Académique Documents

Professionnel Documents

Culture Documents

Introduction of Steel

Transféré par

Ahmad MalickCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Introduction of Steel

Transféré par

Ahmad MalickDroits d'auteur :

Formats disponibles

Introduction of steel:

Steel: Steel is an alloy of iron and carbon Ores of iron: 1) 2) 3) 4) Magnetite Fe3O4 ( 70-75% Iron) Hematite Fe2O3 (70 % Iron) Iron Pyrite FeS2 ( 45% Iron) Siderite FeCo3 (40% Iron) Extraction Process: Oxides of Iron + Flux Pig Iron +Water Billets (Ingots):

Date: 29-01-2014

2300oC Coke

Pig Iron +Water Steel (Molten Form) Billets

A steel billet is a piece of steel that is in the form of a bar or rectangle. Billets are produced by a process called casting but are of no use until their shaped into more functional sizes and shapes.

75 mm

100mm

Grade 40

Grade 60

100 mm

75 mm

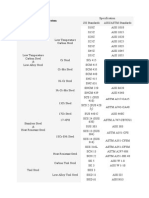

Types Of Steel: Type of steel Low Carbon Medium Carbon High Carbon Ultra High Carbon Mild steel Carbon Content (%) 0.05-0.29 0.3-0.59 0.6-0.99 1-2 0.16-0.29

Note: With the increase in Carbon content strength of material increases while ductility decreases. Composition of Mild steel: Element Carbon Phosphorus Sulphur Maximum %age 0.29 0.06 0.06

Manufacturing Process of Steel: 1) Bessemer Process 2) Blast Furnace 3) Electric Arc Furnace

Electric Arc Furnace:

An electric arc furnace (EAF) is a furnace that heats charged material by means of an electric arc

Electric Arc Process

Basic Layout of EAF:

2) Blast Furnace Method (From Pig Iron)

Step1:

Blast furnace, a vertical shaft furnace that produces liquid metals by the reaction of a flow of air

introduced under pressure into the bottom of the furnace with a mixture of metallic ore, coke, and flux fed into the top. Blast furnaces are used to produce pig iron from iron ore for subsequent processing into steel, and they are also employed in processing lead, copper, and other metals. Rapid combustion is maintained by the current of air under pressure. Blast furnaces produce pig iron from iron ore by the reducing action of carbon (supplied as coke) at a high temperature in the presence of a fluxing agent such as limestone. Ironmaking blast furnaces consist of several zones: a crucible-shaped hearth at the bottom of the furnace; an intermediate zone called a bosh between the hearth and the stack; a vertical shaft (the stack) that extends from

the bosh to the top of the furnace; and the furnace top, which contains a mechanism for charging the furnace. The furnace charge, or burden, of iron-bearing materials (e.g., iron-ore pellets and sinter), coke, and flux (e.g., limestone) descends through the shaft, where it is preheated and reacts with ascending reducing gases to produce liquid iron and slag that accumulate in the hearth. Air that has been preheated to temperatures from 900 to 1,250 C (1,650 and 2,300 F), together with injected fuel such as oil or natural gas, is blown into the furnace through multiple tuyeres (nozzles) located around the circumference of the furnace near the top of the hearth; these nozzles may number from 12 to as many as 40 on large furnaces. The preheated air is, in turn, supplied from a bustle pipe, a large-diameter pipe encircling the furnace. The preheated air reacts vigorously with the preheated coke, resulting in both the formation of the reducing gas (carbon monoxide) that rises through the furnace, and a very high temperature of about 1,650 C (3,000 F) that produces the liquid iron and slag. The stack is kept full with alternating layers of coke, ore, and limestone admitted at the top during continuous operation. Coke is ignited at the bottom and burned rapidly with the forced air from the tuyeres. The iron oxides in the ore are chemically reduced to molten iron by carbon and carbon monoxide from the coke. The slag formed consists of the limestone flux, ash from the coke, and substances formed by the reaction of impurities in the ore with the flux; it floats in a molten state on the top of the molten iron. Hot gases rise from the combustion zone, heating fresh material in the stack and then passing out through ducts near the top of the furnace.

C + O2 Co2 + C Fe2O3 + 3Co

Co2 2Co 2Fe + 3Co2

Step2: Production of steel from Pig Iron:

Mild steel is manufactured from that pig iron by removing the carbon content using any of the process, the reaction would be as following. Pig iron + Admixtures Steel molten Molten Steel Billets

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- AWS Code LibraryDocument2 pagesAWS Code Libraryyoonchankim0911Pas encore d'évaluation

- Ferrous Alloys Metallurgy ReviewDocument80 pagesFerrous Alloys Metallurgy ReviewAlvin Garcia PalancaPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Thermodynamics of Secondary Steel MakingDocument14 pagesThermodynamics of Secondary Steel MakingPinPas encore d'évaluation

- Equivalent Material PDFDocument49 pagesEquivalent Material PDFhirenkumar patel90% (21)

- TIG Amp Calculator Chart for Mild Steel & Stainless SteelDocument2 pagesTIG Amp Calculator Chart for Mild Steel & Stainless SteelEnrico959Pas encore d'évaluation

- Materials For Engineering Unit II 20ME11T DTE KarnataksDocument18 pagesMaterials For Engineering Unit II 20ME11T DTE KarnataksThanmay JS100% (4)

- Equivalent SteelDocument2 pagesEquivalent SteelJustin MorrisPas encore d'évaluation

- ASTM Grades Explained for Pipes, Fittings, Flanges & MoreDocument4 pagesASTM Grades Explained for Pipes, Fittings, Flanges & Moremohan babuPas encore d'évaluation

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirPas encore d'évaluation

- Diameters and Pitches for Tap DrillsDocument2 pagesDiameters and Pitches for Tap Drillsemerson.mineiro100% (1)

- Engineering Engineering Engineering Engineering Standard Standard Standard StandardDocument12 pagesEngineering Engineering Engineering Engineering Standard Standard Standard StandardgustavoPas encore d'évaluation

- Códigos de SoldaduraDocument16 pagesCódigos de SoldadurarenemolinaledezmaPas encore d'évaluation

- Cast Irons: MSE 206-Materials Characterization I Lecture-6Document21 pagesCast Irons: MSE 206-Materials Characterization I Lecture-6Jose Luis Valin RiveraPas encore d'évaluation

- UntitledDocument131 pagesUntitledCristhian Tarqui DuranPas encore d'évaluation

- Spring GradesDocument2 pagesSpring GradesReddy Sadhana0% (1)

- PC5300NC5330 MetricDocument20 pagesPC5300NC5330 MetricSakthi VelPas encore d'évaluation

- Marten SiteDocument2 pagesMarten SiteaqhammamPas encore d'évaluation

- Customer Contact ListDocument7 pagesCustomer Contact ListListonPas encore d'évaluation

- Test PDFDocument1 pageTest PDFKapten 29Pas encore d'évaluation

- Mechanical Properties of Metals and Metal AlloysDocument6 pagesMechanical Properties of Metals and Metal AlloysHakan EzcanPas encore d'évaluation

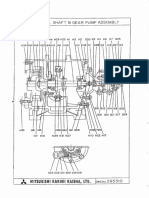

- Mitsubishi SJ400 Horizontal Shaft Mitsubishi SeparatorDocument3 pagesMitsubishi SJ400 Horizontal Shaft Mitsubishi SeparatorSergei KurpishPas encore d'évaluation

- Training Program - SudanDocument4 pagesTraining Program - SudanKhalid HafezPas encore d'évaluation

- T26u PDFDocument1 pageT26u PDFDominicPas encore d'évaluation

- Electrical Motor Workstation Drawing v5Document8 pagesElectrical Motor Workstation Drawing v5Winston NoelPas encore d'évaluation

- DAILY WELDING INSPECTION REPORTDocument1 pageDAILY WELDING INSPECTION REPORTBWQPas encore d'évaluation

- Universal WPS for pipe to plate fillet weldingDocument1 pageUniversal WPS for pipe to plate fillet weldingIbrahim shaikPas encore d'évaluation

- Metalurgi LasDocument23 pagesMetalurgi Lasapepglory8Pas encore d'évaluation

- NumberinghistoryDocument503 pagesNumberinghistoryMoraru DanielPas encore d'évaluation

- JIS DIN ASTM Steel, Alloy, Cast Iron SpecificationsDocument1 pageJIS DIN ASTM Steel, Alloy, Cast Iron SpecificationsBao Duy NguyenPas encore d'évaluation