Académique Documents

Professionnel Documents

Culture Documents

Statistical Modeling of Head Loss Components in Water Distribution Within Buildings

Transféré par

starykltCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Statistical Modeling of Head Loss Components in Water Distribution Within Buildings

Transféré par

starykltDroits d'auteur :

Formats disponibles

International Journal of Science and Technology Volume 3 No.

2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

101

Statistical Modeling of Head Loss Components in Water Distribution within

Buildings

J. I. Sodiki

Department of Mechanical Engineering

Rivers State University of Science and Technology

P. M. B. 5080

Port Harcourt, Nigeria

ABSTRACT

Fractions of the total head loss which constitute the loss through fittings were computed for varying lengths of first index pipe run,

total flow rate and number of sanitary appliances supplied, in a water distribution system within a building. The results were used in a

regression analysis to obtain second order equations which gave a general increase of the fraction from 0.263 to 0.420 for an increase

in length of first index pipe run of 28.3m to 140.3m; from 0.262 to 0.429 for an increase in the total flow rate of 0.6L/s to 4.4L/s; and

from 0.238 to 0.393 for an increase in the number of supplied sanitary appliances of 8 to 120. The correlation coefficients between the

ratio of loss through fittings to the total head loss and each of the variables of pipe length, flow rate and number of appliances were

0.97, 0.95 and 0.91, respectively; which were found to be acceptable for a 99% confidence level. The ratios are useful for quick estimate

of losses in water distribution systems in buildings, needed in determining the suitability of water reservoir elevations and lift pump

head requirements.

Keywords: Loss ratios, pipe fittings, water distribution within buildings, regression analysis.

1. INTRODUCTION

The available pressure at a given point in a building water

distribution system pipe work is progressively reduced away

from the pressure source (which is usually on elevated

storage). This reduction is due to pipe frictional loss and loss

through pipe fittings such as elbows, tees, reducers and valves.

The latter loss is sometimes called separation loss.

Thus, extensive pipe runs would result in increased frictional

loss, while multiplicity of pipe fittings would be associated

with increased separation loss. However, the number and types

of fittings installed in a given pipe run are specified such as to

achieve system functionality; and it can be assumed that, for a

given system configuration, the ratio between the frictional

loss and the separation loss for an index pipe run may vary with

varying length of pipe run.

In an earlier paper (Sodiki and Orupabo, 2011) it has been

established that the fraction of the total loss which constitutes

the total separation loss increases as the first index pipe length

increases, in simple water distribution systems; an increase in

length of water distribution first index pipe usually implying

increases in the total design water flow rate and in the number

of sanitary appliances being supplied.

In this paper, the ratio of total separation loss to total head loss

is regressed, in turn, on the variables length of first index pipe

run, design flow rate, and number of sanitary appliances, to

obtain equations for predicting the relationship of each variable

with the ratio. Second order relationships are utilized in the

regression analysis, as indicated by the slopes of the curves

obtained earlier (Sodiki and Orupabo, 2011) and the

coefficients of correlation are calculated to check the

usefulness of the resulting equations.

2. HEAD LOSS COMPONENTS

The frictional loss hf and the loss through pipe fittings hp are

analysed as follows:

2.1 Frictional Loss: This loss, for each section of the first

index pipe run, has been derived for plastic pipe

material as (Sodiki, 2002)

hf = 1.1374 x 10

-3

ld

-4.867

q

1.85

- - - - - (1)

where l = pipe length (m)

d = pipe diameter (m)

and q = flow rate (m

3

/s)

Thus, the head loss per metre pipe run is

hf / l = 1.1374 x 10

-3

d

-4.867

q

1.85

- - - - - (2)

A graphical representation of Eqn. 2 (Institute of

Plumbing, 1977) is utilized in the analysis.

2.2 Loss through Fittings: This has been derived for

each fitting as (Sodiki, 2003)

hp = 0.08256kd

-4

q

2

- - - - - (3)

where k is a head loss coefficient of the fitting which is taken

for this analysis as 0.75 for an elbow, 2.0 for a tee and 0.25 for

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

102

a gate valve (Giles, 1977). For reducers, k is expressed in terms

of the ratio of upstream diameter d1 to downstream diameter d2

as in Table 1 (Giles, 1977); with the k values, so obtained,

being referred to the downstream diameter in Eqn. 3.

Table 1: Values of K for Reducers, in Terms of Ratio of Upstream Diameter (d1) to Downstream Diameter (d2)

(Giles, 1977)

Ratio d1/d2 k

1.2 0.08

1.4 0.17

1.6 0.26

1.8 0.34

2.0 0.37

2.5 0.41

3.0 0.43

4.0 0.45

5.0 0.46

3. THE DISTRIBUTION SYSTEM

CONFIGURATION

The configuration utilized in the analysis is one in which water

is distributed by gravity from a high level reservoir to a range

of identical toilet rooms of a hotel building (Fig. 1). Each room

contains a water closet, a bath tub, a wash basin and a water

heater. The selected pipe work arrangement represents a

commonly occurring scenario in simple water distribution

systems.

3.1 Methods of Estimate

The analysis was first done for the pipe run from A to B and

up to the farthest fixture supplied by the branch from B

(considering the extension on the main distribution pipe from

B towards C as non-existent). In the next step, the analysis was

done for the pipe run from A to C and up to the farthest fixture

supplied by the branch from C (again, considering the

extension from point C towards D as non-existent). Subsequent

steps were carried out in like manner for extended index pipe

runs up to the last step (for the index run from A to P up to the

farthest appliance outlet supplied from P). The progressive

extensions of the first index run provided a variation of the

complexity of pipe work.

The graphical method adopted for pipe sizing and estimation

of frictional losses is illustrated using the pipe run from A to C

and up to pipe section 6 (which was the second step in the

analysis procedure described earlier).

This pipe run is shown as an isometric sketch in Fig. 2 in which

the pipe sections are labeled using boxes. The number to the

left of the box is the pipe section number, the number to the top

right is the measured pipe length (in m), and that on the bottom

right is the flow rate in the section (in L/s).

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

103

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

104

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

105

In the analysis, loading units, which account for the non-

simultaneous use of all the installed sanitary appliances, were

utilized to obtain the flow rates from the graph of loading units

versus flow rates (Fig. 3) (Institute of Plumbing, 1977). These

units were taken as 2 for a water closet cistern, 1.5 for a wash

basin, 10 for a bath tub and 2 for a water heater cylinder.

Cumulative units were, thus, utilized for each pipe section. For

loading units below 10 which are not presented in Fig. 3, linear

extrapolations were made to obtain corresponding flow rates.

Now, for a reservoir height above point A, in Fig. 2, of 10m

and a height of the water heater in pipe section 6 (which is the

final section of this index run) above point A of 2.5m, the

pressure head H available in the first index run = 10m - 2.5m

= 7.5m. The measured length of the index run is L = 36.3m.

Then, the rate of head loss per metre run (H/L) should not

exceed 7.5/36.3 = 0.207m/m run.

This H/L value and the sectional flow rates were used to select

pipe sizes from Fig. 4 (Institute of Plumbing, 1977). For

instance, for pipe section 2 which carries a flow rate of 0.6L/s,

a 25mm pipe was selected (at point A in Fig. 4). The actual

values of H/L were obtained at the intersection of the lines of

flow rate and pipe diameter. For pipe section 2, as an example,

the actual H/L value (at point A in Fig. 4) is 0.085m/m run and

the measured pipe length is 11.0m. Thus, the head loss due to

friction for this pipe section is 0.085 x 11.0m = 0.935m

Table 2 gives a summary of the pipe sizing estimates and the

calculated head losses for this index run.

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

106

Table 2: Parameters of Distribution System for 36.3m First Index Run, 16 Appliances, 0.95L/s Flow Rate

1 2 3 4 5 6 7 8 9 10 11

Pipe

section

No.

Loading

units

Design

flow (L/s)

Pipe

length (m)

Permissible

maximum

H/L

Dia (mm) Actual H/L Frictional head

loss, hf (m)

Fittings (other than

reducers)

Reducers

(mm x mm)

Loss thru

fittings, hp

(m)

1 62.0 0.95 20.0 0.207 32 0.07 1.400 3 elbows

2 gate valves

1 tee

- 0.338

2 31.0 0.60 11.0 0.207 25 0.085 0.935 3 elbows

2 gate valves

1 tee

32 x 25 0.370

3 19.0 0.45 0.1 0.207 20 0.2 0.02 1 tee 25 x 20 0.220

4 7.0 0.24 2.5 0.207 20 0.065 0.163 1 tee - 0.059

5 3.5 0.12 0.2 0.207 15 0.15 0.03 1 tee 20 x 15 0.050

6 2.0 0.07 2.5 0.207 15 0.06 0.15 1 elbow

1 gate valve

- 0.008

36.3 2.698 1.045

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

107

With the pipe sizes obtained, locations of reducers in the

first index run were determined. Other types of fitting

(elbows, tees and valves) in the first index run were

specified in consideration of system functionality. In pipe

section 6, for instance, there are one elbow and one gate

valve, such that hp for this section (from Eqn. 3) = (0.75

+ 0.25) x 0.08256 x 0.015

-4

x (0.07 x 10

-3

)

2

= 0.008m,

where d = 0.015m and q = 0.07 x 10

-3

m

3

/s.

Similarly, in pipe section 5, there are one 20mm x 15mm

reducer (which has d1/d2 = 1.33) and one tee k for the

reducer (from Table 1) is 0.139. Then, from Eqn. 3, hp for

pipe section 5= (0.139 + 2) x 0.08256 x 0.015

-4

x

(0.12x10

-3

)

2

= 0.050m

3.2 Resulting Parameters for the Different Index

Runs

In the manner illustrated in section 3.1, the other pipe

configurations which number fourteen were analyzed.

However, in order to maintain brevity, only the isometric

sketches of the shortest and longest first index pipe runs

are presented in Figs. 5a and 5b, respectively. Also,

rather than listing all fourteen tables of calculation

summary corresponding to the fourteen other first index

pipe runs, only the two corresponding to the shortest and

longest runs are presented in Tables 3 and 4, respectively.

Table 5 summarizes the calculated total frictional and

separation losses, as well as the ratios of separation loss

to total loss for the varying complexities of pipe work.

The presentations in Excel graphics of Fig. 6 depict the

variation of the ratio of loss through fittings to total loss

with pipework complexity. Measures of pipework

complexity are presented as length of first index pipe run,

total flow rate from the reservoir and number of sanitary

appliances supplied from the reservoir.

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

108

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

109

Table 3: Parameters of Distribution System for 28.3m First Index Run, 8 Appliances, 0.60L/s Flow Rate

1 2 3 4 5 6 7 8 9 10 11

Pipe

section

No.

Loading

units

Design

flow

(L/s)

Pipe

length

(m)

Permissible

maximum

H/L

Dia (mm) Actual H/L Frictional head

loss, hf (m)

Fittings (other

than reducers)

Reducers

(mm x mm)

Loss thru

fittings, hp

(m)

1 31.0 0.60 23.0 0.265 25 0.085 1.955 6 elbows

3 gate valves

1 tee

- 0.552

2 19.0 0.45 0.1 0.265 20 0.200 0.020 1 tee 25 x 20 0.220

3 7.0 0.24 2.5 0.265 20 0.065 0.163 1 tee - 0.059

4 3.5 0.12 0.2 0.265 15 0.150 0.030 1 tee 20 x 15 0.050

5 2.0 0.07 2.5 0.265 15 0.060 0.150 1 elbow, 1

gate valve

- 0.008

28.3 2.318 0.889

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

110

Table 4: Parameters of Distribution System for 140.3m First Index Run, 120 Appliances, 4.4L/s Flow Rate

1 2 3 4 5 6 7 8 9 10 11

Pipe

section

No.

Loading

units

Design

flow (L/s)

Pipe

length (m)

Permissible

maximum

H/L

Dia (mm) Actual H/L Frictional head

loss, hf (m)

Fittings (other than

reducers)

Reducers

(mm x mm)

Loss thru

fittings, hp

(m)

1. 475.0 4.40 20.0 0.053 65 0.027 0.540 3el, 2g.v 1 tee - 0.426

2. 434.0 4.00 8.0 0.053 65 0.024 0.192 1 tee - 0.148

3. 403.0 3.70 8.0 0.053 65 0.020 0.160 1 tee - 0.127

4. 372.0 3.50 8.0 0.053 65 0.019 0.152 1 tee - 0.113

5. 341.0 3.20 8.0 0.053 50 0.050 0.400 1 tee 65 x 50 0.440

6. 310.0 2.95 8.0 0.053 50 0.045 0.360 1 tee - 0.230

7. 279.0 2.90 8.0 0.053 50 0.043 0.344 1 tee - 0.222

8. 248.0 2.70 8.0 0.053 50 0.040 0.320 1 tee - 0.193

9. 217.0 2.60 8.0 0.053 50 0.035 0.280 1 tee - 0.179

10. 186.0 2.20 8.0 0.053 50 0.026 0.208 1 tee - 0.163

11. 155.0 1.80 8.0 0.053 50 0.020 0.160 1 tee - 0.086

12. 124.0 1.55 8.0 0.053 50 0.016 0.128 1 tee - 0.059

13. 93.0 1.25 8.0 0.053 40 0.045 0.360 1 tee 50 x 40 0.152

14. 62.0 0.95 8.0 0.053 40 0.029 0.232 1 tee - 0.058

15. 31.0 0.60 11.0 0.053 32 0.030 0.330 3el, 2g.v 1 tee 40 x 32 0.138

16. 19.0 0.45 0.1 0.053 25 0.050 0.005 1 tee 32 x 25 0.091

17. 7.0 0.24 2.5 0.053 25 0.017 0.043 1 tee - 0.024

18. 3.5 0.12 0.2 0.053 20 0.020 0.004 1 tee 25 x 20 0.022

19. 2.0 0.07 2.5 0.053 15 0.037 0.093 1 el, 1g.v 1 tee 20 x 15 0.009

140.3 4.311 2.880

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

111

Table 5: Ratios of Loss through Fittings to Total Loss for Varying Pipe Work Complexities

1 2 3 4 5 6 7

Length of 1

st

index

pipe run (m)

Total flow rate through

main distribution pipe

(L/s)

No. of appliances served by

main distribution pipe

Frictional loss in 1

st

index

run (m)

Loss through fittings in 1

st

index run (m)

Total loss in 1

st

index

run (m)

Ratio of loss through

fittings to total loss

28.3 0.60 8 2.318 0.889 3.207 0.277

36.3 0.95 16 2.698 1.045 3.743 0.279

44.3 1.25 24 3.943 1.302 5.245 0.248

52.3 1.55 32 3.747 1.302 5.049 0.258

60.3 1.80 40 4.777 1.594 6.371 0.250

68.3 2.20 48 4.337 1.627 5.964 0.273

76.3 2.60 56 4.245 1.724 5.969 0.289

84.3 2.70 64 4.625 1.936 6.561 0.295

92.3 2.90 72 5.005 2.069 7.074 0.282

100.3 2.95 80 4.304 2.079 6.383 0.326

108.3 3.20 88 4.379 2.318 6.697 0.346

116.3 3.50 96 4.467 2.666 7.133 0.374

124.3 3.70 104 4.147 2.542 6.689 0.380

132.3 4.00 112 4.059 2.658 6.717 0.396

140.3 4.40 120 4.311 2.880 7.191 0.401

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

112

Loss Through Fittings

Total Loss

0

0.1

0.2

0.3

0.4

0.5

0 10 20 30 40 50 60 70 80 90 100 110 120 130

No. of Appliances (X

3

)

Loss Through Fittings

Total Loss

0

0.1

0.2

0.3

0.4

0.5

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

Design Fllow Rate (X

2

), L/s

Loss Through Fittings

Total loss

0

0.1

0.2

0.3

0.4

0.5

0 20 40 60 80 100 120 140 160

Index Pipe length (X

1

), m

Fig. 6 : Variation of Ratio of Loss Thru Fittings to Total Head Loss with Pipework Complexity

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

113

4. STATISTICAL ANALYSIS OF ESTIMATES

The statistical tool of regression analysis was employed to

obtain equations which represent the variation of the ratio of

fitting loss to total loss with the different measures of pipe

work complexity. Thus, this ratio, denoted as y, was regressed

on the mentioned three measures of complexity, denoted as x1,

x2 and x3, respectively.

An initial investigation had indicated a second order variation

of y with x (Sodiki and Orupabo, 2011) namely

y = a0 + a1 x + a2 x

2

- - - - - (4)

The effort here, therefore, would be to obtain the regression

parameters a0, a1 and a2 for each of the independent variables

x1, x2 and x3 by the solution of the set of analytical

simultaneous equations (Lipson and Seth, 1973)

y = na0 + a1 x+ a2 x

2

yx = a0 x + a1 x

2

+ a2 x

3

- - - - - (5)

yx

2

= a0 x

2

+ a1 x

3

+ a2 x

4

where n = number of data points (in this case, equal to

15).In line with standard methods of statistics, Table 6 was set

up to summarize the computations which aid the analysis. In

Appendix 1, the relationship between y and x1, y and x2, and y

and x3 are established, respectively, as

y =0.2280 1.246 x 10

-3

x1 + 1.558 x 10

-5

x1

2 - --

(6)

y =0.2816 3.538 x 10

-2

x2 + 1.565 x 10

-2

x2

2

--- (7)

and

y =0.2287 + 1.169 x 10

-3

x3 + 1.649 x 10

-6

x3

2

--- (8)

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

114

Table 6: Compilation of Statistical Variables and Terms

Index

Pipe

Length

X1 (m)

Design

Flow

X2 (l/s)

No. of

Appliances

X3

Frictiona

l Loss

(m)

Loss

thru

Fittings

(m)

Total

Loss (m)

Loss Thru

Fittings/ Total

Loss Y

yx1 x1

2

yx1

2

X1

3

x1

4

yx2 x2

2

yx2

2

x2

3

x2

4

yx3 x3

2

yx3

2

x3

3

x3

4

28.3 0.60 8 2.318 0.889 3.207 0.277 7.8391 800.89 221.842 22665.187 641424.792 0.1662 0.3600 0.09772 0.2160 0.1296 2.216 64 17.728 512 4096

36.3 0.95 16 2.698 1.045 3.743 0.279 10.1277 1317.69 367.636 47832.147 1736306.936 0.2651 0.9025 0.25180 0.8574 0.8450 4.464 256 71.424 5832 65536

44.3 1.25 24 3.943 1.302 5.245 0.248 10.9864 1962.49 486. 698 86938.307 3851367.000 0.3100 1.3625 0.38750 1.7531 2.4414 5.952 576 142.878 13824 331776

52.3 1.55 32 3.747 1.302 5.049 0.258 13.4934 2735.29 705.705 143055.667 7481811.384 0.3999 2.4025 0.61985 3.7239 5.7720 8.256 1024 264.192 32768 1048576

60.3 1.80 40 4.777 1.594 6.371 0.250 15.0750 3636.09 909.023 219256.227 13221150.49 0.4500 3.2400 0.81000 5.8320 10.4976 10.000 1600 400.000 64000 2560000

68.3 2.20 48 4.337 1.627 5.964 0.273 18.6459 4664.89 1273.515 318611.987 21761198.71 0.6006 4.8400 1.32132 10.6480 23.9256 13.104 2304 628.992 110592 5308416

76.3 2.60 56 4.245 1.724 5.969 0.289 22.0507 5821.69 1682.468 444194.947 33892074.46 0.7514 6.7600 1.95364 17.5760 45.6976 16.184 3136 906.304 175616 9834496

84.3 2.70 64 4.625 1.936 6.561 0.295 24.8685 7106.49 2096.415 599077.107 50502200.2 0.7965 7.2900 2.15055 19.6830 53.1441 18.880 4096 1208.320 262144 16777216

92.3 2.90 72 5.005 2.069 7.074 0.292 26.9516 8519.29 2487.633 786330.467 72578302.1 0.8468 8.4100 2.45572 24.3890 70.7281 21.024 5184 1513.728 373248 26873856

100.3 2.95 80 4.304 2.079 6.383 0.326 32.6978 10060.09 3279.589 1009027.027 101205410.8 0.9617 8.7025 2.83702 25.6724 75.7335 26.080 6400 2086.400 512000 40960000

108.3 3.20 88 4.379 2.318 6.697 0.346 37.4718 11728.89 4050.196 127023.787 137566860.6 1.1072 10.2400 3.54304 32.7680 104.8576 30.448 7744 2679.424 681772 5996536

116.3 3.50 96 4.467 2.666 7.133 0.374 43.4962 13525.69 5058.608 1573037.747 182944290.0 1.3090 12.2500 4.58150 42.8750 150.0625 35.904 9216 3446.784 884736 84934656

124.3 3.70 104 4.147 2.542 6.689 0.380 47.2340 15450.49 5871.186 1920495.907 238717641.2 1.4060 13.6900 5.20220 50.6530 187.4161 39.520 10816 4110.080 1124864 116985856

132.3 4.00 112 4.059 2.658 6.717 0.396 52.3903 17503.29 6931.303 2315685.267 306365160.8 1.5840 16.0000 6.33600 64.0080 256.0000 44.352 12544 4967.424 1404928 157351936

140.3 4.40 120 4.311 2.880 7.191 0.401 56.2603 19684.09 7893.320 2761677.827 387463399.1 1.7644 19.3600 7.76636 85.1840 374.8096 48.120 14400 5774.400 1728000 207360000

=

1264.5

=

38.3

= 960 = 4.684 =

419.5892

=

124517.35

=

43315.142

=

13518124.61

=

1559928599.5

=

12.7188

= 116.01 =

40.31322

=

286.0308

=

1361.5298

=

324.504

=

79360

=

28218.048

=

7374536

=

730365952

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

115

Furthermore, the coefficient of correlation is given as (Lipson

and Seth, 1973)

r =

2

.

1

|

|

.

|

\

|

y

x y

S

S

(9)

where Sy.x =

( )

3

2

1

=

n

y y

n

i

ic i

(10)

= standard error of estimate,

yi being the actual values

of y, yic being the values of

y computed from the

regression equation and n

the numbers of points

and Sy =

( )

1

2

1

=

n

y y

n

i

i

(11)

= sample standard deviation

of y

n 3 is the number of degrees of freedom, as the number of

regression parameters to be estimated is three, a0, a1 and a2

In Appendix II, the coefficients of correlation between y and

x1, y and x2, and y and x3 are computed, respectively, as 0.97,

0.95 and 0.91.

5. DISCUSSION OF RESULTS

From statistical tables (Lipson and Seth, 1973), r required for

99% confidence is 0.661. Since all three computed values of r

exceed 0.661, there is 99% confidence that the variation of the

fraction of head loss through fittings is interdependent, in turn,

with variations of length of index pipe run, total flow rate and

number of appliances served. It further follows that estimates

of the fraction of head loss can be made using the derived

regression equations.

The fractions of head loss through pipe fittings calculated by

the regression equations in Appendix II show the following

general increases: from 0.263 to 0.420 for increase in first

index pipe length from 28.3m to 140.3m; from 0.262 to 0.429

for an increase in total flow rate from 0.6L/s to 4.4L/s; and

from 0.238 to 0.393 for an increase in number of sanitary

appliances from 8 to 120.

It is, thus, observed that the head loss fractions fall between

0.24 and 0.43 within the limits of system complexity utilized

in the analysis.

In fact, random computations and estimates done on other

water distribution configurations (different from the general

architectural arrangement of toilet rooms and sanitary

appliances employed in this analysis), but utilizing the same

available head of 7.5m and distributing to a single building

floor, as in this analysis, had given fractions of head loss in the

region of 0.2 to 0.4 for first index lengths of between 20m and

120m. Hence, needed estimates of fractions may be made by

interpolating between these limits and adding a safety margin.

Alternatively, the present results may be applied with

reasonable correctness.

6. CONCLUSIONS

Within the limits of system complexity of up to 140m index

pipe length, 4.4L/s flow rate and 120 sanitary appliances a ratio

of loss through fittings to total loss of 0.45 is not likely to be

exceeded for simple water distribution systems under an

available head of 7.5m.

The ratios of head loss obtained from the regression equations

are useful in the analysis of system losses. For instance, for a

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

116

given first index pipe length, the total head loss can quickly be

estimated by adding the relevant fraction to the frictional loss.

The total head loss, so estimated, is useful in determining the

suitability of the given reservoir elevation and, hence, in

assessing the head requirements of the lift pump.

Other water distribution systems such as are utilized for groups

of buildings in housing estates and for distribution in town and

village mains could also be analyzed by the same procedure.

Furthermore, the relationship between the available head and

the computed ratios could be investigated by carrying out the

foregoing analysis for different commonly utilised reservoir

elevations

REFERENCES

[1]. Barry, R. (1977). The Construction of Buildings, Vol. 5:

Supply and Discharge Services. Granada Publishing Ltd,

London.

[2]. Giles, R. V. (1977), Fluid Mechanics and Hydraulics.

McGraw-Hill Book Co., New York

[3]. Institute of Plumbing (1977). Plumbing Services Design

Guide, Essex

[4]. Lipson, C and Seth, N. J. (1973). Statistical Design and

Analysis of Engineering Experiments. McGraw-Hill

Book Co., New York

[5]. Sodiki, J. I. (2002). A Representative Expression for

Swimming Pool Circulator Pump Selection. Nigerian

Journal of Engineering Research and Development. Vol.

1, No. 4, Pp. 24-35

[6]. Sodiki, J. I. (2003). Design Analysis of Water Supply

and Distribution to a Multi-Storey Building Utilizing a

Borehole Source. Nigerian Journal of Industrial and

Systems Studies. Vol. 2, No. 2, Pp 16-32

[7]. Sodiki, J. I. and Orupabo, S. (2011). Estimating Head

and Frictional Losses through Pipe Fittings in Building

Water Distribution Systems. Journal of Applied Science

and Technology. Vol. 16, Nos. 1 & 2, Pp 67-74

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

117

APPENDIX I: REGRESSION EQUATIONS

(i) Regression of y on x1

Substitution of values from Table 6 into Eqn. 5 yields the simultaneous equation

4.684 = 15a0 +1264.5a1 + 124517.35a2 ----- (a)

419.589 = 1264.5a0 + 124517.35a1 + 13518124.61a2 ---- (b)

43315.142 = 124517.35a0 + 13518124.61a1 +1559928599.5a2 --- (c)

Solving for a0, a1 and a2 yields the expression for Eqn. 4 as

y = 0.2280 1.246 x 10

-3

x1 + 1.558 x 10

-5

x1

2

(ii) Regression of y on x2

Substitution of values from Table 6 into Eqn. 5 yields the simultaneous equations

4.684 = 15a0 +38.3a1 + 116.01a2 ----- (d)

12.719 = 38.3a0 + 116.01a1 + 1386.03a2 ---- (e)

40.313 = 116.01a0 + 386.03a1 +1361.53a2 ---- (f)

Solving for a0, a1 and a2 yields the expression for Eqn. 4 as

y = 0.2816 3.538 x 10

-2

x2 + 1.565 x 10

-2

x2

2

(iii) Regression of y on x3

Substitution of values from Table 6 into Eqn. 5 yield the simultaneous equations

4.684 = 15a0 +960a1 + 79360a2 ----- (g)

324.508 = 960a0 + 79360a1 + 7374536a2 ---- (h)

28218.048 = 79360a0 + 7374536a1 +730365952a2 ---- (i)

Solving for a0, a1 and a2 yields the expression for Eqn. 4 as

y = 0.2287 + 1.169 x 10

-3

x3 + 1.649 x 10

-6

x3

2

APPENDIX II: CALCULATION OF COEFFICIENTS

II(i) Coefficient of Correlation for x1

The regression equation is

yc = 0.2880 1.246 x 10

-3

x1 + 1.558 x 10

-5

x1

2

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

118

where, yc is the calculated value of y. In Table A1, A2 and A3 yi is the actual value of y obtained from the analysis of the losses of

pressure head, and y is the mean of the y values.

Table A1: Values for Calculating Correlation Coefficient for x1

i xi yi

yi y (yi y )

2

x 10

4

yic yi yc (yi yic)

2

x 10

4

1 28.3 0.277 -0.0236 5.5696 0.265 0.012 1.44

2 36.3 0.279 -0.0333 11.0889 0.263 0.016 2.56

3 44.3 0.248 -0.0526 27.6676 0.263 -0.015 2.25

4 52.3 0.258 -0.0426 18.1476 0.265 -0.007 0.49

5 60.3 0.250 -0.0506 25.6036 0.270 -0.020 4.00

6 68.3 0.273 -0.0276 7.6176 0.276 -0.003 0.09

7 76.3 0.289 -0.0116 1.3456 0.284 0.005 0.25

8 84.3 0.295 -0.0056 0.3136 0.294 0.001 0.01

9 92.3 0.292 -0.0086 0.7396 0.306 -0.014 1.96

10 100.3 0.326 0.0254 6.4516 0.320 0.006 0.36

11 108.3 0.346 0.0454 20.6116 0.336 0.010 1.00

12 116.3 0.374 0.0734 53.8756 0.354 0.020 4.00

13 124.3 0.380 0.0794 63.0436 0.374 0.006 0.36

14 132.3 0.396 0.0954 91.0116 0.396 0.000 0.00

15 140.3 0.401 0.1004 100.8016 0.420 -0.019 3.60

= 1264.5 = 433.8893 = 22.38

y = 0.3123

Sy.x = 01366 . 0

12

10 38 . 22

4

=

Sy = 05567 . 0

14

10 8893 . 433

4

=

Coefficient of Correlation r = 97 . 0

05567 . 0

01366 . 0

1

2

=

|

.

|

\

|

II(ii): Coefficient of Correlation for x2

The regression equation is

yc = 0.2816 3.538x 10

-2

x2 + 1.565x10

-2

x2

2

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

119

Table A2: Values for Calculating Correlation Coefficient for x2

i xi yi

yi y (yi y )

2

x 10

4

yic yi yc (yi yic)

2

x

10

4

1 060 0.277 -0.0236 5.5696 0.266 0.011 1.21

2 0.95 0.279 -0.0333 11.0889 0.262 0.017 2.89

3 1.25 0.248 -0.0526 27.6676 0.262 -0.014 1.96

4 1.55 0.258 -0.0426 18.1476 0.264 -0.006 0.36

5 1.80 0.250 -0.0506 25.6036 0.269 -0.019 3.61

6 2.20 0.273 -0.0276 7.6176 0.280 -0.007 0.49

7 2.60 0.289 -0.0116 1.3456 0.295 -0.006 0.36

8 2.70 0.295 -0.0056 0.3136 0.300 -0.005 0.25

9 2.90 0.292 -0.0086 0.7396 0.311 -0.019 3.61

10 2.95 0.326 0.0254 6.4516 0.313 0.013 1.69

11 3.20 0.346 0.0454 20.6116 0.329 0.017 2.89

12 3.50 0.374 0.0734 53.8756 0.349 0.025 6.25

13 3.70 0.380 0.0794 63.0436 0.365 0.015 2.25

14 4.0 0.396 0.0954 91.0116 0.390 0.006 0.36

15 4.4 0.401 0.1004 100.8016 0.429 -0.028 7.84

= 36.02

Sy.x = 01733 . 0

12

10 02 . 36

4

=

Sy = 0.05567 (as for x1)

Coefficient of Correlation r = 95 . 0

05567 . 0

01733 . 0

1

2

=

|

.

|

\

|

II(iii): Coefficient of Correlation for x3

The regression equation is

yc = 0.2287 + 1.169 x 10

-3

x3 + 1.649 x 10

-6

x 3

2

Table A3: Values for Calculating Correlation Coefficient for x3

i xi yi

yi y (yi y )

2

x 10

4

yic yi yc (yi yic)

2

x

10

4

1 8 0.277 -0.0236 5.5696 0.238 0.039 15.21

2 16 0.279 -0.0333 11.0889 0.248 0.029 8.41

3 24 0.248 -0.0526 27.6676 0.258 -0.070 1.00

4 32 0.258 -0.0426 18.1476 0.268 -0.010 1.00

International Journal of Science and Technology (IJST) Volume 3 No. 2, February, 2014

IJST 2014 IJST Publications UK. All rights reserved.

120

5 40 0.250 -0.0506 25.6036 0.278 -0.028 7.84

6 48 0.73 -0.0276 7.6176 0.289 -0.016 2.56

7 56 0.289 -0.0116 1.3456 0.299 -0.010 1.00

8 64 0.295 -0.0056 0.3136 0.310 -0.015 2.25

9 72 0.292 -0.0086 0.7396 0.321 -0.029 8.41

10 80 0.326 0.0254 6.4516 0.333 -0.007 0.49

11 88 0.346 0.0454 20.6116 0.344 0.002 0.04

12 96 0.374 0.0734 53.8756 0.356 0.018 3.24

13 104 0.380 0.0794 63.0436 0.368 0.012 1.44

14 112 0.396 0.0954 91.0116 0.380 0.016 2.56

15 120 0.401 0.1004 100.8016 0.393 0.008 6.40

= 61.85

Syx = 0227 . 0

12

10 85 . 61

4

=

Sy = 0.05567 (as for x1)

Coefficient of Correlation r = 91 . 0

05567 . 0

0227 . 0

1

2

=

|

.

|

\

|

Vous aimerez peut-être aussi

- Uow009698 Building Monitoring and Control Systems Design StandardsDocument23 pagesUow009698 Building Monitoring and Control Systems Design StandardsstarykltPas encore d'évaluation

- Aqua 1Document324 pagesAqua 1staryklt100% (1)

- Uow009701 Electrical Services Commissioning StandardDocument26 pagesUow009701 Electrical Services Commissioning StandardstarykltPas encore d'évaluation

- Uow009702 Electronic Monitoring and Access Control Commissioning StandardDocument29 pagesUow009702 Electronic Monitoring and Access Control Commissioning StandardstarykltPas encore d'évaluation

- Uow009699 Building Elements Commissioning StandardDocument28 pagesUow009699 Building Elements Commissioning StandardstarykltPas encore d'évaluation

- CCTV System Commissioning StandardDocument19 pagesCCTV System Commissioning Standards_morrissey_consulting100% (1)

- Floor Waste Installation OverviewDocument2 pagesFloor Waste Installation OverviewstarykltPas encore d'évaluation

- Uow009695 Landscaping Design StandardsDocument43 pagesUow009695 Landscaping Design StandardsstarykltPas encore d'évaluation

- Uow009696 Mechanical Services Design StandardsDocument19 pagesUow009696 Mechanical Services Design StandardsstarykltPas encore d'évaluation

- Uow009693 Fire Services Design StandardsDocument20 pagesUow009693 Fire Services Design StandardsstarykltPas encore d'évaluation

- Uow009694 Hydraulic Services Design StandardsDocument37 pagesUow009694 Hydraulic Services Design StandardsstarykltPas encore d'évaluation

- 7123AF Aquatherm Fusiotherm Hot & Cold Water System 2010Document9 pages7123AF Aquatherm Fusiotherm Hot & Cold Water System 2010starykltPas encore d'évaluation

- Uow009695 Landscaping Design StandardsDocument43 pagesUow009695 Landscaping Design StandardsstarykltPas encore d'évaluation

- Ts Join GuideDocument1 pageTs Join GuidestarykltPas encore d'évaluation

- Enclosed Shower BaysetDocument2 pagesEnclosed Shower BaysetstarykltPas encore d'évaluation

- Private Water Supply GuidelinesDocument40 pagesPrivate Water Supply GuidelinesstarykltPas encore d'évaluation

- Residential Electric Service InstallationDocument56 pagesResidential Electric Service InstallationJ Hevesi100% (1)

- Glossary of Home Construction Terms - HCM-04759Document15 pagesGlossary of Home Construction Terms - HCM-04759starykltPas encore d'évaluation

- Guide To Concrete RepairDocument168 pagesGuide To Concrete Repairhansen_zinck4751100% (11)

- Res StreetsDocument50 pagesRes StreetsVas SteelPas encore d'évaluation

- Ds05 DrivewaysDocument15 pagesDs05 DrivewaysstarykltPas encore d'évaluation

- Concrete Path GuidelinesDocument6 pagesConcrete Path GuidelinesKipegoPas encore d'évaluation

- Purlin Mounted AnchorDocument2 pagesPurlin Mounted AnchorstarykltPas encore d'évaluation

- Power System Sizing Form: G G G GDocument4 pagesPower System Sizing Form: G G G GstarykltPas encore d'évaluation

- Floor Waste Installation OverviewDocument2 pagesFloor Waste Installation OverviewstarykltPas encore d'évaluation

- 0118 Texture Coating For Interior Concrete and MasonryDocument4 pages0118 Texture Coating For Interior Concrete and MasonrystarykltPas encore d'évaluation

- 0621 SIKA Waterproofing - Wet AreasDocument12 pages0621 SIKA Waterproofing - Wet AreasstarykltPas encore d'évaluation

- Lancashire Residential Road Design GuideDocument42 pagesLancashire Residential Road Design Guidesweptpath2012Pas encore d'évaluation

- 100mm Lab TestsDocument17 pages100mm Lab TestsstarykltPas encore d'évaluation

- 75mm Lab TestsDocument19 pages75mm Lab TestsstarykltPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Osisense ManualDocument2 pagesOsisense ManualLki SelfPas encore d'évaluation

- Checklists 4yrDocument2 pagesChecklists 4yrKarla TreviñoPas encore d'évaluation

- Ingrid Olderock La Mujer de Los Perros by Nancy GuzmnDocument14 pagesIngrid Olderock La Mujer de Los Perros by Nancy GuzmnYuki Hotaru0% (3)

- Composition Code ExampleDocument3 pagesComposition Code ExampleREBEL USMANPas encore d'évaluation

- Account Statement: Karthikeyan S 47asumugaflats, Kamarajarstreet Oragadam Ambattur, Ambattur ChennaiDocument2 pagesAccount Statement: Karthikeyan S 47asumugaflats, Kamarajarstreet Oragadam Ambattur, Ambattur ChennaiKarthikeyan MallikaPas encore d'évaluation

- Esna CatalogDocument12 pagesEsna Catalogbalaji_jayadeva9546Pas encore d'évaluation

- Unitrac 80WDocument1 pageUnitrac 80WprogramacionavanzadaPas encore d'évaluation

- Changing Out The Injector Seals On A 2007 PJ Ford Ranger 3.0 TDCiDocument3 pagesChanging Out The Injector Seals On A 2007 PJ Ford Ranger 3.0 TDCiAgustinus D100% (3)

- BLTouch Setup ManualDocument7 pagesBLTouch Setup ManualBobbyPas encore d'évaluation

- Time Impact Analysis by BrewerConsultingDocument3 pagesTime Impact Analysis by BrewerConsultingAAKPas encore d'évaluation

- TM 9-792 M21 AMMUNITION TRAILERDocument128 pagesTM 9-792 M21 AMMUNITION TRAILERAdvocate100% (1)

- Session 2A JonkerDocument15 pagesSession 2A JonkerD_D_APas encore d'évaluation

- 4x16 RM NyyfDocument1 page4x16 RM NyyfjamilPas encore d'évaluation

- NAD Factory Default and Software CheckDocument13 pagesNAD Factory Default and Software CheckNorma FloresPas encore d'évaluation

- Safety Data Sheet: Ingredient Einecs Concentration Symbol(s) Risk Phrases ( )Document9 pagesSafety Data Sheet: Ingredient Einecs Concentration Symbol(s) Risk Phrases ( )panagiotis_panagio_2Pas encore d'évaluation

- 29-Horizontal Subsea Xmas Tree enDocument2 pages29-Horizontal Subsea Xmas Tree encarthik_rajaPas encore d'évaluation

- Bou-Llusar Et Al 2009 EFQM Excellence ModelDocument22 pagesBou-Llusar Et Al 2009 EFQM Excellence Modelfastford14Pas encore d'évaluation

- Reduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentDocument4 pagesReduced Vertical Separation Minimum - RVSM: IVAO HQ Training DepartmentjesusPas encore d'évaluation

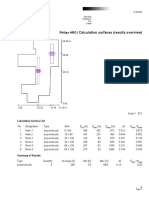

- Calculation Surfaces (Results Overview) : Philips HRODocument4 pagesCalculation Surfaces (Results Overview) : Philips HROsanaPas encore d'évaluation

- Lecture 1 - Auditing & Internal ControlDocument63 pagesLecture 1 - Auditing & Internal ControlLei CasiplePas encore d'évaluation

- 2008 Nissan Teana J32 Service Manual-HacDocument245 pages2008 Nissan Teana J32 Service Manual-HacMrihexPas encore d'évaluation

- Research Paper On Plate Heat Exchanger PDFDocument8 pagesResearch Paper On Plate Heat Exchanger PDFc9s9h7r7100% (1)

- CHAPTER 2 Eff Comm ModelsDocument9 pagesCHAPTER 2 Eff Comm ModelsSubhash SoniPas encore d'évaluation

- Android User GuideDocument15 pagesAndroid User GuideAnonymous 1Wb6JCkPas encore d'évaluation

- SAP ABAP ResumeDocument3 pagesSAP ABAP Resumeshakti1392821Pas encore d'évaluation

- Atlas Bradford (Ver03-Apr05)Document8 pagesAtlas Bradford (Ver03-Apr05)Gabriel IbarraPas encore d'évaluation

- IOT SyllabusDocument3 pagesIOT Syllabuspoojan thakkarPas encore d'évaluation

- Frequency Analysis Vibration Spectrum Analysis Steve GoldmanDocument9 pagesFrequency Analysis Vibration Spectrum Analysis Steve GoldmantylerdurdanePas encore d'évaluation

- Transport ModellingDocument37 pagesTransport ModellingRiza Atiq Abdullah Rahmat100% (6)

- Epicor ERP Embedded Courses A4 FS ENSDocument2 pagesEpicor ERP Embedded Courses A4 FS ENSHuong NguyenPas encore d'évaluation