Académique Documents

Professionnel Documents

Culture Documents

Pneumatic Conveying Flyer

Transféré par

Sen VanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pneumatic Conveying Flyer

Transféré par

Sen VanDroits d'auteur :

Formats disponibles

Pneumatic Conveying Systems

Pneumatic Conveying Systems allow for unloading hopper cars and other bulk transporters without the need for a pit, by transferring dry bulk material through an enclosed pipeline. The purpose of the Pneumatic Conveying System is to ensure that materials are conveyed in a contained environment, utilising air to do so, and avoiding spillage. This is normally done by moving residue or in process materials through a totally enclosed pipeline, in a clean, contained stream of air generated by either a vacuum pump, positive displacement blower, or compressor, which is attached to the system. It is important to note that pneumatic conveying has no moving parts which come in contact with the materials at any time. Because it is a contained system, no dust is able to escape into the atmosphere and no contamination can enter into the system. For food processing and laboratory applications, the equipment used to collect the materials meets the strictest hygiene standards and can be easily cleaned due to the system being of modular design, for ease of routine cleaning and product change. The common elements of a standard pneumatic conveying system involve a blower, a feeder to introduce the dry material to the conveying line, a receiver and a dust collection system. The energy required to move the material through the pneumatic conveying system is created by a pressure differential (measured in psi or bar) and airflow (cubic feet per minute / m3 per hour). The blowers location in the system determines whether it will create either pressure or a vacuum: at the start of the system it creates pressure that pushes the air through the system; at the end it pulls the air, causing a vacuum that drives the airflow. It is the pressure or vacuum created by the blower position that causes the transfer of materials through the system. Conveying capacities up to 200 tonnes per hour are available, depending on the material. Pneumatic conveying is appropriate for use for particles ranging from fine powders to pellets and bulk densities of 16 to 3,200 kg /m3. Most commonly, dry materials such as fly ash, flour, cement, sand, plastic pellets, many types of chemicals, food products and minerals can be conveyed.

t +618 9302 3700 / 1300 733 272 info@apconline.com.au PO Box 1818, WANGARA DC WA 6947 37 Rogers Way, LANDSDALE WA 6065

f +618 9302 3711 www.apconline.com.au

Types of Pneumatic Conveying Systems

There are two main types of Pneumatic Conveying Systems: Dilute Phase and Dense Phase.

1.

Dilute Phase

The basic premise of Dilute Phase conveying is that the particles are picked up by the velocity of the airstream and remain airborne throughout the conveying process. The Dilute Phase system typically operates at a relatively high velocity and relatively low pressure. The air speed required depends on the size and density of the particles to be transported. There are three main types of Dilute Phase Conveying Systems: i) Dilute Phase Pressure Operation

ii) Dilute Phase Vacuum Operation

iii) Dilute Phase Pressure-Vacuum Operation

The Dilute Phase system generally has the lowest initial investment cost.

t +618 9302 3700 / 1300 733 272 info@apconline.com.au PO Box 1818, WANGARA DC WA 6947 37 Rogers Way, LANDSDALE WA 6065

f +618 9302 3711 www.apconline.com.au

Types of Pneumatic Conveying Systems 2. Dense Phase

The second type of Pneumatic Conveying System is the Dense Phase type, which uses relatively high pressure with relatively low air velocity. Because of the high frictional resistance of powder and granular particles against the inside wall of the pipe system, particles cannot be transferred along the system in one long, continuous stream. Thus, some systems inject compressed air along the conveyor line to clear any blockages caused by low air volume or pressure. Although this increases the systems energy consumption, it increases the systems efficiency in conveying material. Such a system with air injectors is especially useful for handling abrasive particles by reducing excessive and premature wear on the system. The Dense Phase system is further classified into two systems: i) Closed System

ii)

Open System

The Dense Phase system is the best option for: 1. Materials that could be damaged by the higher velocity Dilute Phase system. 2. Abrasive materials. 3. Where a long conveying line is necessary, as it typically requires a smaller pipe diameter and thus requires less air volume and is much lighter, making installation and replacement easier.

t +618 9302 3700 / 1300 733 272 info@apconline.com.au PO Box 1818, WANGARA DC WA 6947 37 Rogers Way, LANDSDALE WA 6065

f +618 9302 3711 www.apconline.com.au

A Comparison of Dilute and Dense Phase Pneumatic Conveying. Although there is no standard way to categorize a Dilute Phase versus a Dense Phase Pneumatic Conveying System, here is a general comparison of the two types of systems: Dilute Phase Dense Phase Most operate above 15 psi Most operate above 12 inches mercury Most operate at 3,000 fpm or lower Generally much slower than the air velocity

psi Most operate below 15 psi Mercury Most operate below 12 inches

mercury

NB depends on material being conveyed

Air velocity Most operate between 3,500 and

9,000 fpm

Material velocity Nearly the same as the air velocity

Selecting

1. 2. 3. 4.

which type to use. Here are some factors to consider:

The material to be conveyed, including: particle size and shape, bulk density, moisture content, abrasiveness, friability, cohesiveness, hygroscopicity, static charge, explosivity, toxicity, melting point, etc How will the system fit into the location and plant equipment? Does the system achieve the material transfer rate required? Should pressure or vacuum be used? Whether a Dilute or Dense Phase is selected, the decision must still be made as to whether the system should operate under pressure or vacuum. Vacuum is safest for such applications as those that involve toxic or explosive material, because there is no air leakage. Vacuum is also best for materials that pack tightly, are cohesive and tend to build up on surfaces, or are fibrous, because the vacuum separates the particles during the conveying process, rather than pushing them together or into the pipe walls, as a pressure system would.

Advantages of Pneumatic Conveying Systems Environmental (total containment means no dust to atmosphere) Prevents contamination (containment at both ends of the system) Low capital cost (pipe is the primary transport element) Reliability and minimal maintenance (few moving parts) The pipeline can be designed to fit around existing equipment, giving it a relatively small footprint Complies with and compliments OH&S procedures Cost effectiveness Being automated streamlines operations Increases Efficiency Ensures dust free operation No product contamination Hygienic

t +618 9302 3700 / 1300 733 272 info@apconline.com.au PO Box 1818, WANGARA DC WA 6947 37 Rogers Way, LANDSDALE WA 6065

f +618 9302 3711 www.apconline.com.au

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- (Published in The Gazette of India, Extraordinary, Part II, Section 3, Sub-Section (Ii) ) Ministry of Environment and Forests NotificationDocument11 pages(Published in The Gazette of India, Extraordinary, Part II, Section 3, Sub-Section (Ii) ) Ministry of Environment and Forests NotificationSen VanPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Kalki Tamil Alai Osai 1Document105 pagesKalki Tamil Alai Osai 1danapillai100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hiteam Fluid Control Company ProfileDocument13 pagesHiteam Fluid Control Company ProfileSen VanPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Vad 213Document11 pagesVad 213Sen Van0% (1)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Testing and Interpretation of Test Results Glossary of Material CodesDocument11 pagesTesting and Interpretation of Test Results Glossary of Material CodesSen VanPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Basalt-Lined Pipe & Bends: Model 272Document1 pageBasalt-Lined Pipe & Bends: Model 272Sen VanPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- E03 Fabricated Products enDocument14 pagesE03 Fabricated Products enSen VanPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Tamil NaduDocument18 pagesTamil NaduSen VanPas encore d'évaluation

- Application Passport NOCDocument5 pagesApplication Passport NOCSen VanPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

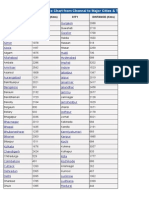

- Distance Chart From Chennai To Major Cities & Towns of IndiaDocument24 pagesDistance Chart From Chennai To Major Cities & Towns of IndiaSen VanPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Cerc Discussion Paper On Terms and Conditions For Tariff From 01.04.2004Document34 pagesCerc Discussion Paper On Terms and Conditions For Tariff From 01.04.2004Farah AnwarPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Benson Beltings LTD.: Product InformationDocument2 pagesBenson Beltings LTD.: Product InformationSen VanPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Aluminium PCMDocument25 pagesAluminium PCMKarthi Kaiean100% (2)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Claudius Peters Pneumatic Conveying Brochure enDocument16 pagesClaudius Peters Pneumatic Conveying Brochure enSen VanPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Ref.: (I) : Transmission Held On 22 September, 2005 at SREB, BangaloreDocument13 pagesRef.: (I) : Transmission Held On 22 September, 2005 at SREB, BangaloreSen VanPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Benson Beltings LTD.: Product InformationDocument2 pagesBenson Beltings LTD.: Product InformationSen VanPas encore d'évaluation

- Nabl 400Document189 pagesNabl 400Sen VanPas encore d'évaluation

- 24 Ratnayake Melaaen DattaDocument6 pages24 Ratnayake Melaaen DattaSen VanPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Ash Handling SystemDocument31 pagesAsh Handling Systemsankalp-1980Pas encore d'évaluation

- Pentex Gas OvenDocument5 pagesPentex Gas OvenRahman PashariPas encore d'évaluation

- TYBTech Syllabus MechanicalDocument49 pagesTYBTech Syllabus MechanicalswapnillkPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Valve PagesDocument5 pagesValve PagesJoyal ThomasPas encore d'évaluation

- Machine Element Design CheatsheetDocument25 pagesMachine Element Design CheatsheetDarien ChiaPas encore d'évaluation

- Fuel Consumption Hyster Rev3Document7 pagesFuel Consumption Hyster Rev3crash2804Pas encore d'évaluation

- Worksheet # 7 - Free Body DiagramDocument2 pagesWorksheet # 7 - Free Body DiagramyabalabahiyaPas encore d'évaluation

- Service Manual: Model Code - Kib19Bp3-CmgDocument11 pagesService Manual: Model Code - Kib19Bp3-Cmgpravin jadavPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Motorized Hydraulic PressDocument4 pagesMotorized Hydraulic PressDhiraj Shinde100% (2)

- Valbart: API 6D & 6A Trunnion Mounted Ball ValvesDocument36 pagesValbart: API 6D & 6A Trunnion Mounted Ball Valvesbabis1980Pas encore d'évaluation

- Gear Mechanism Used in Wrist WatchesDocument5 pagesGear Mechanism Used in Wrist WatchesRaja Rv0% (1)

- Single Head Nest Detail: Turbonest F644-12Mm-S355-04Document5 pagesSingle Head Nest Detail: Turbonest F644-12Mm-S355-04Vv ZzPas encore d'évaluation

- CS193a Android ProgrammingDocument4 pagesCS193a Android Programmingrosy01710Pas encore d'évaluation

- ReactionsDocument30 pagesReactionskaloibestPas encore d'évaluation

- db12 HornDocument3 pagesdb12 HornGerman Andres GarciaPas encore d'évaluation

- Feslog - 1508161122 - Fiat Doblo' (Type 223) Cargo 1.3 Mjet 16vDocument19 pagesFeslog - 1508161122 - Fiat Doblo' (Type 223) Cargo 1.3 Mjet 16vraulUTCNPas encore d'évaluation

- Catalogo Escavadeira CAT 336Document833 pagesCatalogo Escavadeira CAT 336Gledison MartinsPas encore d'évaluation

- Hyundai Heavy Industries - Gas Insulated SwitchgearDocument25 pagesHyundai Heavy Industries - Gas Insulated SwitchgearbadbenzationPas encore d'évaluation

- IV I Results Nov 2015Document91 pagesIV I Results Nov 2015Ann ThomasPas encore d'évaluation

- Shaper Gear CuttingDocument4 pagesShaper Gear Cuttingnevadablue100% (4)

- 180 W PC Main SFX Supply - PHPDocument2 pages180 W PC Main SFX Supply - PHPCici Icic100% (1)

- 8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothDocument15 pages8×8 LED Matrix MAX7219 With Scrolling Text & Android Control Via BluetoothakashlogicPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Column ChromatographyDocument9 pagesColumn ChromatographyMd Shahjalal Sagor67% (3)

- SCELDocument46 pagesSCELzacklawsPas encore d'évaluation

- Glass & Glazing WorkDocument34 pagesGlass & Glazing WorkPratik ThakkarPas encore d'évaluation

- Iso 6395 2008 en PDFDocument11 pagesIso 6395 2008 en PDFjamesPas encore d'évaluation

- Iei Pe MC PDFDocument3 pagesIei Pe MC PDFKulbir ThakurPas encore d'évaluation

- d8n Wiring HardnessDocument2 pagesd8n Wiring HardnessandraPas encore d'évaluation

- Gold Alloy Spinnerets For The Production of Viscose RayonDocument8 pagesGold Alloy Spinnerets For The Production of Viscose RayonPhan MHanhPas encore d'évaluation

- Jeppiaar SRR Engineering College: Title: Smart Wearble Health Monitoring For Patient/Elder PeopleDocument12 pagesJeppiaar SRR Engineering College: Title: Smart Wearble Health Monitoring For Patient/Elder PeopleKurushNishanthPas encore d'évaluation

- Menstruum and Rose Quartz TinctureDocument3 pagesMenstruum and Rose Quartz Tincturetravellerfellow100% (2)