Académique Documents

Professionnel Documents

Culture Documents

Goodafternoon One N All

Transféré par

Abhinav GoyalTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Goodafternoon One N All

Transféré par

Abhinav GoyalDroits d'auteur :

Formats disponibles

Goodafternoon one n all. My name is Abhinav Goyal and I am going to give presentation on my summer internship project at cairn india.

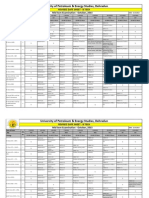

My topics for the office and field are Rig hydraulics & cementation respectively. ---------------------THE WELL FOR WHICH I DID HYDRAULIC ANALYSIS IS MANGALA 159-12-101. HERE THE RESULTS OF 81/2 HOLE SECTION ARE DICUSSED. -------------HYDRAULICS IS THE STUDY OF FLOW OF ANY FLUID AND THE VARIOUS PRESSURES LOSSES ALONG ITS COURSE OF FLOW. THE WORKFLOW FOR THE HYDRAULIC ANALYSIS COMPRISES OF .. -------------------------DRILLING FLUID IS A NON NEWTONIAN FLUID ANS ITS RHEOLOGY IS EXPRESSED BY THE THREE MODELS. AT LOW SHEAR RATES BP OVERPREDICTS THE YIELD STRESSES & PL DOESNOT INCLUDE THE YIELD STRESSES UNDERPREDICT. KEEPING THE HOLE CLEAN IS THE BASE OF HYDRAULICS OPTIMIZATION. BEING A HORIZONTAL WELL CUTTINGS TEND TO FORM STATIONARY BED WHICH NEEDS TO BE REMOVED. HERE LARSON MODEL IS USED FOR HOLE CLEANING CALCULATIONS. THE CHART SHOWS PARAMETERS WHICH EFFECT HOLE CLEANING ALONG WITH THE EXTENT WITH WHICH THEY CAN BE CONTROLLED. THE FIRST GRAPH SHOWS THE WELL INCLINATION WITH DEPTH. HERE THE MINIMUM FLOW RATE FOR THEORITCAL HOLE CLEANING IS 480 GPM AND THE MAXIMUM CONC OF CUTTINGS THAT WOULD BE IN ANNULUS WHILE TRANSPORTING WOULD BE 0.8-1% AND AT RATE ABOVE THE MINIMUM FLOW RATE NO BED HT IN THE ANNULUS. . THIS GRAPH SHOWS THAT AS WE INCREASE THE ROP MORE FLOW RATE WOULD BE NEEDED TO CLEAN THE HOLE AS MORE CUTTINGS WOULD BE GENERATED IN THE ANNULUS DETERMING FLOW REGIME IN THE OPEN HOLE SECTION IS VERY MUCH IMPORTANT AS IN SOFT FORMATIONS AND SHALLOW FORM TURBULENT FLOW CAN CAUSE WASHOUTS WHILE IT IS EFFECTIVE FOR HOLE CLENAING IN HORIZONTAL SECTION. --------------------Single Velocity at which the flow regime changes from laminar to turbulent. AS IT CAN BE SEEN THE CRITICAL VELOCITY DEPENDS ON REYNOLDS NO FLOW INDEX N AND THE ANNULAR CLEARANCE. REYNOLDS NUMBER IS MOST USED CRITERIA FOR DECIDING THE FLOW REGIME TRANSITIONS. ------------------------------PRESSURES LOSSES IN CIRCULATING SYSTEM COMPRISES OF ..

The graph shows the total pressure loss increase with flow rate the maximum flow rate that can be used in this section is 645 gpm .

As the mud in is circulation its effective density increase due to the annular pressure loss contribution and at any time it should not exceed the fracture gradient. This graph shows ecd at 550 gpm and the ecd lies well in the pressure window. In terms of circulating pressures the annulus circulating pressure should be inside the window at any time while drilling. By Hydraulics optimization we try to maximize hydraulic horse power at the bit for optimum bit and hole cleaning, maximizing the impact force of the fluid on the formation for increased rate of penetration, or providing for a compromise between the two. Bit pressure drop--- the formula explains the graph very well . for high flow rates we require more tfa and for more pressure we require less tfa. so thats why when flow rate is increasing tfa is increasing and as tfa is increasing pressure drop across bit is decreasing.

The decrease in horsepower after the peaks is due to the rapid increase in parasitic losses at high flow rates under a constant pump pressure.

prior to running the casing and cementing, the drilling fluid should be conditioned to exhibit easy-to remove properties including low fluid loss, thin rheological properties, and a flat gel profile. Displacement rates should be specified based on the maximum pumping rate that can be obtained without exerting sufficient annulus pressure (due to increased ECDs) to break-down the formation and lose returns The spacer volume should be designed to produce a minimum of 10 minutes annular surface contact time through intervals of critical cement bonding to cause turbulence near the centralizer. Turbulators can affect mud removal +- 5-10 feet from the centralizer location The amount of time for a cement slurry to become too thick to pump

Vous aimerez peut-être aussi

- Hole Cleaning: Downhole Motors in Deviated WellsDocument13 pagesHole Cleaning: Downhole Motors in Deviated WellsJairo CortesPas encore d'évaluation

- Engineering Data IndexDocument11 pagesEngineering Data IndexphaindikaPas encore d'évaluation

- Pro Tech 1 CH 3Document96 pagesPro Tech 1 CH 3weldsv100% (1)

- Gear PumpDocument58 pagesGear Pumpsgupta_615796100% (5)

- Reducing Particulate Emissions with a TurboVenturi ScrubberDocument10 pagesReducing Particulate Emissions with a TurboVenturi Scrubberjosedalceggio1955Pas encore d'évaluation

- Pump & Compressor PositioningDocument32 pagesPump & Compressor PositioningAeffandii SamawiPas encore d'évaluation

- Considerations in Designing Multiphase Flow LinesDocument8 pagesConsiderations in Designing Multiphase Flow LinesCuando la dictadura es un hecho, la Revolución es un derechoPas encore d'évaluation

- Pump Pipe PositioningDocument32 pagesPump Pipe Positioningmohdyashfi mppPas encore d'évaluation

- Hydraulic Data For Pump ApplicationDocument28 pagesHydraulic Data For Pump ApplicationedwinramonPas encore d'évaluation

- Hermetic CAN&CNFDocument20 pagesHermetic CAN&CNFkikechuPas encore d'évaluation

- AIChE method for estimating mass transfer efficiency and column sizingDocument47 pagesAIChE method for estimating mass transfer efficiency and column sizingMeera PatelPas encore d'évaluation

- ChE307-2 Gas Absorption ColumnDocument10 pagesChE307-2 Gas Absorption ColumnJudgement AslemiPas encore d'évaluation

- Selection Control ValvesDocument7 pagesSelection Control ValvesVeera Mani100% (1)

- CMPAPPP Separator Vessel and Filter Design GuideDocument18 pagesCMPAPPP Separator Vessel and Filter Design GuideJWilson73Pas encore d'évaluation

- Otc 22963Document14 pagesOtc 22963Rasheed YusufPas encore d'évaluation

- PUMP SELECTION GUIDEDocument16 pagesPUMP SELECTION GUIDErajkiran_rajPas encore d'évaluation

- D&L Equipment PO 200619 GMAX20 Cyclone IOM Manual - KrebsDocument30 pagesD&L Equipment PO 200619 GMAX20 Cyclone IOM Manual - KrebsPitt Pacheco F100% (3)

- Pages From Chapter 10 Mixing and AgitationDocument4 pagesPages From Chapter 10 Mixing and AgitationDaniel PadillaPas encore d'évaluation

- IndustrialDocument30 pagesIndustrialkcontreras_79309Pas encore d'évaluation

- Inlets-Subsonic and SupersonicDocument10 pagesInlets-Subsonic and SupersonicNoufal NSPas encore d'évaluation

- Sump Pit Design ConsiderationDocument8 pagesSump Pit Design ConsiderationkhalloudeePas encore d'évaluation

- IwsmDocument3 pagesIwsmJAN JERICHO MENTOYPas encore d'évaluation

- Module 3 Aircraft Propulsion notesDocument30 pagesModule 3 Aircraft Propulsion notesPratham M JariwalaPas encore d'évaluation

- Jet PumpDocument21 pagesJet Pumpdewidar1234100% (2)

- Mixing VarietiesDocument64 pagesMixing VarietiesManojkumarPas encore d'évaluation

- Sieve Tray ExtractorDocument12 pagesSieve Tray ExtractorCris-Anne Juangco III100% (2)

- HP237Document20 pagesHP237Asif HameedPas encore d'évaluation

- Downhole Gas Separator Performance Simulation Software Paper SWPSC 2014Document15 pagesDownhole Gas Separator Performance Simulation Software Paper SWPSC 2014angeles mendozaPas encore d'évaluation

- Surge Pressure Prediction For Running LinersDocument13 pagesSurge Pressure Prediction For Running LinersPegasus Vertex, Inc.100% (1)

- Squeeze Cementing Best PracticesDocument92 pagesSqueeze Cementing Best PracticesTariqPas encore d'évaluation

- Hydraulic Pump ContDocument15 pagesHydraulic Pump ContbmdbmdbmdPas encore d'évaluation

- Equi - Design DistillationDocument22 pagesEqui - Design Distillationjoker princePas encore d'évaluation

- Positive Displacement Pump VibrationDocument5 pagesPositive Displacement Pump Vibrationdeddy asPas encore d'évaluation

- Foam and Aerated Mud Drilling GuideDocument16 pagesFoam and Aerated Mud Drilling GuideSantiago Moromenacho RengifoPas encore d'évaluation

- Cavitation in Hydraulic TurbinesDocument7 pagesCavitation in Hydraulic TurbinesAsif HasanliPas encore d'évaluation

- Control Valve Technical Specification For Severe Service - CCIDocument5 pagesControl Valve Technical Specification For Severe Service - CCIVikas SinghPas encore d'évaluation

- 2001, Casappa, Flow DividersDocument20 pages2001, Casappa, Flow DividersVelibor KaranovićPas encore d'évaluation

- Production Technology Wellflo ProjectDocument20 pagesProduction Technology Wellflo ProjectLoh Chun LiangPas encore d'évaluation

- Selection of Gas Compressor-2Document5 pagesSelection of Gas Compressor-2dhanu_aquaPas encore d'évaluation

- Centrifugal PumpDocument13 pagesCentrifugal Pumpafr5364Pas encore d'évaluation

- 6.mud Hydraulics Fundamentals PDFDocument11 pages6.mud Hydraulics Fundamentals PDFمعلومات ممتعه mohammedPas encore d'évaluation

- KOHASA ENGINEERING LINE SIZING CALCULATIONSDocument9 pagesKOHASA ENGINEERING LINE SIZING CALCULATIONSEkundayo JohnPas encore d'évaluation

- MPP PO ItalyDocument11 pagesMPP PO ItalyUmar Ijaz KhanPas encore d'évaluation

- 5 - Bit Hydraulic OptimizationDocument31 pages5 - Bit Hydraulic OptimizationFarouq EngPas encore d'évaluation

- PumpDocument9 pagesPumpNguyen ChuyenPas encore d'évaluation

- ACFr Og ARPIl DHu 8 S Yuww 7 UYmx KBDG ZT1-hge 3 C Ebwit 00 Ua CJ KUSLDOHpi KDocument50 pagesACFr Og ARPIl DHu 8 S Yuww 7 UYmx KBDG ZT1-hge 3 C Ebwit 00 Ua CJ KUSLDOHpi KKasper JensenPas encore d'évaluation

- Unibloc Engineering ManualDocument58 pagesUnibloc Engineering ManualNoe Isaac Marmolejo MolinaPas encore d'évaluation

- Speed Breaker Electric GenerationDocument72 pagesSpeed Breaker Electric Generationparas bhogulkarPas encore d'évaluation

- ENGINEERING - Gear Pump Basics: External Gear Pump Principle of Operation & Adva N Ta G E SDocument2 pagesENGINEERING - Gear Pump Basics: External Gear Pump Principle of Operation & Adva N Ta G E SEagleMenacePas encore d'évaluation

- Reservoir Deliverability Described Reservoir DeliverabilityDocument24 pagesReservoir Deliverability Described Reservoir DeliverabilityLulav BarwaryPas encore d'évaluation

- Modern Engineering For Design of Liquid (123-224)Document102 pagesModern Engineering For Design of Liquid (123-224)Misha's Kitchen And OtherPas encore d'évaluation

- Spillways: 5.1. 5.2. General Formula 5.3. Sharp-Crested Weir 5.4. The Overflow Spillway 5.5. Broad-Crested WeirDocument17 pagesSpillways: 5.1. 5.2. General Formula 5.3. Sharp-Crested Weir 5.4. The Overflow Spillway 5.5. Broad-Crested WeirAlejandro GonzalezPas encore d'évaluation

- Minimum Stable FlowDocument3 pagesMinimum Stable Flowdk4monjurePas encore d'évaluation

- Eimco Dissairflotation MLDocument13 pagesEimco Dissairflotation MLfatima ezzahra rafiPas encore d'évaluation

- Pump Clinic 43Document3 pagesPump Clinic 43fnahas_bhPas encore d'évaluation

- Clickable List: E - HydraulicsDocument9 pagesClickable List: E - Hydraulicssaeed65Pas encore d'évaluation

- Mixing FundaDocument19 pagesMixing FundaVinod SiramPas encore d'évaluation

- Oil and Gas Artificial Fluid Lifting TechniquesD'EverandOil and Gas Artificial Fluid Lifting TechniquesÉvaluation : 5 sur 5 étoiles5/5 (1)

- IADC WellCAP Well Control WorksheetDocument3 pagesIADC WellCAP Well Control WorksheetDirafPas encore d'évaluation

- Profit Loss Report 367436 20203908093927 PDFDocument3 pagesProfit Loss Report 367436 20203908093927 PDFAbhinav GoyalPas encore d'évaluation

- 50 PDFDocument1 page50 PDFAbhinav GoyalPas encore d'évaluation

- Well PlanDocument1 pageWell PlanAbhinav GoyalPas encore d'évaluation

- This Is A Manual of Drilling Technical ManualDocument1 pageThis Is A Manual of Drilling Technical ManualAbhinav GoyalPas encore d'évaluation

- Slimhole Drilling Paper Revised June 2016 PDFDocument28 pagesSlimhole Drilling Paper Revised June 2016 PDFAbhinav GoyalPas encore d'évaluation

- Slimhole Drilling Paper Revised June 2016 PDFDocument28 pagesSlimhole Drilling Paper Revised June 2016 PDFAbhinav GoyalPas encore d'évaluation

- Well Summary Data: Includes Shared Rig Move TimeDocument1 pageWell Summary Data: Includes Shared Rig Move TimeAbhinav GoyalPas encore d'évaluation

- Analysis of Cost EstimationDocument58 pagesAnalysis of Cost Estimationccsreddy100% (3)

- Its CaseDocument1 pageIts CaseAbhinav GoyalPas encore d'évaluation

- Well Stimulation - Hydraulic FracturingDocument3 pagesWell Stimulation - Hydraulic FracturingAbhinav GoyalPas encore d'évaluation

- Annular VelocityDocument1 pageAnnular VelocityAbhinav GoyalPas encore d'évaluation

- ExercisesDocument6 pagesExercisesAbhinav GoyalPas encore d'évaluation

- CompanyDocument1 pageCompanyAbhinav GoyalPas encore d'évaluation

- Case DrillDocument1 pageCase DrillAbhinav GoyalPas encore d'évaluation

- This Minor Makes You Fool HohohoDocument1 pageThis Minor Makes You Fool HohohoAbhinav GoyalPas encore d'évaluation

- Acuprressurefundamentals PDFDocument25 pagesAcuprressurefundamentals PDFBosko Ljubisavljevic88% (8)

- Pipeline ConstructionDocument19 pagesPipeline ConstructionJose Anisio SilvaPas encore d'évaluation

- MotorDocument20 pagesMotortechzonesPas encore d'évaluation

- LoklDocument1 pageLoklAbhinav GoyalPas encore d'évaluation

- Well Control ReportDocument3 pagesWell Control ReportAbhinav GoyalPas encore d'évaluation

- Document ImpDocument1 pageDocument ImpAbhinav GoyalPas encore d'évaluation

- WrteDocument1 pageWrteAbhinav GoyalPas encore d'évaluation

- This O9S For Scridd Lafjalfafmpaqjfqjfg Qfga'FgaDocument1 pageThis O9S For Scridd Lafjalfafmpaqjfqjfg Qfga'FgaAbhinav GoyalPas encore d'évaluation

- ImpdocDocument1 pageImpdocAbhinav GoyalPas encore d'évaluation

- B.tech MidsemoctDocument8 pagesB.tech MidsemoctAbhinav GoyalPas encore d'évaluation

- Chapter 5 - Drill BitDocument18 pagesChapter 5 - Drill BitAbhinav Goyal100% (1)

- MAOP UpratingDocument32 pagesMAOP UpratingAbhinav GoyalPas encore d'évaluation

- CoatingDocument8 pagesCoatingAbhinav GoyalPas encore d'évaluation

- Pipeline SlidesDocument14 pagesPipeline Slidesc丽诗Pas encore d'évaluation

- 2006 Beam Column Joint ICJDocument9 pages2006 Beam Column Joint ICJvishalgorePas encore d'évaluation

- Exam in Fluids1Document4 pagesExam in Fluids1Prince Winderic Gaza AclanPas encore d'évaluation

- Wilden Pump Manual T15Document36 pagesWilden Pump Manual T15Susanto Ricky0% (2)

- Cooling Towers: Section 11Document15 pagesCooling Towers: Section 11sebas guzPas encore d'évaluation

- Physical Pharmacy: Gpat Online ClassesDocument82 pagesPhysical Pharmacy: Gpat Online Classesshripathy1-1Pas encore d'évaluation

- Review - Structural AnalysisDocument31 pagesReview - Structural AnalysisShayne Rose OrtegaPas encore d'évaluation

- Antoine EquationDocument2 pagesAntoine EquationAlfrets Marade SianiparPas encore d'évaluation

- 6 Dam Breach Analysis 27102021 MarceloDocument28 pages6 Dam Breach Analysis 27102021 MarceloZhenhe SongPas encore d'évaluation

- Ex PDFDocument4 pagesEx PDFFernandaFerreiraPas encore d'évaluation

- Rotational Flow and Thermal Behavior of Ternary Hybrid Nanomaterials at Small and High Prandtl NumbersDocument17 pagesRotational Flow and Thermal Behavior of Ternary Hybrid Nanomaterials at Small and High Prandtl NumbersprakashjayavelPas encore d'évaluation

- (Appendix 1) Solids: Oelze ECE/TAM 373 Notes - Chapter 5 PG 27Document8 pages(Appendix 1) Solids: Oelze ECE/TAM 373 Notes - Chapter 5 PG 27AlinaBogoiPas encore d'évaluation

- ECS 238 - Chapter 1a (Intro)Document12 pagesECS 238 - Chapter 1a (Intro)Daisuke UnusagiPas encore d'évaluation

- 2.areator & Flash MixerDocument16 pages2.areator & Flash MixerG.C.PatilPas encore d'évaluation

- MODELLING AND SIMULATION OF (PHD) PDFDocument254 pagesMODELLING AND SIMULATION OF (PHD) PDFygzylmzPas encore d'évaluation

- Mass Transfer Operations Model QuestionsDocument8 pagesMass Transfer Operations Model QuestionsIastraPas encore d'évaluation

- Thermal Engineering-CondenserDocument17 pagesThermal Engineering-CondenserJayPas encore d'évaluation

- Lab 8 - Ciu, Cid Triaxial TestDocument7 pagesLab 8 - Ciu, Cid Triaxial TestAmirah Shafeera0% (1)

- Me6301 Engineering Thermodynamics - Syllabus, 2&16 Mark QuestionsDocument43 pagesMe6301 Engineering Thermodynamics - Syllabus, 2&16 Mark Questionsdellibabu509Pas encore d'évaluation

- Introduction SlidesDocument23 pagesIntroduction SlidesMathiselvan GopalPas encore d'évaluation

- Tutorial 6. Using The Discrete Ordinates Radiation ModelDocument42 pagesTutorial 6. Using The Discrete Ordinates Radiation ModelIjaz FazilPas encore d'évaluation

- Wang 2020 Ijnmf SflowDocument32 pagesWang 2020 Ijnmf Sflowram b nimmaPas encore d'évaluation

- Thermal Mass ConcreteDocument76 pagesThermal Mass ConcreteSandro MendesPas encore d'évaluation

- Technical Specs for 18,000 BTU Portable Water ChillerDocument3 pagesTechnical Specs for 18,000 BTU Portable Water ChillerPARTHIBAN RETECHPas encore d'évaluation

- Supplementary Problems HGEDocument3 pagesSupplementary Problems HGEShiela GonzalesPas encore d'évaluation

- Hmws Civil Final Key-2 - VG PDFDocument54 pagesHmws Civil Final Key-2 - VG PDFMadhu KurmiPas encore d'évaluation

- White Paper UHX PDFDocument20 pagesWhite Paper UHX PDFMeravigliorso76Pas encore d'évaluation

- Kompresibilitas OkDocument9 pagesKompresibilitas OkFeby RochmaniahPas encore d'évaluation

- Worksheet Topic 2 Lesson 2 Physical Changes AnswersDocument3 pagesWorksheet Topic 2 Lesson 2 Physical Changes AnswersSarahPas encore d'évaluation

- ESAS II AnswersDocument16 pagesESAS II AnswersChela Nicole EchonPas encore d'évaluation