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 22/27

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 23/27

3. Use of Lifting Equipment: When lifting a heavy load lifting equipment used. Lifting equipment should be designed so that it is safe to use under all conceivable operating conditions. When using lifting equipment precautions to be observed are:

Check for the availability of mechanical aids before lifting or moving loads. Select the right equipment to complete the task. Do not operate any equipment if you are not trained to use it. Keep the equipment in good and safe operating condition. It saves effort while transporting loads. Make sure equipment is maintained properly and inspected regularly. Visually inspect the equipment for any defects such as loose wheels or damaged platforms before use. Use rolling platforms to assist in carrying and handling heavy objects where limited space does not allow for comfortable body position.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 24/27

Use a hand truck to move bulky objects.

Use a shelf truck to move a variety of objects.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 25/27

Use a platform truck to move heavy, irregularly shaped objects.

Use a semi-live skid for temporary storage of work.

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1 4. Procedures for the safe handling and storage of materials: Provide proper storage facilities such as:

Date: [24-1-13] Rev: 0 Page 26/27

Storage boxes and containers that can be Lifted mechanically rather than requiring manual handling Avoid deep shelving that make retrieving or placing a load difficult Racks or shelf trucks to store material, thus eliminating the need for lifting the containers Storage bins and containers with fold down sides for easier access to loads

When storing loads, employees should: Store loads in easy to access locations Store loads between knuckle and shoulder height Use storage techniques to ease material handling; store loads at waist level, use wall brackets or shelving of appropriate height Ensure filing cabinets and storage shelves are secured to a fixed object Store heavy items at an appropriate height for ease of handling When moving items do not carry too many items at once Store supplies inside cabinets, not on top of them

Module 1: Engineering Skills Principle 1

Learning Unit : Safety Learning Unit No: 1.1

Date: [24-1-13] Rev: 0 Page 27/27

1.1.10. WORKSHEET:

1. In order to comply with safe working practices it is essential that employees should a) Keep their working area tidy b) arrive at work punctually c) Treat their colleagues with respect d) do not waste resources 2. Which one of the following is essential when carrying out oxy-acetylene welding? a )Leather aprons. b) Radiation detectors c) Protective footwear d) Eye protection. 3. A chemical foam type of fire extinguisher must never be used on a burning a) Cardboard box b) paint tin c) Petrol container d) television set 4. When a small particle of grit becomes lodged under a person's eyelid, the first course of action must be to a) Ring for an ambulance b) provide a painkiller tablet c) Apply eye drops d) rinse the eye with clean water 5. Which one of the following fire extinguishers should, not be used to fight an oil fire? a) Carbon dioxide b) water c) Foam. d) Dry Powder 6. An electric soldering iron is earthed to a) increase its efficiency c) Protect against over-current

b )provide fault protection d) increase the temperature of the bit

7. When lifting a very bulky item manually, which one of the following is the safe procedure? a) Bend down very slowly b) Get help from a colleague c) Always wear leather gloves d) Put on training shoes, to avoid slipping 8. A human factor that may lead to an accident in the work place, a) Lack of money b) Lack of training c) Carefulness d) Proper behavior 9. Electrical hazards are often caused by, a) Using cable management systems b) Fuses with too high a rating c) Voltages too low for the equipment d) Terminal screws which are too tight 10. When using mouth to-mouth resuscitation, the patient's head should be tilted a) Forwards b) backward c) To the left side d) to the right side

Vous aimerez peut-être aussi

- ZCS300 ManualDocument24 pagesZCS300 ManualFabricio BorgattaPas encore d'évaluation

- Peo2 001Document7 pagesPeo2 001Jimmy Gray0% (1)

- Oman Building RegulationsDocument31 pagesOman Building RegulationsSachin Mangrulkar100% (3)

- TechnicalExams Dec2017Document29 pagesTechnicalExams Dec2017ming_zhu10Pas encore d'évaluation

- Internship ReportDocument52 pagesInternship Reportmatiyas100% (4)

- Q1 MsaDocument18 pagesQ1 MsadhuntPas encore d'évaluation

- Theoretical and Actual CombustionDocument14 pagesTheoretical and Actual CombustionErma Sulistyo R100% (1)

- M1U1 - Induction Health and SafetyDocument32 pagesM1U1 - Induction Health and SafetyViệt Đặng XuânPas encore d'évaluation

- Et-Gc06 m1 Ohs Note Final r0Document42 pagesEt-Gc06 m1 Ohs Note Final r0Omar AdamPas encore d'évaluation

- School of Engineering Mechanical WorkshopDocument35 pagesSchool of Engineering Mechanical Workshopelectristar4Pas encore d'évaluation

- Courseware in Iws: Industry Workplace and Safety PracticesDocument36 pagesCourseware in Iws: Industry Workplace and Safety PracticesKarenSantiago-Villanueva100% (1)

- Safety ManualDocument33 pagesSafety ManualFareeha WaqarPas encore d'évaluation

- Tension Meter user-manual-DX2-EDocument20 pagesTension Meter user-manual-DX2-EjoomalookPas encore d'évaluation

- Engineering Workshop Safety ManualDocument12 pagesEngineering Workshop Safety Manualsph_ertPas encore d'évaluation

- 3 Lecture 2 N 3-1 Fundamentals of SafetyDocument29 pages3 Lecture 2 N 3-1 Fundamentals of SafetyArjan GhoshPas encore d'évaluation

- INSPECTION REPORT - Group CDocument8 pagesINSPECTION REPORT - Group C205695 Onyeukwu Stephen Gift IndustrialPas encore d'évaluation

- Environmental and Health Safety StepsDocument18 pagesEnvironmental and Health Safety StepsAltaf Ur RehmanPas encore d'évaluation

- Safety in Process Plants: Presented by Group 2. CHE 522 Supervised by Prof. K. OBAHIAGBONDocument24 pagesSafety in Process Plants: Presented by Group 2. CHE 522 Supervised by Prof. K. OBAHIAGBONsunlias100% (1)

- Assignment No#1 Subject: Mechanical Workshop Topic: Safety Submitted To: DR - Syed Amjad Ahmed Submitted By: Moazzam Ali Roll No: 18-MCT-18 Department Mechanical EngineeringDocument11 pagesAssignment No#1 Subject: Mechanical Workshop Topic: Safety Submitted To: DR - Syed Amjad Ahmed Submitted By: Moazzam Ali Roll No: 18-MCT-18 Department Mechanical EngineeringalirazaPas encore d'évaluation

- Office OfficeDocument9 pagesOffice OfficeBea MokPas encore d'évaluation

- IE 555 Safety Engineering Management Online ManualDocument120 pagesIE 555 Safety Engineering Management Online Manualmhmd salemPas encore d'évaluation

- 11 IndspilldocDocument20 pages11 IndspilldocAlejandro VescovoPas encore d'évaluation

- The Civil Defence Manual For Industrial SafetyDocument33 pagesThe Civil Defence Manual For Industrial SafetyPriyanka JPas encore d'évaluation

- Hydro Fuel CellDocument48 pagesHydro Fuel CellRoberto Rojas FlorentinoPas encore d'évaluation

- Safety Engineering: 7. 1. AccidentsDocument5 pagesSafety Engineering: 7. 1. AccidentsSk jahidul IslamPas encore d'évaluation

- MO3 - Preparing Raw MaterialDocument81 pagesMO3 - Preparing Raw MaterialGadisaPas encore d'évaluation

- CarpentryDocument33 pagesCarpentrykwezi mwakaPas encore d'évaluation

- Overview of General Workshop Safety and Care FacilitiesDocument3 pagesOverview of General Workshop Safety and Care FacilitiesKenasa JambarePas encore d'évaluation

- Ministry of Higher Education and Scientific Research University of Kirkuk College of Engineering Mechanical Department 3 Stage Evening StudyDocument4 pagesMinistry of Higher Education and Scientific Research University of Kirkuk College of Engineering Mechanical Department 3 Stage Evening StudyUmit OsmanPas encore d'évaluation

- Safety PlanDocument41 pagesSafety PlanNicos PapadopoulosPas encore d'évaluation

- Safety in Petroleum and Gas EngineeringDocument14 pagesSafety in Petroleum and Gas EngineeringTayyab Bhutta100% (1)

- Group # 28-Introduction To ISO 45001-Mini-ProjectDocument14 pagesGroup # 28-Introduction To ISO 45001-Mini-ProjectA to z type videosPas encore d'évaluation

- SJM Builders Construction Safety ProgramDocument27 pagesSJM Builders Construction Safety ProgramJohn Francis SumandalPas encore d'évaluation

- Introduction To The Workshop Environment: Industrial InsulationDocument21 pagesIntroduction To The Workshop Environment: Industrial InsulationBurning TrainPas encore d'évaluation

- Safety Procedures and Practices Manual: January 22, 1996Document78 pagesSafety Procedures and Practices Manual: January 22, 1996Malik Athar HussainPas encore d'évaluation

- Safety PDFDocument7 pagesSafety PDFPratik SudraPas encore d'évaluation

- Industrial Safety and Hazard ManagementDocument89 pagesIndustrial Safety and Hazard ManagementRoshanPas encore d'évaluation

- Scha 3010Document106 pagesScha 3010AFEC AGIROPas encore d'évaluation

- SOP Example Use Correct Type of Personal Protective EquipmentDocument1 pageSOP Example Use Correct Type of Personal Protective EquipmentSynergene EHSPas encore d'évaluation

- Assignment 3Document13 pagesAssignment 3Thurei IIPas encore d'évaluation

- Ethics in Safety Equipment BusinessDocument15 pagesEthics in Safety Equipment BusinessRevati WablePas encore d'évaluation

- Risk Assessment (Hirarc)Document17 pagesRisk Assessment (Hirarc)MNashPas encore d'évaluation

- Higrometro-Ficha Técnia AvanzadaDocument16 pagesHigrometro-Ficha Técnia AvanzadaLumina OgsoPas encore d'évaluation

- Operating Instructions: Ecotec PlusDocument16 pagesOperating Instructions: Ecotec PlusKit GallagherPas encore d'évaluation

- Vehicle Servicing: Unit of CompetenceDocument69 pagesVehicle Servicing: Unit of CompetencetselothaiilemariamPas encore d'évaluation

- بحث جاهز للطباعةDocument36 pagesبحث جاهز للطباعةشوقي القاضيPas encore d'évaluation

- PAD214 Lesson 13Document21 pagesPAD214 Lesson 13norPas encore d'évaluation

- Safety Measures in Chemical Process IndustriesDocument35 pagesSafety Measures in Chemical Process IndustriesDevendra Sharma75% (8)

- Ins FullDocument102 pagesIns FullSudeep PenumalaPas encore d'évaluation

- 1.1.0. Introduction To Health and SafetyDocument6 pages1.1.0. Introduction To Health and SafetyMashal KhanPas encore d'évaluation

- Ohs ManualDocument98 pagesOhs ManualAyodeji Fasan SimeonPas encore d'évaluation

- Vehicle Servicing: Unit of CompetenceDocument70 pagesVehicle Servicing: Unit of Competenceabel assefaPas encore d'évaluation

- Intro To Indus Arts - Midterm TopicDocument7 pagesIntro To Indus Arts - Midterm Topicjhayarangote473Pas encore d'évaluation

- Q& HseDocument26 pagesQ& HsebalajirajasekaranPas encore d'évaluation

- PR-CSF-CSS-P-035 PpeDocument17 pagesPR-CSF-CSS-P-035 Ppetamoor sarwarPas encore d'évaluation

- Safety ManualDocument21 pagesSafety ManualAli ImamPas encore d'évaluation

- No. Matrikulasi: No. Kad Pengnealan: No. Telefon: E-MelDocument12 pagesNo. Matrikulasi: No. Kad Pengnealan: No. Telefon: E-MelNaru TosPas encore d'évaluation

- Eal Qpeo2001 ADocument5 pagesEal Qpeo2001 A4612011Pas encore d'évaluation

- Qpeo2 001Document7 pagesQpeo2 001Daniel Cowie0% (1)

- Working Practices in Engineering: Unit 1Document40 pagesWorking Practices in Engineering: Unit 1Narendar SaggamPas encore d'évaluation

- Safety Book-RevisedDocument12 pagesSafety Book-RevisedFardeen KhanPas encore d'évaluation

- Faculty of EngineeringDocument13 pagesFaculty of EngineeringSaliya SamarajeevaPas encore d'évaluation

- Safety Manual: National Thermal Power Corporation LTDDocument287 pagesSafety Manual: National Thermal Power Corporation LTDHari Krishna.M100% (2)

- Dole SafetyDocument19 pagesDole SafetyRamil SeriozaPas encore d'évaluation

- MS For Grounding and Cadwelding WorkDocument34 pagesMS For Grounding and Cadwelding WorkGanga Daran100% (2)

- Handbook of Emergency Response to Toxic Chemical Releases: A Guide to ComplianceD'EverandHandbook of Emergency Response to Toxic Chemical Releases: A Guide to CompliancePas encore d'évaluation

- RCD Testing Options AN40Document2 pagesRCD Testing Options AN40obaidur_rehman_3Pas encore d'évaluation

- The Electricity Supply Regulations - Second EditionDocument28 pagesThe Electricity Supply Regulations - Second EditionSheik Peer MohideenPas encore d'évaluation

- Electrical - Engineering - ExcellenceDocument20 pagesElectrical - Engineering - Excellenceobaidur_rehman_3Pas encore d'évaluation

- Make It Right Handling Carbon Steel SmoothlyDocument9 pagesMake It Right Handling Carbon Steel Smoothlyobaidur_rehman_3Pas encore d'évaluation

- Client Training Manual 2 KVADocument13 pagesClient Training Manual 2 KVAobaidur_rehman_3100% (1)

- Air Handler - WikipediaDocument5 pagesAir Handler - Wikipediaobaidur_rehman_3Pas encore d'évaluation

- Electrical Technician With Green Skills (CS)Document140 pagesElectrical Technician With Green Skills (CS)obaidur_rehman_3Pas encore d'évaluation

- DEA-567 - SG Series UPS 10-150 kVA (Mar 2015) (High-Res Print)Document12 pagesDEA-567 - SG Series UPS 10-150 kVA (Mar 2015) (High-Res Print)obaidur_rehman_3Pas encore d'évaluation

- Motor Control CircuitsDocument9 pagesMotor Control Circuitsobaidur_rehman_3Pas encore d'évaluation

- IFMA Space Management Survey 2020Document20 pagesIFMA Space Management Survey 2020obaidur_rehman_3Pas encore d'évaluation

- Abb - Technical Guide VFDDocument44 pagesAbb - Technical Guide VFDThejas HK100% (1)

- Ett Study GuideDocument8 pagesEtt Study Guidepatitay036817Pas encore d'évaluation

- B D A H U: ELT Rive IR Andling NitsDocument8 pagesB D A H U: ELT Rive IR Andling Nitsobaidur_rehman_3Pas encore d'évaluation

- Plumbing PDFDocument206 pagesPlumbing PDFobaidur_rehman_3Pas encore d'évaluation

- TroubleshootingDocument23 pagesTroubleshootingPrasantaKumarMallikaPas encore d'évaluation

- PLC Plan PDFDocument125 pagesPLC Plan PDFobaidur_rehman_3Pas encore d'évaluation

- ABB Technical Guide No 4 REVCDocument5 pagesABB Technical Guide No 4 REVCobaidur_rehman_3Pas encore d'évaluation

- 13Document6 pages13adalcayde2514Pas encore d'évaluation

- Course Mapping For Electrical CoursesDocument6 pagesCourse Mapping For Electrical Coursesobaidur_rehman_3Pas encore d'évaluation

- Extract Fan/Exhaust Fan - 3M Task SheetDocument3 pagesExtract Fan/Exhaust Fan - 3M Task Sheetobaidur_rehman_3Pas encore d'évaluation

- Extract Fan/Exhaust Fan - 3M Task SheetDocument3 pagesExtract Fan/Exhaust Fan - 3M Task Sheetobaidur_rehman_3Pas encore d'évaluation

- Top10hvacinterviewquestionswithanswers 141217205616 Conversion Gate01 PDFDocument140 pagesTop10hvacinterviewquestionswithanswers 141217205616 Conversion Gate01 PDFAnonymous 5PsGXCPas encore d'évaluation

- Procedure Online Degree AttestaionDocument4 pagesProcedure Online Degree AttestaionAsif KhanPas encore d'évaluation

- RL-HVAC - Fan Coil Unit - Yearly - RRDocument2 pagesRL-HVAC - Fan Coil Unit - Yearly - RRobaidur_rehman_3Pas encore d'évaluation

- Kristin White - Plumbing TaskDocument14 pagesKristin White - Plumbing Taskobaidur_rehman_3Pas encore d'évaluation

- Lockout-Tagout Affected EmployeesDocument22 pagesLockout-Tagout Affected Employeesobaidur_rehman_3Pas encore d'évaluation

- PumpDocument40 pagesPumpobaidur_rehman_3Pas encore d'évaluation

- Chapter 7 Heating Ventilation Air Conditioning PDFDocument28 pagesChapter 7 Heating Ventilation Air Conditioning PDFengineer74273Pas encore d'évaluation

- 39HQ - AhuDocument96 pages39HQ - AhuperezismaelPas encore d'évaluation

- Air Handling UnitDocument27 pagesAir Handling Unitobaidur_rehman_3Pas encore d'évaluation

- Final Project Report Natural CoagulationDocument48 pagesFinal Project Report Natural CoagulationSareeg Thomas0% (1)

- General Electric - Inlet Air RecommendationDocument28 pagesGeneral Electric - Inlet Air Recommendationhussain mominPas encore d'évaluation

- Monarch's Waterproofing PDFDocument31 pagesMonarch's Waterproofing PDFMonarch DigitalPas encore d'évaluation

- SMM COMSOL Simulation MontiDocument6 pagesSMM COMSOL Simulation Montitamarco85Pas encore d'évaluation

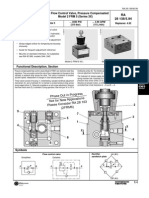

- 2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Document4 pages2-Way Flow Control Valve, Pressure Compensated Model 2 FRM 5 (Series 3X)Dias EliPas encore d'évaluation

- Victaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsDocument2 pagesVictaulic Firelock Sprinkler Coating Data Sheet: See Victaulic Publication 10.01 For More DetailsRobson Custódio de SouzaPas encore d'évaluation

- Brass - WikipediaDocument18 pagesBrass - WikipediaTahafanMaggedonPas encore d'évaluation

- Extraction of Metals: - The Chemistry BehindDocument25 pagesExtraction of Metals: - The Chemistry BehindSujit Singh100% (1)

- High Performance LubricantsDocument20 pagesHigh Performance Lubricantsmaicol21n100% (2)

- ASTM D3359-17 - Adhesion TestDocument9 pagesASTM D3359-17 - Adhesion TestAizacPas encore d'évaluation

- Katalog PDFDocument32 pagesKatalog PDFiinPas encore d'évaluation

- 09 Counter CellDocument3 pages09 Counter CellTana AzeezPas encore d'évaluation

- Recrystallization NotesDocument9 pagesRecrystallization NotesanrychoPas encore d'évaluation

- No. Questions Answer Pressure Rate Maximum Flow Stop LeakageDocument7 pagesNo. Questions Answer Pressure Rate Maximum Flow Stop LeakageTrường Tùng LýPas encore d'évaluation

- NBK TA Brochure 2016-EmailDocument11 pagesNBK TA Brochure 2016-EmailPietrus NimbusPas encore d'évaluation

- Copper Loops For 222 and 440MHzDocument5 pagesCopper Loops For 222 and 440MHzBenjamin Dover100% (1)

- Worm Gear OilDocument2 pagesWorm Gear OilDavidPas encore d'évaluation

- IGCSE Chemistry DefinitionsDocument5 pagesIGCSE Chemistry DefinitionsTanmay Karur100% (1)

- High Density Polyethylene - HDPE - Pipe and FittingsDocument8 pagesHigh Density Polyethylene - HDPE - Pipe and Fittingsnilesh_erusPas encore d'évaluation

- Rock Cycle Crayon LabDocument4 pagesRock Cycle Crayon Labapi-251355123Pas encore d'évaluation

- Steel Angles D 1322Document2 pagesSteel Angles D 1322Shanmuga SundaramPas encore d'évaluation

- Polyamide (PA) - Grilamid TR 90Document36 pagesPolyamide (PA) - Grilamid TR 90anilsamuel0077418Pas encore d'évaluation

- E FSS5 Attm3 Tooling-manual-Lathe Rev1 090330 PDFDocument9 pagesE FSS5 Attm3 Tooling-manual-Lathe Rev1 090330 PDFonnoPas encore d'évaluation

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279Pas encore d'évaluation