Académique Documents

Professionnel Documents

Culture Documents

HP Case

Transféré par

Juan Camilo ZarrukDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

HP Case

Transféré par

Juan Camilo ZarrukDroits d'auteur :

Formats disponibles

Hewlett Packard Case

1. What are the causes of the inventory/service crisis that Hewlett-Packard faces? Develop a relatively comprehensive list. The company had a wide offering of printer models and options. Besides this, the different models needed to be customized for each of the different geographies. Demand was difficult to forecast and the Productions individual forecasts were not accurate, leading to excess inventory of some models while at the same time having shortage of others. There was no consensus around the cost of capital used to calculate the holding cost of the inventory, nor the target service level. Variability in these key components of the EOQ would lead to very different safety stock levels. The company organizations (engineering, production, distribution and marketing) had a series of misaligned incentives and organizational problems (to be addressed in the next question)-

2. From an organizational perspective, what problems does Hewlwtt-Packard face? The Vancouvers management group was pulled from different HP divisions with different practices, making difficult to have a unified culture The different organizations objectives were not aligned. People cared about their individual organization and P&L, instead of thinking about the organization as a whole: o Vancouver plant had a policy of not having any finished goods at the factory, posing a perverse incentive of shipping products to Distribution Centers (even if they were not needed) o DCs main performance measures were based on filling as much orders as possible, and considered inventory levels as a secondary measure o DCs were meant to be considered warehouses with no responsibility or support for the manufacturing processes 3. Evaluate the air freight alternative suggested in the case. What are the advantages and disadvantages of this alternative over the current approach? Advantages: o Lower response time to adapt to demand changes o Lower inventory Disadvantages: o Higher cost of the freight o Having less inventory would mean a lower reaction capacity to immediate orders

4. Put yourself in the shoes of Engineering (R&D). What dont you like about this proposal? What do you like?

Dont like: o A new generic printer will have to be developed. o Theres a big challenge in the design of this printer, because it has to be able to deliver high quality (to keep up with competition), but at the same time, be modular enough to derive in different models. Like: o After focusing in the design of a very good vanilla-box, the development of new models will be easier

5. Put yourself in the shoes of the Distribution Center. Answer the questions in 4). Dont like: o The organization will have to adapt from a Warehouse culture to a Production culture. o More personal will be required at the DCs and they will have to be trained, in the final assembly process. Like: o Indicators of customer satisfaction will improve due to fewer stockouts: Line Item Fill Rate and Order Fill Rate would be increased. o DCs will be able to react faster to changes in customers preferences and demand.

6. Put yourself in the shoes of Material Management (whole organization). Asses the pros and cons of this proposal for HP as a whole. Pros: o Production of the vanilla-box printer and postponement of the localization will allow to better forecasts because aggregate demand is less variable than individual demand. o The pooling system of the generic printers will reduce the inventory levels because the vanilla-box can be used to fill orders of different models, and inventory leftovers will only consist of the power supply, manual and other specific (minor) parts of each model. o Inventories can be reduced even further if the vanilla-boxes are shipped by sea, but the specific (smaller and lighter) parts are shipped by air. Cons: o Organizational changes will be required, specially on the DCs. o Investment will be required on the DCs side, to build the production facilities required for localization, and to hire new teams in charge of doing this task. o Overall production per printer will be more costly, because the economies of scale of producing many printers in the same location are lost (although only for the part of the product not considered generic).

o Company might lose control of the quality of the final products, as a result of having them finalized in different locations.

Vous aimerez peut-être aussi

- Hewlett Packard Compay Network Printer Design For UniversalityDocument7 pagesHewlett Packard Compay Network Printer Design For UniversalityNantha KumarPas encore d'évaluation

- KLF Electronics QuestionDocument5 pagesKLF Electronics QuestionSumit GuptaPas encore d'évaluation

- LeClub Wine Inventory OptimizationDocument2 pagesLeClub Wine Inventory OptimizationCharles Wetherbee100% (4)

- HP Deskjet Supply ChainDocument5 pagesHP Deskjet Supply ChainAnand1832Pas encore d'évaluation

- Case Report 4 - HP Deskjet PrintersDocument3 pagesCase Report 4 - HP Deskjet PrintersnicktimmonsPas encore d'évaluation

- Whelan PharmaceuticalsDocument1 pageWhelan PharmaceuticalsHe QIu0% (1)

- 01 - Mango Financial Management Essentials (232p)Document232 pages01 - Mango Financial Management Essentials (232p)Book File100% (6)

- Hewlett Packard DeskJet Supply ChainDocument13 pagesHewlett Packard DeskJet Supply ChainMaria Cassandra O. RamosPas encore d'évaluation

- HP Deskjet Case SummaryDocument1 pageHP Deskjet Case SummaryManish ParmarPas encore d'évaluation

- Eli LDocument6 pagesEli LKaruna GaranPas encore d'évaluation

- Assignment 3 HP DeskJet-7Document4 pagesAssignment 3 HP DeskJet-7GinanjarSaputraPas encore d'évaluation

- Case SportsDocument2 pagesCase SportsMickey Haldia50% (2)

- Frito Lay PresDocument8 pagesFrito Lay PresAmber LiuPas encore d'évaluation

- Case Analysis Worksheet: Define The ProblemDocument2 pagesCase Analysis Worksheet: Define The Problemannie67% (3)

- Industry Analysis Case Study - STRAMA Group 5Document19 pagesIndustry Analysis Case Study - STRAMA Group 5HilaryPas encore d'évaluation

- SCM-2013-Coordinated Product and Supply Chain Design-1.0Document51 pagesSCM-2013-Coordinated Product and Supply Chain Design-1.0Hrishikesh MahapatraPas encore d'évaluation

- HP Case RevisedDocument6 pagesHP Case RevisedKenneth ChuaPas encore d'évaluation

- Hewlett-Packard DeskJet Supply ChainDocument13 pagesHewlett-Packard DeskJet Supply ChainAshutosh Sharma0% (1)

- HP CaseDocument5 pagesHP CaseDara Fallahi100% (1)

- HP DeskJet - Consolidated (Iosif)Document9 pagesHP DeskJet - Consolidated (Iosif)Fares BelghithPas encore d'évaluation

- Hewlett Packard Case StudyDocument6 pagesHewlett Packard Case Studyvikash121100% (1)

- HP DeskJet Case ReportDocument9 pagesHP DeskJet Case ReportSimon Nguyen100% (2)

- HP DeskJet Report POM 20150413Document5 pagesHP DeskJet Report POM 20150413Carolina DelgadoPas encore d'évaluation

- OM DeskJet SupplyChainDocument3 pagesOM DeskJet SupplyChainIrphan WijayaPas encore d'évaluation

- HP DeskJet Printer Supply Chain - Group 10 - SecFDocument11 pagesHP DeskJet Printer Supply Chain - Group 10 - SecFshahzad2689Pas encore d'évaluation

- Case Overview HP Chap.11Document4 pagesCase Overview HP Chap.11baitusluckmanhakim100% (1)

- Assignment 3 - Predicting Consumer Tastes With Big Data at GAPDocument2 pagesAssignment 3 - Predicting Consumer Tastes With Big Data at GAPPRADNYA SHIVSHARANPas encore d'évaluation

- OM Hewlett Packard CaseDocument10 pagesOM Hewlett Packard Casematt_dellinger12Pas encore d'évaluation

- Group 9 - Section E - HPDocument12 pagesGroup 9 - Section E - HPShubham ShuklaPas encore d'évaluation

- HP Deskjet - Supply ChainDocument15 pagesHP Deskjet - Supply Chainsaurabhku12100% (4)

- Operations Management: Hewlett-Packard: Deskjet Printer Supply ChainDocument6 pagesOperations Management: Hewlett-Packard: Deskjet Printer Supply ChainAnand1832Pas encore d'évaluation

- HP Deskjet Printer Supply Chain Case Group HomeworkDocument1 pageHP Deskjet Printer Supply Chain Case Group Homeworklord vicoPas encore d'évaluation

- HP ReportDocument8 pagesHP ReportranukhadePas encore d'évaluation

- HP Case AnalysisDocument8 pagesHP Case AnalysisSuman PradhanPas encore d'évaluation

- HP - Supplying The DeskJet Printer in EuropeDocument4 pagesHP - Supplying The DeskJet Printer in Europeroberto0% (1)

- Sports Obermeyer WACCDocument10 pagesSports Obermeyer WACCAyesha TahirPas encore d'évaluation

- Final Merger and CompaqDocument15 pagesFinal Merger and CompaqmonuPas encore d'évaluation

- Steel Works IncDocument12 pagesSteel Works Incsandeep_chanda_2Pas encore d'évaluation

- Question 3. What Recommendations Would You Make To Rolfs in Order To Address The Both Near-And Longer-Term Issues? AnswerDocument1 pageQuestion 3. What Recommendations Would You Make To Rolfs in Order To Address The Both Near-And Longer-Term Issues? AnswerAchal GoelPas encore d'évaluation

- Sport Obermeyer PaperDocument10 pagesSport Obermeyer PaperDarkhorse MbaorgrePas encore d'évaluation

- Le Club Francais CaseDocument8 pagesLe Club Francais CaseTushar GoelPas encore d'évaluation

- Hewlett-Packard Co - DeskJet Printer Supply Chain (B)Document2 pagesHewlett-Packard Co - DeskJet Printer Supply Chain (B)Shashan Shashan MukherjeePas encore d'évaluation

- (C7) HP Deskjet Printer Supply ChainDocument26 pages(C7) HP Deskjet Printer Supply Chain06818908d100% (1)

- 02 Kitty-Hawk Case NotesDocument2 pages02 Kitty-Hawk Case NotesGary Putra RizaldyPas encore d'évaluation

- Case Study of Scientific GlassDocument6 pagesCase Study of Scientific GlassT/ROXPas encore d'évaluation

- Beer GameDocument2 pagesBeer Gameemuro001Pas encore d'évaluation

- American Connector CompanyDocument9 pagesAmerican Connector CompanyAntariksha GangulyPas encore d'évaluation

- 2017 Spring Case Study Questions SCM 479 NewDocument4 pages2017 Spring Case Study Questions SCM 479 NewSaddam AwanPas encore d'évaluation

- Barilla Spa (Hbs 9-694-046) - Case Study Submission: Executive SummaryDocument3 pagesBarilla Spa (Hbs 9-694-046) - Case Study Submission: Executive SummaryRichaPas encore d'évaluation

- Sport Obermeyer: Written Analysis of CaseDocument9 pagesSport Obermeyer: Written Analysis of CaseIzzahIkramIllahiPas encore d'évaluation

- HP Compaq Valuation: Assignment 2Document4 pagesHP Compaq Valuation: Assignment 2UmeshPas encore d'évaluation

- (C10) Solectron From Contract Manufacturer To Global Supply Chain Integrator2009Document48 pages(C10) Solectron From Contract Manufacturer To Global Supply Chain Integrator2009Gaurav AroraPas encore d'évaluation

- 07 Hewlett PackardDocument16 pages07 Hewlett Packard9874567Pas encore d'évaluation

- Plaza, The Logistics Park of ZaragozaDocument11 pagesPlaza, The Logistics Park of ZaragozaRahulTiwariPas encore d'évaluation

- Barilla SpA NotesDocument7 pagesBarilla SpA NotesArvie Camille VIllavicencioPas encore d'évaluation

- Case Write-Up: Grocery Gateway: Customer Delivery OperationsDocument4 pagesCase Write-Up: Grocery Gateway: Customer Delivery OperationsCHARANJEET SINGHPas encore d'évaluation

- Genentech Answer 2Document1 pageGenentech Answer 2Navnee RajputPas encore d'évaluation

- Sealed Air Case CommentsDocument5 pagesSealed Air Case CommentsChristopher Ward100% (1)

- All ChaptersDocument612 pagesAll ChaptersMarco ChanPas encore d'évaluation

- HP: Supplying The Desk Jet Printer To EuropeDocument20 pagesHP: Supplying The Desk Jet Printer To EuropeFez Research Laboratory95% (19)

- Report HP Version 2.0Document19 pagesReport HP Version 2.0Sutri LastyoPas encore d'évaluation

- Postponement Teaching NoteDocument20 pagesPostponement Teaching NoteZakiah Abu KasimPas encore d'évaluation

- VKG - Bill 392Document3 pagesVKG - Bill 392salesPas encore d'évaluation

- Chapter Sixteen: Personal Selling and Sales PromotionDocument42 pagesChapter Sixteen: Personal Selling and Sales PromotionRashmeet AroraPas encore d'évaluation

- Income Tax AssignmentDocument5 pagesIncome Tax AssignmentsasmallulusitakantPas encore d'évaluation

- Prudential NormsDocument17 pagesPrudential NormsGuru RaghuPas encore d'évaluation

- Portillo's Inc.: United States Securities and Exchange Commission Form S-1 Registration StatementDocument254 pagesPortillo's Inc.: United States Securities and Exchange Commission Form S-1 Registration StatementAnn DwyerPas encore d'évaluation

- Slide1 Slide 2 What Is Competition ActDocument2 pagesSlide1 Slide 2 What Is Competition Actrobin hoodPas encore d'évaluation

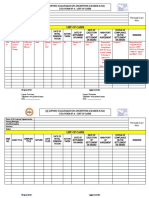

- XXXXXX: Principal Cardholder InformationDocument1 pageXXXXXX: Principal Cardholder InformationBoy GuapoPas encore d'évaluation

- Domino's Pizza:: Writing The Recipe For Digital MasteryDocument12 pagesDomino's Pizza:: Writing The Recipe For Digital MasteryHarsh Vardhan AgrawalPas encore d'évaluation

- Cha4 Econ101 GLDocument29 pagesCha4 Econ101 GLGidisa LachisaPas encore d'évaluation

- FORM 7 A List of CasesDocument2 pagesFORM 7 A List of CasesGianPas encore d'évaluation

- ANZ Bank Analysis: Name: Lucky Steven F Noris ID: 11900055Document11 pagesANZ Bank Analysis: Name: Lucky Steven F Noris ID: 11900055Ein LuckyPas encore d'évaluation

- EXAM Intermediate Accounting 2Document8 pagesEXAM Intermediate Accounting 2Grace100% (1)

- Problems On Redemption of Pref SharesDocument7 pagesProblems On Redemption of Pref SharesYashitha CaverammaPas encore d'évaluation

- The Impact of Stock Market On Indian Economy Introduction: Conference PaperDocument11 pagesThe Impact of Stock Market On Indian Economy Introduction: Conference PaperfunnyPas encore d'évaluation

- Business Plan Questions-3Document3 pagesBusiness Plan Questions-3Ibrahim OlaidePas encore d'évaluation

- Risk, Return, and The Security Market Line: B. Unsystematic C. D. Unsystematic E. FDocument15 pagesRisk, Return, and The Security Market Line: B. Unsystematic C. D. Unsystematic E. FTú Anh Nguyễn ThịPas encore d'évaluation

- Materials Managements An Overview: Itm 4 (Material Technology Management and Quality Control)Document10 pagesMaterials Managements An Overview: Itm 4 (Material Technology Management and Quality Control)Fatima Mae NadangaPas encore d'évaluation

- Guidance For Outward International Swift Payment Off201117nwiDocument4 pagesGuidance For Outward International Swift Payment Off201117nwijamalazoz05Pas encore d'évaluation

- vAJ1-Graham Formula Spreadsheet FreeDocument2 pagesvAJ1-Graham Formula Spreadsheet FreeCm ShegrafPas encore d'évaluation

- WWW - Edutap.co - In: Bills of Exchange Accounting Treatment For Bills of ExchangeDocument20 pagesWWW - Edutap.co - In: Bills of Exchange Accounting Treatment For Bills of Exchangeshaifali pandeyPas encore d'évaluation

- Inventory Systems: Review of Inventory Systems Perpetual Inventory System Periodic Inventory SystemDocument11 pagesInventory Systems: Review of Inventory Systems Perpetual Inventory System Periodic Inventory SystemDemi OrocPas encore d'évaluation

- Nigeria's Business Environment: Issues Challenges and ProspectsDocument7 pagesNigeria's Business Environment: Issues Challenges and ProspectsShólànké Ezekiel ShówúnmiPas encore d'évaluation

- EPC Is Here To StayDocument8 pagesEPC Is Here To Stayamitkjha.mba5211Pas encore d'évaluation

- NICSI Process Review - V1Document22 pagesNICSI Process Review - V1Aarzoo DewanPas encore d'évaluation

- Chapter 11: Depreciation, Impairments and DepletionDocument24 pagesChapter 11: Depreciation, Impairments and DepletionRahat KhanPas encore d'évaluation

- MGT Chap 6Document5 pagesMGT Chap 6tomPas encore d'évaluation

- CIR v. Seagate Technology (Philippines), G.R. No. 153866, Feb. 11, 2005Document22 pagesCIR v. Seagate Technology (Philippines), G.R. No. 153866, Feb. 11, 2005samaral bentesinkoPas encore d'évaluation

- Cheque Collection PolicyDocument9 pagesCheque Collection Policynitu kumariPas encore d'évaluation