Académique Documents

Professionnel Documents

Culture Documents

Piroga

Transféré par

Leonel PereiraDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Piroga

Transféré par

Leonel PereiraDroits d'auteur :

Formats disponibles

Classic Cajun Pirogue

Thank you for purchasing my plans. Should you have any questions while building your pirogue don't hesitate to email, unclejohn@unclejohns.com or call, 337-527-9696. I'm happy to help. Your boat may be built from 12' to 15' 7" using two sheets of 1/4" plywood. The amount of fiberglass cloth and paint required will vary with the length built and the amount of coverage. As will the length of the material used for the rub rails will be determined by the length of the boat. And, the number of screws needed will be determined by the number of clamps you have. It is for this reason a normal materiels list has not been included. We do not recommend building less than 12 feet. Should you want to strengthen your boat you may use 3/8" plywood on the bottom, 1/4" for the sideboards and add gussets to the ribs. If you want to square the transom, first build the kit and then fit a 3/4" plywood transom, cut off the end of the boat to the transom. Building the boat first will assure the boat is plumb. Caution should be exercised when using a motor. An electric trolling motor is more than adequate to propel a craft of this size and weight. MATERIEL LIST: The materiels needed will vary with the length boat you build. Two sheets of 1/4" plywood, exterior grade. 3/4" x 1 1/4" clear lumber for rub rails. one quart of waterproof glue. 3/4" screws paint fiberglass and resin How much load will a Pirogue carry? My Pirogue is 14' long and According to the USCG formula a fourteen foot craft built from my kit will carry a load of 336 pounds. The Coast Guard formula to compute the safe load of a home built boat is as follows. Determine the amount of weight it takes to "sink" your boat. Put the boat in the water and fill it with water counting the number of gallons it takes for the gunwales to be even with the water. Water weighs eight pounds per gallon. Multiply the number of gallons by eight and you will know the total amount of weight it takes to "sink" your boat. The boat will not actually sink because wood is buoyant. The Coast Guard then recommends multiplying the total weight by a factor of .3 to determine the "maximum safe load". My boat is 14' long, it takes 140 gallons of water to reach the gunwales, 140 gallons x 8 (pounds per gallon) = 1120 pounds x .3 = 336 pounds "safe load". The safe load of your boat will be determined by the length you build.

NOTICE: Care should be exercised in the completion of the steps involved in constructing this boat to assure a sturdy craft. The safety of this boat is determined by the builder and user. This craft has not been rated for either number of occupants or maximum weight capacity. The purpose of these plans is to provide the builder with a set of easy to follow building instructions. Uncle John's assumes no liability for the finished project. As with any water-craft, life-jackets should be worn and caution exercised in regard to weather and water conditions.

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

Sheet #2 ~ getting Started,

By following these simple steps you can be confident that you will successfully build a serviceable boat which will serve you well for years. Take your time, do not "make" things complicated. The strength and durability of your boat will be in the finishing. Fiberglass both sides of all seams and joints, use a quality paint and never store your boat in contact with the ground. Paint: Epoxy must be protected from sunlight or it will degrade. Painting is easy and durable. 100% acrylic exterior latex (water based) house paint works well. It is economical, fast drying and very durable. Water based paints generally stick well to epoxy where some oil based paints have adhesion problems and often require more preparation. If you wish to stain your boat and use a clear finish you should use a water or alcohol and not oil based stain. Allow the stain to dry thoroughly before applying the resin. A good marine varnish will protect the epoxy and show the beauty of the wood. Plywood: The basic difference between most marine plywood and exterior plywood is that marine plywood does not contain voids. Both contain essentially the same glues. Taping the seams and edges with fiberglass will effectively seal the edges. Exterior plywood is considerably more economical and is a standard stock item at lumberyards. We have had good results with both A/C fir and B/C pine. Lauan mahogany is used by many small boat builders. Lauan is pretty, easy to work with and very economical. Glue and fasteners: There are numerous waterproof and water resistant glues on the market. For the most part, glues, nails and screws hold the structure together prior to tapeing the seams with fiberglass. Once the seams are taped, the fiberglass will provide a strong waterproof joint. For this reason, the type of glue is of less importance than tapeing both sides of all seams and joints with fiberglass.

cutting the side boards and bottom

Cut the side boards and bottom pieces from two sheets of 1/4" plywood.

10" 10"

(sideboard) (sideboard) (bottom)

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

Sheet #3 ~ joining the sideboards and bottom

Scarf all of the pieces of the same width at the same time. By doing them all at the same time, they will all have the same angle. Stack the pieces offsetting each from the one below by 2". A piece of scrap placed on top will aid in achieving a smooth bevel. Tacking the pieces to a flat work surface will stabilize the pieces while you are scarfing. (#1) Place the first piece on the work surface and tack it down at least two and one half inches from the end. (#2) Place the second piece on top offsetting by 2" and tack it down. The tacks should be placed so as not to be in the area that is to be worked. (#3) Continue to stack the pieces as shown . (#4) Using an electric plane, belt sander, random orbit sander or even a piece of coarse sandpaper wrapped around a piece of two by four "grind" the pieces until a smooth surface is achieved .

2 1/2" 2" 2 1/2" 2" 2 1/2" 2"

(#1)

Work surface

#2

2"

#3

2" 2"

Work surface

Work surface

#4

gluing

3" wax paper

finish nail or screw

Work surface

wax paper (holes in plywood are filled after jig is removed.)

using a butt joint

Some individuals prefer to use a butt joint. Quicker and easer but not a pretty and more difficult to hide. To use a butt joint, simply butt the two ends together and fiber glass both sides with four to five inches of cloth

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

Sheet #4 ~ cutting the stems

The stems which are the single most critical pieces must be cut with care on a table saw. Start with " x " stock, follow the setup steps carefully. After each "cut #1" is made, the piece is turned end for end then "cut #2" is made. In "setup #1" the distance between the fence and the blade should be such that the lower edge of the " x " stock is not cut but used as the guide when setting the fence. Care must be exercised when cutting, as material is removed the piece will tend to twist. This may be prevented by inserting pieces the thickness of your saw blade into the kerf. This is normally not needed until step #2, cut #2. Minor adjustments in setup step #3 may be necessary to compensate for blade thickness. You will need two stems.

step #1

f e n c e

cut #1

cut #2

table

set blade at degrees

step #2

cut #1

cut #2

step #3

cut #1

cut #2

end view

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

Sheet #5 ~ attaching the side boards

Cut sideboards to length with a degree angle on each end. (see fig. #1). Stacking the sideboards and cutting both at the same time will assure identical lengths. The length of the boat will be determined by length of sideboards. We do not recommend building less than 12 feet.

fig. #1

length + "

(sideboard)

Align stems and sideboards as shown in fig. #2. Attach sideboards to stems in sequence (steps 1 through 3 shown below) using both a waterproof glue and four " screws on each side of the stem. It is common to remove the screws after the glue has cured and fill the holes. The compound angles of the stems will cause the sides to bow outward and upward creating a rocker (or bow in the bottom).

1

Use four 1" screws on each side.

sideboard

Align the bottom of the sideboard and the bottom of the stem.

fig. #2

sideboard

ste m

stem

stem

bottom

2

pul

l en

ds t

oge

the

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

Sheet #6 ~ building the rib sets

Rib sets A and C are identical, the uprights are beveled seven and one half degrees to fit the angle formed by the sideboards. The rib sets are constructed from 3/4" x 1 1/4" stock. Gussets may be added to the joints for increased strength. Should you choose to increase the height of the sideboards or the width of the bottom, adjust the lengths perportiantily as needed.

sideboard

sideboard

sideboard

A/C

The ends are cut on o and joined using a lap joint. To strengthen, add 1/4" gussets

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

Sheet #7 ~attaching the rib sets

If you use three standard rib sets, your boat will have a 25" bottom width. Should you wish to widen your boat use four rib sets. One "A", two "B" and one "C".

Three rib sets: Attach wide rib set "B" in the center of hull (fig.#1) aligning the bottom

of the sideboards as shown (fig. #2), glue and fasten with 1" screws. Rib set "A" is beveled forward, rib set "C" is beveled aft.

fig. #1

fig. #2

oard sideb

rib

center center

center

rib

When using four rib sets insert rib sets "B" between the side boards and position them so as to create a smooth curve in the side boards. Your "eye" will tell you when they are in the correct position. After positioning "B" rib sets, position the "A" sets. You can control the width by positioning the "B" sets, the father apart, the wider the bottom.

Four rib sets:

Attach rub rails with " screws, spaced " apart. Use " x " clear (no knots) for the rub rails. Attaching the rub rail will stiffen and shape the boat. Begin in the middle of the boat and work to each end.

Attach rub rails

rub ra il

Shape rub rails to blend with stem.

rub rail

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

rib

Sheet #8 ~attaching the bottom

Turn boat upside-down, tack bottom in place and mark hull shape, add " all around fig #5, remove and cut bottom to shape. Replace bottom and glue in place. Trim bottom flush with sideboards fig.#6 and ease the edge, (fig. #7). When attaching bottom it should be remembered that the strength will come from fiber glassing the seams inside and out, not from the glue or fasteners. Using brads or small nails when attaching the bottom to the sideboards can prove to be difficult. The easiest method to attach the bottom is to use what I generally refer to as the "glue and stack" method. Put the glue on the bottom of the sideboards and ribs, put the bottom in place and "stack" weight on top to hold the bottom in place until the glue is set. However, using screws into the rib bottoms is recommended. The main purpose of the glue is to hold the parts in place while the bottom is "faired" to the sideboards prior to fiber glassing. The fiberglass will "lock" the boat together and seal the seams.

fig. #5

fig. #6

oard sideb

bottom

trim flush and ease

FINISHING. For maximum durability the entire hull could be covered with 6 oz. cloth.

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

Sheet #9 ~ fiber glassing the seat units

If you wish to stain your boat and use a clear finish you should use a water or alcohol and not oil based stain. Allow the stain to dry thoroughly before applying the resin. All seams and joints should be fiber glassed inside and out with 3" wide 6 oz. cloth for strength and to seal the edges. Epoxy resin is the best, polyester is the most economical and the easiest to obtain. Polyester resin can be found lumberyards and auto parts stores. A good source for epoxy may be found from www.raka.com

Use a tongue depressor to create a cove on the inside seams with a mixture of fiberglass resin mixed with filler or fine sawdust.

1st.

2nd.

Paint resin on the area to be glassed. If you use polyester resin, for the first application, add one tablespoon of acetone to each ounce of resin, thinning the resin to increase penetration into the wood fiber and holding strength. This is not necessary when using epoxy and is only for the first coat using polyester.

3rd.

Put cloth in place and saturate with resin. When the cloth is saturated it will become virtually invisible. It is important to saturate the cloth but not to the extent to "float" the cloth off the surface. The texture of the weave may be floated with a second coat of resin. Overlap cloth by 2" where needed.

4th.

After the resin has cured, puncture any bubbles and re-glass. The edges of the cloth may be feather on by sanding to blend the cloth into the wood.

Taping the seams on both sides is the minimum recommended, the most common is to cloth the seams and joints on the inside and cloth the entire bottom on the outside. Painting the entire boat with resin prior to finishing is highly recommended.

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

Check out our other kits and plans at www.unclejohns.com

Skiff

Length 9' 7" or 11' 5" Beam: 46" Sail Area: 26 to 41 Displ: 500 to 700 lbs.

Jon-Boat

Length 10' to 15' 8" Beam: 47" Displ: 500 to 700 lbs.

Uncle John's

5229 Choupique Road - Sulphur, LA 70665 - www.unclejohns.com - copyright 2002

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Capitalization and Punctuation RulesDocument7 pagesCapitalization and Punctuation RulesBern Balingit-ArnaizPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Coffin Texts Vol 8Document0 pageCoffin Texts Vol 8shasvinaPas encore d'évaluation

- Shift Your Energy Empowerment PDFDocument5 pagesShift Your Energy Empowerment PDFSergio Velazquez Vicenttin100% (1)

- Renaissance and Reformation Study GuideDocument6 pagesRenaissance and Reformation Study GuideRachel FrankenfieldPas encore d'évaluation

- Fahrenheit 451 One Pager Project Directions RubricDocument2 pagesFahrenheit 451 One Pager Project Directions Rubricapi-553323766Pas encore d'évaluation

- Golden Dawn - The Invoking Pentagram Ritual of AirDocument2 pagesGolden Dawn - The Invoking Pentagram Ritual of AirFranco LazzaroniPas encore d'évaluation

- North African Music 2Document24 pagesNorth African Music 2NessaladyPas encore d'évaluation

- The Financial ExpertDocument16 pagesThe Financial ExpertVinay Vishwakarma0% (1)

- R. M. Ballantyne: The Coral IslandDocument4 pagesR. M. Ballantyne: The Coral IslandValentina VinogradovaPas encore d'évaluation

- What Is Metafiction and Why Are They Saying Such Awful Things About It?Document3 pagesWhat Is Metafiction and Why Are They Saying Such Awful Things About It?Adrian DiazPas encore d'évaluation

- JessesIceCreamStand3 5Document5 pagesJessesIceCreamStand3 5yoPas encore d'évaluation

- Filipino AuthorsDocument6 pagesFilipino Authorsyoshimitsu yoshidaPas encore d'évaluation

- The World of Apu - RayDocument21 pagesThe World of Apu - Rayjim kistenPas encore d'évaluation

- Class I Instruction Based Homework - 15th April 2020Document3 pagesClass I Instruction Based Homework - 15th April 2020hadee-saberPas encore d'évaluation

- Small Wooden Disc Attached To A String From The Finger) As ADocument2 pagesSmall Wooden Disc Attached To A String From The Finger) As Adandan samadPas encore d'évaluation

- Empathy at Work: - Ability To Share Someone Else's Feelings orDocument5 pagesEmpathy at Work: - Ability To Share Someone Else's Feelings orVital Jorge Do CantoPas encore d'évaluation

- Línea Del Tiempo México 1700 A 1824Document5 pagesLínea Del Tiempo México 1700 A 1824AngelUDGPas encore d'évaluation

- Madame Du Barry - Noel Williams 1909Document421 pagesMadame Du Barry - Noel Williams 1909Kassandra M Journalist100% (1)

- Annotated Bibliography 2Document6 pagesAnnotated Bibliography 2api-252394912Pas encore d'évaluation

- The Tibu PeopleDocument21 pagesThe Tibu PeopleAshBarlowPas encore d'évaluation

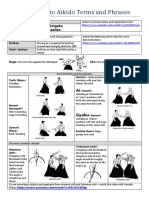

- A Short Guide To Aikido Terms and Phrases PDFDocument2 pagesA Short Guide To Aikido Terms and Phrases PDFProud to be Pinoy (Devs)Pas encore d'évaluation

- Adjective ExercisesDocument9 pagesAdjective Exerciseslok eshPas encore d'évaluation

- Donna R. Casella - What Women Want - The Films of Dorothy ArznerDocument37 pagesDonna R. Casella - What Women Want - The Films of Dorothy ArznerVictor GuimaraesPas encore d'évaluation

- Patents OnlyDocument19 pagesPatents OnlyJanine SalvioPas encore d'évaluation

- SOP - MassEdit For NIOS 6.8.6Document12 pagesSOP - MassEdit For NIOS 6.8.6Fahmi YasserPas encore d'évaluation

- DiscographyDocument513 pagesDiscographyebong100% (1)

- A.I (Alien Invasion) Guard: Android-Based Tower Defense GameDocument16 pagesA.I (Alien Invasion) Guard: Android-Based Tower Defense GameMeyoor OneacPas encore d'évaluation

- Who Sends The Letter Dyas Tugas Bahasa InggrisDocument5 pagesWho Sends The Letter Dyas Tugas Bahasa InggrisCandra Halim PerdanaPas encore d'évaluation

- Young Sobre Como Era Gostoso Meu FrancesDocument11 pagesYoung Sobre Como Era Gostoso Meu FrancesMarina MogPas encore d'évaluation