Académique Documents

Professionnel Documents

Culture Documents

Polybond 3150 TDS

Transféré par

jai_dceCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Polybond 3150 TDS

Transféré par

jai_dceDroits d'auteur :

Formats disponibles

www.chemtura.

com

Effecti ve: 06.26.2008

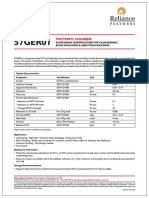

Polybond 3150 is a chemically modified polyolefin.

Chemical Structure

Copyright 2007 Chemtura Corporation. All rights reserved Page 1

Composition: Maleic anhydride modified homopolymer polypropylene

Features

Chemical coupling agent for glass, mica, and talc reinforced polypropylene giving enhanced physical and thermal

properties.

Compatibilizer for blends such as polypropylene/polyamide and polypropylene/EVOH to improve processability and

mechanical properties.

Processing on any conventional thermoplastic processing equipment is feasible.

Stabilized for both processing and long-term heat aging resistance.

Typical Physical Properties

Appearance Pellets

Melt Flow Rate (230/2.16) 50.0 g/10 min. (ASTM D-1238)

Density @ 23C 0.91 g/cc (ASTM D-792)

Melting Point 157C (DSC)

Maleic Anhydride Level 0.5 weight %

Properties in 30% Glass-filled Polypropylene

Increase in Properties due to Addition of Polybond 3150

PROPERTY 1% PB 3150 2% PB 3150 3% PB 3150 5% PB 3150

Tensile Strength 17% 21% 23% 22%

Flexural Strength 18% 21% 22% 22%

Izod Impact

Unnotched 64% 86% 86% 103%

Notched 0% 55% 68% 66%

Generation of above data was via twin screw extrusion. Polybond addition level is based on total weight of composite. Glass

type is PPG 3242 1/8.

Suggested Processing Temperatures

Extrusion and Injection Molding

Feed Zone 190C

Middle Zone 200C

Front Zone 205C

Die/Nozzle 210C

Melt Temp 205C - 220C

Storage and Handling Precautions

Keep Polybond 3150 dry prior to processing since it is hygroscopic in nature. Tie liners of open gaylords when not in use to

prevent exposure to moisture. If exposure occurs, Polybond 3150 can be dried in a hopper dryer or oven for a few hours at

105C to remove moisture.

A slight pungent odor is normal during processing of Polybond 3150. Purge equipment with polypropylene before and after

running Polybond 3150.

For additional handling information, please see the Material Safety Data Sheet.

Polybond

3150

Polymer Modifier

The information contained herein relates to a specific Chemtura product and its use, and is based on information available as of the date hereof. Additional

information relating to the product can be obtained from the pertinent Material Safety Data Sheets. Nothing in this Technical Data Sheet shall be construed to

modify any of Chemtura standard terms and conditions of sale under which the product is sold by Chemtura. NOTHING IN THIS TECHNICAL DATA SHEET

SHALL BE CONSTRUED TO CONSTITUTE A REPRESENTATION OR WARRANTY, EXPRESS OR IMPLIED, REGARDING THE PRODUCTS CHARSCTERISTICS,

USE, QUALITY, SAFETY, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Nothing contained herein shall constitute permission or

recommendation to practice any intellectual property without the permission of the owner.

Chemtura and the Chemtura logo are trademarks of Chemtura Corporation or one of its subsidiaries.

Copyright 2007 Chemtura Corporation. All rights reserved.

Vous aimerez peut-être aussi

- E&i QC Inspector Resum and DocumentsDocument24 pagesE&i QC Inspector Resum and DocumentsIrfan 786pakPas encore d'évaluation

- Taewoo Kim Et Al. v. Jump TradingDocument44 pagesTaewoo Kim Et Al. v. Jump TradingCrainsChicagoBusiness100% (1)

- Merchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersDocument43 pagesMerchant Accounts Are Bank Accounts That Allow Your Business To Accept Card Payments From CustomersRohit Kumar Baghel100% (1)

- Smarajit Ghosh - Control Systems - Theory and Applications-Pearson (2006) PDFDocument629 pagesSmarajit Ghosh - Control Systems - Theory and Applications-Pearson (2006) PDFaggarwalakanksha100% (2)

- Bottles, Preforms and Closures: A Design Guide for PET PackagingD'EverandBottles, Preforms and Closures: A Design Guide for PET PackagingÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Form IEPF 2 - 2012 2013FDocument2 350 pagesForm IEPF 2 - 2012 2013FYam ServínPas encore d'évaluation

- Chemicals Zetag DATA Powder Magnafloc 155 - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc 155 - 0410PromagEnviro.comPas encore d'évaluation

- Checklist Code ReviewDocument2 pagesChecklist Code ReviewTrang Đỗ Thu100% (1)

- BTL Marketing CompanyDocument30 pagesBTL Marketing Companypradip_kumarPas encore d'évaluation

- Total Quality Process Control for Injection MoldingD'EverandTotal Quality Process Control for Injection MoldingÉvaluation : 5 sur 5 étoiles5/5 (1)

- Chemicals Zetag DATA Powder Magnafloc 5250 - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc 5250 - 0410PromagEnviro.comPas encore d'évaluation

- Atmer Anti-Fog BrochureDocument4 pagesAtmer Anti-Fog BrochureVeenu Chitty100% (1)

- TDS-Dow SPECFIL FT630 & SPECFIL FE100-EN - 20181226Document2 pagesTDS-Dow SPECFIL FT630 & SPECFIL FE100-EN - 20181226Mallampati RamakrishnaPas encore d'évaluation

- RELATIVE CLAUSES 1º Bachillerato and KeyDocument3 pagesRELATIVE CLAUSES 1º Bachillerato and Keyrapitanoroel0% (2)

- PVC 57ger01Document1 pagePVC 57ger01rajesh patelPas encore d'évaluation

- Design and Implementation of Hotel Management SystemDocument36 pagesDesign and Implementation of Hotel Management Systemaziz primbetov100% (2)

- Chemicals Zetag DATA Powder Magnafloc 919 - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc 919 - 0410PromagEnviro.comPas encore d'évaluation

- Bayflex 110-50 BMSDocument2 pagesBayflex 110-50 BMSGareth Kenworthy100% (1)

- Stepanfoam Ri 9912Document2 pagesStepanfoam Ri 9912A MahmoodPas encore d'évaluation

- Technical Data Sheet - PE Granules-BasellDocument3 pagesTechnical Data Sheet - PE Granules-Basellbtv.mylepham.208Pas encore d'évaluation

- Amercoat 3279 DatasheetDocument0 pageAmercoat 3279 Datasheetmekag94Pas encore d'évaluation

- Liquid Slilcone Rubber For Mould Making Tse 3455tDocument4 pagesLiquid Slilcone Rubber For Mould Making Tse 3455tsumit1022Pas encore d'évaluation

- Fevicol Sa 7505 M Hot Melt AdhesiveDocument1 pageFevicol Sa 7505 M Hot Melt AdhesiveYash JoshanPas encore d'évaluation

- Sylgard 160Document3 pagesSylgard 160diogocPas encore d'évaluation

- PA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66Document2 pagesPA66-RG301: Flame Retardant, 30% Glass Fiber Reinforced PA66watnaPas encore d'évaluation

- A541-Ccag Aoc Eco TekDocument2 pagesA541-Ccag Aoc Eco TekHemmingsPas encore d'évaluation

- Properties Data Sheet: HDPE - 5220BNDocument1 pageProperties Data Sheet: HDPE - 5220BNSergio Rubens Oliveira SantosPas encore d'évaluation

- Pe HD50MA180Document1 pagePe HD50MA180Suraj DavdaPas encore d'évaluation

- Sobitan MonoleateDocument2 pagesSobitan MonoleateAttique AlviPas encore d'évaluation

- Phenoline 187 Primer PDSDocument2 pagesPhenoline 187 Primer PDSVajid MadathilPas encore d'évaluation

- Xiameter 65Document2 pagesXiameter 65santi2100Pas encore d'évaluation

- Hdpe 5200B1Document1 pageHdpe 5200B1Sergio Rubens Oliveira SantosPas encore d'évaluation

- EL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingDocument2 pagesEL-Pro P440J: Polypropylene Impact Copolymer For Injection MoldingTan Chen TatPas encore d'évaluation

- Adhesives Cyanoacrylates Apollo 2150Document2 pagesAdhesives Cyanoacrylates Apollo 2150Vinaya Almane DattathreyaPas encore d'évaluation

- Desmocoll 540Document2 pagesDesmocoll 540lobocerna100% (3)

- Aircol PG 185Document2 pagesAircol PG 185carmaPas encore d'évaluation

- LM Pe 6550 (CC10036550BG) - TDSDocument2 pagesLM Pe 6550 (CC10036550BG) - TDSBogdan ShevchenkoPas encore d'évaluation

- Sika PDS E SikaPoro G-230Document3 pagesSika PDS E SikaPoro G-230lwin_oo2435Pas encore d'évaluation

- Molykote (R) in India From Project Sales Corp SMS +91-98851-49412Document339 pagesMolykote (R) in India From Project Sales Corp SMS +91-98851-49412Project Sales CorpPas encore d'évaluation

- Aircol PG 185Document2 pagesAircol PG 185nauta007Pas encore d'évaluation

- Molykote Bearing GreasesDocument4 pagesMolykote Bearing GreasesCTN2010Pas encore d'évaluation

- P740JDocument2 pagesP740JTan Chen TatPas encore d'évaluation

- 2035e - 5R (TDS)Document2 pages2035e - 5R (TDS)matwan29Pas encore d'évaluation

- Sag 10 ShowTechnicalDataSheetDocument2 pagesSag 10 ShowTechnicalDataSheetGustavo E Aguilar EPas encore d'évaluation

- Technical Data Sheet: EPIKURE™ Curing Agent 3274Document4 pagesTechnical Data Sheet: EPIKURE™ Curing Agent 3274Kelvin Allan Soler LopezPas encore d'évaluation

- P840J Feb, 09Document2 pagesP840J Feb, 09Tan Chen TatPas encore d'évaluation

- Polyethylene: For Blow Moulding & Blown Film GradeDocument1 pagePolyethylene: For Blow Moulding & Blown Film GradeRikinPas encore d'évaluation

- SOFTAK1637Document3 pagesSOFTAK1637Marco JuarezPas encore d'évaluation

- Stepanpol PS 3152Document2 pagesStepanpol PS 3152A MahmoodPas encore d'évaluation

- Molykote HP 300Document2 pagesMolykote HP 30013AngelesPas encore d'évaluation

- Hoja Técnica Lanco 1890 CDocument2 pagesHoja Técnica Lanco 1890 CBryan GavilanezPas encore d'évaluation

- Makrolon 2458Document6 pagesMakrolon 2458markcoates100% (1)

- Licocare® RBW 300 Flakes TPDocument3 pagesLicocare® RBW 300 Flakes TP王偉仲Pas encore d'évaluation

- MNZBKDJFFKJDDocument1 pageMNZBKDJFFKJDMd MinhajPas encore d'évaluation

- Alathon H5618Document2 pagesAlathon H5618Ing Ipn VbaPas encore d'évaluation

- 550FC With AC61 Data PageDocument3 pages550FC With AC61 Data PageRio de MarioPas encore d'évaluation

- LubricantDocument2 pagesLubricantbuanaPas encore d'évaluation

- P640JDocument2 pagesP640JTan Chen TatPas encore d'évaluation

- Technical Data Sheet - ISO PE LYONDELLDocument3 pagesTechnical Data Sheet - ISO PE LYONDELLNur AzizahPas encore d'évaluation

- Byk 410Document4 pagesByk 410Oswaldo Manuel Ramirez MarinPas encore d'évaluation

- TDS - Plastistrength 770 - ArkemaDocument2 pagesTDS - Plastistrength 770 - ArkemaOscar Jimenez GonzalezPas encore d'évaluation

- Sigmacover 246Document5 pagesSigmacover 246Carlos Monsalve VejarPas encore d'évaluation

- Polyflex UltrachemDocument2 pagesPolyflex UltrachemBraulio Candela NoriegaPas encore d'évaluation

- Greenflex ML60Document2 pagesGreenflex ML60Grzegorz WierzbaPas encore d'évaluation

- H5818J Feb, 09Document2 pagesH5818J Feb, 09Tan Chen TatPas encore d'évaluation

- Exceed 0015XCDocument2 pagesExceed 0015XCzhen liuPas encore d'évaluation

- Elvaloy 4170 TDS - DowDocument3 pagesElvaloy 4170 TDS - DowIngedemy EducacionPas encore d'évaluation

- H110MADocument1 pageH110MAkprsannaPas encore d'évaluation

- Lawsuit!: Reducing the Risk of Product Liability for ManufacturersD'EverandLawsuit!: Reducing the Risk of Product Liability for ManufacturersPas encore d'évaluation

- VHP Series Five P9394Gsi S5: With Esm2 and Empact Emission Control SystemDocument2 pagesVHP Series Five P9394Gsi S5: With Esm2 and Empact Emission Control SystemGabrielito PachacamaPas encore d'évaluation

- Segmentation of Qarshi Industries Private Limited PakistanDocument6 pagesSegmentation of Qarshi Industries Private Limited PakistanReader100% (1)

- RRC & RabDocument14 pagesRRC & RabSyed Waqas AhmedPas encore d'évaluation

- Statement 1680409132566Document11 pagesStatement 1680409132566úméshPas encore d'évaluation

- Tesla - Electric Railway SystemDocument3 pagesTesla - Electric Railway SystemMihai CroitoruPas encore d'évaluation

- HearstDocument16 pagesHearstapi-602711853Pas encore d'évaluation

- Unknown 31Document40 pagesUnknown 31Tina TinaPas encore d'évaluation

- Course Specifications: Fire Investigation and Failure Analysis (E901313)Document2 pagesCourse Specifications: Fire Investigation and Failure Analysis (E901313)danateoPas encore d'évaluation

- Dur MalappuramDocument114 pagesDur MalappuramSabareesh RaveendranPas encore d'évaluation

- 15-3-2020 Chapter 4 Forward Kinematics Lecture 1Document29 pages15-3-2020 Chapter 4 Forward Kinematics Lecture 1MoathPas encore d'évaluation

- CV's of M.ishtiaqDocument3 pagesCV's of M.ishtiaqishtiaqPas encore d'évaluation

- Industrial Training ReportDocument19 pagesIndustrial Training ReportKapil Prajapati33% (3)

- 1and5.microscopes, Specializedstem Cells, Homeostasis - Answer KeyDocument1 page1and5.microscopes, Specializedstem Cells, Homeostasis - Answer KeyMCarmen López CastroPas encore d'évaluation

- Real Estate (Regulation and Development) Act 2016 (RERA) CompliancesDocument15 pagesReal Estate (Regulation and Development) Act 2016 (RERA) CompliancesM S PrasadPas encore d'évaluation

- Cs09 404 Programming Paradigm (Module 1 Notes)Document24 pagesCs09 404 Programming Paradigm (Module 1 Notes)Rohith BhaskaranPas encore d'évaluation

- VERITAS NetBackup 4 (1) .5 On UnixDocument136 pagesVERITAS NetBackup 4 (1) .5 On UnixamsreekuPas encore d'évaluation

- Analysis of Mozarts k.475Document2 pagesAnalysis of Mozarts k.475ASPASIA FRAGKOUPas encore d'évaluation

- Standards Guide 1021 1407Document8 pagesStandards Guide 1021 1407Anjur SiPas encore d'évaluation

- Python PyDocument19 pagesPython Pyakhilesh kr bhagatPas encore d'évaluation

- 20171025141013chapter-3 Chi-Square-Test PDFDocument28 pages20171025141013chapter-3 Chi-Square-Test PDFNajwa WawaPas encore d'évaluation