Académique Documents

Professionnel Documents

Culture Documents

Design

Transféré par

scribddisantoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design

Transféré par

scribddisantoDroits d'auteur :

Formats disponibles

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

J ob Tag : Description :

J ob Name : Drawing No :

Vessel Tag :

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 1 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Table of Contents

Update this field to get the table of contents.

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 2 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Input data list

Design Parameters.

Design pressure code : API 650 12th Ed. 2013-03

Karman Effects Prevented by 3

Helicoidal Plates at 120 :

No

Local Load Design Method : / Design length for vertical vessels : 500 mm

Flange Standard : ASME B16.5-2009/B16.47-2006 Specific Gravity : 8

Piping standard in acc. With : ASME B36.10M-2004/B36.19M-2004 Design and optimize : Yes

Apply UG 45 : Yes Design check : No

Apply UG 36(c)(3) : Yes MAWP calculation req'd. : No

Apply PD A.3.6 : No With Stiffeners : Yes

Apply UG 23 (d) : No Plate associated with stiffeners : Yes

Apply UBC 1612.3.2 (33%) : No Support rings as stiffening : No

Apply DIN 18800 part 4 : No Min. distance between stiffeners : 0 mm

Materials database : C:\Users\...\Config\Material.emdm Gas Pressure in Vessel : Yes

Considered Piping Platform Ladder Fireproofing Insulation Trays Scaffolding

Lifted / / / / / / /

Erected M+W M+W M+W / / / /

Operating M+W M+W M+W M+W M+W M /

Shutdown M+W M+W M+W M+W M+W M /

Test M+W M+W M+W / / / /

M =means that the weight of the component is taken into

consideration.

W =the effect of wind load resulting fromthe component is

considered.

Load Case

Lifted Erected Operating Shutdown Test

Freight

weight

Corroded

Weight

No No Yes No Yes No Yes

Default Values.

Rounded Up Dist. Flange / Axis : 0 mm Dist. Insulation / Flange : 0 mm

Extension for Welded Tubes : / Safety factor for flanges in operation/test : 1 1

Rule limiting available area in opening reinforcement f(T) :

Friction Factor for Bolt Torque - Thread / Nut supporting surface : 0 0

Geometry Definition.

No. Type Tag Designation

Thk. (*) Corr. Tol. Temp..

(mm) (mm) (mm) (C)

01 [44] BottomPlates 44 6.000 0.0 0.0 20.0

02 [01] Shell 1 vir Virola 6.000 0.0 0.0 20.0

03 [01] Shell 2 vir Barrel 6.000 0.0 0.0 20.0

04 [01] Shell 31.07 Barrel 6.000 0.0 0.0 20.0

05 [01] Shell 31.08 Barrel 6.000 0.0 0.0 20.0

06 [01] Shell 31.09 Barrel 6.000 0.0 0.0 20.0

07 [01] Shell 31.10 Barrel 6.000 0.0 0.0 20.0

08 [45] Roof 45 6.000 0.0 0.0 20.0

(*) minimum input thickness.

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 3 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

List of Materials.

Shell

Shells / heads : SA516GR60

SA516GR60 ASME II (Plate, Carbon Steel, 2013)

K02100 P-No. : 1 Group No. : 1 Specific gravity: 7.85 Poisson Factor: 0.3

Chemical comp. (%)

C Mn

0.3 1

Modulus of Elasticity (ASME II part D table TM)

C -200 -125 -75 25 100 150 200 250 300 350 400 450 500 550

MPa10

3

216 212 209 202 198 195 192 189 185 179 171 162 151 137

Thermal expansion coefficients (ASME II part D table TE)

C 20 50 75 100 125 150 175 200 225 250 275 300 325 350 400

mm/mm10

-6

11.5 11.8 11.9 12.1 12.3 12.4 12.6 12.7 12.9 13 13.2 13.3 13.4 13.6 13.8

C 425 450 475 500 550 575 600 625 675 700 725 750 775 800 825

mm/mm10

-6

14 14.1 14.2 14.4 14.6 14.7 14.8 14.9 15.1 15.1 15.2 15.3 15.3 15.4 15.5

Strength

C -30 375 400 425 450 475 500 525

MPa 414 414 408 382 352 319 285 253

Yield strength 0.2%

C -30 40 65 100 125 150 175 200 225 250 275 300 325 350 375

MPa 221 221 208 201 198 195 192 189 185 182 177 172 167 162 157

C 400 425 450 475 500 525

MPa 153 149 144 140 137 133

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 4 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Codes, Guidelines and Standards Implemented.

Pressure vessel design code:

API 650 12th Ed. 2013-03

Earthquake design code:

ASCE/SEI 7-10

Wind design code:

ASCE/SEI 7-10

Anchor design method:

Thompson

Standard of flange ratings:

ASME B16.5-2009

Standard for pipes:

ASME B36.10M-2004/B36.19M-2004

Material standard(s) and update(s):

ASME II 2013 SA516GR60 Plate

Units:

SI

g =9.80665 m/s

2

[ Weight (N) =Mass (kg) g ]

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 5 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Design Conditions.

Compartment 1 / /

Internal pressure : 0 MPa / /

Required MAWP : / /

Design Temperature : 20 C / /

Height of liquid : 16 000 mm / /

Operating fluid spec. gravity : 1 / /

Corrosion : 0 mm / /

External pressure : / /

External temperature : / /

Test Pressure : / /

Test fluid spec. gravity : 1 / /

Insulation Thickness : 0 mm / /

Weight/density of insulation : 35 kg/m

3

/ /

Construction Category : / /

Nominal stress : / /

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 6 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Allowable stresses and safety factors

API 650 - 5.6.2

S Allowable tensile stress.

S

T

Minimum value of tensile strength.

S

Y

Minimum value of yield strength at design/roomtemperature

Allowable tensile stress S

Materials Normal Conditions Exceptional and test conditions

Excluding

bolting

Carbon steel MIN{ (S

T

0.4) , (S

Y

0.67) } MIN{ (S

T

0.43) , (S

Y

0.75) }

Austenitic stainless

steel

MIN{ (S

T

0.4) , (S

Y

0.67) } MIN{ (S

T

0.43) , (S

Y

0.75) }

Copper MIN{ (S

T

0.4) , (S

Y

0.67) } MIN{ (S

T

0.43) , (S

Y

0.75) }

Aluminium MIN{ (S

T

0.4) , (S

Y

0.67) } MIN{ (S

T

0.43) , (S

Y

0.75) }

Nickel MIN{ (S

T

0.4) , (S

Y

0.67) } MIN{ (S

T

0.43) , (S

Y

0.75) }

Titanium MIN{ (S

T

0.4) , (S

Y

0.67) } MIN{ (S

T

0.43) , (S

Y

0.75) }

Bolting

Carbon steel MIN{ (S

T

0.4) , (S

Y

0.67) } MIN{ (S

T

0.43) , (S

Y

0.75) }

Austenitic stainless

steel

MIN{ (S

T

0.4) , (S

Y

0.67) } MIN{ (S

T

0.43) , (S

Y

0.75) }

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 7 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Hydraulic Test Pressure

F.7.6 : p

t

=1.25 p =0 MPa

p =Design Pressure

p

t

=test pressure

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 8 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Hydrostatic Pressure

Type of

components

Operating Test

Specific Gravity

liquid level hydrostatic height

Hydrostatic

pressure

Specific Gravity

liquid level hydrostatic height

Hydrostatic

pressure

(mm) (mm) (MPa) (mm) (mm) (MPa)

Shell(s)

01 44 1 0.00 16 000.00 0.1569 1 0.00 16 000.00 0.1569

02 1 vir 1 3 000.00 16 000.00 0.1569 1 3 000.00 16 000.00 0.1569

03 2 vir 1 3 000.00 13 000.00 0.1275 1 3 000.00 13 000.00 0.1275

04 31.07 1 3 000.00 10 000.00 0.0981 1 3 000.00 10 000.00 0.0981

05 31.08 1 3 000.00 7 000.00 0.0686 1 3 000.00 7 000.00 0.0686

06 31.09 1 3 000.00 4 000.00 0.0392 1 3 000.00 4 000.00 0.0392

07 31.10 1 1 000.00 1 000.00 0.0098 1 1 000.00 1 000.00 0.0098

08 45 1 0.00 0.00 0.0000 1 0.00 0.00 0.0000

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 9 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Tank Design

Shell design

5.6.3 Calculation of Thickness by the 1-Foot Method

t

d

=

( )

CA

S

G H D

d

+

3 . 0 9 . 4

t

t

=

( )

t

S

H D 3 . 0 9 . 4

t

d

=Shell thickness t

t

=hydrostatic test shell thickness

H =Liquid Level G =Liquid Specific Gravity

S

d

=Allowable stress at Temp. S

t

=allowable stress for the hydrostatic test condition

CA =Corrosion allowance t

min

=5.6.1.1 Minimumthickness

D =Nominal Diameter =22 m

Course H (m) G S

d

(MPa) S

t

(MPa) CA (mm) t

d

(mm) t

t

(mm)

t

min

(mm)

t

use

(mm)

1

2

3

4

5

6

16

13

10

7

4

1

1

1

1

1

1

1

147

147

147

147

147

147

165

165

165

165

165

165

0

0

0

0

0

0

11.513

9.313

7.113

4.913

2.713

0.513

10.257

8.297

6.337

4.377

2.417

0.457

6

6

6

6

6

6

12

10

8

6

6

6

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 10 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Bottom plate design

5.4.1 Bottomplate thickness

Minimum thickness required excluding CA =6 mm CA =Corrosion allowance =0 mm

Minimum thickness required including CA =6 mm Provided BottomPlate Thickness =6 mm

5.5 Annular bottomplate

Effective product height =HG 23 m

Stress product =(t

d

/as constructed t exclusive of CA) (S

d

) =141.0383 MPa

Hydrostatic Test Stress =(t

t

/as constructed t) (S

t

) =141.0383 MPa

Table 5-1 Annular BottomPlate Thickness t

b

=6 mm

Provided Annular Bottom-Plate Thickness =6 mm

Required radial width =

( )

5 . 0

215

HG

t

b

=322.5 mm

Minimum outside radial width =50 mm

Minimum inside radial width =600 mm

Minimum radial width of annular plate =662 mm

Provided radial width of annular plate =662 mm

Provided outside radial width of annular plate =50 mm

Provided inside radial width of annular plate =600 mm

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 11 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Self-supporting Roof

t

n

=thickness =26 mm =angle of cone elements to the horizontal =12

D =Nominal Diameter =22 m r

r

=roof radius =0 m

CA =Corrosion allowance =0 mm =Density =7 850 kg/m

3

Insulation : thickness =0 mm; Density =35 kg/m

3

5.2.1

L

r

=MinimumRoof Live Load P

e

=External Pressure

D

L

=dead load S

b

=0.84S

S =Snow load S

u

=1.5S

b

5.2.2

T =Greater load combinations e(1) and e(2) with balanced snow load S

b

( ) ( ) { }

r b e L e r b L

L S P D P L S D T ; max 4 . 0 ; 4 . 0 ; max max + + + + =

U =Greater load combinations e(1) and e(2) with unbalanced snow load S

u

( ) ( ) { }

r u e L e r u L

L S P D P L S D U ; max 4 . 0 ; 4 . 0 ; max max + + + + =

P

e

(kPa) S (kPa) L

r

(kPa) D

L

(kPa) S

b

(kPa) S

u

(kPa) T (kPa) U (kPa)

Operation

test

0

0

0

0

1

0

2.0015

2.0015

0

0

0

0

3.0015

2.0015

3.0015

2.0015

Top Stiffener (Externally Set) =L5x5x1/2 127 12.7 (Z =51 931 mm

3

) ; Location =16 000 mm; Material =

SA516GR60

Minimum Top Angle Size

5.1.5.9 (e) : L75x75x10 (Z =13 782 mm

3

)

5.9.3 : L65x65x6 (Z =6 444 mm

3

)

5.10.5.1

(2:12) tan() (9:12)

t

min

=Minimumthickness required excluding CA =5 mm t

max

=Maximal required thickness excluding CA =13 mm

E

ratio

=module of elasticity ratio (Appendix M.5.1) E =modulus of elasticity

t

T

= CA

T D

E

ratio

+

2 . 2 sin 8 . 4

t

U

= CA

U D

E

ratio

+

2 . 2 sin 5 . 5

t =max( t

T

, t

U

; t

min

+CA ) Temp. =Temperature

Temp. (C) E (MPa) E

ratio

CA (mm) t

T

(mm) t

U

(mm) t (mm)

Operation

test

20

20

202 350

202 350

1

1

0

0

25.749

21.027

22.472

18.351

25.749

21.027

5.10.5.2

F

yr

=Yield Strength (Roof) F

a

=0.6 min(F

yr

; F

ys

; F

ya

)

=

tan 8

2

a

r

F

pD

A

F

ys

=Yield Strength (Shell) p =max(T,U)

F

ya

=Yield Strength (Stiffener)

p (kPa) F

yr

(MPa) F

ys

(MPa) F

ya

(MPa) F

a

(MPa) A

r

(mm

2

)

Operation

test

3.0015

2.0015

221

221

221

221

221

221

132.6

132.6

6 442.9

4 296.36

Frangible Roof

5.10.2.6 (d)

The slope of the roof should not exceed 2:12. (false) (0.2126 >0.1667)

The support elements of the roof must not be attached to the roof. (unknown)

The roof is attached to the top angle with a single continuous fillet weld on the top side (only) that should not exceed

5 mm. (unknown)

The Roof-to-Top angle compression ring is restricted to details a-e in Figure F-2. (true)

The roof-to-shell joint cross-sectional area is less than the limit: D

LS

/ (2F

y

tan). (false)

The anchorage should be designed for 3 times the failure pressure calculated by F.6 as specified in 5.12. (unknown)

The roof joint is not frangible

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 12 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Appendix F

Figure F-1 Decision tree

P =internal pressure =0 kPa

Does tank have internal pressure ?

Does internal pressure exceed weight of roof plates ?

Does internal pressure exceed the weight of the shell, roof and attached framing ?

Does internal pressure exceed 18 kPa ?

Basic Design

An anchorage is not required per Appendix F

Appendix F Figure F-2 Detail a

t

a

=thickness of angle leg t

h

=thickness of roof plate

t

b

=thickness of bar t

s

=largest shell thickness

t

c

=thickness of shell plate t

f

=t

a

+t

c

w

c

=0.6 (R

c

t

c

)

1/2

w

h

=min{ 0.3(R

2

t

h

)

1/2

; 300 mm}

R

c

=inside radius of tank shell R

2

=R

c

/ (sin )

L

e

=250t

a

/ (F

y

)

1/2

F

y

=minimumspecified yield strength

A

a

=stiffener area A

s

=shell plate area

A

r

=roof area A =A

a

+A

s

+A

r

t

a

(mm) t

b

(mm) t

c

(mm) t

h

(mm) t

s

(mm) t

f

(mm) R

c

(mm) R

2

(mm)

Operation

test

Operation

12.7

12.7

12.7

0

0

0

6

6

6

26

26

26

0

0

0

18.7

18.7

18.7

10 994

10 994

10 994

52 878.21

52 878.21

52 878.21

w

c

(mm) w

h

(mm) L

e

(mm) F

y

(MPa) A

a

(mm

2

) A

s

(mm

2

) A

r

(mm

2

) A (mm

2

)

Operation

test

Operation

154.101

154.101

154.101

300

300

300

213.574

213.574

213.574

221

221

221

3 064.51

3 064.51

3 064.51

924.6

924.6

924.6

7 800

7 800

7 800

11 789.11

11 789.11

11 789.11

F.4.1

A =area resisting the compressive force =0.012 m

2

F

y

=lowest yield strength of the materials in the roof-to-shell junction =221 MPa

=Angle =12

D =Diameter =22 m

D

LR

=nominal weight of roof plate plus any attached structural components =777 847.6 N

P

F4.1

=

2 2

00127 . 0

200

tan

D

D

D

AF

LR

y

+

=7.76 kPa

F.4.2

D =Diameter =22 m

D

LS

=nominal weight of the shell and any framing (but not roof plates) supported by the shell and roof =

718 343.6 N

D

LR

=nominal weight of roof plate plus any attached structural components =777 847.6 N

M

w

=overturning moment fromhorizontal plus vertical wind pressure =0 Nm

P

F4.2

=P

max

=

3 2 2

00153 . 0 00127 . 0 000849 . 0

D

M

D

D

D

D

w LR LS

+ =3.3 kPa

F.4.3

P

max

>0.8 P

f

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 13 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

F.5.1

A =total compression area required at the roof-to-shell junction =11 789.11 mm

2

P

i

=internal pressure =0 kPa

D

LR

=nominal weight of roof plate plus any attached structural components =777 847.6 N

D =Diameter =22 m

F

y

=lowest yield strength of the materials in the roof-to-shell junction =221 MPa

=Angle =12

A

F5.1

=

|

.

|

\

|

tan

00127 . 0

200

2

2

y

LR

i

F

D

D

P D

=-4 205.92 mm

2

F.6

P =under internal pressure =0 kPa

D

LR

=nominal weight of roof plate plus any attached structural components =777 847.6 N

D =Diameter =22 m

P

f

=

2

000746 . 0

6 . 1

D

D

P

LR

=-1.2 kPa

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 14 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Appendix E

Maximum design product level : H =16 m Nominal tank diameter : D =22 m

Specific Gravity : G =1

E.4.5.1 Impulsive Natural Period

Equivalent uniformthickness of tank shell : t

u

=6 mm Elastic Modulus of tank material : E =202 350 MPa

Liquid Specific Gravity : =1 000 kg/m

3

|

|

.

|

\

|

|

|

.

|

\

|

|

|

.

|

\

|

=

E D t

H C

T

u

i

i

2000

1

=0.292 s

C

i

=Figure E-1 =6.073

E.4.5.2 Convective (Sloshing) Period

|

.

|

\

|

=

D

H

K

s

68 . 3

tanh

578 . 0

=0.581

D K T

s c

8 . 1 = =4.903 s

E.4.6.1 Spectral Acceleration Coefficients

I =1.25 SUG =II K =1.5 Q =0.667 R

wi

=4 T

L

=4 s

S

DS

=0.267 S

D1

=0.16 S

1

=0.1

DS v

S A 47 . 0 = =

0.125

R

wc

=2

DS D S

S S T

1

= =0.6 s

Impulsive spectral acceleration parameter : Convective spectral acceleration parameter :

(

(

|

|

.

|

\

|

= 007 . 0 ; max

wi

DS i

R

I

S A =0.083

(

(

|

|

.

|

\

|

|

|

.

|

\

|

=

i

wc c

L

D c

A

R

I

T

T

KS A ; min

2 1

=0.025

S

ai

=0.267 S

ac

=0.267

E.6.1.1 Effective Weight of Product

Total weight of the tank : W

p

=59 645 250 N Total weight of shell : W

s

=718 343.6 N

Total weight of fixed tank roof : W

r

=777 847.6 N Weight of the tank bottom: W

f

=175 580.7 N

Effective impulsive portion of the liquid weight :

p i

W

H

D

H

D

W

866 . 0

866 . 0 tanh |

.

|

\

|

= =41 615 750 N

Effective convective portion of the liquid weight :

p c

W

D

H

H

D

W |

.

|

\

|

=

67 . 3

tanh 230 . 0 =18 682 420 N

Uplift load due to product pressure : w

int

=0 N/m Roof load acting on the tank shell : W

rs

=777 847.6 N

E.6.1 Seismic base shear

Design base shear due to impulsive component :

( )

i f r s i i

W W W W A V + + + = =3 607 293 N

Design base shear due to convective component :

c c c

W A V = =466 281.4 N

Total design base shear :

2 2

c i

V V V + = =3 637 304 N

E.6.1.2.1 Center of Action for Ringwall Overturning Moment

H X

i

375 . 0 = =6 m H

D

H

D

H

D

H

X

c

(

(

(

(

|

.

|

\

|

|

.

|

\

|

=

67 . 3

sinh

67 . 3

1

67 . 3

cosh

0 . 1 =10.78 m

E.6.1.2.2 Center of Action for Slab Overturning Moment

H

H

D

H

D

X

is

(

(

(

(

|

|

|

|

.

|

\

|

|

.

|

\

|

+ = 0 . 1

866 . 0 tanh

866 . 0

333 . 1 0 . 1 375 . 0 =9.47 m H

D

H

D

H

D

H

X

cs

(

(

(

(

|

.

|

\

|

|

.

|

\

|

=

67 . 3

sinh

67 . 3

937 . 1

67 . 3

cosh

0 . 1 =11.57 m

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 15 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

E.6.1.4 Dynamic Liquid Hoop Forces

( )

(

=

D

H

D

Y H

GD A

N

c

c

68 . 3

cosh

68 . 3

cosh 85 . 1

2

|

.

|

\

|

(

(

|

.

|

\

|

=

H

D

H

Y

H

Y

GDH A N

i i

866 . 0 tanh 5 . 0 48 . 8

2

Y =Distance fromliquid surface to analysis point

Product hydrostatic membrane force :

( ) 3 . 0 9 . 4 = H DG N

h

t

N

h

h

=

( )

t

N A N N

h v c i

s

2 2 2

5 . 2 + +

=

Total combined hoop stress in the shell :

s h T

=

Allowable Hoop Stress : ( )

j y d h

E F S F 9 . 0 ; 333 . 1 min =

Y (m)

N

i

(N/mm)

N

c

(N/mm)

N

h

(N/mm)

h

(MPa)

s

(MPa)

T

(MPa)

S

d

(MPa)

F

y

(MPa)

E

j

F

h

(MPa)

1

2

3

4

5

6

16

16

16

16

16

16

103.33

103.33

103.33

103.33

103.33

103.33

3.06

3.06

3.06

3.06

3.06

3.06

1 692.

46

1 692.

46

1 692.

46

1 692.

46

1 692.

46

1 692.

46

141.04

169.25

211.56

282.08

282.08

282.08

11.14

13.37

16.72

22.29

22.29

22.29

152.18

182.62

228.27

304.37

304.37

304.37

147

147

147

147

147

147

221

221

221

221

221

221

0.85

0.85

0.85

0.85

0.85

0.85

169.07

169.07

169.07

169.07

169.07

169.07

E.6.1.5 Overturning Moment

Height fromthe bottomof the tank shell to the tank's

center of gravity : X

s

=0 m

Height fromthe bottomof the tank shell to the roof's

center of gravity : X

r

=16.78 m

Ringwall moment :

( ) | | ( ) | |

2 2

c c c r r s s i i i rw

X W A X W X W X W A M + + + = =

22.4653510

6

Nm

Slab moment :

( ) | | ( ) | |

2 2

cs c c r r s s is i i s

X W A X W X W X W A M + + + = =

34.3382610

6

Nm

E.6.2.1.1.2 Required minimumwidth of thickened bottomannular ring measured fromthe inside of the shell

|

|

.

|

\

|

|

|

.

|

\

|

=

e

y

a

HG

F

t D L 01723 . 0 ; 45 . 0 max ; 035 . 0 min =0.45 m

( )

v e

A G G 4 . 0 1 = =0.95

L

s

=0.45 m

t

a

=6 mm F

y

=221 MPa

E.6.2.1.1 Uplift resistance force in annular region

s e a

L HG w 5742 = =34 424.99 N/m

w

rs

=W

rs

/D

E.6.2.1.1.1 Anchorage Ratio

Shell and roof weight :

(

=

rs

s

t

w

D

W

w =21 647.84 N/m

( ) | |

int

2

4 . 0 4 . 0 1 w w A w D

M

J

a v t

rw

+

= =0.844

An anchorage is not required per Appendix E

E.6.2.1.2 Mechanically-Anchored

Uplift load on anchors :

( )|

.

|

\

|

=

v t

rw

AB

A w

D

M

w 4 . 0 1

273 . 1

2

=38 525.03 N/m

Bolt loads :

|

|

.

|

\

|

=

A

AB AB

n

D

w P =95 095 N

Number of bolts :

n

a

=28

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 16 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

E.6.2.2 MaximumLongitudinal Shell-Membrane Compression Stress at the bottomof the shell

Maximum longitudinal shell compression stress :

( )

s

rw

v t c

t D

M

A w

1000

1 273 . 1

4 . 0 1

2

|

.

|

\

|

+ + = =6.818 MPa

Allowable longitudinal shell compression stress :

( ) | |

+ = <

=

y s c

s c

F GH D t F t GHD

D t F t GHD

5 . 0 ; 5 . 7 5 . 2 83 min 44

83 44

2 2

2 2

F

c

=45.27 MPa

Stresses at the bottomof each shell course (linear variation of M

rw

=(Y/H) M

rw

) :

X (m) Y/H W

s

(N) w

t

(N/m)

c

(MPa) F

c

(MPa)

1

2

3

4

5

6

0

0

0

0

0

0

1

1

1

1

1

1

718 343.6

526 905.5

367 359.2

239 710.5

143 965.3

48 220.2

21 647.84

18 877.99

16 569.57

14 722.67

13 337.37

11 952.07

6.818

7.891

9.561

12.425

12.182

11.94

45.27

37.73

30.18

22.64

22.64

22.64

E.6.2.3 Overturning bearing force based on the maximumlongitudinal shell compression at the base of shell

( ) |

.

|

\

|

+ + =

2

273 . 1

4 . 0 1

D

M

A w P

rw

v t f

=81 820.71 N/m

E.7.2 Freeboard

A

f

|

|

.

|

\

|

=

2 1

4

C

D

T

I KS =0.05

height of the sloshing wave above the product design height :

s

=

f

DA 42 . 0 =0.46 m

Height of freeboard =0 m freeboard recommended =0.7

s

E.7.3.1 Estimated displacement resulting fromtank uplift

b

y

u

t

L F

y

2

10 . 12

= =0.09 m

E.7.6 Sliding resistance

( )( )

v p f r s s

A W W W W V 4 . 0 0 . 1 + + + = =23 297 200 N

=0.4 V V

s

E.7.7 peak local tangential shear per unit length

D

V

V

=

2

max

=105 253.6 N/m

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 17 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Anchor bolt design

Table 5-21a

Uplift load case U (N) S

b

(MPa) t

b

(N) A

r

(mm

2

)

Design Pressure

( ) | | | |

1

2

4 785 08 . 0 W D M D t P

Hu h

+

-1 508 619 100 -53 879.3 0

Test Pressure

( ) | | | |

1

2

4 785 08 . 0 W D M D t P

Hut h t

+

-1 508 619 170 -53 879.3 0

Failure Pressure

( ) | |

3

2

785 08 . 0 5 . 1 W D t P

h f

-2 191 892 100 -78 281.9 0

wind Load

| |

2

2

4 785 W D M D P

WH WR

+

/ / / /

seismic load

| | ( )

V rw

A W D M 4 . 0 1 4

2

2 663 428 150 95 122.4 634.15

Design Pressure+Wind

( ) | | ( ) | |

1

2

4 785 08 . 0 W D M M D t P P F

Hu WH h WR p

+ + +

/ / / /

Design Pressure+effect of horizontal/vertical load seismic

forces

( ) | | ( ) | | ( )

V Hu rw h p

A W D M M D t P F 4 . 0 1 4 785 08 . 0

1

2

+ +

2 612 004 150 93 285.9 621.91

Frangibility Pressure

( ) | |

3

2

785 08 . 0 3 W D t P

h f

-2 875 165 100 -102 684.5 0

U =Net uplift load t

b

=Load per bolt =U/N

S

b

=Allowable bolting stress A

r

=Required area =t

b

/S

b

F

p

=pressure combination factor =0.4

W

1

=dead load of shell minus any corrosion allowance plus any dead load other than roof plate acting on the shell

minus any corrosion allowance =718 343.6 N

W

2

=dead load of shell minus any corrosion allowance plus any dead load including roof plate acting on the shell

minus any corrosion allowance =1 496 191 N

W

3

=dead load of the shell using nominal thicknesses plus any dead load other than roof plate acting on the shell using

nominal thicknesses =718 343.6 N

Spacing between anchors =2.5 m 3 m Minimum required number of anchors =4

M

Hu

=0 Nm (user defined) M

Hut

=0 Nm (user defined)

A

v

=0.125 % g P =0 kPa

t

h

=26 mm(Nominal) P

t

=0 kPa

M

WH

=P

WS

DH

2

/2 =0 Nm P

f

=-1.2 kPa

M

rw

=22.4653510

6

Nm P

WR

=0 kPa

d

B

=Bolt diameter =33 mm P

WS

=0 N/m

2

N =Number of bolts =28 D =22 m

A

B

=647.2 mm

2

H =16 m

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 18 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Anchoring

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 19 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Summary

[01]

[44]

[45]

Shell

BottomPlates

Roof

Summary of Stiffeners.

Stiffener

Location

(mm)

Area

(mm

2

)

Inertia

(mm

4

)

Type and dimensions

(mm)

Remarks

1 16 000.0 3 064.51 4 703 415 L5x5x1/2 127 127 12.7

Summary of Geometry.

Type

Tag

Diameter

outside

Length

Cumulative

height

Thickness Angle Mass Flanges

ratings

Specifi

c

Gravity

Material

(mm) (mm) (mm) (mm) () (kg)

01[44] 44 22 000.0 0.0 0.0 6.000 0 17 904.3 7.85 SA516GR60

02[01] 1 vir 22 000.0 3 000.0 3 000.0 12.000 0 19 521.3 7.85 SA516GR60

03[01] 2 vir 22 000.0 3 000.0 6 000.0 10.000 0 16 269.2 7.85 SA516GR60

04[01] 31.07 22 000.0 3 000.0 9 000.0 8.000 0 13 016.5 7.85 SA516GR60

05[01] 31.08 22 000.0 3 000.0 12 000.0 6.000 0 9 763.3 7.85 SA516GR60

06[01] 31.09 22 000.0 3 000.0 15 000.0 6.000 0 9 763.3 7.85 SA516GR60

07[01] 31.10 22 000.0 1 000.0 16 000.0 6.000 0 3 254.4 7.85 SA516GR60

08[45] 45 22 100.0 0.0 16 000.0 26.000 12 79 318.4 7.85 SA516GR60

Angle : half angle at apex for a concentric cone ; maximumangle between cone and cylinder for an eccentric cone.

Material: (N) =normalized

NB: Italic line indicates an element for which the calculation under pressure has not been done.

Summary of Foundation Loads

Tank parameters

Nominal Diameter 22 m

Total height 16 m

Liquid height 16 m

Anchor bolts 28 33 mm

Bolt Circle Diameter 22 250 mm

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 20 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Weight new Corroded additional weight

Shell 70 204 daN 70 204 daN 0 daN

Bottom 17 558 daN 17 558 daN 0 daN

Roof 77 785 daN 77 785 daN 0 daN

Nozzles 0 daN 0 daN

Rafter 0 daN

Girder 0 daN

Column 0 daN

Top Stiffener 1 631 daN

Stiffeners 0 daN

Ladder & Stair 0 daN

Platforms 0 daN

Anchor 0 daN

Insulation 0 daN

Weight of liquid 5 964 525 daN

Total empty weight 167 177 daN 167 177 daN

Operating weight 6 131 703 daN 6 131 703 daN

Hydrostatic test weight 6 131 703 daN

External Force & Moment

Equivalent horizontal load F

Hu

= 0 daN

Overturning Moment M

Hu

= 0 daNm

Equivalent vertical load F

Vu

= 0 daN

Overturning Moment M

Vu

= 0 daNm

Wind loads

Base Shear Force F

w

= 0 daN

Base Moment M

w

= 0 daNm

Seismic loads

Base Shear Force V = 363 730 daN

Base Moment M

rw

= 2 246 536 daNm

Base Moment M

s

= 3 433 827 daNm

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 21 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

List of customisable files.

Materials C:\Users\Public\Documents\AutoPIPE Vessel\Config\Material.emdm (?)

Shapes

C:\Users\Public\Documents\AutoPIPE Vessel\Config\dimsha.doc (Wed Jan 22 10:31:32

2014)

C:\Users\Public\Documents\AutoPIPE Vessel\Config\dimsha.emsd (Wed Jan 22 10:31:32

2014)

Brackets /

Saddles /

Anchoring

C:\Users\Public\Documents\AutoPIPE Vessel\Config\dimanc.doc (Wed Jan 22 10:31:32

2014)

C:\Users\Public\Documents\AutoPIPE Vessel\Config\dimanc.emsd (Wed Jan 22 10:31:32

2014)

Gussets /

Legs /

Reinforcing pads /

Projection of nozzles /

Tubes /

Pipe fittings /

Trade thickness /

Flanges /

Gaps for exchanger /

Bolts

C:\Users\Public\Documents\AutoPIPE Vessel\Config\boltISO.doc (Wed Jan 22 10:31:32

2014)

C:\Users\Public\Documents\AutoPIPE Vessel\Config\boltISO.emsd (Wed Jan 22 10:31:32

2014)

C:\Users\Public\Documents\AutoPIPE Vessel\Config\boltUN.doc (Wed Jan 22 10:31:32

2014)

C:\Users\Public\Documents\AutoPIPE Vessel\Config\boltUN.emsd (Wed Jan 22 10:31:32

2014)

C:\Users\Public\Documents\AutoPIPE Vessel\Config\boltGOST.doc (Wed Jan 22 10:31:32

2014)

C:\Users\Public\Documents\AutoPIPE Vessel\Config\boltGOST.emsd (Wed Jan 22

10:31:32 2014)

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 22 prodia2 V33.2.0.6 Bentley Systems, Inc.

DSD

.

.

Design Calculations

2014-03-21

Revision :

C:\Users\...\Tank\New1.emvd

(2014-03-20)

Summary of Errors and Warnings.

No. Explanation ( the number is used for technical support support@bentley.com)

Error (s) :

311 WIND: dynamic pressure missing.

377 ANCHORAGE: No calculation made, allowable stress of plates missing.

797 ROOF : corroded thickness shall not be more than 13 mm.

805 SEISMIC DESIGN : combined hoop stress in the shell not maintained.

809 SEISMIC DESIGN : minimumrequired freeboard not maintained.

Warning (s) :

128 CHECKING DATA : no design for wind load.

768 ROOF: the roof is not frangible.

Total: 5 error(s) and 2 warning(s).

AutoPIPE Vessel (Microprotol) procal V33.2.0.6 23 prodia2 V33.2.0.6 Bentley Systems, Inc.

Vous aimerez peut-être aussi

- AutoPIPE Vessel Tutorial Pressure Vessel OutputDocument37 pagesAutoPIPE Vessel Tutorial Pressure Vessel OutputfnyaclsPas encore d'évaluation

- Design CalcDocument308 pagesDesign CalcPeja Jusoh100% (1)

- Design 1Document29 pagesDesign 1Nikki RobertsPas encore d'évaluation

- AutoPIPE Vessel Tutorial Pressure Vessel 2 OutputDocument62 pagesAutoPIPE Vessel Tutorial Pressure Vessel 2 OutputDarshan PanchalPas encore d'évaluation

- Air Receiver Sample CalcDocument49 pagesAir Receiver Sample CalcBrian Edwin RodriguezPas encore d'évaluation

- Part 2 Pressure Vessel DesignDocument281 pagesPart 2 Pressure Vessel DesignSyedZainAli100% (1)

- Stiffening Effect of Refractory Lined Piping - Carmagen EngineeringDocument1 pageStiffening Effect of Refractory Lined Piping - Carmagen EngineeringnaeandPas encore d'évaluation

- Pv-Elite He 101 - Rev 7Document118 pagesPv-Elite He 101 - Rev 7Dwi Putra100% (1)

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuPas encore d'évaluation

- Electric Boiler Design Calculations-ASME SEC.I, PART-PEB, EDITION 2019 PDFDocument48 pagesElectric Boiler Design Calculations-ASME SEC.I, PART-PEB, EDITION 2019 PDFSuresh Damu BhadPas encore d'évaluation

- 10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JHDocument26 pages10 Runkel - Sulphuric 2009 - Pyrite Roasting - Runkel Sturm - OUTOTEC JHvahidPas encore d'évaluation

- Design of Pressure Vessel - CADEMDocument88 pagesDesign of Pressure Vessel - CADEMgkdora574Pas encore d'évaluation

- GERMANY TANK FULL REPORT-9 Updated As Per Client CommentDocument45 pagesGERMANY TANK FULL REPORT-9 Updated As Per Client CommentSalmanPas encore d'évaluation

- Heater 10m2 (ASME Tubesheet)Document17 pagesHeater 10m2 (ASME Tubesheet)Omil RastogiPas encore d'évaluation

- Vacuum Insulated CO2Document13 pagesVacuum Insulated CO2dragosm78Pas encore d'évaluation

- Pipe Wall Thickness Calculations: Burnex Burner HeadDocument16 pagesPipe Wall Thickness Calculations: Burnex Burner Headpramodptvpm_65797156Pas encore d'évaluation

- Finite Element Analysis and Reliability Assessment of Spherical LPG ...Document6 pagesFinite Element Analysis and Reliability Assessment of Spherical LPG ...Suleyman HaliciogluPas encore d'évaluation

- Pressure Vessel Calculation ReportDocument82 pagesPressure Vessel Calculation ReporteeghbaliPas encore d'évaluation

- Mechanical Design of ColumnDocument12 pagesMechanical Design of ColumnfarahanisiliasPas encore d'évaluation

- Calculations Tank S6Document19 pagesCalculations Tank S6Joshue Adele100% (1)

- Design of Large Opening Nozzle by Bulletin WRC-107Document12 pagesDesign of Large Opening Nozzle by Bulletin WRC-107ALONSO GOMEZPas encore d'évaluation

- AutoPIPE Vessel GuideDocument5 pagesAutoPIPE Vessel Guidefiuto_rights_1404802Pas encore d'évaluation

- ASCE 7-05 Table 15-4-2Document1 pageASCE 7-05 Table 15-4-2barouniaminePas encore d'évaluation

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraPas encore d'évaluation

- Coke Drum Skirt ExampleDocument10 pagesCoke Drum Skirt Example2009tamerPas encore d'évaluation

- MecaStack MatindokDocument59 pagesMecaStack MatindokmedyPas encore d'évaluation

- VERIFICATIONDocument3 pagesVERIFICATIONshaishavPas encore d'évaluation

- Calculation of BuckstayDocument8 pagesCalculation of BuckstaydehriyaPas encore d'évaluation

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TPas encore d'évaluation

- Stresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFDocument8 pagesStresses in Vessel On Two Sad... Ports Using ZICK Analysis PDFanishPas encore d'évaluation

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDocument12 pages8 AS4041 ASME B31 3 Pipe Wall Thicknesswhah11Pas encore d'évaluation

- 18 Desing of Support For Pressure VesselDocument27 pages18 Desing of Support For Pressure VesselAmit KananiPas encore d'évaluation

- Design Calculation: Fuel Gas Scrubber TAG NO: V-6011Document239 pagesDesign Calculation: Fuel Gas Scrubber TAG NO: V-6011Peja JusohPas encore d'évaluation

- 2400 Tema DCDocument7 pages2400 Tema DCMasoodMiyanPas encore d'évaluation

- Review Paper On CFD Analysis of Cyclone Separator With Discrete Phase ModellingDocument4 pagesReview Paper On CFD Analysis of Cyclone Separator With Discrete Phase ModellingInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Ejma7r2 Bellows Worksheet 1Document8 pagesEjma7r2 Bellows Worksheet 1NamıkPas encore d'évaluation

- Comparison ASME KTADocument7 pagesComparison ASME KTAAndres_Pastor1987Pas encore d'évaluation

- Stack Design CalculationDocument27 pagesStack Design Calculationrupam dey100% (6)

- PV Elite IntroDocument52 pagesPV Elite IntroGodwinPas encore d'évaluation

- Tank Stability 10.0: Shell Dimension, NewDocument4 pagesTank Stability 10.0: Shell Dimension, NewjonedPas encore d'évaluation

- 3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankDocument4 pages3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankNurul HudaPas encore d'évaluation

- Skirt Support Analysis TransportDocument5 pagesSkirt Support Analysis TransportHunnymijie NorPas encore d'évaluation

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariPas encore d'évaluation

- PC-01 - Process Column Design Calculations Using CademPVD SoftwareDocument127 pagesPC-01 - Process Column Design Calculations Using CademPVD SoftwareCADEM SoftwaresPas encore d'évaluation

- Shell Design Variable Point Method PDFDocument9 pagesShell Design Variable Point Method PDFBNRPas encore d'évaluation

- 019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Document26 pages019-02 - 50 KL Mee Feed Storage Tank 21ST-017 & 21ST-018Bhaumik BhuvaPas encore d'évaluation

- Jeddah South Thermal Power Plant Stage-I: ProjectDocument18 pagesJeddah South Thermal Power Plant Stage-I: ProjectAmr AbdeinPas encore d'évaluation

- Analysis of Seismic Behavior of Underground Structures A Case Study On Bolu TunnelsDocument145 pagesAnalysis of Seismic Behavior of Underground Structures A Case Study On Bolu TunnelsAhmad Mubarak100% (1)

- STHE Design (Training Material)Document37 pagesSTHE Design (Training Material)Herman_ms2000100% (2)

- Design of ChimneyDocument13 pagesDesign of Chimneyjay_p_shahPas encore d'évaluation

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoePas encore d'évaluation

- Single Col - Tank-2013Document35 pagesSingle Col - Tank-2013Hgagselim SelimPas encore d'évaluation

- Atmospheric Tank Design CalculationDocument2 pagesAtmospheric Tank Design CalculationmusaveerPas encore d'évaluation

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988D'EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockPas encore d'évaluation

- Sample4 PVEliteDocument66 pagesSample4 PVEliteSourav Hait100% (1)

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohPas encore d'évaluation

- VD-SRU-V-004-100-Rev ADocument51 pagesVD-SRU-V-004-100-Rev ASYedZYnAlePas encore d'évaluation

- AutoPIPE Vessel Tutorial Pressure Vessel 2 Output PDFDocument62 pagesAutoPIPE Vessel Tutorial Pressure Vessel 2 Output PDFktejankarPas encore d'évaluation

- Hydromation Filter MHydromation FilterDocument26 pagesHydromation Filter MHydromation FilterArt G. EnziPas encore d'évaluation

- PV Elite Vessel Analysis Program: Input DataDocument90 pagesPV Elite Vessel Analysis Program: Input DatajahiranazriPas encore d'évaluation

- Draft ListDocument3 pagesDraft ListscribddisantoPas encore d'évaluation

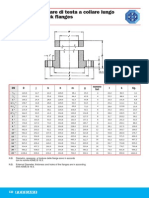

- Seamless Lap Joint Stub EndsDocument1 pageSeamless Lap Joint Stub Endsscribddisanto100% (1)

- Materials Stud Bolts: ASTM A197 B7Document5 pagesMaterials Stud Bolts: ASTM A197 B7scribddisantoPas encore d'évaluation

- Long Welding Neck Flanges 1500Document1 pageLong Welding Neck Flanges 1500scribddisantoPas encore d'évaluation

- Long Welding Neck Flanges 900Document1 pageLong Welding Neck Flanges 900scribddisantoPas encore d'évaluation

- Long Welding Neck Flanges 150Document1 pageLong Welding Neck Flanges 150scribddisantoPas encore d'évaluation

- Long Welding Neck Flanges 600Document1 pageLong Welding Neck Flanges 600scribddisantoPas encore d'évaluation

- Unit Systems PDFDocument2 pagesUnit Systems PDFscribddisantoPas encore d'évaluation

- Stainless Steel Material PropertiesDocument4 pagesStainless Steel Material PropertiesMohammed RiyazPas encore d'évaluation

- BS EN 1515-4:2009 Flanges BoltingDocument22 pagesBS EN 1515-4:2009 Flanges BoltingAlexDdd123100% (1)

- Control Card HyperMesh and BatchMesher PDFDocument33 pagesControl Card HyperMesh and BatchMesher PDFscribddisantoPas encore d'évaluation

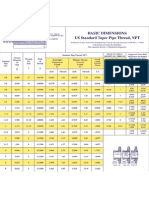

- S E S S U e ,: BA Ic Dim N S Standard Taper Thread NPTDocument1 pageS E S S U e ,: BA Ic Dim N S Standard Taper Thread NPTscribddisantoPas encore d'évaluation

- Surface To Surface ContactDocument13 pagesSurface To Surface ContactscribddisantoPas encore d'évaluation

- 2nd Semester Latest 21Document75 pages2nd Semester Latest 21Mugars Lupin ArsenePas encore d'évaluation

- The Andromedan Compendium - 7bDocument10 pagesThe Andromedan Compendium - 7bAnonymous XSNBQQ4yPas encore d'évaluation

- Ibraim Overview Influence of Pozzolanic Materials PDFDocument12 pagesIbraim Overview Influence of Pozzolanic Materials PDFrobertsj21Pas encore d'évaluation

- t9 PDFDocument21 pagest9 PDFselvaganapathy1992Pas encore d'évaluation

- 2017 - OPUS Quant Advanced PDFDocument205 pages2017 - OPUS Quant Advanced PDFIngeniero Alfonzo Díaz Guzmán100% (1)

- AppNote 07 FPSO and Offshore PlatformsDocument4 pagesAppNote 07 FPSO and Offshore PlatformsRao MadepalliPas encore d'évaluation

- Algebra2 Glenco EOCDocument62 pagesAlgebra2 Glenco EOCDeborah LeePas encore d'évaluation

- Instrumentation: Biochemistry Laboratory Prepared By: Shanny G. Estera, RPHDocument39 pagesInstrumentation: Biochemistry Laboratory Prepared By: Shanny G. Estera, RPHMika ForwardPas encore d'évaluation

- Constant Effort SupportsDocument31 pagesConstant Effort SupportsKen SidhartaPas encore d'évaluation

- Engine Control SystemDocument7 pagesEngine Control SystemFaisal Al HusainanPas encore d'évaluation

- Syllabus - Mathematical EconomicsDocument2 pagesSyllabus - Mathematical EconomicsMRVPas encore d'évaluation

- Nastran DST Group TN 1700Document69 pagesNastran DST Group TN 1700Minh LePas encore d'évaluation

- Binders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsDocument13 pagesBinders: 1. Compaction Behaviour of Organic Binders in Alumina Ceramics (PVA & PEG) General FactsPranav KumarPas encore d'évaluation

- Shodex SEC ColumnsDocument40 pagesShodex SEC ColumnsAlfred HuangPas encore d'évaluation

- Bio Well InformationDocument5 pagesBio Well InformationPradyuman PatelPas encore d'évaluation

- PhysicsDocument28 pagesPhysicsamritam yadavPas encore d'évaluation

- User Guide: Elcometer 147Document4 pagesUser Guide: Elcometer 147sergioPas encore d'évaluation

- Chul Park The Limits of Two-Temperature ModelDocument13 pagesChul Park The Limits of Two-Temperature ModellazharPas encore d'évaluation

- RC2Document92 pagesRC2Chrisneil DelosreyesPas encore d'évaluation

- Project DPPMDocument3 pagesProject DPPMjelmerPas encore d'évaluation

- HAZOP Work Sheet ZaltoprofenDocument26 pagesHAZOP Work Sheet Zaltoprofenkirandevi1981Pas encore d'évaluation

- Indian Standard: Specificati-OnDocument14 pagesIndian Standard: Specificati-On661982Pas encore d'évaluation

- Hypocycloid - AnimatedDocument29 pagesHypocycloid - AnimatedJairus SamuelPas encore d'évaluation

- A History of PhotographyDocument49 pagesA History of PhotographyderghalPas encore d'évaluation

- Answer of Midterm Exam 2 PDFDocument6 pagesAnswer of Midterm Exam 2 PDFFaisal Al-assafPas encore d'évaluation

- Dss Question Bank 2022Document7 pagesDss Question Bank 2022vcb57xbtd5Pas encore d'évaluation

- Calculated MAWP MAPDocument4 pagesCalculated MAWP MAPhataefendiPas encore d'évaluation

- PDFDocument2 pagesPDFbhavesh patelPas encore d'évaluation

- Stiffness Analysis of FramesDocument37 pagesStiffness Analysis of FramesCarolina VacaPas encore d'évaluation

- ClimateDocument30 pagesClimateSujitnkbpsPas encore d'évaluation