Académique Documents

Professionnel Documents

Culture Documents

ZULFI E6013 Welding Electrodes

Transféré par

Junard M. Lu HapCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ZULFI E6013 Welding Electrodes

Transféré par

Junard M. Lu HapDroits d'auteur :

Formats disponibles

MATERIAL SAFETY DATA SHEET

This Material Safety Data Sheet (MSDS) complies with the requirements of OSHAs Hazard Communication Standard.

6013 WELDING ELECTRODE Emergency Phone Number: 1-866-272-4378

Date: May 05, 2011 Product Name/Class Product Number Manufacturer Product Information Number: 575-874-9188 SECTION 1 PRODUCT IDENTIFICATION AWS E6013 Welding Electrode E6013 Archer Company USA, Inc. 1665 Futurity Dr. Sunland Park, NM 88063

SECTION 5 REACTIVITY DATA (continued) Determine the composition and quantity of fumes and gases to which workers are exposed by taking an air sample from inside the welders helmet if worn or in the workers breathing zone. Improve ventilation if exposures are not below limits. See ANSI/AWS F1.1, F1.2, F1.4, and F1.5, available from the American Welding Society, 550 N.W. LeJeune Road, Miami, FL 33126. SECTION 6 HEALTH HAZARD DATA Carcinogenicity: The composition of welding or brazing fumes may contain carcinogens, depending on several factors that are unknown and unknowable to the product manufacturer (see Section 5). Always assume that welding or brazing fumes may contain toxic and/or carcinogenic materials, and follow sound Work/Hygiene practices as recommended by ANSI Z49.1. Threshold Limit Value: The ACGIH recommended general limit for Welding Fume NOC (Not otherwise Classified) is 5 mg/m3. ACGIH-1987-88 preface states that the TLV-TWA should be used as guides in the control of health hazards and should not be used as fine lines between safe and dangerous concentrations. See Section 5 for specific fume constituents which may modify this TLV. Threshold Limit Values are figures published by the American Conference of Government Industrial Hygienists. Units are milligrams per cubic meter of air. Effects of Overexposure: Electric arc welding may create one or more of the following health hazards: Fumes and Gases can be dangerous to your health. Common entry is by inhalation. Other possible routes are skin contact and ingestion. Short-term (acute) overexposure to welding fumes may result in discomfort such as metal fume fever, dizziness, nausea, or dryness or irritation of nose, throat, or eyes. May aggravate pre-existing respiratory problems (e.g. asthma, emphysema). Exposure to extremely high levels of fluorides can cause abdominal pain, diarrhea, muscular weakness, and convulsions. In extreme cases it can cause loss of consciousness and death. Long-term (chronic) overexposure to welding fumes can lead to siderosis (iron deposits in lung) and may affect pulmonary function. Manganese overexposure can affect the central nervous system, resulting in impaired speech and movement. Bronchitis and some lung fibrosis have been reported. Repeated exposure to fluorides may cause excessive calcification of the bone and calcification of ligaments of the ribs, pelvis and spinal column. May cause skin rash. Arc Rays can injure eyes and burn skin. Skin cancer has been reported. Electric Shock can kill. If welding must be performed in damp locations or with wet clothing, on metal structures or when in cramped positions such as sitting, kneeling or lying, if there is a high risk of unavoidable or accidental contact with workpiece, use the following equipment: Semiautomatic DC Welder, DC Manual (Stick) Welder, or AC Welder with Reduced Voltage Control. Emergency and First Aid Procedures: Call for medical aid. Employ first aid techniques recommended by the American Red Cross. IF BREATHING IS DIFFICULT give oxygen. IF NOT BREATHING employ CPR (Cardiopulmonary Resuscitation) techniques. IN CASE OF ELECTRICAL SHOCK, turn off power and follow recommended treatment. In all cases, call a physician. HMIS Rating HMIS Scale NFPA Rating NFPA Scale 4 = Severe Hazard 4 = Severe Hazard Health = 2 Health = 1 3 = Serious Hazard 3 = Serious Hazard Flammability = 0 Flammability = 0 2 = Moderate Hazard 2 = Moderate Hazard Reactivity = 0 Reactivity = 0 1 = Slight Hazard 1 = Slight Hazard Other = N/A 0 = Minimal Hazard 0 = Minimal Hazard SECTION 7 PRECAUTIONS for SAFE HANDLING and USE Read and understand the manufacturers instruction and the precautionary label on the product. See American National Standard Z49.1, Safety in Welding and Cutting, published by the American Welding Society, 550 N.W. LeJeune Road, Miami, FL 33126 and OSHA Publication 2206 (29CFR1910), U.S. Government Printing Office, Washington, D.C. 20402 for more details on many of the following: Disposal Information: Discard any product, residue, disposable container, or liner as ordinary waste in an environmentally acceptable manner according to Federal, State and Local Regulations unless otherwise noted. SECTION 8 CONTROL MEASURES Respiratory Protection (Specify Type) Use respirable fume respirator or air supplied respirator when welding in confined space or general work area when local exhaust or ventilation does not keep exposure below TLV. Ventilation: Use enough ventilation, local exhaust at the arc, or both to keep the fumes and gases from the workers breathing zone and the general area. Train the welder to keep his head out of the fumes. Keep exposure as low as possible. Eye Protection: Wear helmet or use face shield with filter lens shade number 12 or darker. Shield others by providing screens and flash goggles. Other Protective Clothing or Equipment: Wear hand, head, and body protection which help to prevent injury from radiation, sparks and electrical shock. See Z49.1. At a minimum this includes welders gloves and a protective face shield, and may include arm protectors, aprons, hats, shoulder protection, as well as dark substantial clothing. Train the welder not to permit electrically live parts or electrodes to contact skin or clothing or gloves if they are wet. Insulate from work and ground. OTHER INFORMATION REQUIRED BY STATE OR FEDERAL LAW California Proposition 65 Information: Warning: This product contains a chemical known to the State of California to cause cancer. New Jersey Right-To-Know Information: 5 most predominant ingredients/hazardous and non-hazardous) 1. Carbon steel; 2. Titanium dioxides (as Ti); 3. Iron; 4. Mineral silicates; 5. Manganese and/or manganese alloys and compounds (as Mn). SARA Title III Notification Information: All chemical compounds marked with an asterisk (*) are toxic chemicals subject to the reporting requirements of Section 313 of Title III of the Super Fund Amendments and Reauthorization Act (SARA) of 1986 and 40 CFR Part 372. Disclaimer of Expressed and Implied Warranties: The information in this document is believed to be correct as of the date issued. However, no warranty of merchantability, fitness for any particular purpose, or any other warranty is expressed or is to be implied regarding the accuracy or completeness of this information, the results to be obtained from the use of this information or the product, the safety of this product, or the hazards related to its use.

SECTION 2 HAZARDOUS INGREDIENTS IMPORTANT! This section covers the materials from which this product is manufactured. The fumes and gases produced during welding with the normal use of this product are covered by Sections 5 through 8. See these sections for industrial hygiene information. CAS Number shown is representative for the ingredients listed. All ingredients listed may not be present in all sizes. The term hazardous in Hazardous Materials should be interpreted as a term required and defined in the Hazards Communication Standard and does not necessarily imply the existence of any hazard. TLV PEL Ingredients: CAS No. Weight % Supplemental Information: mg/m3 mg/m3 Titanium dioxides (as Ti)*** Iron Mineral silicates Silicates and other binders Manganese and/or manganese alloys and compounds (as Mn)*** Limestone and/or calcium carbonate Cellulose and other carbohydrates Zinc and/or zinc oxides*** Aluminum and/or aluminum alloys (as Al)*** Carbon steel core wire Boiling Point: N/A Vapor Pressure (mm Hg.) N/A Vapor Density (Air = 1) N/A 13463-67-7 7439-89-6 1332-58-7 1344-09-8 7439-96-5 1317-65-3 65996-61-4 1314-13-2 7429-90-5 7439-89-6 10 5 <5 <5 <5 <5 <5 <0.5 <0.5 60 10 10* 5** 10* 0.2 10 10* 10 10 10* 10 10* 5** 10* 1.0(c) 15 10* 10 15 10* *Not listed. Nuisance value maximum is 10 mg/m3. PEL value for iron oxide is 10 mg/m3. TLV value for iron oxide is 5 mg/m3 ** As respirable dust. *** Subject to the reporting requirements of Sections 311, 312, and 313 of the Emergency Planning and Community Right-to-Know Act of 1986 and of 40 CFR 370 and 372. (c) Values are for manganese fume. STEL (Short Term Exposure Limit) is 3.0 mg/m3

SECTION 3 PHYSICAL CHARACTERISTICS Specific Gravity (H2O = 1): N/A Solubility in Water: N/A Melting Point %Volatile: N/A N/A Evaporation Rate (Butyl Acetate =1) Appearance and Odor: N/A N/A

SECTION 4 FIRE and EXPLOSION HAZARD DATA Non Flammable. Welding arc and sparks can ignite combustibles and flammables.

Refer to American National Standard Z49.1 for fire prevention during the use of welding and allied procedures.

SECTION 5 REACTIVITY DATA Hazardous Decomposition Products: Welding fumes and gases cannot be classified simply. The composition and quantity of both are dependent upon the metal being welded, the process, procedure and electrodes used. Other conditions which also influence the composition and quantity of the fumes and gases to which workers may be exposed include: coatings on the metal being welded (such as paint, plating, or galvanizing), the number of welders and the volume of the worker area, the quality and amount of ventilation, the position of the welders head with respect to the fume plume, as well as the presence of contaminants in the atmosphere (such as chlorinated hydrocarbon vapors from cleaning and degreasing activities). When the electrode is consumed, the fume and gas decomposition products generated are different in percent and form from the ingredients listed in Section 2. Decomposition products of normal operation include those originating from the volatilization, reaction, or oxidation of the materials shown in Section 2, plus those from the base metal and coating, etc. as noted above. Reasonably expected fume constituents of this product would include: Primarily iron oxide and fluorides; secondarily complex oxides of manganese, potassium, silicon, sodium, and zinc. Maximum fume exposure guideline for this product (based on manganese content) is 4.0 milligrams per cubic meter. Gaseous reaction products may include carbon monoxide and carbon dioxide. Ozone and nitrogen oxides may be formed by the radiation from the arc.

Vous aimerez peut-être aussi

- MSDS Er70s 6Document1 pageMSDS Er70s 6RosyidiMuhammadMahfudzPas encore d'évaluation

- Material Safety Data Sheet: Emergency Phone Number: 1-866-272-4378Document1 pageMaterial Safety Data Sheet: Emergency Phone Number: 1-866-272-4378So MayePas encore d'évaluation

- MSDS Tungsten Electrode Safety DataDocument2 pagesMSDS Tungsten Electrode Safety DataSerkan ApayPas encore d'évaluation

- 360, 370, 380 Brazing Rod MG MSDS 6-09Document3 pages360, 370, 380 Brazing Rod MG MSDS 6-09orcbane27Pas encore d'évaluation

- 103 Solution EC Msds 5-08Document3 pages103 Solution EC Msds 5-08Brian HernandezPas encore d'évaluation

- La 71 MSDSDocument2 pagesLa 71 MSDSdeepak2803Pas encore d'évaluation

- Material Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Document2 pagesMaterial Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Rama Krishna Reddy DonthireddyPas encore d'évaluation

- Heat Fence Inorganic MineralsDocument3 pagesHeat Fence Inorganic MineralsmePas encore d'évaluation

- Aluminum Wires and Rods 1Document2 pagesAluminum Wires and Rods 1OteranmoralesPas encore d'évaluation

- 62super Ti Se en 0Document4 pages62super Ti Se en 0Jhony MedranoPas encore d'évaluation

- Aluminum Msds 8-05Document3 pagesAluminum Msds 8-05mohamed AdelPas encore d'évaluation

- Nic-L-Weld 99 59Document9 pagesNic-L-Weld 99 59CezaryCezasPas encore d'évaluation

- Msds Product Name: Aws E7018 Welding ElectrodeDocument2 pagesMsds Product Name: Aws E7018 Welding ElectrodeAdel AbduoPas encore d'évaluation

- Product Name: Galvalume Sheet Severstal Sparrows Point LLCDocument4 pagesProduct Name: Galvalume Sheet Severstal Sparrows Point LLCT Bagus Tri LusmonoPas encore d'évaluation

- Reactivity Data and Health Hazards of Welding ElectrodeDocument1 pageReactivity Data and Health Hazards of Welding ElectrodeSona MahardhikaPas encore d'évaluation

- MSDS AlloysDocument15 pagesMSDS AlloysMaryam EradewiPas encore d'évaluation

- Material Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?Document9 pagesMaterial Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?haharameshPas encore d'évaluation

- MSDS Section 5 Reactivity Data for 7018 Welding ElectrodeDocument1 pageMSDS Section 5 Reactivity Data for 7018 Welding ElectrodeAhmad Abu Basil Izzuddin Nur Al AslamPas encore d'évaluation

- Material Safety Data Sheet (MSDS)Document2 pagesMaterial Safety Data Sheet (MSDS)Heri SusantoPas encore d'évaluation

- S 800wtxm 12k Msds EngDocument2 pagesS 800wtxm 12k Msds Eng이상훈Pas encore d'évaluation

- MSDS NiCrDocument2 pagesMSDS NiCrBety FajriaPas encore d'évaluation

- Safety Data Sheet: 1. Chemical Product and Company IdentificationDocument7 pagesSafety Data Sheet: 1. Chemical Product and Company IdentificationKyi HanPas encore d'évaluation

- M - ENG - MSDS v1.2Document157 pagesM - ENG - MSDS v1.2sunthron somchaiPas encore d'évaluation

- Material Safety Data SheetsDocument5 pagesMaterial Safety Data SheetsSuryanarayanan VenkataramananPas encore d'évaluation

- MSDS For G490HM (KMWT) R01Document7 pagesMSDS For G490HM (KMWT) R01Zvonimir OzanPas encore d'évaluation

- Safety Data Sheet for All-State AquaSafe No. 100 FluxDocument5 pagesSafety Data Sheet for All-State AquaSafe No. 100 Fluxmohamed AdelPas encore d'évaluation

- ARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02Document3 pagesARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02PubcrawlPas encore d'évaluation

- Flux Core Welding WireDocument3 pagesFlux Core Welding Wiremuhamad bukhari abu hassanPas encore d'évaluation

- Tungsten Electrodes MSDSDocument4 pagesTungsten Electrodes MSDSsalcabesPas encore d'évaluation

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelPas encore d'évaluation

- 51 EX Msds 9-07Document3 pages51 EX Msds 9-07Mohamed AdelPas encore d'évaluation

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoPas encore d'évaluation

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoPas encore d'évaluation

- Safety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228Document5 pagesSafety Data Sheet (MSDS CHT711 2023.1.1) (CHT711 JT-71T1-) From Atlantic 20231228sergio.lopezPas encore d'évaluation

- Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - IdentificationluisarmandomayonietoPas encore d'évaluation

- PDMS MSDSDocument6 pagesPDMS MSDSRazleen RashidiPas encore d'évaluation

- 3m C2a1 Filter MsdsDocument7 pages3m C2a1 Filter MsdsGLOCK35Pas encore d'évaluation

- Lincoln 5P+ MsdsDocument2 pagesLincoln 5P+ MsdssalcabesPas encore d'évaluation

- Ceramic Crucible Sds 4Document3 pagesCeramic Crucible Sds 4ernesto ArteagaPas encore d'évaluation

- Material Safety Data Sheet for IronDocument7 pagesMaterial Safety Data Sheet for IronRiza ApreliaPas encore d'évaluation

- Material Safety Data Sheet for IronDocument7 pagesMaterial Safety Data Sheet for IronIlham NugrahaPas encore d'évaluation

- Material Safety Data Sheet Gold - Core Material: Section 1: Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet Gold - Core Material: Section 1: Product and Company Identificationfabiosan5Pas encore d'évaluation

- MSDS for #112NZ-ISO46 Lubricating OilDocument2 pagesMSDS for #112NZ-ISO46 Lubricating OilDavide BoreanezePas encore d'évaluation

- Coreshield 8003 - ESABDocument6 pagesCoreshield 8003 - ESABBiju_PottayilPas encore d'évaluation

- Safety Data Sheet for OXWELD 200 CUTTING & SCARFING POWDERDocument4 pagesSafety Data Sheet for OXWELD 200 CUTTING & SCARFING POWDERmohamed AdelPas encore d'évaluation

- MSDS for US Forge E 6010 Covered ElectrodeDocument3 pagesMSDS for US Forge E 6010 Covered Electrodemohamed AdelPas encore d'évaluation

- Pulsalube Ultra 6Hgs Synthetic Hydraulic & Gear Oil: Safety Data SheetDocument10 pagesPulsalube Ultra 6Hgs Synthetic Hydraulic & Gear Oil: Safety Data Sheeteko riyantoPas encore d'évaluation

- Brassmsds 2007Document4 pagesBrassmsds 2007api-256162920Pas encore d'évaluation

- Material Safety Data SheetDocument2 pagesMaterial Safety Data SheetghezelasheghiPas encore d'évaluation

- Novec1230 MSDSDocument6 pagesNovec1230 MSDSoscarninanPas encore d'évaluation

- Welding Alloys USA Inc. Safety Data Sheet: Section 1: Product and Company IdentificationDocument9 pagesWelding Alloys USA Inc. Safety Data Sheet: Section 1: Product and Company IdentificationUmar YaqoobPas encore d'évaluation

- Kevlar MSDSDocument5 pagesKevlar MSDSsoumsarkar1Pas encore d'évaluation

- I. Product Identification: Material Safety Data SheetDocument5 pagesI. Product Identification: Material Safety Data SheetSteel BridgePas encore d'évaluation

- Material Safety Data Sheet: Section 1 - Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Section 1 - Product and Company IdentificationMicheal MattheyPas encore d'évaluation

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoPas encore d'évaluation

- MSDS Alseal 518 CoatingsDocument5 pagesMSDS Alseal 518 CoatingsHernan GirautPas encore d'évaluation

- Bezpečnostní List S-717 - EngDocument8 pagesBezpečnostní List S-717 - Engz9zsbwnnfvPas encore d'évaluation

- Electrical Codes, Standards, Recommended Practices and Regulations: An Examination of Relevant Safety ConsiderationsD'EverandElectrical Codes, Standards, Recommended Practices and Regulations: An Examination of Relevant Safety ConsiderationsÉvaluation : 5 sur 5 étoiles5/5 (5)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesD'EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesÉvaluation : 5 sur 5 étoiles5/5 (2)

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesD'EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesPas encore d'évaluation

- JUNARD Cover Letter 2020Document2 pagesJUNARD Cover Letter 2020Junard M. Lu HapPas encore d'évaluation

- Junard M. Lu Hap, RNDocument6 pagesJunard M. Lu Hap, RNJunard M. Lu HapPas encore d'évaluation

- Hussain Mustafa Al-Shakhori: QA/QC InspectorDocument3 pagesHussain Mustafa Al-Shakhori: QA/QC InspectorJunard M. Lu HapPas encore d'évaluation

- NYCDocument1 pageNYCJunard M. Lu HapPas encore d'évaluation

- UWorld NCLEX Drug ListDocument16 pagesUWorld NCLEX Drug ListAngie Mandeoya91% (11)

- GMC Cover Letter 2020Document1 pageGMC Cover Letter 2020Junard M. Lu HapPas encore d'évaluation

- Experienced Baker and Pastry Chef with International Work ExperienceDocument3 pagesExperienced Baker and Pastry Chef with International Work ExperienceJunard M. Lu HapPas encore d'évaluation

- Top 5 HazardsDocument13 pagesTop 5 HazardsJunard M. Lu HapPas encore d'évaluation

- Health and Safety Practical Report TemplateDocument1 pageHealth and Safety Practical Report TemplateJunard M. Lu HapPas encore d'évaluation

- GC3 Executive SummaryDocument1 pageGC3 Executive SummaryJunard M. Lu HapPas encore d'évaluation

- Basic Care and Comfort RationaleDocument2 pagesBasic Care and Comfort RationaleRae Krystylynne CodillaPas encore d'évaluation

- Unit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationDocument1 pageUnit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationJunard M. Lu HapPas encore d'évaluation

- Unit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationDocument1 pageUnit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationJunard M. Lu HapPas encore d'évaluation

- NEBOSH International General Certificate in Occupational Health and SafetyDocument1 pageNEBOSH International General Certificate in Occupational Health and SafetyJunard M. Lu HapPas encore d'évaluation

- GC3 Mark Sheet-Second PageDocument1 pageGC3 Mark Sheet-Second PageJunard M. Lu HapPas encore d'évaluation

- Browse House LogoDocument11 pagesBrowse House LogoJunard M. Lu HapPas encore d'évaluation

- Unit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationDocument1 pageUnit Gc3 - The Health and Candidate Report Template Safety Practical ApplicationVinoth SudalaiPas encore d'évaluation

- Word Bank InvestigationDocument3 pagesWord Bank InvestigationJunard M. Lu HapPas encore d'évaluation

- Job Summary TKDocument5 pagesJob Summary TKJunard M. Lu HapPas encore d'évaluation

- 2 Word Bank Intro To OshDocument3 pages2 Word Bank Intro To OshJunard M. Lu HapPas encore d'évaluation

- Audit: English Word Arabic Translation English Meaning Arabic MeaningDocument2 pagesAudit: English Word Arabic Translation English Meaning Arabic MeaningJunard M. Lu HapPas encore d'évaluation

- Writing Introduction: The Graph Below ShowsDocument4 pagesWriting Introduction: The Graph Below ShowsJunard M. Lu HapPas encore d'évaluation

- RL 2018Document1 pageRL 2018Junard M. Lu HapPas encore d'évaluation

- Browse House LogoDocument11 pagesBrowse House LogoJunard M. Lu HapPas encore d'évaluation

- Print Out Banner LogoDocument1 pagePrint Out Banner LogoJunard M. Lu HapPas encore d'évaluation

- Nclex RN Q - A FB GroupDocument1 pageNclex RN Q - A FB GroupJunard M. Lu HapPas encore d'évaluation

- 1601E August 2008 GuidelinesDocument1 page1601E August 2008 GuidelinesAce NelsonPas encore d'évaluation

- Job Hazard Analysis RiskassessmentDocument4 pagesJob Hazard Analysis RiskassessmentJunard M. Lu HapPas encore d'évaluation

- Job Summary TKDocument1 pageJob Summary TKJunard M. Lu HapPas encore d'évaluation

- Al Naba Answer KeyDocument11 pagesAl Naba Answer KeyJunard M. Lu HapPas encore d'évaluation

- Everything You Need to Know About CoughsDocument12 pagesEverything You Need to Know About CoughsLany T. CataminPas encore d'évaluation

- Contingency Contract For AutismDocument14 pagesContingency Contract For AutismNor HaslizaPas encore d'évaluation

- Case Presentation LM PotencyDocument33 pagesCase Presentation LM PotencyVaseem Azizii100% (3)

- How To Stop Pornography AddictionDocument2 pagesHow To Stop Pornography AddictionJabo LeroPas encore d'évaluation

- NURS 6521 Final Exam Study GuideDocument3 pagesNURS 6521 Final Exam Study GuideTracy MPas encore d'évaluation

- Enc of FibromyalgiaDocument214 pagesEnc of Fibromyalgiadeb4paul100% (3)

- Gene Therapy - PresentationDocument19 pagesGene Therapy - PresentationElectRon ShajalPas encore d'évaluation

- Chapter 16 - Chemistry in Everyday LifeDocument10 pagesChapter 16 - Chemistry in Everyday LiferamPas encore d'évaluation

- The Secret of Being HappyDocument282 pagesThe Secret of Being Happylcs1234678100% (3)

- Eye Conditions: DiplopiaDocument10 pagesEye Conditions: DiplopiaAngel Dela RosaPas encore d'évaluation

- Science Measures The Human Energy FieldDocument7 pagesScience Measures The Human Energy FieldNICOL JOHANA ANGULO ORTIZPas encore d'évaluation

- Pall CareDocument81 pagesPall Careडा. सत्यदेव त्यागी आर्यPas encore d'évaluation

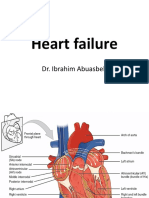

- Heart FailureDocument49 pagesHeart Failureأبوأحمد الحكيمPas encore d'évaluation

- NCPDocument10 pagesNCPJose CousinsPas encore d'évaluation

- OPMBCSDocument180 pagesOPMBCSCharles Anthony VegaPas encore d'évaluation

- Beginners' Guide To Health and FitnessDocument25 pagesBeginners' Guide To Health and FitnessMahmood HikmetPas encore d'évaluation

- Anxiety and Depression in Young PeopleDocument11 pagesAnxiety and Depression in Young PeopleKyle SaylonPas encore d'évaluation

- SCMD-03-CH01-Introduction Stormwater Conveyance Modeling DesignDocument17 pagesSCMD-03-CH01-Introduction Stormwater Conveyance Modeling DesignJalijashPas encore d'évaluation

- HD - PhilSocNeph PDFDocument20 pagesHD - PhilSocNeph PDFAlbeldaArnaldo100% (1)

- Cba Ospe RevisedDocument11 pagesCba Ospe RevisedSadia YousafPas encore d'évaluation

- NCP: Prenatal InfectionDocument10 pagesNCP: Prenatal InfectionJaviePas encore d'évaluation

- Clinical Objectives PDFDocument4 pagesClinical Objectives PDFYhuhan James TejadaPas encore d'évaluation

- Admission and Basic Nursing CareDocument26 pagesAdmission and Basic Nursing CareKardana PutraPas encore d'évaluation

- Anxiety Parents Medication GuideDocument20 pagesAnxiety Parents Medication GuideCatalina Walker Alvarez Medico Psiquiatra CSJDMPas encore d'évaluation

- INTRAUTERINE DEATH WidyaDocument11 pagesINTRAUTERINE DEATH WidyaNabilaPas encore d'évaluation

- Diabetes The Differences Between Types 1 and 2Document13 pagesDiabetes The Differences Between Types 1 and 2leonard1971Pas encore d'évaluation

- Chapter4 Infant Formula FeedingDocument20 pagesChapter4 Infant Formula FeedingMuhammad AbdulazizPas encore d'évaluation

- Euthanasia Position PaperDocument26 pagesEuthanasia Position PaperDamon Copeland50% (2)

- Risk for Temperature Regulation IssuesDocument12 pagesRisk for Temperature Regulation IssuesCamelia NuraPas encore d'évaluation

- Tooth Discoloration and HomoeopathyDocument12 pagesTooth Discoloration and HomoeopathyDr. Rajneesh Kumar Sharma MD Hom100% (1)