Académique Documents

Professionnel Documents

Culture Documents

OSHA Safety Checklist

Transféré par

Kabalikat Civicom Metro TaclobanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

OSHA Safety Checklist

Transféré par

Kabalikat Civicom Metro TaclobanDroits d'auteur :

Formats disponibles

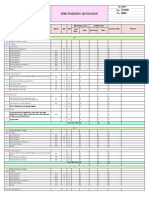

OSHA SAFETY CHECKLIST

NAME: LOCATION: DATE: CHECK: YES NO (Corrective Action is required if you checked no) EMERGENCY ACTION ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ 1. Have you posted all emergency telephone numbers? 2. Have you displayed an emergency evacuation maps? 3. Do you immediately clean up spills? 4. Do you have adequate amount of OSHA-approved first aid kit and supplies? 5. Are hand tools in good working condition? 6. Are air nozzles available if necessary? 7. Do you reduce the air pressure to 30 psi when work surfaces are being cleaned? 8. Do you have a brush attached for cleaning workers clothing and reduce the air pressure to 10 psi? 9. Have you provided an emergency training for all employees and do you have a documented emergency action plan? WALKING WORK SURFACES ____ ____ ____ ____ 1. Are floor surfaces clean and free of obstacles? ____ 2. Do you keep your work surfaces dry? ____ 3. Are your aisles properly marked? LADDERS ____ ____ ____ ____ ____ ____ ____ ____ 1. Do you use non-conductive ladders? 2. Are ladders equipped with anti slip grit? 3. Are ladders free of oil or grease? 4. Do you maintain a distance clearance of 10 feet from overhead lines? WORKPLACE VIOLENCE ____ ____ ____ 1. Does your company have a log book for all visitors, customers, etc. coming in and out of the premises? ____ 2. Does your employees report all threats of (or actual) violence to __________________________________________________________ __________________________________________________________ __________________________________________________________

____

management? ____ 3. Do you check everyone entering the premises for firearms or hazardous devices that might be carried without authorization? FIRE PREVENTION

____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____

____ 1. Do you always keep your outside fire water control valves open? ____ 2. Do you keep a gas shut-off wrench nearby? ____ 3. Are your external exit signs well lighted? ____ 4. Are there signs posted leading to external exits? ____ 5. Are fire extinguishers inspected annually? ____ 6. Are your aisles and walkways free of obstacles? ____ 7. Are fire extinguishers located in an easily accessible location? ____ 8. Do you maintain an 18 clearance below sprinkler heads? ____ 9. Are your sprinkler system tested and inspected regularly? ____ 10. Are your sprinkler water control valves, air and water pressures checked monthly? ____ 11. Are your fire doors in good condition? ____ 12. Do you keep in a two-hour fireproof cabinet or room your flammable liquids? ____ 13. Do you keep your fifty-five-gallon drums of flammable liquids grounded and bonded? ____ 14. Do you use safety cans in dispensing flammable liquids? ____ 15. Do you have a daily disposal of your trash? ____ 16. Have you already completed the fire prevention and portable fire extinguisher training? CHEMICAL SAFETY

____ ____ ____ ____ ____

____ 1. Have you properly labelled all physical or health hazardous containers? ____ 2. Do you maintain on file a Material Safety Data Sheets (MSDS) for each hazardous substance? ____ 3. Do you made available to employees the MSDS and HazCom Program? ____ 4. Whenever possible, do you have a proper documented procedure for cleaning up your own blood? ____ 5. Have you provided training for all employees exposed to hazardous substances? MACHINE GUARDING

____

____ 1. Have you checked if machine guards are in place and working properly?

____ ____

____ 2. Have you checked if rotating or moving parts are adequately guarded? ____ 3. Have you completed training for all operators?

LOCKOUT/TAGOUT ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ 1. Are locks and tags assigned to employees or is it available for use? 2. If pegboard system used, is one key available for each lock? 3. Have you documented a hazard analysis for each piece of equipment? 4. Have you documented a lockout/tagout procedure for each piece of equipment? 5. Have you documented each piece of equipments energy sources? 6. Have you provided an alternative protection for minor servicing operation? 7. Have you provided training for all your employees? 8. Have you completed lockout/tagout annual inspection for each authorized person?

ELECTRICAL SAFETY ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ 1. Have you labelled electrical boxes switch? 2. Are all portable tools and appliances grounded? 3. Do you consider 60 days as a limit for temporary wiring or the use of extension cords? 4. Are cords that run along walls secured in metal sheath? 5. Are cords that run on the floor protected by cord covers? 6. Does outlet have GFCI in damp locations or within five feet of water? 7. Do you have an available voltage detector meter? 8. Have you provided training for all your personnel? PERSONAL PROTECTIVE EQUIPMENT ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ 1. Are there signs posted for areas requiring a hearing protection? 2. Are there available gloves, aprons, glasses and respirators if necessary? 3. Are PPE kept in clean and good condition? 4. Do you use PPE when required? 5. Do you have a documented hearing conservation plan and have you trained affected employees?

Vous aimerez peut-être aussi

- OSHA 10 Fact Sheet - Introduction To OSHADocument1 pageOSHA 10 Fact Sheet - Introduction To OSHAMaurice Anthony0% (1)

- OSHA - 30 General IndustryDocument1 pageOSHA - 30 General IndustryAldrin33% (3)

- OSHA Construction Pre-TestanswersDocument2 pagesOSHA Construction Pre-TestanswersAgencia Privada de Investigacion33% (6)

- Walking and Working SurfacesDocument21 pagesWalking and Working Surfacesahmed naveed100% (1)

- OSHA 10-30 Hour Course List-1Document9 pagesOSHA 10-30 Hour Course List-1kabir0% (1)

- Monthly Safety ReportDocument1 pageMonthly Safety Reportsafety.engPas encore d'évaluation

- Training Requirements in OSHADocument3 pagesTraining Requirements in OSHAXozanPas encore d'évaluation

- OSHA Construction Pre-TestDocument1 pageOSHA Construction Pre-TestAgencia Privada de Investigacion50% (2)

- Sample Written Hazard Communication ProgramDocument3 pagesSample Written Hazard Communication ProgramLiz CPas encore d'évaluation

- Construction SafetyDocument2 pagesConstruction SafetyAristotle RiveraPas encore d'évaluation

- Hearing Conservation Training: Environmental Health and Safety University of TennesseeDocument54 pagesHearing Conservation Training: Environmental Health and Safety University of TennesseeMG NandanPas encore d'évaluation

- Supervisor Safety TrainingDocument26 pagesSupervisor Safety TrainingMutiaPas encore d'évaluation

- Safety ProgramDocument41 pagesSafety Programjay-ar Maravilla100% (2)

- Silica Awareness Toolbox TalkDocument2 pagesSilica Awareness Toolbox TalkSamar Husain0% (1)

- 30-Hr Construction SG 1.2Document177 pages30-Hr Construction SG 1.2c2hardman100% (5)

- Osha 30Document49 pagesOsha 30juliki1Pas encore d'évaluation

- Example Fire Safety Maintenance Checklist: Daily ChecksDocument13 pagesExample Fire Safety Maintenance Checklist: Daily ChecksPampa DasPas encore d'évaluation

- Chapter 1a - OSHA Electricity SafetyDocument60 pagesChapter 1a - OSHA Electricity SafetyGopinath SubramaniPas encore d'évaluation

- Safety PlanDocument165 pagesSafety PlanGerry Triaz100% (6)

- Basic OSHA Compliance ChecklistDocument2 pagesBasic OSHA Compliance ChecklistMary NicksPas encore d'évaluation

- Hazardous MaterialsDocument18 pagesHazardous MaterialsVi Vek100% (1)

- OSHA HazcomDocument3 pagesOSHA Hazcomjoesuhre100% (1)

- Osha Questions and AnswersDocument5 pagesOsha Questions and AnswersOsueni Aitiemigele91% (11)

- Osha Bocket Book - ConstructionDocument36 pagesOsha Bocket Book - ConstructionSAYED83% (6)

- PPE Hazard Assessment FormDocument6 pagesPPE Hazard Assessment Formgabguarse100% (2)

- Safety TalkDocument80 pagesSafety TalkSAYED100% (17)

- Study Guide OSHA 30 Construction Focus Four Electrocuction HazardsDocument86 pagesStudy Guide OSHA 30 Construction Focus Four Electrocuction HazardssuperpiojoPas encore d'évaluation

- Osha Safety AuditsDocument12 pagesOsha Safety AuditsAndy Selecta InfamouzPas encore d'évaluation

- First Aid Risk Assessment TemplateDocument3 pagesFirst Aid Risk Assessment TemplateRameeSahibaPas encore d'évaluation

- HAZCOMDocument30 pagesHAZCOMkenshinkimuraPas encore d'évaluation

- OSHA Fire SafetyDocument20 pagesOSHA Fire SafetyrpbpaPas encore d'évaluation

- OSHA 30 HR Construction Outline - 2009-1Document23 pagesOSHA 30 HR Construction Outline - 2009-1Kashif Nadeem Rana100% (1)

- Micromax Specialists in Automation Machine Safety ChecklistDocument3 pagesMicromax Specialists in Automation Machine Safety Checklistjustine8448Pas encore d'évaluation

- Lab Audit FormDocument6 pagesLab Audit Formmahesh90600Pas encore d'évaluation

- OSHA 2013 AnswersDocument3 pagesOSHA 2013 Answerslacurva67% (3)

- Introduction To Osha: Directorate of Training and Education OSHA Training InstituteDocument36 pagesIntroduction To Osha: Directorate of Training and Education OSHA Training InstituteVivek ParitPas encore d'évaluation

- List of Hazards Control MeasuresDocument29 pagesList of Hazards Control Measuresテレブリコ ジェファーソン0% (1)

- Employee Safety Orientation ManualDocument26 pagesEmployee Safety Orientation ManualSaravana KumarPas encore d'évaluation

- Machinery and Machine Guarding ProgramDocument35 pagesMachinery and Machine Guarding ProgramBenson Harison MajabePas encore d'évaluation

- Site Safety OrientationDocument19 pagesSite Safety OrientationKrischaEverPas encore d'évaluation

- Job Safety AnalysisDocument9 pagesJob Safety AnalysisazerPas encore d'évaluation

- NFPA 101 Life Safety Code Compliance R1sDocument2 pagesNFPA 101 Life Safety Code Compliance R1ssimonsecurityPas encore d'évaluation

- OSHA 10 Construction Final Exam Answer KeyDocument1 pageOSHA 10 Construction Final Exam Answer KeyPraful E. PawarPas encore d'évaluation

- Electrical CampaignDocument9 pagesElectrical CampaignLamtua PurbaPas encore d'évaluation

- Officeriskassess 259943Document2 pagesOfficeriskassess 259943api-332787463Pas encore d'évaluation

- 3786 Frequency & Severity Rates For Industrial InjuriesDocument30 pages3786 Frequency & Severity Rates For Industrial InjuriesVk Seshadri100% (1)

- 11work Xone Traffic SafetyDocument2 pages11work Xone Traffic SafetysolidrepPas encore d'évaluation

- Health and Safety at Work SlidesDocument195 pagesHealth and Safety at Work SlidesZulfiqar Hyder100% (2)

- JHA Template BlankDocument5 pagesJHA Template BlankChristopher Newby100% (1)

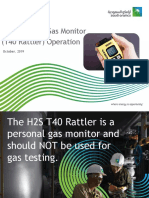

- H2S Personal Gas MonitorDocument14 pagesH2S Personal Gas Monitormaher mansiPas encore d'évaluation

- Paint Booth GuidelinesDocument2 pagesPaint Booth GuidelinesbinayperiwalPas encore d'évaluation

- Safety Inspection ChecklistDocument6 pagesSafety Inspection ChecklistJefferson Palabao LugoPas encore d'évaluation

- New Equipment Inspection ChecklistDocument6 pagesNew Equipment Inspection ChecklistNate100% (2)

- Office Safety ChecklistDocument3 pagesOffice Safety ChecklistAgnesha A KempkesPas encore d'évaluation

- Construction Safety Checklist 2Document3 pagesConstruction Safety Checklist 2Brijgopal YadavPas encore d'évaluation

- HSE TEAM TOUR CHECKLIST Maintenance Block Utilties AreaDocument2 pagesHSE TEAM TOUR CHECKLIST Maintenance Block Utilties Areaf.BPas encore d'évaluation

- Accident Prevention Plan: Review ChecklistDocument5 pagesAccident Prevention Plan: Review ChecklistGamaliel VentoPas encore d'évaluation

- Ascotf Checklist NewDocument4 pagesAscotf Checklist NewChristine Joy BautistaPas encore d'évaluation

- Conductor Sizing and The National Electrical CodeDocument3 pagesConductor Sizing and The National Electrical CodeKabalikat Civicom Metro TaclobanPas encore d'évaluation

- Saudi STD Electric Cables With A Rated Voltage Not Exceeding 450 - 750vDocument22 pagesSaudi STD Electric Cables With A Rated Voltage Not Exceeding 450 - 750vKabalikat Civicom Metro TaclobanPas encore d'évaluation

- Amateur Radio Class Element IIIDocument5 pagesAmateur Radio Class Element IIIKabalikat Civicom Metro TaclobanPas encore d'évaluation

- Amateur Radio Class Element IIDocument5 pagesAmateur Radio Class Element IIKabalikat Civicom Metro Tacloban67% (6)

- Pdea Director Admits Planting Evidence On Known Drug DealersDocument4 pagesPdea Director Admits Planting Evidence On Known Drug DealersKabalikat Civicom Metro TaclobanPas encore d'évaluation

- Measure of SelflessnessDocument3 pagesMeasure of SelflessnessKabalikat Civicom Metro TaclobanPas encore d'évaluation

- Report OJT Fire ProtectionDocument33 pagesReport OJT Fire ProtectionFazir AzlanPas encore d'évaluation

- Dl311 Top Hammer Longhole Drill: Technical SpecificationDocument4 pagesDl311 Top Hammer Longhole Drill: Technical SpecificationcblPas encore d'évaluation

- Marine Lite Catalogue - Part 1Document20 pagesMarine Lite Catalogue - Part 1mkccmPas encore d'évaluation

- Material Safety Data Sheet: Coated Bleach Board - ElegantDocument5 pagesMaterial Safety Data Sheet: Coated Bleach Board - ElegantSaad IqbalPas encore d'évaluation

- AMSA - Part - c4 - January - 2018 - 0 PDFDocument86 pagesAMSA - Part - c4 - January - 2018 - 0 PDFAlfa ZULUPas encore d'évaluation

- السلامة و الصحةالمهنية مترجم ملزمة-1Document10 pagesالسلامة و الصحةالمهنية مترجم ملزمة-1Oussama ZAOUIPas encore d'évaluation

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument8 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company Identificationsuraj rawatPas encore d'évaluation

- Fuel Handlers Study GuideDocument27 pagesFuel Handlers Study Guidekamaleshaiah100% (6)

- Fire Safety Policy and Procedure For A HotelDocument5 pagesFire Safety Policy and Procedure For A Hotelfaisal nadeemPas encore d'évaluation

- ZX200 350 PDFDocument340 pagesZX200 350 PDFThomas Hansen84% (19)

- Operation and Maintenance Manual: 4012-46A Industrial EngineDocument78 pagesOperation and Maintenance Manual: 4012-46A Industrial EnginearitmeticsPas encore d'évaluation

- Fire Technology and Arson InvestigationDocument29 pagesFire Technology and Arson InvestigationAlnashrin Mindug100% (1)

- Round Check ListDocument2 pagesRound Check Listlokesh godaraPas encore d'évaluation

- Chapter 1: Safety and Quality Management: 11-01-2021 - Harley Rose Bautista, RMT RMT 2023Document25 pagesChapter 1: Safety and Quality Management: 11-01-2021 - Harley Rose Bautista, RMT RMT 2023Ricardo Lorenzo AlasPas encore d'évaluation

- Medium Clear PVC Solvent CementDocument2 pagesMedium Clear PVC Solvent Cementguevara170188Pas encore d'évaluation

- Fire Safety Testing and Maintenance Log BookDocument27 pagesFire Safety Testing and Maintenance Log BookSaber HussainiPas encore d'évaluation

- MH227 (HFC-227ea) : Product Information With UL & FM CertificatesDocument6 pagesMH227 (HFC-227ea) : Product Information With UL & FM CertificatesAwais AshrafPas encore d'évaluation

- Phoenix h10 t3 - Fps - BoqDocument19 pagesPhoenix h10 t3 - Fps - BoqarifkhadeerPas encore d'évaluation

- Safety Fire Radio Other Service and MaintenanceDocument30 pagesSafety Fire Radio Other Service and MaintenanceAHMED100% (1)

- GS Yuasa Battery Europe Ltd. Safety Data SheetDocument11 pagesGS Yuasa Battery Europe Ltd. Safety Data SheetVioleta MitićPas encore d'évaluation

- LIQUITAINER Paint SpecificationDocument28 pagesLIQUITAINER Paint Specificationpaulm3565Pas encore d'évaluation

- Information On Architecture and Engineering - v2017-500Document195 pagesInformation On Architecture and Engineering - v2017-500Ləonardo SasingPas encore d'évaluation

- Bonpet: Automatic Self Activated Fire ExtinguisherDocument13 pagesBonpet: Automatic Self Activated Fire ExtinguisherAsemPas encore d'évaluation

- Lab Rules Q and ADocument18 pagesLab Rules Q and Ana-chanPas encore d'évaluation

- Cap. 6 - Fire Protection General InformationDocument8 pagesCap. 6 - Fire Protection General InformationtanaurePas encore d'évaluation

- ts410 PDFDocument44 pagests410 PDFVictor ChuaPas encore d'évaluation

- HANDOUT (Sequence of Compliance) PM ArDocument29 pagesHANDOUT (Sequence of Compliance) PM ArNurul Husna Mohd KamilPas encore d'évaluation

- Material Safety Data Sheet - Esyskimcoat Suprafine White & GreyDocument3 pagesMaterial Safety Data Sheet - Esyskimcoat Suprafine White & GreyJM Subion100% (1)

- Boq FHCDocument3 pagesBoq FHCHang ChethaPas encore d'évaluation

- 1.0 Fire Protection System - IntroductionDocument38 pages1.0 Fire Protection System - IntroductionJonabel Lenares BorresPas encore d'évaluation