Académique Documents

Professionnel Documents

Culture Documents

Well Commanddfsder Holland

Transféré par

ice_PLCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Well Commanddfsder Holland

Transféré par

ice_PLDroits d'auteur :

Formats disponibles

CASE STUDY

Well Information

Location ....................................................................................................................................................................................................... North Sea, Holland

Tool type ..................................................................................................................................................................................................... 5 in. WELL COMMANDER

Milling string .........................................................: 4 in.bit, 5 in. motor, 5 in. stabilizers, 6 x 4 in. drill collars, 5 in. WELL COMMANDER, 5 in.

.......................................................................................................... BALL CATCHER*, 5 in. MAGNOSTAR* HD, 5

1

/16 in. DRILLING JAR, 8 in. MAGNOSTAR HD

Drilling fluid ......................................................................................................................................................................................14.2 lb/gal (1.70 s.g.) WARP

Completion fluid ...............................................................................................................................................................................14.3 lb/gal (1.72 s.g.) OBM

The Situation

An operator in the Holland sector of the North Sea was attempting to set a 5 in. liner when the liner running tool failed, thus preventing

the packer from being set. Consequently, the liner was left in hole, leading the operator to decide to mill the liner to a point that would

enable fishing the remaining length. The operator planned for the milling operation to be undertaken over five runs, with the liner being

recovered on a sixth run.

The Solution

M-I SWACO recommended running the WELL COMMANDER circulating valve in the milling string to boost annular velocities, thereby

enabling mud conditioning at an increased flow rate, while boosting annular velocities (AV) to facilitate hole cleaning. Further, it was

recommended the string also include two powerful MAGNOSTAR HD magnet tools with the capacity to remove large volumes of ferrous

debris from the well. The HD variant features aggressive cutting carbide stabilizer mill sleeves at the box and pin ends of the tool. This

capability is designed to handle large pieces of debris that may be encountered in the wellbore, thus allowing them to be broken down

and circulated past the tool.

The Results

Over the course of the milling/fishing operations, the 5 in. WELL COMMANDER valve was run in the hole five times and activated a total of

ten times. The 7 in. and 9 in. MAGNOSTAR HD tools recovered a cumulative total of 96 kg (212 lb) ferrous debris from the well during

the milling / fishing operations, representing nearly 84% of theoretical amount. The ditch magnets at the shale shakers accounted for

another 6 kg (13 lb), bringing the total percentage to approximately 89%.

Holland: WELL COMMANDER enhances hole cleaning

in challenging milling/fishing job

Our customer was extremely happy with the performance of the WELL COMMANDER*,

especially with being able to re-run the tool, even after jarring when the BHA was stuck.

The operator also was exceptionally pleased with the MAGNOSTAR* HD tools and have

requested they be used in upcoming jobs.

Leon Sol, Area Manager Europe, M-I SWACO Specialized Tools

2011 M-I L.L.C. All rights reserved. *Mark of M-I L.L.C.

SPR.1961g.1106.R1 (E) Litho in U.S.A.

This information is supplied solely for informational purposes and M-I SWACO makes no guarantees or

warranties, either expressed or implied, with respect to the accuracy and use of this data. All product

warranties and guarantees shall be governed by the Standard Terms of Sale. Nothing in this document

is legal advice or is a substitute for competent legal advice.

P.O. Box 42842

Houston, Texas 77242-2842

www.miswaco.slb.com

Email: questions@miswaco.slb.com

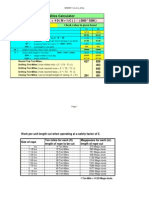

Ball

Number

Ball Size

(in)

Shear Pressure

(psi)

Position after

Ball Drop

Pump rate while

Dropping Ball

(bbl/min)

Operational Equipment

1 1.760 2668 Open 1.7 Conditioning / Weight up Mud

2 1.698 N/A BHA Shut Off 2 Shut Off BHA while circulating

3 1.760 2610 Closed Freefall Close tool

4 1.760 2392 Open 2 Boost AV

5 1.698 N/A BHA Shut Off 2 Displace well at enhanced rate

6 1.760 2465 Closed 2 Close tool

7 1.760 2392 Open 2 Boost AV for hole cleaning after Jarring

8 1.760 2871 Closed 2 Close tool

9 1.760 2407 Open 2 Boost AV / Dry Trip

10 1.760 3625 Closed Freefall Closed at surface

11 1.760 2345 Open 2 Boost AV

12 1.760 2610 Closed 2 Close tool

The Details

The WELL COMMANDER tool spent a cumulative 300 hours below the rotary table and was subjected to jarring during the third milling run,

when the BHA became stuck. The rig jarred the BHA free and thereafter dropping a ball to open the WELL COMMANDER to boost annular

velocity and clean the hole. The WELL COMMANDER tool was tripped in an additional two times and functioned a total of six times - all within

expected parameters.

Questions? Well be glad to answer them.

If youd like to know more about the WELL COMMANDER valve or MAGNOSTAR HD magnet and how its performing for our other customers,

please call the M-I SWACO office nearest you.

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- ASME Paper by Sparks - The Influence of Tension, Pressure & WeightDocument9 pagesASME Paper by Sparks - The Influence of Tension, Pressure & Weightice_PLPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Holliday Steam Well DesignDocument8 pagesHolliday Steam Well Designice_PLPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- MINE5008 Responsible Mining Semester 1 2023 Kalgoorlie CampusDocument13 pagesMINE5008 Responsible Mining Semester 1 2023 Kalgoorlie Campusice_PLPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- History of OCTGDocument7 pagesHistory of OCTGice_PLPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Deformation of Drill Pipe Held in Rotary SlipsDocument20 pagesDeformation of Drill Pipe Held in Rotary Slipsice_PL100% (1)

- Hydra Jar ProceduresDocument3 pagesHydra Jar Proceduresice_PLPas encore d'évaluation

- Doris: Dropped Objects Register of Incidents & StatisticsDocument15 pagesDoris: Dropped Objects Register of Incidents & Statisticsice_PLPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Powerdrive x6Document7 pagesPowerdrive x6ice_PLPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hydra Jar Accelerator AP CsDocument1 pageHydra Jar Accelerator AP Csice_PLPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Well CommanderDocument8 pagesWell Commanderice_PLPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- SLB PosterDocument3 pagesSLB Posterice_PL100% (2)

- Powerpak HandbookDocument0 pagePowerpak HandbookPehr HedströmPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Ton MilesDocument4 pagesTon Milesice_PLPas encore d'évaluation

- Hooke's Law Spring ConstantDocument4 pagesHooke's Law Spring Constantice_PLPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Spe 159894 Pa P PDFDocument0 pageSpe 159894 Pa P PDFice_PLPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Spe 165931 Pa P PDFDocument0 pageSpe 165931 Pa P PDFice_PLPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Spe 165931 Pa P PDFDocument0 pageSpe 165931 Pa P PDFice_PLPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Hooke's Law Spring ConstantDocument4 pagesHooke's Law Spring Constantice_PLPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Measuring Guide For New CoverallsDocument1 pageMeasuring Guide For New Coverallsice_PLPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Basics: Define The Task of Having Braking System in A VehicleDocument27 pagesBasics: Define The Task of Having Braking System in A VehiclearupPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Channel Tables1Document17 pagesChannel Tables1erajayagrawalPas encore d'évaluation

- Low Cost Building ConstructionDocument15 pagesLow Cost Building ConstructionAtta RehmanPas encore d'évaluation

- The Art of Blues SolosDocument51 pagesThe Art of Blues SolosEnrique Maldonado100% (8)

- Rebar Coupler: Barlock S/CA-Series CouplersDocument1 pageRebar Coupler: Barlock S/CA-Series CouplersHamza AldaeefPas encore d'évaluation

- Squirrel Cage Induction Motor Preventive MaintenaceDocument6 pagesSquirrel Cage Induction Motor Preventive MaintenaceNishantPareekPas encore d'évaluation

- Final ExamSOMFinal 2016 FinalDocument11 pagesFinal ExamSOMFinal 2016 Finalkhalil alhatabPas encore d'évaluation

- BluetoothDocument28 pagesBluetoothMilind GoratelaPas encore d'évaluation

- Proceedings of SpieDocument7 pagesProceedings of SpieNintoku82Pas encore d'évaluation

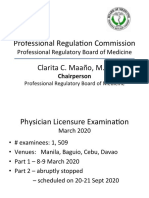

- Professional Regula/on Commission: Clarita C. Maaño, M.DDocument31 pagesProfessional Regula/on Commission: Clarita C. Maaño, M.Dmiguel triggartPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- STM - Welding BookDocument5 pagesSTM - Welding BookAlvin MoollenPas encore d'évaluation

- Asphalt Plant Technical SpecificationsDocument5 pagesAsphalt Plant Technical SpecificationsEljoy AgsamosamPas encore d'évaluation

- Securitron M38 Data SheetDocument1 pageSecuritron M38 Data SheetJMAC SupplyPas encore d'évaluation

- Methodical Pointing For Work of Students On Practical EmploymentDocument32 pagesMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavPas encore d'évaluation

- PFI High Flow Series Single Cartridge Filter Housing For CleaningDocument2 pagesPFI High Flow Series Single Cartridge Filter Housing For Cleaningbennypartono407Pas encore d'évaluation

- Unit 1Document3 pagesUnit 1beharenbPas encore d'évaluation

- 1.1. Evolution of Cloud ComputingDocument31 pages1.1. Evolution of Cloud Computing19epci022 Prem Kumaar RPas encore d'évaluation

- DC Servo MotorDocument6 pagesDC Servo MotortaindiPas encore d'évaluation

- Departmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedDocument37 pagesDepartmental Costing and Cost Allocation: Costs-The Relationship Between Costs and The Department Being AnalyzedGeorgina AlpertPas encore d'évaluation

- Google App EngineDocument5 pagesGoogle App EngineDinesh MudirajPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Embedded Systems DesignDocument576 pagesEmbedded Systems Designnad_chadi8816100% (4)

- Exp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.Document7 pagesExp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.AbhishEk SinghPas encore d'évaluation

- Innovations in Land AdministrationDocument66 pagesInnovations in Land AdministrationSanjawe KbPas encore d'évaluation

- Information Security Chapter 1Document44 pagesInformation Security Chapter 1bscitsemvPas encore d'évaluation

- CHAPTER 3 Social Responsibility and EthicsDocument54 pagesCHAPTER 3 Social Responsibility and EthicsSantiya Subramaniam100% (4)

- Evaluating Project Scheduling and Due Assignment Procedures An Experimental AnalysisDocument19 pagesEvaluating Project Scheduling and Due Assignment Procedures An Experimental AnalysisJunior Adan Enriquez CabezudoPas encore d'évaluation

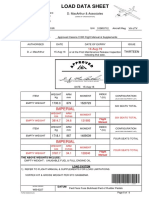

- Load Data Sheet: ImperialDocument3 pagesLoad Data Sheet: ImperialLaurean Cub BlankPas encore d'évaluation

- 48 Volt Battery ChargerDocument5 pages48 Volt Battery ChargerpradeeepgargPas encore d'évaluation

- Sustainable Urban Mobility Final ReportDocument141 pagesSustainable Urban Mobility Final ReportMaria ClapaPas encore d'évaluation

- Government of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Document2 pagesGovernment of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Satyaki Prasad MaitiPas encore d'évaluation

- The Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadD'EverandThe Art of Fear: Why Conquering Fear Won't Work and What to Do InsteadÉvaluation : 4 sur 5 étoiles4/5 (10)

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerD'EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerÉvaluation : 4 sur 5 étoiles4/5 (5)

- Higher Love: Climbing and Skiing the Seven SummitsD'EverandHigher Love: Climbing and Skiing the Seven SummitsÉvaluation : 5 sur 5 étoiles5/5 (5)