Académique Documents

Professionnel Documents

Culture Documents

Compression and Capillary Pipe Fittings

Transféré par

starykltCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Compression and Capillary Pipe Fittings

Transféré par

starykltDroits d'auteur :

Formats disponibles

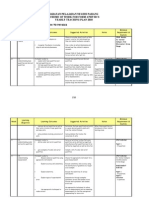

Compression and Capillary Pipe Fittings Standards* to comply with Tests ______________________________________________________________________________ BS EN 1254-1:1998 (Fittings with ends for

capillary soldering or - Leaktightness under internal hydrostatic pressure capillary brazing) - Stress corrosion resistance test - Carbon content test - Carbon film test BS EN 1254-2:1998 (Fittings with compression ends) - Leaktightness under internal hydrostatic pressure (Type A & B) - Resistance to pullout (Type A & B) - Leaktightness under internal hydrostatic pressure whilst subjected to bending (Type A only) - Stress corrosion resistance test ______________________________________________________________________________ * In addition to the Standards stipulated above, the following conditions shall apply: 1.All water fittings shall be legibly marked with the following information where applicable: a) Manufacturer's identification mark, brand name or logo either on body or plate b) Marking of the Standard eg. BS EN 545 : 2010. (if the Standard so requires) c) Nominal size and direction of flow d) Colour code for hot and cold water supply 2.All non-metallic material in contact with water shall comply with SS 375 : 2001 or BS 6920 : 2000 and clause 8 of SS 375 : Part 1 : 2001.For non-metallic materials intended for use in hot water applications, the temperature used for the High Temperature Tests shall be the maximum temperature for which the non-metallic materials are designed for and declared/specified by the manufacturer. In the absence of any documented declaration of this maximum temperature by the manufacturer, the temperature used for the High Temperature Tests shall be the highest specified by the SS 375 : 2001 or BS 6920:2000. The non-metallic materials shall only be used in a potable water reticulation system with maximum water temperature not exceeding the temperature at which the non-metallic materials were tested and found complying with in the High Temperature Tests. Non-metallic seat washers shall also comply with BS 3457 : 1973. 3.All metallic material in contact with water shall comply with the test on 'Extraction of Metals - App H' of AS/NZS 4020 : 2005. The maximum allowable concentrations of metals listed in Table 2 of AS/NZS 4020:2005 shall not exceed the limits specified by the World Health Organisation (WHO) Guidelines for Drinking Water Quality. 4.All copper alloy water fittings except for exposed terminal fittings shall be of gunmetal, bronze or DZR brass materials only. For gunmetal or bronze fittings, they shall comply with BS EN 1982 : 2008^. Those which are of Dezincification resistant type (DZR) shall comply with the tests on 'Composition' and 'Resistance to dezincification' of BS EN 12163 : 1998 or BS EN 12165 : 1998 or BS EN 12420 : 1999. Such fittings shall have an additional marking of 'DZR' or 'CR'. CW602N is the material composition designation for copper alloy with dezincification resistance in accordance with BS EN 12163 : 1998 or BS EN 12165 : 1998 or BS EN 12420 : 1999. 5.All elastomeric seals for joints in pipework, pipelines, water fittings and valve seats for the flushing mechanism of the WC flushing cisterns shall comply with SS 270 : 1996. 6.All other water fittings incorporated in the water fitting shall comply with the relevant Standards stipulated by PUB. 7.All water fittings shall comply with the Standards stipulated by PUB and its use in water service

installations shall conform to the Public Utilities (Water Supply) Regulations and Singapore Standard :CP 48. 8.All water fittings shall also comply with all other relevant statutory requirements. ^ All water fittings of gunmetal or bronze shall be tested to comply with BS EN 1982:2008 with effect from 1 Jun 12. Water fittings of gunmetal or bronze tested before 1 Jun 12 may comply with either BS EN 1982:1999 or BS EN 1982:2008.

Vous aimerez peut-être aussi

- w-p-ss-001 R4Document23 pagesw-p-ss-001 R4Unni CyriacPas encore d'évaluation

- P2 Rules For Piping Design, Construction and Testing P2: End of SectionDocument37 pagesP2 Rules For Piping Design, Construction and Testing P2: End of Sectionjaydee45Pas encore d'évaluation

- Technical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsDocument11 pagesTechnical Notes (General Specification) FOR Flanges, Spectacle Blinds AND Drip RingsMunish100% (1)

- Valve Procurement SpecsDocument39 pagesValve Procurement Specsjoseph.maquez24100% (2)

- Supply Ball Valves Technical Delivery TermsDocument18 pagesSupply Ball Valves Technical Delivery TermssswahyudiPas encore d'évaluation

- Bayu Undan / Darwin LNG Facilities Technical Delivery TermsDocument6 pagesBayu Undan / Darwin LNG Facilities Technical Delivery TermsWidodo MuisPas encore d'évaluation

- ASME Standard & Code ListingDocument7 pagesASME Standard & Code ListingMyron CampbellPas encore d'évaluation

- Technical notes on valvesDocument29 pagesTechnical notes on valvesNilesh Mistry100% (2)

- Standards For Pipes and FittingsDocument13 pagesStandards For Pipes and FittingsRifkanPas encore d'évaluation

- المواسيرDocument15 pagesالمواسيرshamashergyPas encore d'évaluation

- Is 9523Document78 pagesIs 9523Anonymous XBq5J840% (1)

- Auto LPG Dispensing Station SpecificationDocument5 pagesAuto LPG Dispensing Station SpecificationShyBokxPas encore d'évaluation

- Materials System SpecificationDocument13 pagesMaterials System SpecificationMoustafa Bayoumi100% (1)

- SS Weld SpecificationDocument39 pagesSS Weld SpecificationmurugesanPas encore d'évaluation

- Standards For Pipes and FittingsDocument11 pagesStandards For Pipes and FittingsMohammed sabatinPas encore d'évaluation

- Seamless Copper Tube: Standard Specification ForDocument7 pagesSeamless Copper Tube: Standard Specification ForRicardo CurioniPas encore d'évaluation

- Inspection Check List 3Document22 pagesInspection Check List 3r.devendranPas encore d'évaluation

- Specification - Pipes FlangesDocument3 pagesSpecification - Pipes FlangesAco CvijeticPas encore d'évaluation

- Koc MP 020Document16 pagesKoc MP 020Ravi MahetoPas encore d'évaluation

- WSA 109-2011 Flange GasketsDocument39 pagesWSA 109-2011 Flange GasketsTon Phichit100% (1)

- Split Tee Specifications and Drawings - 20130906 - 191217Document17 pagesSplit Tee Specifications and Drawings - 20130906 - 191217Anonymous cuOIjrLIPas encore d'évaluation

- Gb 6479-2000 高压化肥设备用无缝钢管 英文版Document13 pagesGb 6479-2000 高压化肥设备用无缝钢管 英文版aliPas encore d'évaluation

- DI Pipe SpecificationDocument12 pagesDI Pipe Specificationdeep patelPas encore d'évaluation

- SPEC FOR HDPE PIPE LAYINGDocument12 pagesSPEC FOR HDPE PIPE LAYINGalep azizPas encore d'évaluation

- GRP Duct Material For Irrigation Works-ADM SpecificationDocument5 pagesGRP Duct Material For Irrigation Works-ADM Specificationbuddy1971Pas encore d'évaluation

- Technical Data NRL 02301Document8 pagesTechnical Data NRL 02301Attiq Ahmad ChoudhryPas encore d'évaluation

- Fabrication ProcedureDocument16 pagesFabrication ProcedureAryo WicaksonoPas encore d'évaluation

- Astm A216 PDFDocument4 pagesAstm A216 PDFNelson Alves Ferreira JuniorPas encore d'évaluation

- List of Awwa StanderdsDocument6 pagesList of Awwa StanderdstadagidsPas encore d'évaluation

- IS 3589 - 2003-10 - With Amd 1 To 4Document25 pagesIS 3589 - 2003-10 - With Amd 1 To 4hhr2412Pas encore d'évaluation

- Pipe FabricationDocument42 pagesPipe FabricationJanani M Janani67% (6)

- A 861 - 02 QTG2MS0WMG - PDFDocument28 pagesA 861 - 02 QTG2MS0WMG - PDFMung Duong XuanPas encore d'évaluation

- Astm A216 A216m - 16507Document4 pagesAstm A216 A216m - 16507OscarBonePas encore d'évaluation

- Annexure-5-Technical Specification For Structural Steel WorksDocument20 pagesAnnexure-5-Technical Specification For Structural Steel WorksGarapati Bala KrishnaPas encore d'évaluation

- GB 150 Part2 PDFDocument5 pagesGB 150 Part2 PDFDang Hieu NguyenPas encore d'évaluation

- API 6A RadiographyDocument4 pagesAPI 6A RadiographyminakshissawantPas encore d'évaluation

- SPEC FOR T-Y STRAINERSDocument24 pagesSPEC FOR T-Y STRAINERSvishal bhamrePas encore d'évaluation

- Astm A216Document4 pagesAstm A216jefesost100% (1)

- Asme 1325-18 (2007)Document1 pageAsme 1325-18 (2007)Matthew TaylorPas encore d'évaluation

- MSS SP 70.98-Cast Iron Gate Valves - (1998)Document13 pagesMSS SP 70.98-Cast Iron Gate Valves - (1998)thiagorep17Pas encore d'évaluation

- Astm A356Document6 pagesAstm A356Srinivasan KrishnamoorthyPas encore d'évaluation

- Is 3589 - 2001Document21 pagesIs 3589 - 2001Aara MeghPas encore d'évaluation

- Double pipe heat exchangers design guideDocument18 pagesDouble pipe heat exchangers design guideJhonny Rafael Blanco CauraPas encore d'évaluation

- Coryton Engineering Standard Indicator Number: CES/18/001: Subject New: Re-Issue: Re-Issue: Original Issue DateDocument42 pagesCoryton Engineering Standard Indicator Number: CES/18/001: Subject New: Re-Issue: Re-Issue: Original Issue DateSiegfred RaccaPas encore d'évaluation

- Plastic PipeDocument4 pagesPlastic Pipesethu1091Pas encore d'évaluation

- Welding of Ferritic or Austenitic Stainless SteelDocument22 pagesWelding of Ferritic or Austenitic Stainless SteelBehnam RabieePas encore d'évaluation

- 01-Samss-046 10302013Document11 pages01-Samss-046 10302013Anonymous jKuXWubR8Pas encore d'évaluation

- Technical Requirements For Pipes & FittingsDocument7 pagesTechnical Requirements For Pipes & FittingsKyaw Kyaw AungPas encore d'évaluation

- ASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsDocument3 pagesASME VIII Div 1 Part UCL Welded Pressure Vessels Constructed of Material With Corrosion Resistant Integral Cladding, Weld Metal Overlay Cladding, or With Applied LiningsAmanda Ariesta ApriliaPas encore d'évaluation

- Offshore Skid Piping DesignDocument7 pagesOffshore Skid Piping DesignmihahudeaPas encore d'évaluation

- Piping BasisDocument32 pagesPiping Basislowermine100% (2)

- Technical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsDocument10 pagesTechnical Notes FOR Butt Welded, Socket Welded and Screwed Pipe FittingsMunishPas encore d'évaluation

- B05 Seamless Steel Gas Cylinders UlnDocument16 pagesB05 Seamless Steel Gas Cylinders UlnMikel EgurenPas encore d'évaluation

- B729Document3 pagesB729LambertWaynePas encore d'évaluation

- Corrosion: Corrosion ControlD'EverandCorrosion: Corrosion ControlL L ShreirÉvaluation : 5 sur 5 étoiles5/5 (1)

- Cathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesD'EverandCathodic Corrosion Protection Systems: A Guide for Oil and Gas IndustriesÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerD'EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerÉvaluation : 5 sur 5 étoiles5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldD'EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldÉvaluation : 3 sur 5 étoiles3/5 (2)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeD'EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticePas encore d'évaluation

- Uow009702 Electronic Monitoring and Access Control Commissioning StandardDocument29 pagesUow009702 Electronic Monitoring and Access Control Commissioning StandardstarykltPas encore d'évaluation

- CCTV and Lighting Upgrade Commissioning StandardDocument19 pagesCCTV and Lighting Upgrade Commissioning Standards_morrissey_consulting100% (1)

- Aqua 1Document324 pagesAqua 1staryklt100% (1)

- Uow009695 Landscaping Design StandardsDocument43 pagesUow009695 Landscaping Design StandardsstarykltPas encore d'évaluation

- Uow009698 Building Monitoring and Control Systems Design StandardsDocument23 pagesUow009698 Building Monitoring and Control Systems Design StandardsstarykltPas encore d'évaluation

- Uow009699 Building Elements Commissioning StandardDocument28 pagesUow009699 Building Elements Commissioning StandardstarykltPas encore d'évaluation

- Uow009701 Electrical Services Commissioning StandardDocument26 pagesUow009701 Electrical Services Commissioning StandardstarykltPas encore d'évaluation

- Uow009696 Mechanical Services Design StandardsDocument19 pagesUow009696 Mechanical Services Design StandardsstarykltPas encore d'évaluation

- Residential Electric Service InstallationDocument56 pagesResidential Electric Service InstallationJ Hevesi100% (1)

- Ts Join GuideDocument1 pageTs Join GuidestarykltPas encore d'évaluation

- Uow009694 Hydraulic Services Design StandardsDocument37 pagesUow009694 Hydraulic Services Design StandardsstarykltPas encore d'évaluation

- Floor Waste Installation OverviewDocument2 pagesFloor Waste Installation OverviewstarykltPas encore d'évaluation

- Uow009693 Fire Services Design StandardsDocument20 pagesUow009693 Fire Services Design StandardsstarykltPas encore d'évaluation

- Uow009695 Landscaping Design StandardsDocument43 pagesUow009695 Landscaping Design StandardsstarykltPas encore d'évaluation

- Private Water Supply GuidelinesDocument40 pagesPrivate Water Supply GuidelinesstarykltPas encore d'évaluation

- Power System Sizing Form: G G G GDocument4 pagesPower System Sizing Form: G G G GstarykltPas encore d'évaluation

- 7123AF Aquatherm Fusiotherm Hot & Cold Water System 2010Document9 pages7123AF Aquatherm Fusiotherm Hot & Cold Water System 2010starykltPas encore d'évaluation

- 0118 Texture Coating For Interior Concrete and MasonryDocument4 pages0118 Texture Coating For Interior Concrete and MasonrystarykltPas encore d'évaluation

- Guide To Concrete RepairDocument168 pagesGuide To Concrete Repairhansen_zinck4751100% (11)

- BUILDING IN ALASKA CLIMATEDocument15 pagesBUILDING IN ALASKA CLIMATEstarykltPas encore d'évaluation

- Lancashire Residential Road Design GuideDocument42 pagesLancashire Residential Road Design Guidesweptpath2012Pas encore d'évaluation

- Enclosed Shower BaysetDocument2 pagesEnclosed Shower BaysetstarykltPas encore d'évaluation

- Ds05 DrivewaysDocument15 pagesDs05 DrivewaysstarykltPas encore d'évaluation

- Res StreetsDocument50 pagesRes StreetsVas SteelPas encore d'évaluation

- Floor Waste Installation OverviewDocument2 pagesFloor Waste Installation OverviewstarykltPas encore d'évaluation

- Purlin Mounted AnchorDocument2 pagesPurlin Mounted AnchorstarykltPas encore d'évaluation

- 100mm Lab TestsDocument17 pages100mm Lab TestsstarykltPas encore d'évaluation

- 75mm Lab TestsDocument19 pages75mm Lab TestsstarykltPas encore d'évaluation

- Concrete Path GuidelinesDocument6 pagesConcrete Path GuidelinesKipegoPas encore d'évaluation

- 0621 SIKA Waterproofing - Wet AreasDocument12 pages0621 SIKA Waterproofing - Wet AreasstarykltPas encore d'évaluation

- Model and Analyze Hydraulic SystemsDocument16 pagesModel and Analyze Hydraulic Systemsعلي كامل الاسديPas encore d'évaluation

- Carbon Fibre ReportDocument14 pagesCarbon Fibre ReportyoyotoyoPas encore d'évaluation

- Formulas For Press - Shrink Fit CalculationsDocument3 pagesFormulas For Press - Shrink Fit CalculationsgarciarodrigoPas encore d'évaluation

- ST5012-Design of Sub StructuresDocument15 pagesST5012-Design of Sub StructuresNarayanan Moorthy33% (3)

- Electrical Conductivity Lab ReportDocument3 pagesElectrical Conductivity Lab ReportMartin Yamane0% (3)

- Physics Form 4 Yearly Lesson Plan 2010Document26 pagesPhysics Form 4 Yearly Lesson Plan 2010Mohd Khairul AnuarPas encore d'évaluation

- ALU DELTA II T and T/PDocument23 pagesALU DELTA II T and T/PMax HeadroomPas encore d'évaluation

- ProjectDocument16 pagesProjectEhmida PofjraPas encore d'évaluation

- Exp 1 CMT450Document9 pagesExp 1 CMT450NURANISAH NADIAH MOHD NIZAMPas encore d'évaluation

- International Temperature Scale of 1990 PDFDocument4 pagesInternational Temperature Scale of 1990 PDFSamPas encore d'évaluation

- Chem Grade 10 WK 3Document5 pagesChem Grade 10 WK 3Anasatcia Mcpherson 9c FPas encore d'évaluation

- Tubulars Design Course: OCTG ConnectionsDocument51 pagesTubulars Design Course: OCTG ConnectionsOscarPas encore d'évaluation

- Seismic Bridge Design GuideDocument6 pagesSeismic Bridge Design GuideMMaulanaPas encore d'évaluation

- Fundamentals of Petroleum Lec. 5Document10 pagesFundamentals of Petroleum Lec. 5Marco PlaysPas encore d'évaluation

- Aluminum A413Document2 pagesAluminum A413Fabio Miguel RodriguesPas encore d'évaluation

- 5054 w16 QP 11 PDFDocument20 pages5054 w16 QP 11 PDFMuhammad SaifPas encore d'évaluation

- BR HighFlowDocument4 pagesBR HighFlowRocky SarmientoPas encore d'évaluation

- Chap 6 SteelDocument18 pagesChap 6 SteelDaniel VasquezPas encore d'évaluation

- Fonko Staro UpatstvoDocument27 pagesFonko Staro UpatstvoToni TalevskiPas encore d'évaluation

- Presentation On Circular PrestressingDocument18 pagesPresentation On Circular PrestressingAnand Raj100% (1)

- Tutorial 2 (ME332) : Problems On Strain Rate, Stokes Laws, Surface Forces and Basic Equations & Boundary ConditionsDocument2 pagesTutorial 2 (ME332) : Problems On Strain Rate, Stokes Laws, Surface Forces and Basic Equations & Boundary ConditionsPrateeksha ShakyaPas encore d'évaluation

- Biot Response SpectrumDocument10 pagesBiot Response SpectrumMacPas encore d'évaluation

- Pipingchevronoffshore 2Document56 pagesPipingchevronoffshore 2Velpandian ManiPas encore d'évaluation

- The Reactive System Screening Tool (RSST) : An Inexpensive and Practical Approach To Sizing Emergency Relief SystemsDocument6 pagesThe Reactive System Screening Tool (RSST) : An Inexpensive and Practical Approach To Sizing Emergency Relief SystemsKam KamPas encore d'évaluation

- Tutorial 2Document2 pagesTutorial 2sakinah azizanPas encore d'évaluation

- RDS-PS Satuated SteamDocument3 pagesRDS-PS Satuated SteamyoonghmPas encore d'évaluation

- M 236 ContentDocument103 pagesM 236 ContentgeetanandnPas encore d'évaluation

- Volume Flow Measuring SystemDocument1 pageVolume Flow Measuring SystemTrung Trịnh BảoPas encore d'évaluation

- 120B SyllabusDocument2 pages120B SyllabusAngela LeePas encore d'évaluation

- Garrison: Oceanography An Invitation To Marine Science, 8e FinalDocument22 pagesGarrison: Oceanography An Invitation To Marine Science, 8e FinalBagas IndiantoPas encore d'évaluation