Académique Documents

Professionnel Documents

Culture Documents

ML 071420268

Transféré par

LoffeguttTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ML 071420268

Transféré par

LoffeguttDroits d'auteur :

Formats disponibles

Division of Spent Fuel Storage and Transportation Interim Staff Guidance - 1, Revision 2 Classifying the Condition of Spent Nuclear

Fuel for Interim Storage and Transportation Based on Function1 Issue This Interim Staff Guidance (ISG) provides guidance to the staff on classifying spent nuclear fuel as either (1) damaged, (2) undamaged, or (3) intact, before interim storage or transportation. This is not a regulation or requirement and can be modified or superseded by an applicant with supportable technical arguments. Regulatory Basis Fuel-Specific Regulations: A fuel-specific regulation means a characteristic or performance requirement of the fuel specifically named in the applicable Code of Federal Regulations (CFR). These are regulations that specify capabilities that the spent nuclear fuel (SNF) must have. Examples include: 10 CFR 71.55(d) states, in part: A package used for the shipment of fissile material must be so designed and constructed and its contents so limited that under the tests specified in 10 CFR 71.71 (Normal conditions of transport) (1) The contents would be subcritical. (2) The geometric form of the package contents would not be substantially altered. 10 CFR 72.44(c) states, in part: Technical specifications must include requirements in the following categories: (1) Functional and operating limits . . . (I) . . . for an ISFSI or MRS are limits on fuel or waste handling and storage conditions that are found to be necessary to protect the integrity of the stored fuel or waste container, to protect employees against occupational exposures and to guard against the uncontrolled release of radioactive materials . . . 10 CFR 72.122(h)(1) states: The spent fuel cladding must be protected during storage against degradation that leads to gross ruptures or the fuel must be otherwise confined such that degradation of the fuel during storage will not pose operational safety problems with respect to its removal from storage. This may be accomplished by canning of consolidated fuel rods or unconsolidated assemblies or other means as appropriate. 10 CFR 72.122(l) states: Retrievability. Storage systems must be designed to allow ready retrieval of spent fuel, . . . for further processing or disposal.

Formerly entitled Damaged Fuel. ISG-1, Rev. 2

System-Related Regulations: A transportation and storage system must satisfy all applicable regulations in 10 CFR Parts 71 or 72. A system-related regulation is a performance requirement placed on the fuel for the system (i.e., transportation or storage cask) to meet a regulation that does not specifically require performance capabilities of the SNF. Examples include: 10 CFR 71.55(e) states in part: A package used for the shipment of fissile material must be so designed and constructed and its contents so limited that under the tests specified in 10 CFR 71.73 (Hypothetical accident conditions), the package would be subcritical. Note: This regulation does not place a specific requirement on the SNF. However, if the package requires the SNF to maintain its geometric configuration to ensure subcriticality, then a function is imposed on the SNF. 10 CFR 72.122(h)(5) states: The high level radioactive waste and reactor related GTCC waste must be packaged in a manner that allows handling and retrievability without the release of radioactive materials to the environment or radiation exposures in excess of Part 20 limits . . . 10 CFR 72.124(a) states: Design for criticality safety. Spent fuel handling, packaging, transfer, and storage systems must be designed to be maintained subcritical and to ensure that, before a nuclear criticality accident is possible, at least two unlikely, independent, and concurrent or sequential changes have occurred in the conditions essential to nuclear criticality safety. The design of handling, packaging, transfer, and storage systems must include margins of safety for the nuclear criticality parameters that are commensurate with the uncertainties in the data and methods used in calculations and demonstrate safety for the handling, packaging, transfer, and storage conditions and in the nature of the immediate environment, under accident conditions. Note: If the SNF must have certain characteristics or behave in a specified manner to maintain the required margins, a function is placed on the SNF. 10 CFR 72.128 states in part: Spent fuel storage . . . must be designed to ensure adequate safety under normal and accident conditions. These systems must be designed with (2) suitable shielding for radioactive protection under normal and accident conditions, (3) confinement structures and systems . . . Note: If proper functioning of the shielding or containment requires that the SNF maintain its configuration, then a function is placed on the SNF. Applicability This guidance applies to reviews of dry cask storage systems and transportation casks conducted in accordance with NUREG-1536, Standard Review Plan for Dry Cask Storage Systems (January 1997); NUREG-1567, Standard Review Plan for Spent Fuel Dry Storage Facilities (March 2000); or NUREG-1617, Standard Review Plan for Transportation Packages for Spent Nuclear Fuel (March 2000). This revision of ISG-1 supersedes any definitions of damaged, grossly damaged, or intact fuel in the above Standard Review Plans. ISG-1, Rev. 2 2

This revision supersedes ISG-1, Revision 1, Damaged Fuel, in its entirety, and is applicable to both as-built and reconstituted fuel assemblies. Definitions 1. Spent Nuclear Fuel (SNF) - See 10 CFR Part 72.3 for definition. This term has been used in the nuclear industry, at different times, to mean the fuel pellets, the rod, or entire fuel assembly. Unless specifically modified, the term will refer to both the rods and fuel assembly. 2. Damaged SNF - Any fuel rod or fuel assembly that cannot fulfill its fuel-specific or system-related functions. 3. Undamaged SNF - SNF that can meet all fuel-specific and system-related functions. As shown in Figure 1, undamaged fuel may be breached. Fuel assembly classified as undamaged SNF may have assembly defects. 4. Breached spent fuel rod - Spent fuel rod with cladding defects that permit the release of gas from the interior of the fuel rod. A breached spent fuel rod may also have cladding defects sufficient to permit the release of fuel particulate. A breach may be limited to a pinhole leak or hairline crack, or may be a gross breach. 5. Pinhole leaks or hairline cracks - Minor cladding defects that will not permit significant release of particulate matter from the spent fuel rod, and therefore present a minimal aslow-as-is-reasonably-achievable concern, during fuel handling and retrieval operations. (See discussion of gross defects for size concerns.) 6. Grossly breached spent fuel rod - A subset of breached rods. A breach in spent fuel cladding that is larger than a pinhole leak or a hairline crack. An acceptable examination for a gross breach is a visual examination that has the capability to determine the fuel pellet surface may be seen through the breached portion of the cladding. Alternatively, review of reactor operating records may provide evidence of the presence of heavy metal isotopes indicating that a fuel rod is grossly breached. (See discussion for size concerns.) 7. Intact SNF - Any fuel that can fulfill all fuel-specific and system-related functions, and that is not breached. Note that all intact SNF is undamaged, but not all undamaged fuel is intact, since under most situations, breached spent fuel rods that are not grossly breached will be considered undamaged. 8. Can for Damaged Fuel - A metal enclosure that is sized to confine one damaged spent fuel assembly. A fuel can for damaged spent fuel with damaged spent-fuel assembly contents must satisfy fuel-specific and system-related functions for undamaged SNF required by the applicable regulations.

ISG-1, Rev. 2

9. Assembly Defect - Any change in the physical as-built condition of the assembly with the exception of normal in-reactor changes such as elongation from irradiation growth or assembly bow. Examples of assembly defects: (a) missing rods; (b) broken or missing grids or grid straps (spacers); and (c) missing or broken grid springs, etc. An assembly with a defect is damaged only if it can't meet its fuel-specific and system-related functions required by the applicable regulations. Note: See Appendix for default definition of damaged SNF. Background Damaged Fuel Previous definitions of damaged fuel have identified specific characteristics of the fuel that classify it as damaged, irrespective of whether the fuel is being stored or transported and independent of the design of the storage or transportation system. In this guidance, damaged fuel is defined in terms of the characteristics needed to perform the fuel-specific and system-related functions. Thus, the characteristics of damaged spent fuel may depend on (1) whether the fuel is being stored or transported, and (2) the design of the storage or transportation system. The materials properties, and possibly the physical condition, of a fuel rod or assembly can be altered during irradiation, storage, or transportation. If this alteration is large enough to prevent the fuel or assembly from performing its fuel-specific or system-related functions during storage, transportation, or both then the fuel assembly is considered damaged. To determine whether a fuel assembly is undamaged, the following should be delineated: 1) Whether the definition is applicable to storage, transportation or both; 2) The functions the applicant has imposed on the fuel rods and assembly by either fuelspecific or system-related functions to meet a regulatory requirement for the designated phase (storage, transportation, or both); 3) The mechanisms of change (alteration mechanisms) or the characteristics of the fuel that could potentially cause the fuel to fail to meet its fuel-specific or system-related functions; 4) An acceptable analysis showing that the fuel with the designated characteristics will meet the fuel-specific and system-related functions when the mechanisms considered in item #3, above, are evaluated; and 5) The physical characteristics of the fuel, based on item #4, above, that could cause the fuel or assembly to be classified as "damaged." The "Discussion" section illustrates this methodology in the example. Damaged SNF, as defined in this guidance, will only be approved for the activity (storage, transportation, or both) for which the application is being submitted. Note that the "default" definition of damaged SNF, derived from ANSI N14.33-2005, is provided in the appendix of this ISG-1, Rev. 2 4

guidance for those that do not want to perform the assessment outlined in item numbers 1 through 5 above [2]. The default definition, however, may not take full advantage of the flexibility of the performance-based definition of damaged fuel provided in this guidance. This default definition may be more restrictive than necessary, depending on the design of the storage or transportation cask. For example, the default definition of damaged SNF indicates that SNF must be classified as damaged if an individual fuel rod is missing from an assembly. However, if an analysis shows that all fuel-specific and system-related functions will be met (e.g., subcriticality will be maintained, that the SNF assembly will be retrievable and that the structural properties of the assembly are not compromised by the missing rod) the assembly may be classified as undamaged, per this ISG. Discussion The performance-based definition [3,4] of damaged SNF provided in this ISG minimizes the quantity of damaged fuel requiring alternative handling paths, while still addressing applicable system-related regulations concerning criticality control, thermal limitations, structural integrity, confinement, and shielding. A. Grossly Breached SNF Cladding The regulations in 10 CFR 72.122(h) state The spent fuel cladding must be protected during storage against degradation that leads to gross ruptures or the fuel must be otherwise confined such that degradation of the fuel during storage will not pose operational safety problems with respect to its removal from storage. However, there is no such requirement in 10 CFR 71. Hence, grossly breached fuel is always considered damaged for storage, but may, or may not, be considered damaged for the purposes of transportation depending on whether other regulations, such as criticality, can be met. In dry cask storage and transportation systems, a gross cladding breach should be considered as any cladding breach that could lead to the release of fuel particulate greater than the average size fuel fragment. A pellet is ~1.1 centimeters in diameter in 15 x 15 Pressurized-Water Reactor (PWR) assemblies. Pellets from a Boiling-Water Reactor (BWR) are somewhat larger, and those from 17 x 17 PWR assemblies are somewhat smaller. The pellet's length is slightly longer than its diameter. During the first cycle of irradiation in-reactor, the pellet fragments into 25-35 smaller interlocked pieces, plus a small amount of finer powder, due to, pellet-to-pellet abrasion. When the rod breaches, about 0.1 gram of this fine powder may be carried out of the fuel rod at the breach site [5]. Modeling the fragments as either spherical- or pie-shaped pieces indicates that a cladding-crack width of at least 2-3 millimeters would be required to release a fragment. Hence, gross breaches should be considered to be any cladding breach greater than 1 millimeter. A review of reactor operating records, ultrasonic testing, and sipping (if done in a timely fashion) can be used to classify rods as unbreached or, breached. Evidence of only gaseous or volatile decay products (no heavy metals) in the reactor coolant system is accepted as evidence that a cladding breach is no larger than a pinhole leak or hairline crack. Records that show the presence of heavy metal isotopes that are characteristic of fuel release in the reactor coolant system indicate gross breaches in the cladding. Likewise, visual examination may also be used to determine if a cladding breach is gross, if the breached rod can be positively identified. ISG-1, Rev. 2 5

Because cladding openings larger than 1 millimeter should expose the fuel pellet to visual sighting, visual examination of the breached rod can be used to determine if a breach is gross. However, visual examination is not an acceptable method of confirming intact (undamaged) fuel for assemblies that have indicated leakage. It should be noted; however, that undamaged spent-fuel rods with pinhole leaks and/or hairline cracks will expose the fuel pellets to the canister or cask atmosphere. If that atmosphere is oxidizing, then the fuel pellet may oxidize and expand, placing stress on the cladding. The expansion may eventually cause a large split in the cladding, resulting in spent fuel that must be classified as damaged (for storage and possibly also for transportation) due to gross breaches in the cladding. Since fuel oxidation and cladding splitting follow Arrhenius time-at-temperature behavior, fuel rods with pinholes or hairline cracks that are exposed to an oxidizing atmosphere may experience this type of additional cladding damage. ISG-22 Potential Rod Splitting Due to Exposure to an Oxidizing Atmosphere During Short-Term Cask Loading Operations in LWR or other Uranium Oxide Based Fuels [6] provides information regarding prevention of this phenomenon. Before handling undamaged rods with pinhole leaks and/or hairline cracks in an oxidizing atmosphere, the potential fuel and cladding degradation at the temperature of interest for the duration of the process should be assessed. B. Fuel Assembly with Defects Damage under this guidance refers to alterations of the fuel assembly that prevent it from fulfilling its fuel-specific or system-related functions. Defects such as dents in rods, bent or missing structural members, small cracks in structural members, missing rods, etc., need not be considered damaged if the applicant can show that the fuel assembly with these defects still fulfils its fuel-specific and system-related functions. This may be done using calculations based on approved codes, situation-specific data, or reasoned engineering arguments. C. Canning Damaged Fuel Spent fuel that has been classified as damaged for storage must be placed in a can designed for damaged fuel, or in an acceptable alternative. The purpose of a can designed for damaged fuel is to (1) confine gross fuel particles, debris, or damaged assemblies to a known volume within the cask; (2) to demonstrate that compliance with the criticality, shielding, thermal, and structural requirements are met; and (3) permit normal handling and retrieval from the cask. The can designed for damaged fuel may need to contain neutron-absorbing materials, if results of the criticality safety analysis depend on the neutron absorber to meet the requirements of 10 CFR 72.124(a). D. Relationship of Spent Fuel Populations The applicant will designate the population of spent fuel for which the cask system was designed (e.g., type of fuel, minimum cooling time, burnup limitations, arrays, manufacturers, cladding types, etc.) This population may contain breached rods. Some of these breached rods may be grossly breached. It may also contain assemblies with defects, such as missing rods, missing grid spacers, or damaged spacers. The populations of breached rods, grossly breached rods, and assemblies with defects are determined by in-reactor behavior and exreactor handling. ISG-1, Rev. 2 6

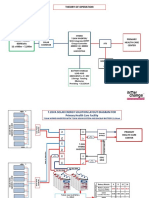

Each of these populations must be classified as damaged or undamaged after the storage or transportation system has been designated. For example, an applicant might propose the use of air as a cover gas in its design of a storage cask. The applicant might also propose this cask for use in storing spent fuel with cladding breaches that are hairline cracks or pinhole leaks. However, if the spent fuel in the cask will operate at a sufficiently high temperature for a long enough time, then oxidation of fuel pellets in breached rods could occur resulting in gross breaches. If this is the case, the breached spent fuel should be considered damaged because grossly breached rods do not meet the requirements of 10 CFR 72.122(h)(1). Also, in this case because the geometric form of the package contents could be substantially altered, the spent fuel would also be classified as damaged for transportation because the requirements of 10 CFR 71.55(d)(2) might not be met. If an inert atmosphere was used instead of air, only grossly breached rods would be considered damaged for storage. This concept is illustrated in Figure 1, "Relationship of Spent Fuel Populations."

Figure 1 - Relationship of Spent Fuel Populations

ISG-1, Rev. 2

E. Example of Methodology The following example is given to illustrate the general methodology adopted in this ISG. This is only an example of the methodology and should not be construed as approved characterization of damaged fuel. Example: Situation - The vendor of a dual-purpose cask wants to store and transport low-burnup PWR fuel in an inert atmosphere and within the temperature limits recommended in ISG-11, Revision 3, Cladding Considerations for the Transportation and Storage of Spent Fuel [7]. The vendor wants to store assemblies having rods with breaches containing only pinholes or hairline cracks, and assemblies having one or more outer grid straps with defects at three or more grid locations without canning them. The vendor is only applying for a storage license at this time but wants to be reasonably certain that the fuel will also be transportable. Activity - Storage and transportation Fuel-specific or system-related functions imposed on rods and assemblies - 10 CFR 72.122(h)(1), regarding gross ruptures, and 10 CFR 72.122(l), concerning retrievability, must be met for storage. 10 CFR 71.55(d), requiring the system to remain subcritical and unchanged during normal transport, must be met. The vendor believes that all the remaining system requirements, except for the subcriticality requirement, can be met, without imposing any limitations on the fuel, if the fuel is within the bounds stated in the situation. Mechanisms - There are no mechanisms for the pinhole leaks and hairline cracks to evolve into gross breaches since the atmosphere is inert and the temperature is controlled. To be retrievable, the assemblies with missing grid straps must be able to withstand design basis events in a storage cask. Since the applicant also wants these assemblies to be considered undamaged for transportation, the behavior of the assemblies under both normal and hypothetical accident transportation conditions in 10 CFR 71 must be evaluated. For example, for normal transportation conditions, the applicant must show that the assemblies with the most missing grid straps in the worst locations can withstand both normal vibration and a one-foot drop and remain in their original physical configuration. Additionally, for hypothetical accident conditions, the analysis must indicate, among other things, that the system will meet shielding and subcriticality requirements when placed under the mechanical and thermal loads specified in 10 CFR 71. Analysis - The applicant conducts an analysis to satisfactorily demonstrate that the assembly with three missing grid straps in the worst configuration remains intact for 1) normal transportation conditions; 2) cask tip-over; and 3) regulatory accident conditions. Further acceptable analysis indicates that all the system-related regulations are met, if the fuel with the characteristic limitations (as noted in Characteristics section below), stays structurally intact. Characteristics - Assemblies containing breached rods with up to three grid straps missing will be considered undamaged for the purposes of storage. Analysis shows that these assemblies could probably also be considered undamaged for transportation, but fuel with these characteristics will be evaluated and approved as part of a later application for the transportation cask certification. ISG-1, Rev. 2 8

Records Records documenting the classification of spent fuel shall comply with the provisions of 10 CFR 72.174, Quality Assurance Records; 10 CFR 72.72, Material Balance, Inventory, and Records Requirements for Stored Material; 10 CFR 71.91, Records; and 10 CFR 71.135, Quality Assurance Records. Inspection records will be maintained for the lifetime of the container. Quality Assurance Activities related to inspection, evaluation, and documentation of damaged spent fuel for dry storage shall be performed in accordance with a quality assurance program, as required in 10 CFR Part 72, Subpart G, Quality Assurance. Activities related to inspection, evaluation, and documentation of damaged spent fuel for transport shall be performed in accordance with a quality assurance program, as required in 10 CFR Part 71, Subpart H, Quality Assurance. Recommendations The staff recommends that: (1) the definitions in NUREG-1536, NUREG-1567, NUREG-1617, ISG-8, Revision 2 and ISG-11, Revision 3 be revised to incorporate the definitions listed above; and (2) the appropriate chapters of each NUREG be revised to include the discussion section of this ISG. In addition, the suggestion in NUREG-1617 (canning damaged fuel is necessary for the purposes of transportation) should be modified to be consistent with this ISG, nothing that canning damaged fuel may, in some cases, be necessary to meet the requirements of 10 CFR Part 71. The words intact fuel, in the Applicability section of Revision 2 of ISG-8, Burnup Credit in the Criticality Safety Analyses of PWR Spent Fuel in Transport and Storage Casks, should be replaced with undamaged fuel. Intact commercial spent fuel" in the last paragraph of the Issue section of Revision 3 of ISG-11, Cladding Considerations for the Transportation and Storage of Spent Fuel, should read undamaged commercial spent fuel. The first sentence of the Issue Section of ISG-22 should be modified to be consistent with the current definitions. Rev 1, should be changed to Rev 2, with the new title to ISG-1 Rev 2 and intact fuel should be changed to unbreached fuel. Approved : /RA/ E. William Brach, Director Division of Spent Fuel Storage and Transportation Attachment: Appendix May 11, 2007 Date

ISG-1, Rev. 2

APPENDIX Default Definition of Damaged Fuel2 Default definition of damaged Spent Nuclear Fuel (SNF) - SNF assemblies must be classified as damaged, for both dry storage and/or transportation purposes, if any one of the following conditions exist: On removal of SNF selected for dry storage or transport from the spent fuel pool, any of the following apply: 1. There is visible deformation of the rods in the SNF assembly. Note: This is not referring to the uniform bowing that occurs in the reactor. This refers to bowing that significantly opens up the lattice spacing. 2. Individual fuel rods are missing from the assembly. Note: The assembly may be reclassified as intact if a dummy rod that displaces a volume equal to, or greater than, the original fuel rod, is placed in the empty rod location. 3. The SNF assembly has missing, displaced, or damaged structural components such that either: 3.1 3.2 Radiological and/or criticality safety is adversely affected (e.g., significantly changed rod pitch). The assembly cannot be handled by normal means (i.e., crane and grapple).

4. Reactor operating records (or other records) indicate that the SNF assembly contains fuel rods with gross breaches. 5. The SNF assembly is no longer in the form of an intact fuel bundle (e.g., consists of, or contains, debris such, as loose fuel pellets or rod segments).

Derived from ANSI Standard N14.33-2005, Storage and Transport of Damaged Spent Nuclear Fuel, September 2005. ISG-1, Rev. 2 10

REFERENCES 1. NRC Spent Fuel Project Office Interim Staff Guidance - 2, Fuel Retrievability. 2. ANSI Standard N14.33 2005, Storage and Transport of Damaged Spent Nuclear Fuel, September 2005. 3. RE Einziger, CL Brown, GP Hornseth, SR Helton, NL Osgood, and CG Interrante, Damage in Spent Nuclear Fuel Defined by Properties and Requirements, Presented at IAEA Technical Workshop on Damaged Fuel, Dec 2005, Vienna, Austria, Proceedings of IAEA International Conference on Management of Spent Fuel from Nuclear Power Reactors, Vienna, Austria, June 2006. 4. MW Hodges, Status of Technical Issues in Storage and Transportation, Proceedings of Spent Fuel Management Seminar XXIII, Washington, D.C., Institute for Nuclear Materials Management, January 2006. 5. RA Lorenz, et al., Fission Product Release from BWR Fuel Under LOCA Conditions, Oak Ridge National Laboratory, Oak Ridge, TN, NUREG/CR-1773, July 1981. 6. NRC Spent Fuel Project Office Interim Staff Guidance - 22, Potential Rod Splitting Due to Exposure to an Oxidizing Atmosphere During Short Term Cask Loading Operations of LWR or Other Uranium Oxide Based Fuels, May 2006. 7. NRC Spent Fuel Project Office Interim Staff Guidance - 11, Rev 3, Cladding Considerations for Transportation and Storage of Spent Fuel, November 2003.

ISG-1, Rev. 2

11

Vous aimerez peut-être aussi

- Isg 11R3 PDFDocument11 pagesIsg 11R3 PDFali_kntuPas encore d'évaluation

- C1562-10 Standard Guide For Evaluation of Materials Used in Extended Service of Interim Spent Nuclear Fuel Dry Storage SystemsDocument26 pagesC1562-10 Standard Guide For Evaluation of Materials Used in Extended Service of Interim Spent Nuclear Fuel Dry Storage Systemsastewayb_964354182Pas encore d'évaluation

- Auxiliary Systems: 9.1 Fuel Storage and HandlingDocument124 pagesAuxiliary Systems: 9.1 Fuel Storage and HandlingRc KhresatPas encore d'évaluation

- Offshore Mooring StandardsDocument8 pagesOffshore Mooring StandardsradrottenPas encore d'évaluation

- Regulatory Guide 1.90Document23 pagesRegulatory Guide 1.90Luis Juan Trejo CruzPas encore d'évaluation

- TB Rule Reference 1st January 2019Document408 pagesTB Rule Reference 1st January 2019Pippo TopolinoPas encore d'évaluation

- RG 3.54 - R2 - 2018-Spent Fuel Heat Generation in An Independent Spent Fuel Storage InstallationDocument28 pagesRG 3.54 - R2 - 2018-Spent Fuel Heat Generation in An Independent Spent Fuel Storage InstallationTing Yi LiaoPas encore d'évaluation

- Regulatory Guide 1.13 Spent Fuel Storage Facility Design BasisDocument12 pagesRegulatory Guide 1.13 Spent Fuel Storage Facility Design BasisEnformablePas encore d'évaluation

- IMO Carriage of Cargoes & Containers Seventh Session (CCC 7)Document13 pagesIMO Carriage of Cargoes & Containers Seventh Session (CCC 7)Srikant mPas encore d'évaluation

- Usgs ML102230344 PDFDocument13 pagesUsgs ML102230344 PDFWichian RatanatongchaiPas encore d'évaluation

- SPCC GuidanceDocument6 pagesSPCC GuidancejoesuhrePas encore d'évaluation

- TB Rule Referenc 1st January 2015 IssueDocument387 pagesTB Rule Referenc 1st January 2015 IssueArdiansyah DahlanPas encore d'évaluation

- TB Rule Reference 1 Jan 2022Document409 pagesTB Rule Reference 1 Jan 2022RyanPas encore d'évaluation

- Igf - Fuel Containment System - 5.12.Document9 pagesIgf - Fuel Containment System - 5.12.nipper7Pas encore d'évaluation

- Regulatory GuideDocument13 pagesRegulatory GuideMohammad AliPas encore d'évaluation

- International Code of Safety For Ships Using Gases or Other Low-Flashpoint Fuels (Igf Code)Document16 pagesInternational Code of Safety For Ships Using Gases or Other Low-Flashpoint Fuels (Igf Code)Andrei100% (1)

- Regulatory Guide 1.71Document5 pagesRegulatory Guide 1.71Siis IngenieriaPas encore d'évaluation

- STD 169Document25 pagesSTD 169Jonas PadillaPas encore d'évaluation

- Guidelines For Survey of Oil Floating Storage Vessels Fixed at Anchorage, 2017Document8 pagesGuidelines For Survey of Oil Floating Storage Vessels Fixed at Anchorage, 2017fatkhan fatahillahPas encore d'évaluation

- Notice No.3 Lloyd's RegisterDocument11 pagesNotice No.3 Lloyd's RegisterJesus Enrique Figueroa GilPas encore d'évaluation

- Latest Ammendments UpdatedDocument10 pagesLatest Ammendments UpdatedVipin T.A.Pas encore d'évaluation

- Regulatory Guide: Regulatory Guide RG 1.29 Seismic Design Classification For Nuclear Power PlantsDocument11 pagesRegulatory Guide: Regulatory Guide RG 1.29 Seismic Design Classification For Nuclear Power PlantsAmar MistryPas encore d'évaluation

- Storage Tank Management Manual (USCG)Document47 pagesStorage Tank Management Manual (USCG)MHavocPas encore d'évaluation

- Coating Performance Standard (CPS) : Guide For The Class NotationDocument11 pagesCoating Performance Standard (CPS) : Guide For The Class NotationGilberto Zamudio100% (1)

- ML18012A022 - Enclosure 1 - Federal Register Notice, Proposed RuleDocument298 pagesML18012A022 - Enclosure 1 - Federal Register Notice, Proposed RuleTing Yi LiaoPas encore d'évaluation

- FAA FTS Policy Statement SFAR 88Document16 pagesFAA FTS Policy Statement SFAR 88Poshak Prasad GnawaliPas encore d'évaluation

- Hel05 PDFDocument6 pagesHel05 PDFLeonardo Lannes VieiraPas encore d'évaluation

- Helideck Perimeter Net - Safety Guidance Issue 1-1Document4 pagesHelideck Perimeter Net - Safety Guidance Issue 1-1RICROD71Pas encore d'évaluation

- IACS Common Structural Rules For Double Hull Oil Tankers Corrigenda1 PDFDocument51 pagesIACS Common Structural Rules For Double Hull Oil Tankers Corrigenda1 PDFBasong SanPas encore d'évaluation

- Tailshaft SurveyDocument6 pagesTailshaft SurveyArun S100% (1)

- Specification: Rev. A English Sep / 2002Document7 pagesSpecification: Rev. A English Sep / 2002marceloPas encore d'évaluation

- LGC Storage Guide E-Nov16Document8 pagesLGC Storage Guide E-Nov16이훈Pas encore d'évaluation

- Oisd 169Document25 pagesOisd 169kiranphalak100% (1)

- Petrol TanksDocument58 pagesPetrol TanksKroya HunPas encore d'évaluation

- Regulatory Guides 3.49 Design of An ISFSI (Water-Basin Type) - R0 - 1981Document4 pagesRegulatory Guides 3.49 Design of An ISFSI (Water-Basin Type) - R0 - 1981廖庭億Pas encore d'évaluation

- Chapter 6 Facility Diagram And: DescriptionDocument23 pagesChapter 6 Facility Diagram And: DescriptionJohn ChenPas encore d'évaluation

- NRC Generic Letter 98-04Document21 pagesNRC Generic Letter 98-04jbasdPas encore d'évaluation

- IMO MSC.285 (86) Interim Guidelines On Safety For Natural Gas-Fuelled EnginesDocument41 pagesIMO MSC.285 (86) Interim Guidelines On Safety For Natural Gas-Fuelled EnginesEric Berger100% (1)

- Reg Interim IGF CodeDocument41 pagesReg Interim IGF CodeThomas BranleyPas encore d'évaluation

- RP 148Document20 pagesRP 148Vasant Kumar VarmaPas encore d'évaluation

- Oisd 169Document25 pagesOisd 169sajiljithPas encore d'évaluation

- Helideck Perimeter Net - Safety Guidance IssueDocument4 pagesHelideck Perimeter Net - Safety Guidance IssueDzaky SamaPas encore d'évaluation

- Port State Control Guidance For Examination of Fixed CO2 Firefighting SystemsDocument6 pagesPort State Control Guidance For Examination of Fixed CO2 Firefighting Systemsvdeviv0% (1)

- ML12300A122Document14 pagesML12300A122Rizqi PriatnaPas encore d'évaluation

- Tank DesignDocument51 pagesTank Designtheerapolj86% (7)

- Revised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDocument18 pagesRevised Guidelines For The Approval of Equivalent Fixed Gas Fire-Extinguishing Systems, As Referred To in Solas 74, For Machinery Spaces and Cargo Pump-RoomsDanial Haidhar YusoffPas encore d'évaluation

- Deepesh Merchant Jan 2013 - Apr 2013Document117 pagesDeepesh Merchant Jan 2013 - Apr 2013Rajesh Kumar Chaubey100% (1)

- 112 LNG Propulsion GuideDocument74 pages112 LNG Propulsion Guidebernardinodino100% (1)

- Msis-12 c-8 2Document25 pagesMsis-12 c-8 2bharatsureshkaskarPas encore d'évaluation

- Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationD'EverandAgeing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationPas encore d'évaluation

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsD'EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsPas encore d'évaluation

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationD'EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationPas encore d'évaluation

- Marine and Offshore Pumping and Piping SystemsD'EverandMarine and Offshore Pumping and Piping SystemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Major Process Equipment Maintenance and RepairD'EverandMajor Process Equipment Maintenance and RepairÉvaluation : 4 sur 5 étoiles4/5 (4)

- Practices for Interim Storage of Research Reactor Spent Nuclear FuelD'EverandPractices for Interim Storage of Research Reactor Spent Nuclear FuelPas encore d'évaluation

- Safety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesD'EverandSafety Analysis and Licensing Documentation for Nuclear Fuel Cycle FacilitiesPas encore d'évaluation

- Handbook of Adhesive Bonded Structural RepairD'EverandHandbook of Adhesive Bonded Structural RepairÉvaluation : 5 sur 5 étoiles5/5 (1)

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsD'EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsPas encore d'évaluation

- Federal Register / Vol. 79, No. 180 / Wednesday, September 17, 2014 / NoticesDocument2 pagesFederal Register / Vol. 79, No. 180 / Wednesday, September 17, 2014 / NoticesLoffeguttPas encore d'évaluation

- Federal Register / Vol. 79, No. 139 / Monday, July 21, 2014 / NoticesDocument1 pageFederal Register / Vol. 79, No. 139 / Monday, July 21, 2014 / NoticesLoffeguttPas encore d'évaluation

- Federal Register / Vol. 79, No. 155 / Tuesday, August 12, 2014 / NoticesDocument2 pagesFederal Register / Vol. 79, No. 155 / Tuesday, August 12, 2014 / NoticesLoffeguttPas encore d'évaluation

- NRC 2013 0037 0024Document481 pagesNRC 2013 0037 0024LoffeguttPas encore d'évaluation

- Federal Register / Vol. 79, No. 180 / Wednesday, September 17, 2014 / NoticesDocument2 pagesFederal Register / Vol. 79, No. 180 / Wednesday, September 17, 2014 / NoticesLoffeguttPas encore d'évaluation

- Federal Register / Vol. 79, No. 167 / Thursday, August 28, 2014 / NoticesDocument2 pagesFederal Register / Vol. 79, No. 167 / Thursday, August 28, 2014 / NoticesLoffeguttPas encore d'évaluation

- NRC 2009 0279 0038Document79 pagesNRC 2009 0279 0038LoffeguttPas encore d'évaluation

- APPENDIX 2 Occupational Radiation Dose Distribution at Loviisa and Olkiluoto Nuclear Power Plants in 2012Document30 pagesAPPENDIX 2 Occupational Radiation Dose Distribution at Loviisa and Olkiluoto Nuclear Power Plants in 2012LoffeguttPas encore d'évaluation

- NRC 2014 0030 0002Document242 pagesNRC 2014 0030 0002LoffeguttPas encore d'évaluation

- ML14028A565Document644 pagesML14028A565LoffeguttPas encore d'évaluation

- Appendix 1 Stuk'S Safety Performance Indicators For Npps in 2012Document39 pagesAppendix 1 Stuk'S Safety Performance Indicators For Npps in 2012LoffeguttPas encore d'évaluation

- ML14028A565Document644 pagesML14028A565LoffeguttPas encore d'évaluation

- Operational Radiation Safety: Guide ST 1.6 / 10 D 2009Document22 pagesOperational Radiation Safety: Guide ST 1.6 / 10 D 2009LoffeguttPas encore d'évaluation

- SCGlobal IWAYSTDVers4Document18 pagesSCGlobal IWAYSTDVers4LoffeguttPas encore d'évaluation

- Nureg 0800Document18 pagesNureg 0800LoffeguttPas encore d'évaluation

- The IWAY Forestry StandardDocument1 pageThe IWAY Forestry StandardLoffeguttPas encore d'évaluation

- Exercise 2 Nuclear Reactions, Binding Energy and Rate of Decay ObjectivesDocument5 pagesExercise 2 Nuclear Reactions, Binding Energy and Rate of Decay Objectivescreate foxesPas encore d'évaluation

- Safety Measures in Nuclear Power PlantsDocument3 pagesSafety Measures in Nuclear Power PlantsJaydeep RaoPas encore d'évaluation

- Chronic Radiation SicknessDocument8 pagesChronic Radiation SicknessDany SamuelPas encore d'évaluation

- Chapter 25 WorksheetDocument3 pagesChapter 25 WorksheetRizky HermawanPas encore d'évaluation

- TP Nuclear PowerDocument2 pagesTP Nuclear PowerLuciana R LarregainPas encore d'évaluation

- Therapeutic Radiation MachinesDocument43 pagesTherapeutic Radiation MachinesAhmet Kürşat ÖzkanPas encore d'évaluation

- Physical Science: Semester I/II-Week 2Document31 pagesPhysical Science: Semester I/II-Week 2Reign MayorPas encore d'évaluation

- RadioactivityDocument113 pagesRadioactivityGavin MohamedPas encore d'évaluation

- Principles of RadioBio123Document5 pagesPrinciples of RadioBio123riomjPas encore d'évaluation

- Atomic Nucleus and RadioactivityDocument59 pagesAtomic Nucleus and Radioactivitymladen lakic100% (2)

- Cammish DecisionDocument9 pagesCammish DecisionChris BusbyPas encore d'évaluation

- Mark Scheme (Results) Summer 2012: GCSE Physics 5PH2F/01Document14 pagesMark Scheme (Results) Summer 2012: GCSE Physics 5PH2F/01Alexia DimitriouPas encore d'évaluation

- 3.8 Relations Among Reflectivity, Absorptivity and TransmissivityDocument2 pages3.8 Relations Among Reflectivity, Absorptivity and TransmissivityakhmadfadholiPas encore d'évaluation

- Weapons Grade Uranium-233Document60 pagesWeapons Grade Uranium-233gandalftbPas encore d'évaluation

- Nuclear Radiation Lab CHEM136Document3 pagesNuclear Radiation Lab CHEM136NatPas encore d'évaluation

- Black Body RadiationDocument4 pagesBlack Body RadiationAniketh ReddyPas encore d'évaluation

- TA Plts PerahuDocument25 pagesTA Plts PerahuRahmadPas encore d'évaluation

- PPTDocument70 pagesPPTvikirhythmPas encore d'évaluation

- Light ColorsDocument34 pagesLight ColorsROSIEL MANDRIQUEPas encore d'évaluation

- Wextrends 2023 PricelistDocument1 pageWextrends 2023 PricelistDennis FielPas encore d'évaluation

- RADPRODocument26 pagesRADPRORamon De Guia100% (1)

- Radiography Formulas1 PDFDocument1 pageRadiography Formulas1 PDFSathish JayaprakashPas encore d'évaluation

- Nuclear BatteryDocument20 pagesNuclear Batteryraghavprince80% (1)

- Nuclear Safety and Radiation Protection Act 19 of 1995..Document24 pagesNuclear Safety and Radiation Protection Act 19 of 1995..Yusuf BabaPas encore d'évaluation

- Overview of Chernobyl DiariesDocument7 pagesOverview of Chernobyl DiariesChristoper TaranPas encore d'évaluation

- Geiger Counter Example Report 1Document8 pagesGeiger Counter Example Report 1emaad hamdaniPas encore d'évaluation

- Typical Primary Health Center Solar SolutionDocument2 pagesTypical Primary Health Center Solar Solutionpeter LamurenPas encore d'évaluation

- NucleusDocument57 pagesNucleusSuhail KunjavaPas encore d'évaluation

- PV&TDocument10 pagesPV&TbalaPas encore d'évaluation

- Unit 4: Thermochemistry and Nuclear Chemistry Chemistry AP Chapter 23: Nuclear Chemistry 23.1: The Nature of Nuclear ReactionsDocument16 pagesUnit 4: Thermochemistry and Nuclear Chemistry Chemistry AP Chapter 23: Nuclear Chemistry 23.1: The Nature of Nuclear ReactionsPankaj Kumar50% (4)