Académique Documents

Professionnel Documents

Culture Documents

s2k Manual

Transféré par

spartako84Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

s2k Manual

Transféré par

spartako84Droits d'auteur :

Formats disponibles

TECHNICAL INFORMA TION INFORMATION

S2 k S2k SONIC CHL ORINA TOR CHLORINA ORINAT

Manual control applications at a down-toearth price Mounts directly on a cylinder Capacities to 100 pounds per day Easy to install, operate, and service Backed by factory-trained and authorized service personnel

FEA TURES FEATURES

A Down-To-Earth Price Heres proof that quality doesnt have to be expensive. For low capacity chlorination, you wont find better value than the S2k. Combining the sonic-flow principle with innovative design makes the initial low cost possibleyet keeps USF/ W&Ts time-proven quality and reliability. Cylinder Mounted The S2k Chlorinator is easy to mount directly on the valve of a chlorine cylinder. Direct mounting means all-vacuum operation. There are no lines or components carrying gas under pressure. Manifold Mounting The chlorinator can also be mounted on 5- or 10-cylinder manifolds. Captive-Yoke Mounting A unique, self-aligning captive-yoke clamp makes it easy to line up and connect the chlorinator to the gasketed outlet of a cylinder valve. The heavy-duty yoke resists damage from repeated usage and rough handling. Easy to Install, Operate, and Maintain The S2k Chlorinator is simple in design, having fewer than 50 parts. Its compact and easy to handle and install. Injector installation requires only connection to a water supply and running plastic tubing to a main or open channel. A knob adjustment changes gas feedrate, which is indicated on a 3-inch-scale rotameter. The injector need not be shut off when changing cylinders. Maintenance requires only a wrench and a screwdriver. Wide Range of Feedrates, Dual Scales Dual-scale rotameters, calibrated in pounds per day and grams per hour, come in five capacities between 5 and 100 pounds per day and 100 and 2,000 grams per hour. Single-scale rotameters, calibrated in pounds per day or kilograms per 24 hours, come in two capacities 1.2 pounds per day and 0.5 kilograms per 24 hours. These capacities and a 20:1 operating range let the operator select any desired feedrate. A Mini-Chlorination Center The S2k and a USF/W&T Two-cylinder Scale bring the feed rate adjustment, feed rate indication, and a readout of the available gas supply conveniently together. Design and Construction The S2k Chlorinator is all-vacuum operated. Direct-cylinder mounting puts the vacuum-regulating valve right at the gas source, immediately reducing gas pressure to a vacuum. This valve closes automatically should operating vacuum stop for any reason. When a cylinder is exhausted, a diaphragm in the valve creates a seal. This prevents the entrance of air when cylinders are changed. The vacuum-regulating and gas-control components are in a chemical-resistant ABS housing. Besides the vacuumregulating valve they include: a porous Teflon felt filter at the gas inlet; a pressure-relief valve that vents to a safe

TECHNICAL INFORMA TION INFORMATION

S2 k S2k SONIC CHL ORINA TOR CHLORINA ORINAT

area should pressure in the system increase above atmospheric pressure; an adjustable orifice that controls gas flowrate; and a 3-inch-scale rotameter that measures it. The rotameter is easy to remove and replace. The injector is a fixed-throat type. It is made of PVC/ABS, which resists

Captive-Yoke Mounting

Start-Stop or Program Control These control methods are easily achieved by starting and stopping water flow through the injector, thus operating vacuum. This is done by installing an optional two-way solenoid valve in the injector-water line or an optional vacuum solenoid valve in the gas line. The solenoid valves are wired into the control circuit of a pump, timer, or controller.

OPERA TION OPERATION

corrosion and erosion. In the injector, the check valves elastomeric material and large surface area create a reliable seal against backpressure, helping keep injector water from flooding the chlorinator.

The S2k operates under a vacuum. Produced at the injector, this vacuum is transmitted to the chlorinator by plastic tubing. Gas under pressure enters the chlorinator at the vacuum-regulating valve where it is filtered and reduced to a vacuum. Here, a diaphragm senses atmospheric pressure on one side and a vacuum on the other.

100 PPD Injector

METHODS OF CONTROL

The feedrate is controlled by changing control-orifice area and/or interrupting injector-water supply to shut off operating vacuum. Manual Control Achieved by changing control orifice area via an adjusting knob on the front of the chlorinator.

The dual-scale rotameter can be rotated to display pounds per day or grams per hour.

The S2k Chlorinators simple design makes installation and service easy.

2

TECHNICAL INFORMA TION INFORMATION

S2 k S2k SONIC CHL ORINA TOR CHLORINA ORINAT

This pressure differential displaces a spring-loaded stem off a seat, permitting gas to enter. The diaphragm also controls a pressure-relief valve, which vents to a safe area if vacuum is lost and pressure builds above atmospheric. Vacuum from the injector creates a critical pressure differential across the metering orifice for gas flow regulation. The pressure differential causes the velocity of the gas in the chlorinator to reach the speed of sound as it moves through the orifice, which is part of the control valve. Gas flowrate is selected by changing orifice size. After the vacuum-regulating valve, gas enters the rotameter where its flow rate is measured. Next is the control valve where flow is regulated according to orifice size. Gas then passes to the injector.

TECHNICAL D ATA DA

At the injector, metered gas is dissolved in the water stream. The resultant solution is discharged at the point of application. A built-in check valve is designed to prevent injector water from flooding the chlorinator on injector shutdown.

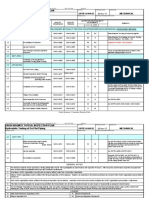

Capacities Dual-scale rotameters: lbs/day 5 10 25 50 100 grams/hr 100 200 500 1000 2000

Single-scale rotameters: Available for 1.2 pounds per day (0.5 kilograms per day). Connections The chlorinator is mounted directly on the cylinder valve by a self-aligning yoketype clamp. Gas connections at the chlorinator and injector and the vent connection are 1/4-inch NPT compression fittings for 3/8-inch OD polyethylene tubing. The injector has water inlet and discharge connections for 3/4-inch flexible pipe or 3/4-inch male NPT for rigid pipe.

Accuracy 4% of indicated flow. Operating Range 20:1 Ambient Temperature Limits Chlorinator, 10 to 130F; injector, 32 to 130F. Vent Vent line must exhaust to a safe area where gas fumes cannot cause injury or damage.

Typical Installation

3

TECHNICAL INFORMA TION INFORMATION

S2 k S2k SONIC CHL ORINA TOR CHLORINA ORINAT

Electrical Requirements The chlorinator requires no electricity. There may be other requirements for a solenoid valve for start-stop operation or for a booster pump. Installation Packages Standard package contains: Chlorinator; injector; rotameter for one capacity; gas filter; vent screen; lead gaskets; and instruction book. NOTE: Not included but necessary to complete an installation: rigid pipe or hose for the injector inlet, and flexible tubing for chlorinator-to-injector and vent connections. Options For start-stop operation, a 2-way solenoid for the injector-water line or gas vacuum line. Related options include: auxiliary cylinder valves and connections; manifolds; vent, injector-water and injector-outlet lines and clamps; main connections; water-line pressure gauge; gas masks; residual test kits; injector-vacuum gauge; spare parts; booster pumps; chlorine-leak detector; USF/W&T Two-cylinder Scales with dial or digital readout.

Wallace & Tiernan Products 1901 West Garden Road Vineland, NJ 08360 856.507.9000 phone 856.507.4125 fax

Products manufactured and marketed by United States Filter Corporation (USFilter) and its affiliates are protected by patents issued or pending in the United States and other countries. USFilter reserves the right to change the specifications referred to in this literature at any time, without prior notice. PM Kits is a registered trademark of USFilter Corporation and its subsidiaries. Teflon is a registered trademark of EI Dupont Dow Elastimers.

Control Modes Manual by an adjusting knob or start-stop by interrupting injector-water flow with a 2-way solenoid valve. Mounting Mounts directly on a cylinder valve via a self-aligning yoke. Also mounts directly on 5- or 10-cylinder manifolds. Injector-Water Supply Must be reasonably clean. Maximum temperature is 130F. Maximum inlet pressure is 300 psig to 100F, 150 psig to 300F. Pressure at Application Point Maximum with flexible polyethylene pipe is 75 psig. Rigid pipe or high-pressure hose for the solution line will allow application against backpressures to 160 psig. Compliance The S2k Chlorinator is designed to comply with Chlorine Institute and Compressed Gas Association recommendations.

AFTER -SALE SUPPORT AFTER-

To keep your equipment operating at top efficiency, USF/W&T offers the most inclusive after-sale support in the industry. Replacement Parts Genuine USF/W&T replacement parts not only protect your investment in USF/ W&T equipment, they also offer assurance against failure in critical publichealth-related applications. Avoid the hazard and hidden costs of cheap imitations. USF/W&T offers fast delivery of original-quality replacement parts. Use of such parts helps maintain equipment in good working order ... eliminate equipment breakdowns and costly downtime. PM Kits These kits contain original USF/W&T replacements for those parts most susceptible to wear and/or most often replaced. They facilitate scheduled maintenance and emergency repairs.

http://www.wallaceandtiernan.usfilter.com Literature # TI 25.260 UA 6/03

2003 USFilter

Vous aimerez peut-être aussi

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsD'EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsPas encore d'évaluation

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryD'EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryPas encore d'évaluation

- WT.025.055.000.IE - ps.0714 Evoqua ChlorinatorDocument8 pagesWT.025.055.000.IE - ps.0714 Evoqua ChlorinatorNguyễn Đăng QuýPas encore d'évaluation

- Capital Controls Series 600 Gas ChlorinatorDocument4 pagesCapital Controls Series 600 Gas ChlorinatorFranco ArellanoPas encore d'évaluation

- V2000 Gas Feed Models PDFDocument8 pagesV2000 Gas Feed Models PDFRandy LangleyPas encore d'évaluation

- High Capacity Gas Chlorinator: MODEL 2101Document4 pagesHigh Capacity Gas Chlorinator: MODEL 2101Al Patrick Dela CalzadaPas encore d'évaluation

- S10K Chlorinator EvoquaDocument4 pagesS10K Chlorinator EvoquameloszPas encore d'évaluation

- HPG Range: Direct High-Pressure Gas ActuatorsDocument8 pagesHPG Range: Direct High-Pressure Gas ActuatorsLuan HuynhPas encore d'évaluation

- Capital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityDocument8 pagesCapital Controls® Series Nxt3000: Modular Design Gas Feed System With Self Contained Automatic Switchover CapabilityLoan NguyênPas encore d'évaluation

- GAS Chlorinators: The Most Durable Gas Chlorinator On The MarketDocument4 pagesGAS Chlorinators: The Most Durable Gas Chlorinator On The MarketAl Patrick Dela CalzadaPas encore d'évaluation

- Turbine Bypass ValveDocument12 pagesTurbine Bypass ValveRam MohanPas encore d'évaluation

- Superior Gas Chlorinators BrochureDocument16 pagesSuperior Gas Chlorinators BrochureAqua Technology GroupPas encore d'évaluation

- ProductsDocument8 pagesProductsLe ChauvePas encore d'évaluation

- Autotrol Brand 255 Valve / 400 Series Controls Installation InstructionsDocument32 pagesAutotrol Brand 255 Valve / 400 Series Controls Installation InstructionsWattsPas encore d'évaluation

- Pressure Vacuum BleedersDocument4 pagesPressure Vacuum BleedersGustavo AlcaPas encore d'évaluation

- 189 010 - en 15.710057 V3.0Document12 pages189 010 - en 15.710057 V3.0balzac191Pas encore d'évaluation

- 1500 Series Mechanical Level Brochure Bro1378Document20 pages1500 Series Mechanical Level Brochure Bro1378FranciscoPas encore d'évaluation

- Forbes Marshall Turbine Bypass ValvesDocument28 pagesForbes Marshall Turbine Bypass Valveser_sanjaypatelPas encore d'évaluation

- Perfect Chloro Systems - Gas ..Document6 pagesPerfect Chloro Systems - Gas ..nazar750Pas encore d'évaluation

- 255 400 Homeowners Manual 1018075Document28 pages255 400 Homeowners Manual 1018075menard9037661Pas encore d'évaluation

- 08-Conv Valves Product InfoDocument18 pages08-Conv Valves Product Infoakrk777Pas encore d'évaluation

- Series LL40 and LLL40 Specification SheetDocument2 pagesSeries LL40 and LLL40 Specification SheetWattsPas encore d'évaluation

- R431002626 AventicsH 3Controlair®ValveswithRollerDocument2 pagesR431002626 AventicsH 3Controlair®ValveswithRollerHamza ChenakerPas encore d'évaluation

- Instruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaDocument14 pagesInstruction Manual - EJ17 Ejector Chlorine, Sulfur Dioxide and AmmoniaAlexandre EmmerickPas encore d'évaluation

- Specification CL-1016-2016Document2 pagesSpecification CL-1016-2016Docente 361 UMECITPas encore d'évaluation

- Wcenbr1040 01Document12 pagesWcenbr1040 01shahganPas encore d'évaluation

- API - Valve StandardsDocument38 pagesAPI - Valve StandardsK LandryPas encore d'évaluation

- 1063 Forged Brass Spring Check ValveDocument5 pages1063 Forged Brass Spring Check ValveSyed FazluPas encore d'évaluation

- Cryogenic CatalogDocument12 pagesCryogenic CatalogjbaptistaaPas encore d'évaluation

- Reliable Deluge Valve Model DDXDocument8 pagesReliable Deluge Valve Model DDXmanbkk100% (1)

- Ejector Cloro17Document14 pagesEjector Cloro17Robinson SanchezPas encore d'évaluation

- Control ValvesDocument38 pagesControl ValvesSridhar GudapatiPas encore d'évaluation

- DAN-EX Brochure WebDocument12 pagesDAN-EX Brochure Webzakkyf6455Pas encore d'évaluation

- INBAL GeralDocument10 pagesINBAL GeralAlisson Gustavo KalilPas encore d'évaluation

- RH Series Coiled Tubing Hangers - Wellhead Control ProductsDocument29 pagesRH Series Coiled Tubing Hangers - Wellhead Control Productsclaudio godinezPas encore d'évaluation

- ValvesDocument44 pagesValvesأحمد محمد قدريPas encore d'évaluation

- HYDRMAN Hydrocyclone ManualDocument8 pagesHYDRMAN Hydrocyclone ManualPeterson Magro100% (1)

- Diaphragm Pump CharacteristicsDocument9 pagesDiaphragm Pump CharacteristicslamiaPas encore d'évaluation

- Forbes Marshall Turbine Bypass Valves PDFDocument28 pagesForbes Marshall Turbine Bypass Valves PDFAnonymous lmCR3SkPrKPas encore d'évaluation

- Water Softeners Residential 6700XTR Upflow Valve Softeners Canadian ENGLISH ManualDocument12 pagesWater Softeners Residential 6700XTR Upflow Valve Softeners Canadian ENGLISH ManualPromagEnviro.comPas encore d'évaluation

- Air-Oxygen Blender: Service ManualDocument34 pagesAir-Oxygen Blender: Service ManualJames de LunaPas encore d'évaluation

- Pressure Seal Valves-GateDocument24 pagesPressure Seal Valves-GateHieu NguyenPas encore d'évaluation

- Aquestia OCV AVIATIONDocument16 pagesAquestia OCV AVIATIONSony Nd AshaPas encore d'évaluation

- Viking Series 90 Operating & Maintenance Instructions: FiltersDocument15 pagesViking Series 90 Operating & Maintenance Instructions: FiltersninatenaPas encore d'évaluation

- ValvesDocument135 pagesValvesShivang Gaur100% (4)

- Control Valves: Rejath Jacob ThomasDocument77 pagesControl Valves: Rejath Jacob ThomasIndunil Prasanna Bandara WarnasooriyaPas encore d'évaluation

- Reliableb1acc 1Document6 pagesReliableb1acc 1salajeanuPas encore d'évaluation

- BioChem Pinch Valve User ManualDocument33 pagesBioChem Pinch Valve User ManualthynameisraymondPas encore d'évaluation

- HFD Catalog GuardianDocument8 pagesHFD Catalog GuardianPartsGopher.comPas encore d'évaluation

- 100 0400Document8 pages100 0400Benito.camelasPas encore d'évaluation

- 10 ValvesDocument23 pages10 ValvesPower PlantPas encore d'évaluation

- Service ManualDocument48 pagesService ManualhectorPas encore d'évaluation

- Trane Rtwa 217Document10 pagesTrane Rtwa 217Dalila AmmarPas encore d'évaluation

- Large Size Quarter Turn Control Valves Can Improve Safety in PipelinesDocument19 pagesLarge Size Quarter Turn Control Valves Can Improve Safety in PipelinesgpuzonePas encore d'évaluation

- Turbine Bypass ValvesDocument6 pagesTurbine Bypass ValvesadehriyaPas encore d'évaluation

- Control ValvesDocument38 pagesControl ValvesAmol PawarPas encore d'évaluation

- Prevention of Actuator Emissions in the Oil and Gas IndustryD'EverandPrevention of Actuator Emissions in the Oil and Gas IndustryPas encore d'évaluation

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingD'EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingÉvaluation : 5 sur 5 étoiles5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- Handbook 2012Document396 pagesHandbook 2012aezead50% (4)

- Handbook 2012Document396 pagesHandbook 2012aezead50% (4)

- HDD Crossing DesignDocument12 pagesHDD Crossing DesignJeff KayPas encore d'évaluation

- v10k ManualDocument8 pagesv10k Manualspartako84Pas encore d'évaluation

- 4 ANSI Forged Fittings B16.11Document10 pages4 ANSI Forged Fittings B16.11dandan29Pas encore d'évaluation

- Catalogo - Norma - Astm - Catalog PDFDocument2 pagesCatalogo - Norma - Astm - Catalog PDFspartako84Pas encore d'évaluation

- BOQ Weligama PDFDocument3 pagesBOQ Weligama PDFMuhammadWazimAkramPas encore d'évaluation

- Tijaarat Developers Limited: Canyon Views Developments Defence Housing Authorities Phase Ii (Ext) Islamabad, PakistanDocument9 pagesTijaarat Developers Limited: Canyon Views Developments Defence Housing Authorities Phase Ii (Ext) Islamabad, PakistanMuhammadIqbalMughalPas encore d'évaluation

- Casa MilàDocument16 pagesCasa MilàKrisha Marie OrbisoPas encore d'évaluation

- Plumber or Pipe FitterDocument2 pagesPlumber or Pipe Fitterapi-76974390Pas encore d'évaluation

- Torque Data Card PDFDocument2 pagesTorque Data Card PDFAlenPas encore d'évaluation

- Dgca Module 06Document15 pagesDgca Module 06SatyamPas encore d'évaluation

- Manual WiloDocument25 pagesManual Wilocarr123Pas encore d'évaluation

- Rigid Pavement Unit 4Document76 pagesRigid Pavement Unit 4Deepak SahPas encore d'évaluation

- DRIP Tech ManualDocument2 pagesDRIP Tech ManualGunasridharan LakshmananPas encore d'évaluation

- Installation Manual For Low-Cost Polyethylene Tube DigestersDocument28 pagesInstallation Manual For Low-Cost Polyethylene Tube DigestersNathalia LeitePas encore d'évaluation

- Construction of Railway TracksDocument15 pagesConstruction of Railway TracksJunaid AmeenPas encore d'évaluation

- GIW Technical Series: GroutingDocument1 pageGIW Technical Series: GroutingTravis SkinnerPas encore d'évaluation

- Tuttnauer 1730,2340,2540,3140,3850,3870 Autoclave - Service Manual PDFDocument67 pagesTuttnauer 1730,2340,2540,3140,3850,3870 Autoclave - Service Manual PDFtravieso112100% (3)

- 3.2.9.A SizingSpreadFootingDocument2 pages3.2.9.A SizingSpreadFootingEmma GoebelPas encore d'évaluation

- NCHRP 9-44Document265 pagesNCHRP 9-44farihaPas encore d'évaluation

- Mechanical Services Particular SpecificationDocument12 pagesMechanical Services Particular SpecificationAhmed Mohamed AliPas encore d'évaluation

- To: Project: Location Labor & Materials Total Unit Cost Total Amount Item Description QTY UnitDocument18 pagesTo: Project: Location Labor & Materials Total Unit Cost Total Amount Item Description QTY UnitMarylan SalazarPas encore d'évaluation

- Fip Mec SferopolDocument16 pagesFip Mec Sferopolsotos raptopoulosPas encore d'évaluation

- InstallationManual - ThermoPower VDFDocument19 pagesInstallationManual - ThermoPower VDFSunMaxx SolarPas encore d'évaluation

- Cemex Solid K4 - Raw Meal SiloDocument3 pagesCemex Solid K4 - Raw Meal Silojoselito navarroPas encore d'évaluation

- Mac-Bak-000525 - Rev D V1Document1 pageMac-Bak-000525 - Rev D V1Erikson JeremiasPas encore d'évaluation

- Waterman Group PLC: Preliminary Results Announcement For The Year Ended 30 June 2011Document29 pagesWaterman Group PLC: Preliminary Results Announcement For The Year Ended 30 June 2011d_baddy_manPas encore d'évaluation

- Satip A 004 02Document10 pagesSatip A 004 02mohammadPas encore d'évaluation

- DTMP of Morang 2010Document160 pagesDTMP of Morang 2010Mishal LimbuPas encore d'évaluation

- Engineering CalculatorDocument48 pagesEngineering CalculatorgunarxPas encore d'évaluation

- 01A Design Criteria For TowersDocument3 pages01A Design Criteria For TowersNisarg TrivediPas encore d'évaluation

- TC BRGDocument6 pagesTC BRGArun SPas encore d'évaluation

- Option: 1: S.No. Description Qty. CodeDocument28 pagesOption: 1: S.No. Description Qty. CodeNitin GuptaPas encore d'évaluation

- HYSTER c108Document21 pagesHYSTER c108sergio reca0% (1)

- Heat Exchanger Aftercooler and SeparatorDocument16 pagesHeat Exchanger Aftercooler and Separatorjaskaran singhPas encore d'évaluation