Académique Documents

Professionnel Documents

Culture Documents

KLINGER Bestaendigkeit

Transféré par

jbertral0 évaluation0% ont trouvé ce document utile (0 vote)

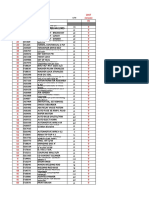

36 vues6 pagesChemical Resistant table for Klinger Products. Tabla de compatibilidad o resistencia química de los productos Klinger.

Copyright

© Attribution Non-Commercial (BY-NC)

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentChemical Resistant table for Klinger Products. Tabla de compatibilidad o resistencia química de los productos Klinger.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

36 vues6 pagesKLINGER Bestaendigkeit

Transféré par

jbertralChemical Resistant table for Klinger Products. Tabla de compatibilidad o resistencia química de los productos Klinger.

Droits d'auteur :

Attribution Non-Commercial (BY-NC)

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 6

The chemical resistance table serves

as a guide for the resistance to media

of all asbestos-free gaskets. All

information is provided in accordance

with the current state of knowledge

and subject to alteration.

If in doubt, please

use our free

technical fax

service. Details

are given inside.

Chemical

resistance

table

Chemical resistance table

T

o

p

-

s

i

l

-

M

L

1

T

o

p

-

g

r

a

p

h

2

0

0

0

C

-

4

1

0

6

C

-

4

3

0

0

C

-

4

4

0

0

C

-

4

4

3

0

/

4

4

3

3

C

-

4

5

0

0

C

-

6

3

0

7

C

-

8

2

0

0

C

-

4

4

0

8

C

-

4

4

0

9

C

-

4

5

0

9

Acetaldehyde

Acetamide

Acetic acid 10%

Acetic acid 100% (glacial acetic acid)

Acetic acid ester

Acetone

Acetylene

Adipic acid

Air

Aliphatic hydrocarbons (see under specific name)

Alcohol (see under specific name)

Alum

Aluminum acetate

Aluminum chlorate

Aluminum chloride

Ammonia

Ammonium carbonate

Ammonium chloride

Ammonium hydrogenphosphate (diammonium phosphate)

Ammonium hydroxide

Amyl acetate

Aniline

Anon (Cyclohexanone)

Arcton 12 (Frigen or Freon 12)

Arcton 22 (Frigen or Freon 22)

Aromatic hydrocarbons (see under specific name)

Asphalt (tar)

Barium chloride

Benzene

Benzoic acid

Blast furnace gas

Bleaching liquor (chloride of lime)

Boiler feed water and boiler water (alkaline)

Borax

Boric acid

Brine

Butane

Butanol (butyl alcohol)

Butanone (2) (M.E.K.)

Butyl acetates

Butyl alcohol

Butylamine

Butyric acid

CH

3

CHO

CH

3

CONH

2

CH

3

COOH

CH

3

COOH

CH

3

COOC

2

H

5

CH

3

COCH

3

C

2

H

2

HOOC(CH

2

)

4

COOH

KAl(SO

4

)

2

(CH

3

COO)

2

Al OH

Al(ClO

3

)

3

AlCl

3

NH

3

(NH

4

)

2

CO

3

NH

4

Cl

(NH

4

)

2

HPO

4

NH

4

OH

CH

3

COOC

5

H

11

C

6

H

5

NH

2

C

6

H

10

O

CCl

2

F

2

CHF

2

Cl

BaCl

2

C

6

H

6

C

6

H

5

COOH

Na

2

B

4

O

7

.

10H

2

O

B (OH)

3

NaCl

C

4

H

10

C

4

H

9

OH

CH

3

COC

2

H

5

CH

3

COOC

4

H

9

C

4

H

9

OH

C

4

H

9

NH

2

C

3

H

7

COOH

Subject to technical alternations. 05.2004

Medium Chemical formula Gasket material

Resistant* Condit. recommended Not recommended

* Resistant

means:

Suitable

for the

appropriate

use as a

compressed

gasket

between

flange

surfaces.

For your choice of the right

gasket we offer you a proven commu-

nication concept which leads you

step by step to the right decision.

1. Application survey

A comparison of the sealing material

characteristics with the criteria for

typical fields of application gives

you a first general survey.

2. Documentation of the product:

A technical data sheet is available

for every material including the

pT diagram, which demonstrates

different material behaviour to further

facilitate your choice.

3. Resistance to media:

Here you find statements on the

resistance of every Klinger gasket

material.

T

o

p

-

s

i

l

-

M

L

1

T

o

p

-

g

r

a

p

h

2

0

0

0

C

-

4

1

0

6

C

-

4

3

0

0

C

-

4

4

0

0

C

-

4

4

3

0

/

4

4

3

3

C

-

4

5

0

0

C

-

6

3

0

7

C

-

8

2

0

0

C

-

4

4

0

8

C

-

4

4

0

9

C

-

4

5

0

9

Calcium chloride

Calcium hydroxide

Calcium hypochlorite

Calcium sulfate

Carbolic acid 100% (phenol)

Carbon dioxide

Carbon disulfide

Carbon tetrachloride

Castor oil

Chlorine (dry)

Chlorine (wet)

Chlorine water (circa 0,5%)

Chloroform

Chromic acid

Citric acid

Clophen T 64

Coagulating baths (up to 10%)

Condensation water

Copper acetate

Copper sulfate

Cresol

Cyclohexanol

Cyclohexanone (see anon)

Decaline

Dibenzyl ether

Dibutyl phthalate

Diesel oil

Diethyl ether

Dimethyl formamide

Diphyl (Dowtherm A)

Dye baths (alkaline, neutral, acidic)

Ethane

Ethanol (ethyl alcohol)

Ethyl acetate (acetic ethylester)

Ethyl alcohol

Ethyl chloride

Ethylene

Ethylene chloride

Ethylenediamine

Ethylene glycol

Fatty acids from C

6

upwards (see palmitic, stearic and oelic acids)

Fluorosilicic acid

Formaldehyde

CaCl

2

Ca(OH)

2

Ca(OCl)

2

CaSO

4

C

6

H

5

OH

CO

2

CS

2

CCl

4

Cl

2

Cl

2

CHCl

3

H

2

CrO

4

(CH

2

COOH)

2

C(OH)COOH

H

2

SO

4

H

2

O

(CH

3

COO)

2

Cu

CuSO

4

C

6

H

4

(OH)CH

3

C

6

H

11

OH

C

10

H

18

(C

6

H

5

CH

2

)

2

O

C

6

H

4

(COOC

4

H

9

)

2

C

2

H

5

OC

2

H

5

HCON(CH

3

)

2

C

2

H

6

C

2

H

5

OH

CH

3

COOC

2

H

5

C

2

H

5

OH

C

2

H

5

Cl

C

2

H

4

(CH

2

Cl)

2

(CH

2

NH

2

)

2

(CH

2

OH)

2

H

2

SiF

6

HCHO

Subject to technical alternations. 05.2004

Medium Chemical formula Gasket material

Resistant* Condit. recommended Not recommended

* Resistant

means:

Suitable

for the

appropriate

use as a

compressed

gasket

between

flange

surfaces.

KLINGERexpert

for the experienced

specialist. It helps to answer all

questions on construction, design and

maintenance. Software and on-line-

help on CD-ROM.

6. The best way: to test

We will deliver original material for a

test under your service conditions.

7. On-the-spot advice

With very difficult tasks we will

advise you on the spot. We offer

adapted designs you on the basis of

our standard qualities and special

designs for your needs.

4. Technical fax service:

Provide us with the data for your

sealing situation and you will receive

a reliable response from Klinger, often

within 24 hours.

5. Sealing calculation with the

help of your PC:

The efficient computer program

T

o

p

-

s

i

l

-

M

L

1

T

o

p

-

g

r

a

p

h

2

0

0

0

C

-

4

1

0

6

C

-

4

3

0

0

C

-

4

4

0

0

C

-

4

4

3

0

/

4

4

3

3

C

-

4

5

0

0

C

-

6

3

0

7

C

-

8

2

0

0

C

-

4

4

0

8

C

-

4

4

0

9

C

-

4

5

0

9

Formamide

Formic acid 10%

Formic acid 85%

Freon 12, Frigen 12, Arcton 12

Freon 22, Frigen 22, Arcton 22

Fuel oil

Generator gas

Glacial acetic acid

Glycerol

Heating oil

Heptane

Hydraulic oil (mineral)

Hydraulic oil (phosphate ester type)

Hydraulic oil (glycol based)

Hydrazine hydrate

Hydrochloric acid 20%

Hydrochloric acid 37%

Hydrofluoric acid 10%

Hydrofluoric acid 40%

Hydrogen

Hydrogen chloride (dry)

Hydrogen peroxide (up to 6% by weight)

Isooctane (2, 2, 4 trimethylpentan)

Isopropyl alcohol

Kerosene

Lactic acid 50%

Lead acetate (sugar of lead)

Lead arsenate

Lime water

Linseed oil

Lubricating oil (see mineral oils)

Magnesium sulfate

Malic acid

M.E.K. (2-butanone)

Methane

Methyl alcohol (methanol)

Methyl chloride

Methylene chloride

Mineral oil - ASTM Oil No. 1

Mineral oil - ASTM Oil No. 3

Monochlormethane

HCONH

2

HCOOH

HCOOH

CCl

2

F

2

CHF

2

Cl

CH

3

COOH

(CH

2

OH)

2

CHOH

C

7

H

16

(NH

2

)

2

H

2

O

HCl

HCl

HF

HF

H

2

HCl

H

2

O

2

(CH

3

)

3

CCH

2

CH(CH

3

)

2

(CH

3

)

2

CHOH

CH

3

CHOH COOH

(CH

3

COO)

2

PB

Pb

3

(AsO

4

)

2

Ca(OH)

2

MgSO

4

HOOC-CHOH-CH

2

-COOH

CH

3

COC

2

H

5

CH

4

CH

3

OH

CH

3

Cl

CH

2

Cl

2

CH

3

Cl

Subject to technical alternations. 05.2004

Medium Chemical formula Gasket material

Resistant* Condit. recommended Not recommended

* Resistant

means:

Suitable

for the

appropriate

use as a

compressed

gasket

between

flange

surfaces.

The recommendations given

here are intended to be an aid in the

selection of the suitable gasket

quality. It is not possible to provide

a warranty because the function and

durability of the products depend

largely a number of factors over

which the manufacturer has no

influence. Should there be special

approval regulations, these have to be

complied with.

T

o

p

-

s

i

l

-

M

L

1

T

o

p

-

g

r

a

p

h

2

0

0

0

C

-

4

1

0

6

C

-

4

3

0

0

C

-

4

4

0

0

C

-

4

4

3

0

/

4

4

3

3

C

-

4

5

0

0

C

-

6

3

0

7

C

-

8

2

0

0

C

-

4

4

0

8

C

-

4

4

0

9

C

-

4

5

0

9

Naphtha

Natural gas

Nitric acid 20%

Nitric acid 40%

Nitric acid 96%

Nitrobenzene

Nitrogen

Octane

Oleic acid

Oleum (fuming sulfuric acid))

Oxalic acid

Oxygen (check local regulations for use)

Palmitic acid

Paraffin (kerosene)

Pentane

Perchlorethylene

Petrol (fuel)

Petroleum

Petroleum ether

Phenol

Phosphoric acid (all concentrations)

Phthalic acid

Potassium acetate

Potassium carbonate

Potassium chlorate

Potassium chloride

Potassium chromium sulfate

Potassium cyanide

Potassium dichromate

Potassium hydroxide

Potassium hypochlorite (eau de Javelle)

Potassium iodide

Potassium nitrate (salpetre)

Potassium permanganate

Propane

Pyridine

Rapeseed oil

R134a

Salicylic acid

Salt (rock salt)

Sea water

Silicone oil

Skydrol 500

HNO

3

HNO

3

HNO

3

C

6

H

5

NO

2

N

2

C

8

H

18

C

17

H

33

COOH

H

2

SO

4

with free SO

3

(COOH)

2

O

2

C

15

H

31

COOH

C

5

H

12

C

2

Cl

4

C

6

H

5

OH

H

3

PO

4

C

6

H

4

(COOH)

2

CH

3

COOK

K

2

CO

3

KClO

3

KCl

KCr(SO

4

)

2

.

12H

2

O

KCN

K

2

Cr

2

O

7

KOH

KOCl

KJ

KNO

3

KMnO

4

C

3

H

8

C

5

H

5

N

CH

2

FCF

3

C

6

H

4

(OH)COOH

NaCl

Subject to technical alternations. 05.2004 Resistant* Condit. recommended Not recommended

The nomenclature of the media

corresponds to the IUPAC (German

nomenclature commission):

e.g. chemical compounds which are

written with Ae are changed to E and

can be found under this letter in the

alphabet.

Medium Chemical formula Gasket material

* Resistant

means:

Suitable

for the

appropriate

use as a

compressed

gasket

between

flange

surfaces.

KLINGER GmbH

P.O.Box 1370, D-65503 Idstein

Rich.-Klinger-Strae 8,

D-65510 Idstein

Phone +49 (0) 6126 9500

Fax +49 (0) 6126 950340/ 950341

e-mail: mail@klinger-gmbh.de

http://www.klinger-gmbh.de

Certified according to

DIN EN ISO 9001: 2000

T

o

p

-

s

i

l

-

M

L

1

T

o

p

-

g

r

a

p

h

2

0

0

0

C

-

4

1

0

6

C

-

4

3

0

0

C

-

4

4

0

0

C

-

4

4

3

0

/

4

4

3

3

C

-

4

5

0

0

C

-

6

3

0

7

C

-

8

2

0

0

C

-

4

4

0

8

C

-

4

4

0

9

C

-

4

5

0

9

Soap

Soda (sodium carbonate)

Sodium aluminate

Sodium hydrogencarbonate

Sodium hydrogensulfite

Sodium chloride (Salt)

Sodium cyanide

Sodium hydroxide

Sodium silicate (water-glass)

Sodium sulfate

Sodium sulfide

Spirit

Starch

Steam (temperature limit see pT-diagram)

Stearic acid

Sugar

Sulfur dioxide

Sulfuric acid 20%

Sulfuric acid 50%

Sulfuric acid 96%

Sulfurous acid

Tannic acid

Tar (asphalt)

Tartaric acid

Tetrachlorethane

Tetralin (1, 2, 3, 4 -tetrahydronaphtalene)

Toluene

Town gas

Transformer oil

Trichlorethylene

Triethanolamine

Turpentine

Urea

Vinyl acetate

Water

Water-glass

White Spirit

Xylene

Na

2

CO

3

Na

3

AlO

3

NaHCO

3

NaHSO

3

NaCl

NaCN

NaOH

Na

2

SiO

3

K

2

SiO

3

Na

2

SO

4

Na

2

S

(C

6

H

10

O

5

)

n

H

2

O

C

17

H

35

COOH

SO

2

H

2

SO

4

H

2

SO

4

H

2

SO

4

H

2

SO

3

C

76

H

52

O

46

(CHOHCOOH)

2

C

2

H

2

Cl

4

C

10

H

12

C

6

H

5

CH

3

C

2

HCl

3

N(CH

2

CH

2

OH)

3

(NH

2

)

2

CO

CH

3

COOC

2

H

3

H

2

O

Na

2

SiO

3

K

2

SiO

3

C

6

H

4

(CH

3

)

2

Subject to technical alternations. 05.2004

* Resistant

means:

Suitable

for the

appropriate

use as a

compressed

gasket

between

flange

surfaces.

Resistant* Condit. recommended Not recommended

Medium Chemical formula Gasket material

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Ptfe HandbookDocument38 pagesPtfe Handbookparthihce100% (1)

- GORE Joint Sealant DF Datasheet enDocument2 pagesGORE Joint Sealant DF Datasheet enjbertralPas encore d'évaluation

- Aseptic Processing: A Review of Current Industry Practice: James Agalloco, James Akers, and Russell MadsenDocument13 pagesAseptic Processing: A Review of Current Industry Practice: James Agalloco, James Akers, and Russell MadsenjbertralPas encore d'évaluation

- FEEPA - Stress-StrainDocument74 pagesFEEPA - Stress-StrainjbertralPas encore d'évaluation

- Kill The BioburdenDocument2 pagesKill The BioburdenjbertralPas encore d'évaluation

- THERMAX - Temperature SensorsDocument2 pagesTHERMAX - Temperature SensorsjbertralPas encore d'évaluation

- Accesorios Roscados para PlásticosDocument32 pagesAccesorios Roscados para PlásticosjbertralPas encore d'évaluation

- Graphonic Garlock PDFDocument40 pagesGraphonic Garlock PDFjbertralPas encore d'évaluation

- C 660Document7 pagesC 660jbertralPas encore d'évaluation

- Hapkido NormsDocument25 pagesHapkido NormsjbertralPas encore d'évaluation

- Viton - Processing GuideDocument24 pagesViton - Processing Guidejbertral100% (1)

- Diamond Like Carbon DLCDocument5 pagesDiamond Like Carbon DLCjbertralPas encore d'évaluation

- Aluminium Magnesium BorideDocument2 pagesAluminium Magnesium BoridejbertralPas encore d'évaluation

- MSS SP 6 2007Document7 pagesMSS SP 6 2007jbertralPas encore d'évaluation

- Dimensions Stub EndsDocument1 pageDimensions Stub EndsjbertralPas encore d'évaluation

- Flender HandbookDocument79 pagesFlender Handbookjbertral100% (1)

- W.G.rathmann ClampsDocument2 pagesW.G.rathmann ClampsjbertralPas encore d'évaluation

- Klingersil: Optimum Flange SecurityDocument7 pagesKlingersil: Optimum Flange SecurityjbertralPas encore d'évaluation

- Ball MillDocument14 pagesBall MillISLAM I. Fekry95% (20)

- Garlock: Compression Packing Technical ManualDocument28 pagesGarlock: Compression Packing Technical ManualjbertralPas encore d'évaluation

- ERIKS - High Purity Elastomer GuideDocument56 pagesERIKS - High Purity Elastomer GuidejbertralPas encore d'évaluation

- PVC - Polyvinyl ChlorideDocument13 pagesPVC - Polyvinyl ChloridejbertralPas encore d'évaluation

- Profile SurveyDocument10 pagesProfile Surveygalici2002Pas encore d'évaluation

- The First Step in Gasket SelectionDocument5 pagesThe First Step in Gasket SelectionjbertralPas encore d'évaluation

- Air AtomisingDocument1 pageAir AtomisingjbertralPas encore d'évaluation

- Seal Data Sheets: Wipers Rod Seals Piston Seals Rotary Seals Guide Elements Backup ElementsDocument0 pageSeal Data Sheets: Wipers Rod Seals Piston Seals Rotary Seals Guide Elements Backup ElementsjbertralPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Worksheet Ch1Document36 pagesWorksheet Ch1Shazia FarheenPas encore d'évaluation

- For EntingDocument5 pagesFor EntingVicente TanPas encore d'évaluation

- Role of Solvent in SNDocument9 pagesRole of Solvent in SNsarahPas encore d'évaluation

- Litacell LC50QDocument2 pagesLitacell LC50QavastfPas encore d'évaluation

- FinalExam B AnsKeyDocument12 pagesFinalExam B AnsKeyDVRaoPas encore d'évaluation

- Gas Processing Fundamentals Manual1Document12 pagesGas Processing Fundamentals Manual1Ahmed Khamees ShatlaPas encore d'évaluation

- Sae J122-2017Document12 pagesSae J122-2017phan hoai nam PhanPas encore d'évaluation

- Experimental and CFD Analysis of Aluminium Heat Sinks For Avionics ApplicationsDocument7 pagesExperimental and CFD Analysis of Aluminium Heat Sinks For Avionics ApplicationsIJIRSTPas encore d'évaluation

- Jis B 2291-1994Document9 pagesJis B 2291-1994Ilka RaffaelliPas encore d'évaluation

- 10em Chem 1 Foundation Chap-1Document46 pages10em Chem 1 Foundation Chap-1Legendary MathematicianPas encore d'évaluation

- CNG Cylinder Design and SafetyDocument53 pagesCNG Cylinder Design and SafetyMartha GamalPas encore d'évaluation

- 21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsDocument13 pages21 - Suitability of Shredded Tires For Use in Landfill Leachate Collection SystemsbelavelosoPas encore d'évaluation

- Reinforcement Worksheet of Chemical BondingDocument7 pagesReinforcement Worksheet of Chemical BondingAreeba IftikharPas encore d'évaluation

- Template Synthesis of Nanomaterials PDFDocument20 pagesTemplate Synthesis of Nanomaterials PDFVandam65Pas encore d'évaluation

- Inspection Report PART 3Document53 pagesInspection Report PART 3renzo1221Pas encore d'évaluation

- Design and Analysis of A Tapered Composite Leaf Spring K. Diwakar, N. Bhaskar, A. Surendra, Y. Uday Kumar & C. Srikar RaoDocument11 pagesDesign and Analysis of A Tapered Composite Leaf Spring K. Diwakar, N. Bhaskar, A. Surendra, Y. Uday Kumar & C. Srikar RaoRôpíp PhanPas encore d'évaluation

- Understanding Sour Service Performace of Coiled TubingDocument12 pagesUnderstanding Sour Service Performace of Coiled TubingMubeenPas encore d'évaluation

- Cement Class 52.5R (Given) Aggregate Type: Coarse Crushed (Given) Graph From (Lecture 8, Slide 22) Compressive Strength 55mpa (Found)Document11 pagesCement Class 52.5R (Given) Aggregate Type: Coarse Crushed (Given) Graph From (Lecture 8, Slide 22) Compressive Strength 55mpa (Found)Shael BridgelalPas encore d'évaluation

- Outline SpecsDocument171 pagesOutline Specsmohamed fawzyPas encore d'évaluation

- Origin of Color in Complex IonsDocument5 pagesOrigin of Color in Complex IonsThya efePas encore d'évaluation

- 100 QUESTIONS FOR 100 1 XII Class PDFDocument15 pages100 QUESTIONS FOR 100 1 XII Class PDFAadikeshav SinhaPas encore d'évaluation

- Unit Test-II (SOM) 1Document2 pagesUnit Test-II (SOM) 1hasanPas encore d'évaluation

- Intermolecular Forces and Its Applications: For General Chemistry 2/grade 12 (STEM) Quarter 3/week 1.a-DDocument19 pagesIntermolecular Forces and Its Applications: For General Chemistry 2/grade 12 (STEM) Quarter 3/week 1.a-DSherwin Jay PalaspasPas encore d'évaluation

- 8 - Monographie Pyridoxine-Hydrochloride-1631Document1 page8 - Monographie Pyridoxine-Hydrochloride-1631asmae.labindusPas encore d'évaluation

- PFM920I-6U-U Datasheet 20221020Document2 pagesPFM920I-6U-U Datasheet 20221020GgopPas encore d'évaluation

- Chemistry Quiz Chapter 4 Form 4 @Document3 pagesChemistry Quiz Chapter 4 Form 4 @Mohd Norihwan100% (1)

- 4 Combustion Problems With SolutionsDocument25 pages4 Combustion Problems With SolutionsMunawar Lal JoshiPas encore d'évaluation

- Paints and Varnishes - General Tests Methods - Vol 1.1 - IndexDocument5 pagesPaints and Varnishes - General Tests Methods - Vol 1.1 - IndexGilberto ManhattanPas encore d'évaluation

- Chemical Bonding and StructureDocument199 pagesChemical Bonding and StructureRichard Nestor100% (1)

- 7 The Mole ConceptDocument8 pages7 The Mole ConceptCris CorsinoPas encore d'évaluation