Académique Documents

Professionnel Documents

Culture Documents

AP GB

Transféré par

Titu NicuTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AP GB

Transféré par

Titu NicuDroits d'auteur :

Formats disponibles

OIL PUMP TYPE AP GEAR SIZES 47-57-67

This is a general specification leaflet; for specific applications not covered herein, contact Suntec.

The SUNTEC AP oil pump has a built-in solenoid which provides a two-mode pressure operation. APPLICATIONS - Light oil. - 2 firing rates (with a sole nozzle line). - Two-pipe or one-pipe system. - Requires a separate cut-off valve. PUMP OPERATING PRINCIPLE The gear-set draws oil from the tank through the built-in filter and transfers it to the pressure regulating valve. The high pressure mode is obtained with the solenoid valve activated (ie. closed); activating this solenoid valve closes the by-pass channel to the return. Oil is then transferred to the nozzle line at the pressure given by the high pressure regulating valve. The low pressure mode is obtained with the solenoid valve open (ie. non activated); the by-pass channel is open, the oil is supplied to the nozzle line via the by-pass hole and the low pressure adjustment is made by the screw on the solenoid tube. It is preferable to set the high pressure given by the pump valve (with solenoid activated) before the low pressure, with solenoid non activated. Care should be taken not to overtighten the low pressure adjusting screw of the solenoid tube, as this may eliminate the low pressure range. For two pipe installation, the by-pass plug fitted in the return port allows any oil not required at the nozzle to be dumped back to the tank. For one pipe installation, the by-pass plug must be removed and the return port plugged, oil which is not required at the nozzle is then returned back to the suction port in the gear set . Bleed : Bleeding is assured by the by-pass hole of the nozzle plug. For the first start up, bleeding can be accelerated by loosening the plug of a pressure port . Note : Owing to the presence of the nozzle by-pass hole, the pump has no cut-off function; cut-off must be provided by an external solenoid valve.

Solenoid valve open ( low pressure mode ) Low pressure adjustment By-pass channel High pressure adjustment

AP

AP - 11 - Ed 6 - June 2001

PUMP IDENTIFICATION

( Not all model combinations are available. Consult your Suntec representative)

AP : two step model (one nozzle line and two pressure modes) without cut-off Gear set capacity (see pump capacity curves) Shaft rotation and nozzle location (seen from shaft end) A : clockwise rotation / right hand nozzle. B : clockwise rotation / left hand nozzle. C : anti clockwise rotation / left hand nozzle. D : anti clockwise rotation / right hand nozzle. Pump series 1000 : standard 7000 : with side pressure ports 4 : hub 54 mm 5 : hub 32 mm model number

AP

47 C 1 5 xx

P 05 00

Revision number Installation P : by-pass plug installed in return port for two-pipe operation Solenoid coil voltage 01 : 110 - 120 V ; 50/60 Hz 02 : 24 V ; 50/60 Hz 05 : 220 - 240 V ; 50/60 Hz Connector cable length 00 : no cable 35 : 35 cm 45 : 45 cm 60 : 60 cm 10 : 1 m

Solenoid valve closed ( high pressure mode )

To nozzle By-pass hole Shaft seal Pressure gauge port Gear set

Back to suction Oil under suction Oil under pressure By-passed oil returned to tank or to suction By-pass plug removed ONE PIPE INSTALLATION By-pass plug inserted TWO PIPE INSTALLATION

Vacuum gauge port

Return Suction SUNTEC INDUSTRIES FRANCE - 1, rue Lavoisier - BP 102 - 21603 LONGVIC Cedex - Tel. 33 3 80 70 60 70 - Fax 33 3 80 70 61 11 - http://www.suntec.fr

Return plugged

TECHNICAL DATA General

Mounting Connection threads Inlet and return Nozzle outlet Pressure gauge port Vacuum gauge port Valve function Strainer Shaft By-pass plug Flange or hub mounting according to EN 225 cylindrical according to ISO 228/1 G 1/4 (with facilities for conical sealing on revision 5 models) G 1/8 G 1/8 G 1/8 Pressure regulation open area :14 cm2 - opening size : 150 m 8 mm according to EN 225 inserted in return port for two-pipe system ; to be removed from return port with a 4 mm Allen key for one pipe system. 1,1 - 1,5 kg (depending on the model)

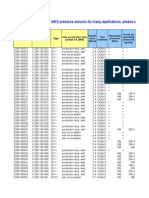

Pump capacity - High mode

Capacity (l/h) 100 90 80 70 60 50 40 30 20 10 Nozzle pressure Delivery pressure range* settings 3 -15 bars 9 bars 10 - 28 bars 22 bars 5 -15 bars 9 bars 10 - 28 bars 22 bars refer to the specified range of the particular 0 5 Pressure (bars) Viscosity= 5 cSt - Rated speed = 2850 rpm Data shown take into account a wear margin. Do not oversize the pump when selecting the gear capacity. 10 15 20 25

AP 67

AP 57 AP 47

Weight

Hydraulic Data

Gear size 47/57

Low mode : High mode : 67 Low mode : High mode : * Other ranges available on request, fuel unit. Operating viscosity 2-12 cSt Oil temperature 0 - 60C max. in the pump Inlet pressure 2 bars max. Return pressure 2 bars max. Suction height 0,45 bars max. vacuum to prevent air separation from oil Rated speed 3600 rpm max. Torque (@ 45 rpm) 0,10 N.m (AP 47/57) - 0,12 N.m (AP 67)

Power consumption

Power (W) 200

Solenoid valve characteristics

Voltage Consumption Ambient temperature Maximum pressure Protection class 220 - 240 or 110 - 120 or 24 V; 50/60 Hz 9 V.A (@ voltage = 230 or 110 or 24 V) 0 - 60C 28 bars IP 41 according to IEC 529, when used with SUNTEC connector cable

150

100

AP 67

50

Connector characteristics

Material Cable type Cross section area Wire end terminals Polyamide H03 VV-F 0,5 mm per conductor in accordance with DIN 46228 D1-7Ms PUMP (Example shows "C" rotation and nozzle outlet)

42

AP 57 AP 47

0 5 25 Pressure (bars) Viscosity = 5 cSt - Rated speed = 2850 rpm CONNECTOR

350 or 450 or 610 or 1000 10

10

15

20

DIMENSIONS

47

\ Z [

51 41 39

88

705

21 32 54 10,5 74

Inlet and Return with direct sealing for revision 5 models (sealing with washers can also be used)

118

35

]

13 25 21 7 8 13,5 13,5 63 92

Suction Return and internal by-pass plug Nozzle outlet Pressure gauge port

[ adjustment \

High pressure Low pressure adjustment

15

Z Vacuum gauge port

Pressure port (only for "7000" series)

G1/4

We reserve the right to change specifications without prior notice.

AP - 11 - Ed 6 - June 2001

Vous aimerez peut-être aussi

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideD'EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideÉvaluation : 4 sur 5 étoiles4/5 (8)

- Bosch Injector Data SheetDocument124 pagesBosch Injector Data SheetThibaut Lrt56% (9)

- Kia Picanto II Gen. (TA) EWD - Engine Control System (General Head Lamp Type)Document9 pagesKia Picanto II Gen. (TA) EWD - Engine Control System (General Head Lamp Type)mutaz ahmed100% (4)

- GrimmerSchmidt CompressorsDocument43 pagesGrimmerSchmidt CompressorsJulioCalderonOrtiz73% (11)

- Controls InstrumentationDocument245 pagesControls InstrumentationFreddy Yánez100% (1)

- Catalogue Sensors For Engine Management Incl Oxygen Sensors 4 0Document428 pagesCatalogue Sensors For Engine Management Incl Oxygen Sensors 4 0Timon2005100% (1)

- A6 VDocument40 pagesA6 VWesame Shnoda100% (1)

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabPas encore d'évaluation

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Power Electronics For Renewable Energy Systems PDFDocument160 pagesPower Electronics For Renewable Energy Systems PDFSUSHITAPas encore d'évaluation

- Ra 92711Document39 pagesRa 92711Agus Yulfizar100% (3)

- Bom A4VG - REXROTHDocument44 pagesBom A4VG - REXROTHnamduong368100% (4)

- VMCDocument32 pagesVMCJoanaRicardo FigueiredoPas encore d'évaluation

- Kris Gethin Muscle Building - Nutrition OverviewDocument8 pagesKris Gethin Muscle Building - Nutrition OverviewLuisLopezPas encore d'évaluation

- Re 92012Document12 pagesRe 92012Ahmed Abd Elhakeem100% (1)

- Axial Variable Duoble PumpDocument40 pagesAxial Variable Duoble Pumpveljeg100% (1)

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (1)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsD'EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsPas encore d'évaluation

- Oil & Gas Financial JourneyDocument85 pagesOil & Gas Financial Journeyabsolutvacio82Pas encore d'évaluation

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Heat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)Document14 pagesHeat Transfer and Pressure Drop Characteristics of Finned Tube Banks in Forced Convection (Comparison of The Heat Transfer Characteristics Between Spiral Fin and Serrated Fin)nadir adel100% (1)

- Catalogo de Bombas de Caudal VariableDocument29 pagesCatalogo de Bombas de Caudal VariableRaul Rivera100% (1)

- DSM Carbon Footprint StudyDocument12 pagesDSM Carbon Footprint StudyAbdul Rahman100% (1)

- Ezstim Ii: Operator'S ManualDocument29 pagesEzstim Ii: Operator'S ManualBabajee NavirajPas encore d'évaluation

- Bomba Rexroth PDFDocument36 pagesBomba Rexroth PDFplasticos_jfm6580100% (11)

- Intelligent Lithium Battery ESM 48100B1 Datasheet Draft A 01074746 010 ...Document2 pagesIntelligent Lithium Battery ESM 48100B1 Datasheet Draft A 01074746 010 ...Eduardo Morales Ferrer100% (1)

- ASgbDocument2 pagesASgbathaya013Pas encore d'évaluation

- Oil Pump Type E 1001 Gear Sizes 4-6-7Document2 pagesOil Pump Type E 1001 Gear Sizes 4-6-7Titu NicuPas encore d'évaluation

- Oil Pump Type D GEAR SIZES 45-47-55-57-67Document2 pagesOil Pump Type D GEAR SIZES 45-47-55-57-67Titu NicuPas encore d'évaluation

- SUNTEC Pompa AL Fisa-TehnicaDocument2 pagesSUNTEC Pompa AL Fisa-TehnicaStroia Constantin MariusPas encore d'évaluation

- Series 30: Operating PrincipleDocument8 pagesSeries 30: Operating PrincipleDgek LondonPas encore d'évaluation

- All About HidrolicDocument7 pagesAll About Hidrolicpiteng1945100% (3)

- Features: How To Order (AOC-08 Models Only)Document4 pagesFeatures: How To Order (AOC-08 Models Only)CarmenLinoBedoyaPas encore d'évaluation

- Variable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Document8 pagesVariable Vane Pumps: 1 P V 2 V 3 - / RA01MC A 1Dias EliPas encore d'évaluation

- Hydraulic AmplifierDocument4 pagesHydraulic AmplifierLuis Jonathan Bahamaca FernandezPas encore d'évaluation

- 62 Series Servovalves Technical OverviewDocument8 pages62 Series Servovalves Technical OverviewDevendra BangarPas encore d'évaluation

- Models A & B Automatic Pressure Maintenance DevicesDocument4 pagesModels A & B Automatic Pressure Maintenance DevicesHIDRUCOL SASPas encore d'évaluation

- 4.oil Hydraulic Circuit Trainer KitDocument13 pages4.oil Hydraulic Circuit Trainer KitAlmas 1710Pas encore d'évaluation

- Oil Pump TypesDocument2 pagesOil Pump TypesNauman KhanPas encore d'évaluation

- Variable Vane Pump VDCDocument14 pagesVariable Vane Pump VDCDian PramadiPas encore d'évaluation

- Hydraulic Amplifier PDFDocument4 pagesHydraulic Amplifier PDFMohammed TidjaniPas encore d'évaluation

- UVN Series Variable Volume Vane Uni-pumpDocument3 pagesUVN Series Variable Volume Vane Uni-pumpgreatharunPas encore d'évaluation

- SideWinder 40 60 80 CHMCL PMP BrchreDocument4 pagesSideWinder 40 60 80 CHMCL PMP BrchreSH McPas encore d'évaluation

- PVR-108-2 Fueling Model SheetDocument2 pagesPVR-108-2 Fueling Model SheetLetycia RosalesPas encore d'évaluation

- PVS Series NachiDocument19 pagesPVS Series NachiDian Pramadi100% (1)

- Diaphram Plunger Injection PumpDocument8 pagesDiaphram Plunger Injection PumpengrtahirPas encore d'évaluation

- cULus Listed FM Approved Pressure Maintenance DevicesDocument4 pagescULus Listed FM Approved Pressure Maintenance DevicesSavy PhanethPas encore d'évaluation

- Nachi Vane PumpDocument10 pagesNachi Vane PumpengineermarkPas encore d'évaluation

- A10VSO18 Bomba HidraulicaDocument16 pagesA10VSO18 Bomba HidraulicaGuilherme RodriguesPas encore d'évaluation

- Sur-Flo Products Control Valve Liquid Turbine Meter RunDocument40 pagesSur-Flo Products Control Valve Liquid Turbine Meter RunCheng HuangPas encore d'évaluation

- 75A 38010 A03 ContiMasterDocument4 pages75A 38010 A03 ContiMasterjacklyn ade putra100% (1)

- Graficos de Bombas PVBasicsDocument45 pagesGraficos de Bombas PVBasicsLuis Panti EkPas encore d'évaluation

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83Pas encore d'évaluation

- 4WS2EM 6-2X servo directional valve technical documentationDocument12 pages4WS2EM 6-2X servo directional valve technical documentationIbrahim MoamenPas encore d'évaluation

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument16 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyPriscila RodriguesPas encore d'évaluation

- A10v0 Variable Displacement Piston PumpDocument23 pagesA10v0 Variable Displacement Piston PumpVanadia Nohan100% (1)

- SideWinder 42 62 82 CHMCL PMP IOMDocument4 pagesSideWinder 42 62 82 CHMCL PMP IOMSH McPas encore d'évaluation

- Re29564 2007-011Document12 pagesRe29564 2007-011engineer86Pas encore d'évaluation

- D7280 en Pnuematic PumpDocument13 pagesD7280 en Pnuematic PumpRadhakrishnan RbPas encore d'évaluation

- Dropsa YoensaDocument73 pagesDropsa YoensaCAGERIGOPas encore d'évaluation

- 7-EN 520-D - D5S 2-PortDocument16 pages7-EN 520-D - D5S 2-Portabuzer1981Pas encore d'évaluation

- 5-EN 4050-A (Dig) - 2F1CDocument9 pages5-EN 4050-A (Dig) - 2F1Cabuzer1981Pas encore d'évaluation

- 377 Series Trip ValvesDocument8 pages377 Series Trip ValvesMijin28Pas encore d'évaluation

- Sauter B6R Three-Way Valve With Female Thread, PN 16Document4 pagesSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991Pas encore d'évaluation

- Pompe Motorina VD - Carte TehnicaDocument6 pagesPompe Motorina VD - Carte Tehnicar_cristiPas encore d'évaluation

- Flow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3Document4 pagesFlow Control, 3 Way, PR & Temp Compensated, NG6, Type RPC1-T3LibinPas encore d'évaluation

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SD'EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SPas encore d'évaluation

- General Information: 2.2 Crdi 197 HPDocument2 pagesGeneral Information: 2.2 Crdi 197 HPTitu NicuPas encore d'évaluation

- E1069 GBDocument2 pagesE1069 GBTitu NicuPas encore d'évaluation

- CIA - World Factbook - Reference Map - ArcticDocument1 pageCIA - World Factbook - Reference Map - Arcticabhii100% (1)

- Europe HARTA MDocument1 pageEurope HARTA MTitu NicuPas encore d'évaluation

- AP GBDocument2 pagesAP GBTitu NicuPas encore d'évaluation

- Expresii Uzuale Eng-RomDocument46 pagesExpresii Uzuale Eng-RomOnutza RoxyPas encore d'évaluation

- Solar GeometryDocument34 pagesSolar GeometryPatricia Franchette AmoraPas encore d'évaluation

- Cyclotron Booklet Black Final PrintDocument10 pagesCyclotron Booklet Black Final PrintNawaf BamasoudPas encore d'évaluation

- Internship ReportDocument58 pagesInternship ReportSamay Dhirwani100% (1)

- Heat Exchangers of PolypropyleneDocument2 pagesHeat Exchangers of PolypropyleneTan So100% (1)

- Vat Rates enDocument27 pagesVat Rates enpacocastroPas encore d'évaluation

- Catalase TestDocument2 pagesCatalase TestsekaralingamPas encore d'évaluation

- Plastic Road 35pageDocument35 pagesPlastic Road 35pageME A 04 AvisekPas encore d'évaluation

- Class Programme: Type ApprovalDocument12 pagesClass Programme: Type ApprovaltallerusPas encore d'évaluation

- Chemistry Practice Paper SA1 Class 9 CBSEDocument2 pagesChemistry Practice Paper SA1 Class 9 CBSEgurdeepsarora8738Pas encore d'évaluation

- V-3111-002-A-711 - 2 Method Statement For Water Well WorkDocument14 pagesV-3111-002-A-711 - 2 Method Statement For Water Well WorkWidya PrasetyaPas encore d'évaluation

- J300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesDocument6 pagesJ300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesMatt PittmanPas encore d'évaluation

- Chapter 1Document27 pagesChapter 1Omotayo PaulPas encore d'évaluation

- BBBV3 ForegroundReading Solar UPS MarineDocument7 pagesBBBV3 ForegroundReading Solar UPS MarineSaibal BhattacharyyaPas encore d'évaluation

- I2N65 Series: N-Channel Power MOSFET 12A, 650volts DescriptionDocument7 pagesI2N65 Series: N-Channel Power MOSFET 12A, 650volts DescriptionMariusPas encore d'évaluation

- Alabama Power Plant The Right Tree in The Right PlaceDocument4 pagesAlabama Power Plant The Right Tree in The Right PlaceAna GoodPas encore d'évaluation

- Hyundai XG350 3.5L V6 Specs & TolerancesDocument185 pagesHyundai XG350 3.5L V6 Specs & TolerancesAngie Bravo CangasPas encore d'évaluation

- Performance Evaluation of An Oil Fired Boiler A Case Study in Dairy Industry.Document8 pagesPerformance Evaluation of An Oil Fired Boiler A Case Study in Dairy Industry.atul100% (8)

- Sabah TL 1Document1 pageSabah TL 1MT HazriePas encore d'évaluation