Académique Documents

Professionnel Documents

Culture Documents

1

Transféré par

Priyadharshini UlaganathanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1

Transféré par

Priyadharshini UlaganathanDroits d'auteur :

Formats disponibles

Journal of Cell and Molecular Biology 10(1): 1-11, 2012 Hali University, Printed in Turkey. http://jcmb.halic.edu.

tr

Review Article 1

Production and industrial applications of laccase enzyme Muhammad IMRAN*1,2, Muhammad J. ASAD1, Saqib H. HADRI1 and Sajid MEHMOOD2

Department of Biochemistry, Pir Mehr Ali Shah Arid Agriculture University, Rawalpindi, Pakistan Department of Biochemistry and Biotechnology, University of Gujrat, Pakistan (* author for correspondence; mirzaimran42@gmail.com)

2 1

Received: 22 April 2011; Accepted: 15 May 2012

Abstract

Laccase is an enzyme that has potential ability of oxidation. It belongs to those enzymes, which have innate properties of reactive radical production, and its utilization in many fields has been ignored because of its unavailability in the commercial field. There are diverse sources of laccase producing organisms like bacteria, fungi and plants. Textile, pulp and paper industries discharge a huge quantity of waste in the environment, and the disposal of this waste is a big problem. To solve this problem, work has done to discover such an enzyme, which can detoxify these wastes and is not harmful to the environment. Laccases use oxygen and produce water as by product. They can degrade a range of compounds including phenolic and non-phenolic compounds. They also have ability to detoxify a range of environmental pollutants. Their property to act on a range of substrates and also to detoxify a range of pollutants have made them to be usable for several purposes in many industries including paper, pulp, textile and petrochemical industries. Keywords: Laccase, solid state fermentation, oxidation, enzyme, fungi.

Lakkaz enziminin retimi ve endstriyel uygulamalar zet

Lakkaz, potansiyel oksidasyon yetenei olan bir enzimdir. Reaktif radikal retim zellii olan enzimlere dahildir ve birok alandaki kullanm, ticari alanda uygun olmamas nedeniyle gz ard edilmektedir. Bakteri, mantar ve bitki gibi lakkaz reten eitli organizma kaynaklar vardr. Tekstil, kat hamuru ve kat endstrisi evreye byk miktarda atk salmaktadr ve bu atklarn uzaklatrlmas byk bir problemdir. Bu sorunu zmek zere, atklar detoksifiye eden ve evreye zararl olmayan bir enzim kefetmek iin almalar yaplmtr. Bu enzim oksijen kullanr ve yan rn olarak su retir. Lakkaz, fenolik ve fenolik olamayan bileikleri ieren bir dizi bileii paralayabilir. Ayrca, bir dizi evresel kirleticiyi detoksifiye etme yetenei vardr. eitli substratlar zerine etki etme ve ayrca bir dizi kirlilii detoksifiye etme zellii, bu enzimleri eitli amalarla tekstil, kt hamuru, kt ve petrokimya endstrisini kapsayan birok endstride kullanlabilir klmaktadr. Anahtar kelimeler: Lakkaz, kat hal fermentasyonu, oksidasyon, enzim, mantarlar.

Introduction

Laccase was first discovered in the sap of the Japanese lacquer tree Rhus vernicifera, and its characteristic as a metal containing oxidase was discovered by Bertrand in 1985 (Giardina et al., 2010). Since then, laccases have also been found in

various basidiomycetous and ascomycetous fungi and thus far fungal laccases have accounted for the most important group of multicopper oxidases (MCOs) with respect to number and extent of characterization (Giardina et al., 2010). The large quantity of laccases have been widely reported inside white-rot fungi. A number of

2 Muhammad IMRAN et al.

laccase genes have been isolated and distinguished for this purpose (Mayer and Staples, 2002). The improvement in laccase appearance, characterized by an increase in protein and mRNA level, was illustrated with Picnoprus cinnabarinus, Pleurotus sajor caju and Trametes versicolor (Eggert et al. 1996, Solden and Dobson 2001, Collins and Dobson 1997). A number of species of genus Pleurotus have been explained as manufacturers of laccase (Leonowicz et al. 2001). We freshly reported that a strain of P. pulmonarius produce laccase as the main ligninolytic enzymes while cultured on wheat bran solid state medium (Souza et al. 2002). In the current study, numerous phenolic and aromatic compounds structurally related to lignin were calculated for their capability to arouse laccase production by P. pulmonarius. (Solden and Dobson, 2001). P. pulmonarius was proficient of mounting on a wide variety of phenolic and aromatic compounds. Laccase production by P. pulmonarius could be considerably improved by including an equimolar combination of ferulic acid and vanillin as inducer. The construction of different laccase isoform in reply to phenolics implicates a possible task of this enzyme in the detoxification processes (Souza et al., 2002) Numerous white-rot fungi, counting Trametes versicolor, make extra cellular copper-containing phenol oxidases (E C 1.10.3.2), named laccases (Birhanli and Yesilada, 2006). The two major likely natural functions attributed to fungal laccases are, rst, their participation in lignin degradation, mutually with supplementary ligninolytic enzymes such as peroxidases, and second, their function in fungal virulence as key cause in pathogenesis in opposition to plant hosts (Gianfreda et al., 1999). As well, laccases display in vivo other functions that are the foundation of several industrial applications. For instance, in Aspergillus nidulans, laccases take action on pigment development in fungal spores (Smith et al., 1997). A number of fungi also ooze laccases to take away either potentially toxic phenols released through lignin degradation or toxins formed by others organisms. As a result, the enzyme has probable applications in the textile industries, dye, as well as for the degradation of a variety of xenobiotics, which are recognized as ecological pollutants (Rama et al. 1998, Jolivalt et al. 1999, Mougin et al., 2000). Laccase-producing fungi have also been reported to be helpful apparatus for xenobiotic removal in liquid effluents as well as in soil

bioremediation (Gianfreda et al. 1999, Jolivalt et al. 2000). Our outcomes demonstrate that the resulting alteration products themselves are likely to encourage biological effects moreover on degrading or non-target organisms. So, an entire characterization of these compounds is essential for an entire assessment of the remediation processes (Souza et al., 2002). Laccase represents a family of coppercontaining polyphenol oxidases (PPO) & are usually called multicopper oxidases (MCO) (Birhanli and Yesilada, 2006; Arora and Sharma, 2010; Giardina et al., 2010). Laccases catalyze the oxidation of various substituted phenolic compounds by using molecular oxygen as the electron acceptor (Sharma et al., 2007). These enzymes have less substrate specificity and have the ability to degrade a range of xenobiotics including industrial colored wastewaters (Souza et al., 2006). Laccases exhibit broad substrate range, which varies from one laccase to another. Although it is known to be diphenol oxidase, monophenols like 2, 6-dimethoxy phenol or guaiacol are better substrates than phenols (e.g., catechol or hydroquinone) (Baldrian, 2006; Arora and Sharma, 2010). Laccases catalyze monoelectronic oxidation of molecules to corresponding reactive radicals with the help of four copper atoms, which form the main catalytic core of the laccase, accompanied with the diminution of oxygen to water molecules and simultaneous oxidation of substrate to produce radicals (Arora and Sharma, 2010). All substrates cannot be directly oxidized by laccases, either because of their large size which restricts their penetration into the enzyme active site or because of their particular high redox potential. To overcome this hindrance, suitable chemical mediators are used which are oxidized by the laccase and their oxidized forms are then able to interact with high redox potential substrate targets (Arora and Sharma, 2010). In fungi, laccases carry out a variety of physiological roles including morphogenesis, fungal plant pathogen/host interaction, stress defense, and lignin degradation (Gianfreda et al., 1999; Giardina et al., 2010). Laccases have been found in nearly all woodrotting fungi analyzed so far (Heinzkill and Messner, 1997; Giardina et al., 2010) and are almost ubiquitary enzymes as they have been isolated from plants, from some kinds of bacteria, and from insects too (Enguita et al., 2003; Sharma et al., 2007; Giardina et al., 2010).

Production and industrial applications of laccase 3

Laccase has many applications in other fields, like medical diagnosis, pharmaceutical industry. Laccase has also applications in the agriculture area by clearing herbicides, pesticides and some explosives in soil. It is also used in the preparation of some important drugs, like anticancer drugs, and added in some cosmetics to reduce their toxicity. Laccase also has the ability to form polymers of value able importance (Couto and Herrera, 2006). Solid state fermentation (SSF) is a technique in which fungi are grown on solid substrate or substrate moistened with a low quantity of mineral salt solution and it has a great potential to produce enzyme especially where the fermented raw materials are used as a source of nutrients for the fungi. The enzymes produced by this method have several applications in several fields including food and fermentation industry. These enzymes are also used to prepare several bioactive compounds. SSF system is much better than the submerged system because a number of reasons. The benefits of SSF over SMF include the high production of the enzyme, and fewer effluent generation. Moreover, comparably simple equipment is required for SSF (Pandey, 1994). Neurospora is a genus of kingdom fungi that has become a popular experimental model organism (Davis et al., 2002). Laccases have copper atoms at their catalytic sites and are oxidative enzymes (EC 1.10.3.2) which are widely found in many species of fungi, where they are involved in lignin degradation, in higher plants where they are involved in biosynthesis of lignin (Mayer and Staples, 2002; Sharma and Kuhad, 2008), in bacteria (Claus, 2003; Liers et al., 2007), and in insects (Litthauer et al., 2007). Some species of fungi and insects produce laccases as intracellular proteins, but most of the laccases are produced as extracellular proteins by all other types of producers (Arora and Sharma, 2010).

Laccase production in various organisms Production of laccase in fungi

Laccase production occurs in various fungi over a wide range of taxa. Fungi from the deuteromycetes, ascomycetes (Aisemberg et al., 1989) as well as basidiomycetes are the known producers of laccase (Sadhasivam et al., 2008). Among them, basidiomycetes are considered efficient laccase producers, especially white rot fungi (Revankar and lele, 2006; Sadhasivam et al., 2008). Laccase production has not been reported in lower fungi,

i.e., Zygomycetes and Chytridiomycetes. However, these groups have not yet been studied in detail (Arora and Sharma, 2010). Trametes versicolor, Chaetomium thermophilum and Pleurotus eryngii are well known producers of laccase. It has been reported that some Trichoderma species, including T. harzianum has the ability to produce polyphenol oxidases (Kiiskinen et al., 2004; Sadhasivam et al., 2008). Laccase has been produced by many species of soft, white rot fungi, geophilous saprophytic fungi. Laccase has also been produced by many edible mushrooms including the oyster mushroom Pleurotus ostreatus, the rice mushroom Lentinula edodes and champignon Agaricus bisporus. Other laccase producers of wood-rotting fungi include T. hirsuta (C. hirsutus), T. villosa, T. gallica, Cerrena maxima, Lentinus tigrinus, T. ochracea, Pleurotus eryngii, Trametes (Coriolus) versicolor, Coriolopsis polyzona, etc. (Morozova et al., 2007). In fungal physiology, laccases are involved in plant pathogenesis, pigmentation, detoxification, lignin degradation (Sadhasivam et al., 2008) and also in development of morphogenesis of fungi (Baldrian, 2006; Morozova et al., 2007). Laccases of wood-colonizing basidiomycetes (white rot fungi) have been thoroughly studied (not least also with respect to laccase-mediator interaction), and many of them purified and characterized on the protein and gene level (Liers et al., 2007). Mishra et al. (2008) have used cyanobacterial biomass of water bloom, groundnut shell (GNS) and dye effluent as culture medium for the production of laccase by Coriolus versicolor. They found the laccase production to be 10.152.21 U/ml in the medium having groundnut shell and cyanobacterial bloom in a ratio of 9:1 (dry weight basis) at initial pH 5.0 and 282 oC temperature. Half life of enzyme was 74 min at 60 oC. Kinetic analysis of laccase with ABTS were also determined, Km and Vmax were found to be 0.29mM and 9.49mol/min respectively. Azide and hydroxylamine exerted significant inhibition on production of thermostable laccase. It is reported that Phanerochaete chrysosporium NCIM 1197 also secretes extracellular laccase. They also studied effect of several inducers on the production of laccase. Among several inducers tested copper sulphate has the greatest tendency to enhance the produce of laccase. Laccase production increased 3.5 fold in the presence of copper sulfate

4 Muhammad IMRAN et al.

as compared to control. Laccase production under SSF, batch fermentation in a laboratory scale bioreactor and static liquid culture was also compared. The maximum production of laccase was achieved after five days and it was found to be 48.891.82 U/L, 30.211.66 and 22.561.22 U/L, respectively (Gnanamani et al., 2006). The white-rot fungus Trametes pubescens MB 89 is a source of the laccase production at industrial level. Extracellular laccase formation is considerably enhanced by the addition of Cu (II) in the low quantities in the simple glucose medium. When using glucose, a typically repressing substrate, as the main carbon source, significant laccase formation by T. pubescens only started when glucose was completely consumed from the culture medium. In addition, the nitrogen source employed had an important effect on laccase synthesis. When using an optimized medium containing glucose (40 g/L), peptone from meat (10 g/L), and MgSO4.7H2O and stimulating enzyme formation by the addition of 2.0 mM Cu, maximal laccase activities obtained in a batch cultivation were approximately 330 U ml l (Galhaup et al., 2002).

Production of laccase in plants

Laccases are a diverse group of multi-copper proteins with broad substrate specificity, originally discovered in the exudates of Rhus vernicifera, the Japanese lacquer tree and subsequently demonstrated as a fungal enzyme as well (Sharma and Kuhad, 2008). The plants in which the laccase enzyme has been detected include lacquer, mango, mung bean, peach, pine, prune, and sycamore (Arora and Sharma, 2010). Techniques are also being developed to express laccase in the crop plants. Recently, laccase has been expressed in the embryo of maize (Zea mays) seeds (Bailey et al., 2004; Arora and Sharma, 2010). Laccase is envolved in polymerization of lignin units; p coumaryl, coniferyl, sinapyl alcohols and in the synthesis of lignin in the plants (Morozova et al., 2007). If the comparison between plant and fungal laccases is taken up, the former takes part in radical-based polymerization of lignin (Ranocha et al., 2002; Arora and Sharma, 2010), whereas fungal laccase contributes to lignin biodegradation due to which it has gained considerable significance in green technology (Arora and Sharma, 2010).

Production of laccase in bacteria

Laccase in bacteria is present intracellularly and as

periplasmic protoplast (Claus, 2003; Arora and Sharma, 2010). The first bacterial laccase was found in the plant root associated bacterium, Azospirillum lipoferum (Givaudan et al., 1993; Sharma et al., 2007; Sharma and Kuhad, 2008), where it was shown to be involved in melanin formation (Faure et al., 1994; Sharma and Kuhad, 2008). Laccase has been discovered in a number of bacteria including Bacillus subtilis, Bordetella compestris, Caulobacter crescentus, Escherichia coli, Mycobacterium tuberculosum, Pseudomonas syringae, Pseudomonas aeruginosa, and Yersinia pestis (Alexandre and Zhulin, 2000; Enguita et al., 2003; Arora and Sharma, 2010). Recently, Stenotrophomonas maltophilia strain was found to be laccase producing, which was used to degrade synthetic dyes (Galai et al., 2008; Arora and Sharma, 2010). Laccase containing six putative copper binding sites were discovered in marine bacterium Marinomonas mediterranea, but no functional role was assigned to this enzyme (Amat et al., 2001; Sharma and Kuhad, 2008). Some of the reported laccases have the ability to perform the activity at very crucial conditions like in the presence of high conc. of Cl-1 and Cu+2 and even at neutral pH values. The enzyme produced by Sinorhizobium meliloti is a one of the examples of such enzymes and is a protein having two subunits with pI 6.2 and the molecular weight of the subunits is 45 kDa each (Morozova et al., 2007), whereas laccase produced by Pseudomonas putida is also an example of such enzyme and is a single subunit 59 kDa protein which works well at pH 7.0 (Morozova et al., 2007). Both enzymes can oxidize syringaldazine. Niladevi et al. (2009) used response surface methodology for the optimization of different nutritional and physical parameters for the production of laccase by the filamentous bacteria Streptomyces psammoticus MTCC 7334 in submerged fermentation. Incubation temperature, incubation period, agitationrate, concentrations of yeast extract, MgSO4.7H2O, and trace elements were found to influence laccase production significantly. A new laccase gene (cotA) was cloned from Bacillus licheniformis and expressed in Escherichia coli. The recombinant protein CotA was purified and showed spectroscopic properties typical for blue multi-copper oxidases. The enzyme has a molecular weight of ~65kDa and demonstrates activity towards canonical laccase substrates 2, 2azino-bis (3-ethylnenzothiazoline-6sulphonic acid) (ABTS), syringaldazine (SGZ) and 2, 6-

Production and industrial applications of laccase 5

dimethoxyphenol (2, 6-DMP). Kinetic constants Km and kcat for ABTS were of 6.50.2 M and 83s-1, for SGZ of 4.3+0.2 M and 100s-1, and for 2, 6DMP of 56.7+1.0 M and 28 s-1. Highest oxidizing activities towards ABTS were obtained at 85 oC (Koschorreck et al., 2009).

Production of laccase in insects

The laccase enzyme has also been characterized in different insects, e.g., Bombyx, Calliphora, Diploptera, Drosophila, Lucilia, Manduca, Musca, Orycetes, Papilio, Phormia, Rhodnius, Sarcophaga, Schistocerca, and Tenebrio (Arora and Sharma, 2010). In insects, laccases have been suggested to be active in cuticle sclerotization (Dittmer et al., 2004; Sharma and Kuhad, 2008). Recently, two isoforms of laccase 2 gene have been found to catalyse larval, pupal, and adult cuticle tanning in Tribolium castaneum (Arakane et al., 2005; Sharma and Kuhad, 2008)

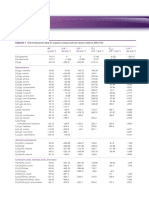

Figure 1. Scheme of applications of laccase (Morozova et al., 2007)

Applications of laccase in food industries Wine stabilization

Laccase is used to improve the quality of drinks and for the stabilization of certain perishable products containing plant oils (Morozova et al., 2007). In food industry, wine stabilization is the main application of laccase (Duran and Esposito, 2000; Rosana et al., 2002). Polyphenols have undesirable effects on wine production and on its organoleptic characteristics, so their removal from the wine is very necessary (Rosana et al., 2002). Many innovative treatments, such as enzyme inhibitors, complexing agents, and sulfate compounds, have been proposed for the removal of phenolics responsible for discoloration, haze, and flavor changes but the possibility of using enzymatic laccase treatments as a specific and mild technology for stabilizing beverages against discoloration and clouding represents an attractive alternative (Cantarelli et al., 1989; Arora and Sharma, 2010). Since such an enzyme is not yet allowed as a food additive, the use of immobilized laccase might be a suitable method to overcome such legal barriers as in this form it may be classified as technological aid. So laccase could find application in preparation of must, wine and in fruit juice stabilization (Minussi et al., 2002; Arora and Sharma, 2010). Baking industry In the bread-making process laccases affix bread and/or dough-enhancement additives to the bread dough, these results in improved freshness of the bread texture, flavour and the improved machinability (Minussi et al., 2002). Laccase is also one of the enzymes used in the baking industry. Laccase enzyme is added in the

Applications of laccase

Laccases have many biotechnological applications because of their oxidation ability towards a broad range of phenolic and non-phenolic compounds (Figure 1) (Mohammadian et al., 2010). Other applications of laccase include the cleaning the industrial effluents, mostly from industries like paper industry, pulp, textile & petrochemical industries. Laccase are also used in the medical diagnostics and for cleaning herbicides, pesticides and some explosives in soil. Laccase has many applications in agricultural, medicinal and industrial areas (Arora and Sharma, 2010). Laccases are also to clean the water in many purification systems. It has also applications in medical side to prepare certain drugs like anticancer drugs and it is added in cosmetics to minimize their toxic effects. Laccase has the enormous ability to remove xenobiotic substances and produce polymeric products and that is why they are being used for many bioremediation purposes (Couto and Herrera, 2006). Now researchers are working on enzymatic synthesis of organic compounds, laccase-based biooxidation, and biotransformation and biosensor development. The yield of laccase can be increased by optimizing different cultural conditions (Arora and Sharma, 2010).

6 Muhammad IMRAN et al.

baking process which results in the oxidizing effect, and also improves the strength of structures in dough and/or baked products. Laccase imparts many characteristics to the baked products including an improved crumb structure, increased softness and volume. A flour of poor quality can be also used in this process using laccase enzyme (Minussi et al., 2002). Applications of laccase in textile industry Synthetic dyes are widely used in such industries as textile, leather, cosmetics, food and paper printing (Forgacsa et al., 2004). Reactive dyes are coloured molecules used to dye cellulose fibres (Tavares et al., 2009). These dyes result in the production of large amounts of high-colored wastewater. A special problem is found in the application of synthetic dyes that they are resistant to biodegradation (Wesenberg et al., 2003, Moilanen et al., 2010). Normally, from 10 to 50% of the initial dye load will be present in the dyebath effluent, giving rise to a highly coloured effluent (Vandevivere et al., 1998; Moilanen et al., 2010). Therefore, the treatment of industrial effluents containing aromatic compounds is necessary prior to final discharge to the environment (Khlifia et al., 2010). Nowadays, environmental regulations in most countries require that wastewater must be decolorized before its discharge (Moilanen et al., 2010) to reduce environmental problems related to the effluent (Tavares et al., 2009). A wide range of physicochemical methods has been developed for the degradation of dye-containing wastewaters (Vandevivere et al., 1998; Tavares et al., 2009). Wastewaters from textile dying process are usually treated by physical or chemical processes, which include physicalchemical processes electrokinetic coagulation, electrochemical destruction, irradiation, precipitation, ozonation, or the Katox method that involves the use of active carbon and the mixture of certain gases (air) (Banat et al., 1996, Khlifia et al., 2010, Tavares et al., 2009). However, due to the chemical nature, molecular size and structure of the reactive dyes these classical processes can cause a problem in the environment and better treatments can be obtained using bioprocesses (Tavares et al., 2009). Recently, enzymatic treatments have attracted much interest in the decolourization/degradation of textile dyes in wastewater as an alternative strategy to conventional chemical and physical treatments, which present serious limitations (Cristovao et al., 2008, Tavares et al., 2009).

Five indigenous fungi P. ostreatus IBL-02, P. chrysosporium IBL-03, Coriolus versicolor IBL04, G. lucidum IBL-05 and S. commune IBL-06 were screened for decolorization of four vat dyes, Cibanon red 2B-MD, Cibanon golden-yellow PKMD, Cibanon blue GFJ-MD and Indanthrene direct black RBS. The screening experiment was run for 10 days with 0.01% dye solutions prepared in alkaline Kirks basal nutrient medium in triplicate (250 ml flasks). Every 48 h samples were read on their respective wavelengths to determine the percent decolorization. It was observed that C. versicolor IBL-04 could effectively decolorized all the four vat dyes at varying incubation times but best results were shown on Cibanon blue GFJ-MD (90.7%) after 7 days, followed by golden yellow (88%), Indanthrene direct black (79.7%) and Cibanon red (74%). P. chrysosporium also showed good decolorization potential on Cibanon blue (87%), followed by Cibanon golden-yellow (74.8%), Red (71%), and Indanthrene direct black (54.6%) (Asghar et al., 2008). Decolourization and detoxification of a textile industry effluent by laccase from Trametes trogii in the presence and the absence of laccase mediators had been investigated. It was found that laccase alone was not able to decolourize the effluent efficiently even at the highest enzyme concentration tested: less than 10% decolourization was obtained with 9 U/mL reaction mixtures. To enhance effluent decolourization, several potential laccase mediators were tested at concentrations ranging from 0 to 1mM. Most potential mediators enhanced decolourization of the effluent, with 1hydroxybenzotriazol (HBT) being the most effective (Khlifia et al., 2010). Moilanen et al. (2010) used the crude laccases from the white-rot fungi Cerrena unicolor and Trametes hirsuta for their ability to decolorize simulated textile dye baths. The dyes used were Remazol Brilliant Blue R (RBBR) (100 mg/L), Congo red (12.5 mg/L), Lanaset Grey (75 mg/L) and Poly R-478 (50 mg/L). They assessed the effect of redox mediators on dye decolorization by laccases. The result was that C. unicolor laccase was able to decolorize all the dyes tested. It was especially effective towards Congo red and RBBR with 91 and 80% of color removal in 19.5 h despite the fact that simulated textile dye baths were used.

Applications in pharmaceutical industry

Laccases have been used for the synthesis of several products of pharmaceutical industry (Arora and Sharma, 2010). The first chemical of the

Production and industrial applications of laccase 7

pharmaceutical importance that has been prepared using laccase enzyme is actinocin that has been prepared from 4-methyl-3-hydroxyanthranilic acid. This compound has anticancer capability and works by blocking the transcription of DNA from the tumor cell (Burton, 2003). Another example of the anticancer drugs is Vinblastine, which is useful for the treatment of leukemia. The plant Catharanthus roseus naturally produces vinblastine. This plant produces small amount of this compound. Katarantine and vindoline are the precursors of this pharmaceutically important compound. These precursors are produced in higher quantities and are easy to purifiy. Laccase is used to convert these precursors into vinblastine. A 40% conversion of these precursors into the final product has been obtained using laccase (Yaropolov et al., 1994). The use of laccase in such conversion reactions has made the preparation of several important compounds with useful properties, like antibiotics, possible (Pilz et al., 2003). Catechins have the antioxidant ability and Laccases can oxidize catechins. These catechins consist of small units of tannins and these are important antioxidants found in tea, herbs and vegetables. Catechins have the tendency to hunt free radicals and their property makes them useful in preventing several diseases including cancer, inflammatory and cardiovascular diseases. The catechins have less antioxidant ability; this property can be increased by using laccase and has resulted in the conversion of catechins in several products with enhanced antioxidant capability (Kurisawa et al., 2003). Laccase has applications in the synthesis of hormone derivatives. Intra et al. (2005) and Nicotra et al. (2004) have reported that laccase has the ability to seperate innovative dimeric derivatives of the -estradiol and of the phytoalexin resveratrol. Isoeugenol oxidation coniferyl alcohol and totarol gave new dimeric derivatives (Ncanana et al., 2007) and a mixture of dimeric and tetrameric derivatives (Shiba et al., 2000) respectively, whereas the oxidation of substituted imidazole has resulted in the production of even more complex substrances. These new formed imidazoles or oligomerization products (24) can be used for pharmacological purposes (Kurisawa et al., 2003). Aromatic and aliphatic amines can be converted into 3-(3, 4-dihydroxyphenyl)-propionic acid using laccase based oxidation. The derivatives have the antiviral natural activity and can be used for

pharmaceutical purposes (Ncanana et al., 2007).

Conclusion

Laccases are produced by various sources like fungi, bacteria and insects. They have many industrial applications because of their innate ability of oxidation of a broad range of phenolic and non-phenolic compounds. Laccase is utilized in drink industry to improve the quality of drinks and for stabilization of some perishable products having plant oils. Laccases have the potential for the synthesis of several useful drugs in pharmaceutical industry because of their high value of oxidation potential. Laccases have also tremendous ability of oxidation of harmful and industrial products and belongs to those enzymes, which have instinctive properties of immediate radical production. Laccase enzyme has the property to act on a range of substrates and to detoxify a range of pollutants, which have made them to be useful in many industries including paper, pulp, textile and petrochemical industries.

References

Aisemberg GO, Grorewold E, Taccioli GE, Judewicz N. A major transcript in the response of Neurospora crassa to protein synthesis inhibition by cycloheximide. Exp Mycol. 13: 121128, 1989. Alexandre G, and Zhulin IB. Laccases are wide spread in bacteria. Trends in Biotech. 18: 41 42, 2000. Amat AS, Elio PL, Fernandez E, Borron JCG, Solano F. Molecular cloning and functional characterization of a unique multipotent polyphenol oxidase from Marinomonas mediterranea. Biochem Biophys Acta. 1547: 104116, 2001. Arakane Y, Muthukrishnan S, Beeman RW, Kanost MR, Kramer KJ. Laccase 2 is the phenoloxidase gene required for beetle cuticle tanning. PNAS. 102: 11337-11342, 2005. Arora DS, Sharma RK. Ligninolytic Fungal Laccases and Their Biotechnological Applications. Appl Biochem Biotechnol. 160: 17601788, 2010.

8 Muhammad IMRAN et al.

Asghar M, Batool S, Bhatti HN, Noreen R, Rahman SU, Asad MJ. Laccase mediated decolorization of vat dyes by Coriolus versicolor IBL-04. Int Biodet Biodeg. 62: 465-470, 2008. Bailey MR, Woodard SL, Callawy E, Beifuss K, Lundback MM, Lane J. Improved recovery of active recombinant laccase from maize seed. Appl Microbiol Biotechnol. 63: 390397, 2004. Baldrian P. Fungal laccases occurrence and properties. FEMS Microbiol Rev. 30: 215242, 2006. Banat IM, Nigam P, Singh D, Marchnt R. Microbial decolorization of textile dye containing effluent: a review. Bioresour Technol. 58: 217227, 1996. Birhanli E and Yesilada O. Increased production of laccase by pellets of Funalia trogii ATCC 200800 and Trametes versicolor ATCC 200801 in repeated-batch mode. Enzy Microb Technol. 39: 12861293, 2006. Burton S. Laccases and phenol oxidases in organic synthesis. Curr Org Chem. 7: 1317-1331, 2003. Cantarelli C, Brenna O, Giovanelli G, Rossi M. Beverage stabilization through enzymatic removal of phenolics. Food Biotechnol. 3: 203 214, 1989. Claus H. Laccases and their occurrence in prokaryotes. Arch Microbiol. 179: 145150, 2003. Collins PJ and Dobson ADW. Regulation of laccase gene transcription in Trametes versicolor. Appl Environ Microbiol. 63: 3444 3450, 1997. Couto SR and Herrera JLT. Industrial and biotechnological applications of laccases: A review. Biotechnol Advances. 24: 500513, 2006. Cristovao RO, Tavares APM, Ribeiro A, Loureiro JM, Boaventura RAR, Macedo EA. Kinetic modelling and simulation of laccase catalyzed degradation of reactive textile dyes. Biores

Technol. 99: 47684774, 2008. Davis RH and Perkins DD. Timeline: Neurospora: a model of model microbes. Nat Rev Genet. 3: 397403, 2002. Dittmer NT, Suderman RJ, Jiang H, Zhu YC, Gorman MJ, Kramer KJ, Kanost MR. Characterization of cDNA encoding putative laccase-like multicopper oxidases and developmental expression in the tobacco hornworm, Manduca sexta, and the malaria mosquito, Anopheles gambiae. Insect Biochem Mol Biol. 34: 2941, 2004. Duran N and Esposito E. Potential applications of oxidative enzymes and phenoloxidase-like compounds in wastewater and soil treatment: a review. Appl Cataly Env. 28: 8399, 2000. Eggert C, Temp U, Eriksson KE. The ligninolytic system of the white rot fungus Pycnoporus cinnabarinus: purification and characterization of the laccase. Appl Environ Microbiol. 62: 11511158, 1996. Enguita FJ, Martins LO, Henriques AO, Carrondo MA. Crystal structure of a bacterial endospore coat component. A laccase with enhanced thermostability properties. J Biol Chem. 278: 1941619425, 2003. Faure D, Bouillant ML, Bally R. Isolation of Azospirillum lipoferum 4T Tn5 mutants affected in melanization and laccase activity. Appl Environ Microbiol. 60, 34133415, 1994. Forgacsa E, Cserhatia T, Oros G. Removal of synthetic dyes from wastewaters: a review. Environ Int. 30: 953971, 2004. Galai S, Limam F, Marzouki MN. A new Stenotrophomonas maltophilia strain producing laccase. Use in decolorization of synthetic dyes. Appl Biochem Biotechnol. 158(2): 416-431 2009. Galhaup C, Wagner H, Hinterstoisser B, Haltrich D. Increased production of laccase by the wooddegrading basidiomycetes Trametes pubescens. Enz Microb Technol. 30: 529536, 2002.

Production and industrial applications of laccase 9

Gianfreda L, Xu F, Bollag JM. Laccases: a useful group of delignication and possible industrial applications. Multi-Copper Oxidases. Messerschmidt A (Ed). Singapore: World Scientic. 201224, 1999. Giardina P, Faraco V, Pezzella C, Piscitelli A, Vanhulle S, Sannia G. Laccases: a never-ending story. Cell Mol Life Sci. 67: 369385, 2010. Givaudan A, Effose A, Faure D, Potier P, Bouillant ML, Bally R. Polyphenol oxidase in Azospirillum lipoferum isolated from rice rhizosphere: evidence for laccase activity in non-motile strains of Azospirillum lipoferum. FEMS Microbiol Lett. 108: 205210, 1993. Gnanamani A, Jayaprakashvel M, Arulmani M, Sadulla S. Effect of inducers and culturing processes on laccase synthesis in Phanerochaete chrysosporium NCIM 1197 and the constitutive expression of laccase isozymes. Enz Microb Technol. 38: 1017-1021, 2006. Heinzkill M, Messner K. The ligninolytic system of fungi. Fungal biotechnology. Anke T (Ed). Chap Hall Weinheim. 213226, 1997. Intra A, Nicotra S, Riva S, Daniel B. Significant and unexpected solvent influence on the selectivity of laccase-catalyzed coupling of tetrahydro-2-naphthol derivatives. Adv Synth Catal. 347: 973-977, 2005. Jolivalt C, Brenon S, Caminade E, Mougin C, Pontie M. Immobilization of laccase from Trametes versicolor on a modied PVDF microltration membrane: characterization of the grafted support and application in removing a phenylurea pesticide in wastewater. J Membr Sci. 180: 103113, 2000. Jolivalt C, Raynal A, Caminade E, Kokel B, Le Gofc F, Mougin C. Transformation of N,N dimethyl-N-(hydroxyphenyl)ureas by laccase from the white rot fungus Trametes versicolor. Appl Microbiol Biotechnol. 51: 676681, 1999. Khlifia R, Belbahria L, Woodwarda S, Ellouza M, Dhouiba A, Sayadia S, Mechichia T.

Decolourization and detoxification of textile industry wastewater by the laccase-mediator system. J Hazard Mater. 175: 80280, 2010. Kiiskinen LL, Ratto M, Kruus K. Screening for novel laccase-producing microbes. J Appl Microbiol. 97: 640646, 2004. Koschorreck K, Schmid RD, Urlacher VB. Improving the functional expression of a Bacillus licheniformis laccase by random and site-directed mutagenesis. J Biotechnol. 9(12): 1-10, 2009. Kurisawa M, Chung JE, Uyama H, Kobayashi S. Laccase-catalyzed synthesis and antioxidant property of poly(catechin). Macromol Biosci. 3: 758-764, 2003. Leonowicz A, Cho NS, Luterek J, Wilkolazka A, Wotjas-Wasilewska M, Matuszewska A, Hofrichter M, Wesenberg D, Rogalski J. Fungal laccase: properties and activity on lignin. J Bas Microbiol. 41: 185227, 2001. Liers C, Ullrich R, Pecyna M, Schlosser D, Hofrichter M. Production, purification and partial enzymatic and molecular characterization of a laccase from the woodrotting ascomycete Xylaria polymorpha. Enz Microb Technol. 41: 785793, 2007. Mayer AM. Polyphenol oxidases in plant: recent progress. Phytochem. 26: 1120, 1987. Mayer AM, Staples RC. Laccase: new functions for an old enzyme. Phytochem. 60: 551565, 2002. Minussi RC, Pastore GM, Duran N. Potential applications of laccase in the food industry. Trends in Food Scien Technol. 13: 205216, 2002. Mishra A, Kumar S, Kumar S. Application of BoxBenhken experimental design for optimization of laccase production Coriolus versicolor MTCC138 in solid-state fermentation. J Sci Indust Res. 67: 1098-1107, 2008.

10 Muhammad IMRAN et al.

Mohammadian M, Roudsari MF, Mollania N, Dalfard AB, Khajeh K. Enhanced expression of a recomninant bacterial laccase at low temperature and microacrobic conditions: purification and biochemical characterization. J Ind Microbiol Biotechnol. 5: 41-45, 2010. Moilanen U, Osma JF, Winquist E, Leisola M, Couto SR. Decolorization of simulated textile dye baths by crude laccases from Trametes hirsute and Cerrena unicolor. Eng Life Sci. 10(3): 16, 2010. Morozova OV, Shumakovich GP, Gorbacheva MA, Shleev SV, Yaropolov AI. Blue Laccases. J Biochem. 72(10): 1136-1150, 2007. Mougin, C., Boyer, F. D., Caminade, E., Rama, R. Cleavage of the diketonitrilederivative of the herbicide isoxautole by extra cellular fungal oxidases. J Agric Food Chem. 48: 45294534, 2000. Ncanana S, Baratto L, Roncaglia L, Riva S, Burton SG. Laccase mediated oxidation of totarol. Adv Synth Catal. 349 : 1507-1513, 2007. Nicotra S, Cramarossa MR, Mucci A, Pagnoni UM, Riva S, Forti L. Biotransformation of resveratrol: synthesis of trans-dehydrodimers catalyzed by laccases from Myceliophtora thermophyla and from Trametes pubescens. Tetrahedron. 60: 595-600, 2004. Niladevi KN, Sukumaran RK, Jacob N, Anisha GS, Prema P. Optimization of laccase production from a novel strain-Streptomyces psammoticus using response surface methodology. Microbiol Res. 164: 105-113, 2009. Pandey A. Solid State Fermentation. Pandey A (Ed). Wiley Eastern Publishers, New Delhi. 3 10, 1994. Pilz R, Hammer E, Schauer F, Krag U. Laccasecatalyzed synthesis of coupling products of phenolic substrates in different reactors. Appl Microbiol Biotechnol. 60: 708-712, 2003. Rama R, Mougin C, Boyer FD, Kollmann A, Malosse C and Sigoillot JC. Biotransformation

of benzo[a]pyrene in bench scale reactor using laccase of Pycnoporus cinnabarinus. Biotechnol Lett. 20: 11011104, 1998. Ranocha P, Chabannes M, Chamayou S, Danoun S, Jauneau A, Boudet AM. Laccase downregulation causes alteration in phenolic metabolism and cell wall structure in poplar. Plant Physiol. 129:111, 2002. Rosana C, Minussi Y, Pastore GM, Durany N. Potential applications of laccase in the food industry. Trends in Food Sci Technol. 13: 205216, 2002. Savoie JM, Mata G, Billette C. Extracellular laccase production during hyphal interactions between Trichoderma sp. and Shiitake, Lentinula edodes. Appl Microbiol Biotechnol. 49: 589-593, 1998. Sadhasivam S, Savitha S, Swaminathan K, Lin FH. Production, purification and characterization of mid-redox potential laccase from a newly isolated Trichoderma harzianum WL1. Process Biochem. 43: 736-742, 2008. Sharma KK and Kuhad RC. Laccase: enzyme revisited and function redefined. Ind J Microbiol. 48: 309316, 2008. Sharma P, Goel R, Caplash N. Bacterial laccases. World J Microbiol Biotechnol. 23: 823-832, 2007. Shiba T, Xiao L, Miyakoshi T, Chen CL. Oxidation of isoeugenol and coniferyl alcohol catalyzed by laccase isolated from Rhus vernicifera Stokes and Pycnoporus coccineus. J Mol Catal Enzym. 10: 605-615, 2000. Smith M, Thurston F, Wood DA. Fungal laccases: role in oxidoreductive enzymes. Bioremed J. 3: 125, 1997. Solden DM and Dobson DW. Differential regulation of laccase gene expression in Pleurotus sajor-caju. Microbiol. 147: 1755 1763, 2001. Souza D and Peralta RM. Production of laccase

Production and industrial applications of laccase 11

isoforms by Pleurotus pulmonarius in response to presence of phenolic and aromatic compounds. J Basic Microbiol. 44(2): 129136, 2004. Souza CGM, Zilly A, Peralta RM. Production of laccase as the sole phenoloxidase by a Brazilian strain of Pleurotus pulmonarius in solid state fermentation. J Bas Microbiol. 42: 8390, 2002. Souza DDT, Tiwari R, Sah AK, Raghukumara C. Enhanced production of laccase by a marine fungus during treatment of colored effluents and synthetic dyes. Enz Microb Technol. 38: 504511, 2006. Tavares APM, Cristovao RO, Gamelas JAF, Loureiro JM, Boaventuraa RAR, Macedoa EA. Sequential decolourization of reactive textile dyes by laccase mediator system. J Chem Technol Biotechnol. 84: 442446, 2009. Vandevivere PC, Bianchi R, Verstraete W. Treatment and reuse of wastewater from the textile wet-processing industry: review of emerging technologies. J Chem Technol Biotechnol. 72: 289302, 1998. Wesenberg D, Kyriakides I, Agathos N. White-rot fungi and their enzymes for the treatment of industrial dye effluents. Biotechnol Adv. 22: 161187, 2003. Yaropolov AI, Skorobogatko OV, Vartanov SS, Varfolomeyev SD. Laccase: Properties, catalytic mechanism and applicability. Appl Biochem Biotechnol. 49: 257280, 1994.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- RingMethod Zuidema WatersDocument2 pagesRingMethod Zuidema WatersJack Yoseph Martinez OrtegaPas encore d'évaluation

- Fore3 ManualDocument48 pagesFore3 ManualMARIA FE GETALLAPas encore d'évaluation

- Type of Chemical ReactionsDocument13 pagesType of Chemical ReactionsSAHARAN ANANDPas encore d'évaluation

- Aerospace Material SpecificationDocument7 pagesAerospace Material SpecificationAnonymous T6GllLl0Pas encore d'évaluation

- 161Document7 pages161KierCliffenvilleGanadosPacientePas encore d'évaluation

- Plate Fin Coil PDFDocument2 pagesPlate Fin Coil PDFHermawan LesmanaPas encore d'évaluation

- 1549373338B.I.P.C. Question Paper PDFDocument14 pages1549373338B.I.P.C. Question Paper PDFVivek BiradarPas encore d'évaluation

- AlkalinityDocument3 pagesAlkalinityNgatchiePas encore d'évaluation

- ECS HFC-227ea - Modular DIOM - October 2014-06-236116-001 - Rev - BADocument152 pagesECS HFC-227ea - Modular DIOM - October 2014-06-236116-001 - Rev - BALuis RicaldiPas encore d'évaluation

- Carbon Dioxide Capture by Amines Increasing The Efficiency by Amine Structure Modification PDFDocument2 pagesCarbon Dioxide Capture by Amines Increasing The Efficiency by Amine Structure Modification PDFJorgeSantosAquinoPas encore d'évaluation

- Sarcosine MsdsDocument41 pagesSarcosine MsdsAnonymous ZVvGjtUGPas encore d'évaluation

- Models - Bfc.li Battery Thermal 2d AxiDocument16 pagesModels - Bfc.li Battery Thermal 2d AxijehadyamPas encore d'évaluation

- Rotary PumpsDocument31 pagesRotary PumpsalbertPas encore d'évaluation

- Superalloys - A Primer and HistoryDocument4 pagesSuperalloys - A Primer and Historyhemakumars100% (1)

- Gen Bio W3-5Document9 pagesGen Bio W3-5Alyson EscuderoPas encore d'évaluation

- PAL RefiningDocument1 pagePAL Refiningjh gdgfgPas encore d'évaluation

- Valves SpecificationDocument13 pagesValves Specificationkselvan_1Pas encore d'évaluation

- Industrial ReportDocument64 pagesIndustrial Reportfuad ullahPas encore d'évaluation

- Dissolution TestDocument5 pagesDissolution TestAlecza Mae SavellaPas encore d'évaluation

- Atkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Document7 pagesAtkins & de Paula Elements of Physical Chemistry 5th TXTBK (Dragged) 2Roselle Mea EderPas encore d'évaluation

- Four Factors Affecting The Rate of Chemical ReactionDocument5 pagesFour Factors Affecting The Rate of Chemical ReactionFeliciano Tristan E.Pas encore d'évaluation

- DELTA-FC 1022 Tds - EngDocument2 pagesDELTA-FC 1022 Tds - EngAhmed HassanPas encore d'évaluation

- A Tribological Study of Synchronizing Devices UsedDocument7 pagesA Tribological Study of Synchronizing Devices UsedthisisjineshPas encore d'évaluation

- National Waste Management Strategy 2019-2023Document64 pagesNational Waste Management Strategy 2019-2023Chikondi KanamaPas encore d'évaluation

- Emulgin HandbookDocument2 pagesEmulgin HandbookCarlos Fernando Jacobo PérezPas encore d'évaluation

- Tsubaki ChainDocument8 pagesTsubaki Chainbmihaiela100% (1)

- Betadex Sulfobutyl Ether SodiumDocument11 pagesBetadex Sulfobutyl Ether SodiumLeidy GonzalezPas encore d'évaluation

- 242 Chemistry Resources CH 5 8Document137 pages242 Chemistry Resources CH 5 8Tina Sima88% (8)

- Ok Kadar Abu KencurDocument7 pagesOk Kadar Abu KencurMuhamad IqbalPas encore d'évaluation