Académique Documents

Professionnel Documents

Culture Documents

Approved Lubrication D

Transféré par

Mostafa MohamedTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Approved Lubrication D

Transféré par

Mostafa MohamedDroits d'auteur :

Formats disponibles

23169NOV2008

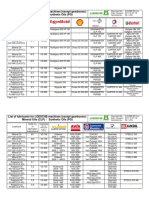

Approved List of Lubricants

For Cone Drive Double Enveloping Worm Speed Reducers & Gearsets

AGMA #7S SYNTHETIC (ISO Viscosity Grade 460)5 MANUFACTURER Chevron/Texaco Chevron/Texaco Cognis Corporation Exxon Mobil Oil Corp. Exxon Mobil Oil Corp. Keystone/Total Fina Elf Royal Purple, Ltd. BRAND NAME Chevron Clarity Synthetic PMO 460 Texaco Pinnacle 460 Emgard 2843 Synthetic WGL Mobil SHC634 Synthetic Lubricant Mobil Glygoyle 460 (Note 6) KSL-460 Synthetic Lubricant Thermyl-Glyde Worm Gear 680 (Note 4)

AGMA #8 COMPOUND (NON-E.P.) (ISO Viscosity Grade 680) MANUFACTURER BRAND NAME

POUR POINT F (C) VISCOSITY SUS@210F

POUR POINT F (C)

VISCOSITY SUS@210F

-33 (-36) -20 (-29) -30 (-34) -44 (-42) -27 (-33) -40 (-40) -20 (-29)

222 SUS 218 SUS 273 SUS 218 SUS 77.2 cSt 227 SUS 45.3 cSt

AGMA #8A COMPOUND (NON-E.P.) (ISO Viscosity Grade 1000) BRAND NAME Energol DC-C 1000 Jax Super Cylinder Steam Cylinder Oil 250

No-Tox Worm Gear Lube (FOOD GRADE H1) Oil ISO 1000

POUR POINT F (C) VISCOSITY SUS@210F

BP Oil NOT AVAILABLE IN THE U.S. Behnke Lubricants Jax Super Cylinder Bel-Ray Company Steam Cylinder Oil 150 Bel-Ray Company Cato Oil & Grease Chevron Citgo Conoco Dryden Oil Co. Engineered Lubricants Exxon Fina Oil Fiske Brothers Refining Fiske Brothers Refining Imperial/Esso Oil Kendall Motor Oil Co. Lubrication Engineers Lyondell Lubricants Mobil Oil Pennzoil Products Pennzoil Products Phillips 66 Company Schaeffer Manufacturing Shell Oil Sunoco Texaco Lubricants

No-Tox Worm Gear Lube (FOOD GRADE H1) Oil ISO 680

30 5 5 5 10 15 30 20 15 20 20 22 20 37 25 15 30 0C 30 36 10 10 20 10 20

190 167 216 212 191 193 165 180 685 CST 184 175 160 173 680 CST 177 191 190 155 680 CST 680 CST 172 190 650 CST 677 190

6 15 10 5

1000 CST 243 205 292 315 252 211 222 916 CST 227 230 925 CST 229

Mystik Power Lube #680 Cylinder Oil W-ISO #680 Cylinder Oil #680-7 Inca Oil #680 Worm Gear Oil #680 Enlubol SCO-3400 Cylesstic TK 680 Cylan Steam Cyl. Oil 680 Lubriplate CP-8 Lubriplate SPO-288 Cylesso TK 680 Kendco 155 Comp. 680 Almasol Modoc #175 Extra Hecla Super Cylinder Oil Cylinder Oil #680 Cylinder Oil #6-NR Hector 630-S #147 Steam Cylinder Oil Valvata J-680 Sun Gear Oil 8C Vanguard 680

Mystik Power Lube #1000 5 Cylinder Oil W-ISO #1000 10 Inca Oil #1000 Worm Gear Oil #1000 Enlubol SCO-193 Comp. Cylesstic TK 1000 Lubriplate CP-8A Cylesso TK 1000 Kendco 206 Comp. 35 20 15 30 35 37 35

Extra Hecla Super Cylinder Oil Mineral Cylinder Oil #1000

3C 30

200 1000 CST

Vanguard 1000

25

220

NOTES: 1... The listed synthetic lubricants are acceptable for use as an AGMA #7, #8 or #8A. AGMA #7 lubricants are primarily used in force feed lubrication systems or other special applications. 2... Manufacturers listed in bold print have product available worldwide. Contact a listed manufacturer for availability in your area. 3... Centistoke (cSt) viscosity values in the AGMA #8 and #8A tables are at 40 centigrade. 4... Thermyl-Glyde Worm Gear 680 is an ISO grade 680 and AGMA 8S lubricant 5... Synthetic lubricants with viscosity grades other than those shown may be recommended by Cone Drive Engineering in some cases. 6... Glygoyle Series lubricants are polyalkylene glycol (PAG) based food grade products. See www.mobilindustrial.com for compatibility guidelines and other specifications unique to this PAG lubricant. Cone Drive reserves the right to improve or change product design and specifications without notice.

Cone Drive Operations, Inc. th 240 E. 12 Street, P.O. Box 272, Traverse City, MI 49684-0272 USA Phone: 231-946-8410, Fax 231-933-8600 www.conedrive.com Sales Phone: 888-994-2663 Sales Fax: 888-907-2663

23169NOV2008

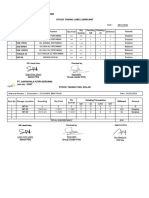

Lubrication Information

For Cone Drive Double Enveloping Worm Speed Reducers & Gearsets

AGMA Lubricant Number Guidelines

CENTER DISTANCE Up to 6 inclusive Over 6 to 12 Over 12 to 18 Over 18 & above WORM SPEED (RPM) 0-700 0-450 0-300 0-200 AMBIENT TEMPERATURE -10C to +10C (14F to 50F) AGMA 7S or AGMA 8 comp +10C to +50C (50F to 125F) AGMA 7S or AGMA 8A comp WORM SPEED ABOVE (RPM) 700-up 450-up 300-up 200-up AMBIENT TEMPERATURE -10C to +50C (14F to 125F) AGMA 7S or AGMA 8 comp

Viscosity Ranges

AGMA NO. ASTM SYSTEM SUS SUS @210F @100F 1919-2346 125-150 1919-2346 150-190 2837-3467 190-250 4171-5098 ISO VISC. CST @40C 414-506 414-506 612-748 900-1100

7S Synthetic 7 Compound 8 Compound 8A Comp.

IMPORTANT: In any applications of Cone Drive Products where breakage, damage, disconnection, any other malfunction of any drive train component, or excessive wear could result in personal injury or property damage, a fail safe device capable of stopping and holding the load in the event of such an occurrence must be incorporated after the drive train.

Lubrication and Maintenance Notes:

1

Type of Oil. For Cone Drive double enveloping worm gear speed reducers use the lubricant information on the nameplate and this Approved List of Lubricants to select the proper lubricant. For Cone Drive gear sets used in other assemblies, use this document to select a lubricant. Contact Cone Drive if in doubt. Ambient Temperature. The lubricants in this list are for use in an ambient temperature range of approximately 15F to 125F with the low end of the range depending on the pour point of the specific oil used. The lubricant Pour Point must be at least 5C (9F) less than the minimum startup temperature expected. If the ambient temperature will be below or above this range please contact Cone Drive for specific recommendations on proper lubricant as well as proper oil seal and shim materials. Sludge. It is necessary that the oil be clean and free from sludge at all times to obtain long life from the gear unit. Sludge in gear units may be caused by excessive heat, from dust and dirt and other contaminates and by the presence of moisture or chemical fumes. Therefore, every precaution should be taken to prevent water and foreign particles from entering the gear case. Oil Change. If an approved synthetic lubricant is used, it should be changed after 5000 hours of operation or once per year, whichever occurs first. If a recommended steam cylinder oil is used, the change interval should be after 2500 hours of operation or every six months, whichever occurs first. These change intervals are recommended for units operating under

favorable conditions. Where operating conditions are severe, such as a rapid rise and fall in temperature of the gear case with accompanied sweating of the inside wall and resulting formation of sludge, or where operation is in moist or dusty atmospheres, or in the presence of chemical fumes or extended running at sump temperatures in excess of 180F, it may be necessary to change the oil at intervals of one to three months. It is recommended a sampling program be established with your lubricant manufacturer where reducers are exposed to the severe operating conditions, mentioned above.

5 6

Oil Level. Oil level should always be checked with the unit stopped. Extreme Pressure (EP) Lubricants. Extreme Pressure (EP) lubricants or cylinder oils with sulfur-phosphorus additives are not acceptable and should not be used with worm gearing. High Speed Applications. Double enveloping worm gears operating at a sliding velocity in excess of 10 m/s (2,000 ft/min) may require force-feed lubrication. For force feed lubrication recommendations, contact Cone Drive Engineering. Greased Bearings. High quality lithium base NLGI #2 or NLGI #3 grease should be applied to fittings at normal maintenance intervals depending on duty cycle. Only bearings requiring added grease will have fittings.

Cone Drive Operations, Inc. th 240 E. 12 Street, P.O. Box 272, Traverse City, MI 49684-0272 USA Phone: 231-946-8410, Fax 231-933-8600 www.conedrive.com Sales Phone: 888-994-2663 Sales Fax: 888-907-2663

Vous aimerez peut-être aussi

- Kusa Chemicals Private Limited: Kusapour 340Document1 pageKusa Chemicals Private Limited: Kusapour 340n.hartonoPas encore d'évaluation

- 1-2 What Is PoliticsDocument17 pages1-2 What Is PoliticsMostafa MohamedPas encore d'évaluation

- 1-2 What Is PoliticsDocument17 pages1-2 What Is PoliticsMostafa MohamedPas encore d'évaluation

- Global Lubricants and Base Oil Market: Trends & Opportunities (2014 Edition) - New Report by Daedal ResearchDocument12 pagesGlobal Lubricants and Base Oil Market: Trends & Opportunities (2014 Edition) - New Report by Daedal ResearchDaedal ResearchPas encore d'évaluation

- A Performance Review of 14 Horizontal Wells in Baronia Field After 12 Years of ProductionDocument9 pagesA Performance Review of 14 Horizontal Wells in Baronia Field After 12 Years of Productionshaumeng9292100% (1)

- Gulf Lubricants Brief ProfileDocument10 pagesGulf Lubricants Brief Profileatripathi2009100% (1)

- Gulf Gear WT: High Performance Industrial Gear OilDocument1 pageGulf Gear WT: High Performance Industrial Gear Oilatripathi2009Pas encore d'évaluation

- MIL-L-2105D Downloaded Gear Oil SpecDocument17 pagesMIL-L-2105D Downloaded Gear Oil Speckamal arabPas encore d'évaluation

- Natural Gas Engines LubricationDocument9 pagesNatural Gas Engines Lubricationjameel babooramPas encore d'évaluation

- Viscosity ClassificationsDocument6 pagesViscosity ClassificationsDarmawan PutrantoPas encore d'évaluation

- Technology Forum - Indoneusa - Gas Engines (Oct.2014) V2Document42 pagesTechnology Forum - Indoneusa - Gas Engines (Oct.2014) V2Frana HadiPas encore d'évaluation

- Product Information Navigo 6 So: DescriptionDocument2 pagesProduct Information Navigo 6 So: DescriptionCOMITYPas encore d'évaluation

- Report On Oil Types and Applications: 3 YearDocument5 pagesReport On Oil Types and Applications: 3 YearMahmoud KassabPas encore d'évaluation

- WT98Q001 04gb PDFDocument8 pagesWT98Q001 04gb PDFrpicho100% (1)

- Synthetic Oil TestingDocument12 pagesSynthetic Oil TestingamsoildealerPas encore d'évaluation

- Chapter 6 LubricationDocument24 pagesChapter 6 Lubricationchala nigussiePas encore d'évaluation

- MAN 270 Diesel Engine Oil: Products For The Specification Approved by NameDocument2 pagesMAN 270 Diesel Engine Oil: Products For The Specification Approved by NameSyed JunaidPas encore d'évaluation

- Shell Turbo T46 PDFDocument2 pagesShell Turbo T46 PDFdionisio emilio reyes jimenezPas encore d'évaluation

- Velvex Industrial Oil - Nandan Petrochem LTDDocument27 pagesVelvex Industrial Oil - Nandan Petrochem LTDNandan Petrochem Ltd0% (1)

- The Next Generation Gas Engine Oil Mobil Pegasus 1005Document46 pagesThe Next Generation Gas Engine Oil Mobil Pegasus 1005Sandeep100% (1)

- Lube Oil AnalysisDocument8 pagesLube Oil AnalysisVuthpalachaitanya KrishnaPas encore d'évaluation

- Gear OilsDocument3 pagesGear OilsPurchase ZenoilPas encore d'évaluation

- Using Membrane Patch Color 1708408Document8 pagesUsing Membrane Patch Color 1708408Hesham MahdyPas encore d'évaluation

- HP Lubes GuideDocument196 pagesHP Lubes GuideJen Ekx100% (1)

- 1.2. BTR - Lubrication NotesDocument17 pages1.2. BTR - Lubrication Notesvishnu vishnu G.T.Pas encore d'évaluation

- Turbine Oil Condition Monitoring: Oil is the LifebloodDocument13 pagesTurbine Oil Condition Monitoring: Oil is the LifebloodJagadish PatraPas encore d'évaluation

- Lubs, Properties & TeatingDocument33 pagesLubs, Properties & Teatingjamesv52_743942786Pas encore d'évaluation

- Gulf Oil Brand HistoryDocument32 pagesGulf Oil Brand HistoryIng Kelvys Gonzalez100% (2)

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Document8 pagesList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaPas encore d'évaluation

- Ubricants Brand ComparisonDocument6 pagesUbricants Brand ComparisonUtkarshPas encore d'évaluation

- UNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015Document46 pagesUNIT III: Lubricants: Soami P. Satsangee CHM 181 7/10/2015anjali sharmaPas encore d'évaluation

- Synthetic Gear Oil SelectionDocument9 pagesSynthetic Gear Oil Selectionsmallik3Pas encore d'évaluation

- Lubricants and LubricationDocument5 pagesLubricants and LubricationsafowanPas encore d'évaluation

- Engine Oil: Operation and Maintenance ManualDocument5 pagesEngine Oil: Operation and Maintenance ManualАлександр БудзинскийPas encore d'évaluation

- Base Stocks 基础油Document18 pagesBase Stocks 基础油Yesica RozoPas encore d'évaluation

- Volvo Oil AnalysisDocument5 pagesVolvo Oil Analysisgilar herliana putraPas encore d'évaluation

- Fuel DilutionDocument18 pagesFuel DilutionMuHaZir0% (1)

- Gearbox LubricationDocument5 pagesGearbox LubricationTaranpreet Singh100% (1)

- Gulf Industrial Lubricant Portfolio GuideDocument21 pagesGulf Industrial Lubricant Portfolio Guideatripathi2009Pas encore d'évaluation

- Base Oil Markets and Drivers Nov 2016 PDFDocument28 pagesBase Oil Markets and Drivers Nov 2016 PDFSERGIO PAVA100% (1)

- Diesel Engine Lubrication SystemsDocument27 pagesDiesel Engine Lubrication SystemsMohammad HazbehzadPas encore d'évaluation

- En Additin RC 2540Document3 pagesEn Additin RC 2540Dinesh babuPas encore d'évaluation

- Mobil GuideDocument19 pagesMobil GuidemademanPas encore d'évaluation

- Construction Lube Apps 18 Jan 16Document46 pagesConstruction Lube Apps 18 Jan 16José Cesário NetoPas encore d'évaluation

- How To Select and Service Turbine OilsDocument5 pagesHow To Select and Service Turbine OilsmvanzijpPas encore d'évaluation

- Lubricants FinalDocument18 pagesLubricants FinalRonak GandhiPas encore d'évaluation

- Petro Canada Lubricants Handbook 2012 English PDFDocument212 pagesPetro Canada Lubricants Handbook 2012 English PDFsoumya ghoshPas encore d'évaluation

- Gulf Marine Corporate Presentation Ppt2009 07Document22 pagesGulf Marine Corporate Presentation Ppt2009 07Philippe-Andre BoileauPas encore d'évaluation

- Xaerus Product CatalogueDocument4 pagesXaerus Product CatalogueBurhan AdnanPas encore d'évaluation

- Innovations in Lube Marketing: Indian Perspective Challenges & Way AheadDocument27 pagesInnovations in Lube Marketing: Indian Perspective Challenges & Way AheadBhagyesh DokePas encore d'évaluation

- Evaluation of Hydrocarbon Heat Transfer Fluids: Standard Guide ForDocument3 pagesEvaluation of Hydrocarbon Heat Transfer Fluids: Standard Guide ForahmedPas encore d'évaluation

- Is 13656 2002 PDFDocument24 pagesIs 13656 2002 PDFSiddharth GuptaPas encore d'évaluation

- Classification of Engine Oil ViscosityDocument1 pageClassification of Engine Oil ViscosityRio aji RiyantoPas encore d'évaluation

- SAE J300 Viscosity Grades Below 20 Grade-SAE Power Trains Fuels and Lubricants-2010Document11 pagesSAE J300 Viscosity Grades Below 20 Grade-SAE Power Trains Fuels and Lubricants-2010Irfan ShaikhPas encore d'évaluation

- Bearing Design and Metallurgy GuideDocument46 pagesBearing Design and Metallurgy GuideKumarPas encore d'évaluation

- Viscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedDocument39 pagesViscosity & Viscosity Modifiers: © INFINEUM INTERNATIONAL LIMITED 2017. All Rights ReservedJahmia CoraliePas encore d'évaluation

- Lubricant Base Stocks: OutlineDocument23 pagesLubricant Base Stocks: OutlineJahmia Coralie100% (1)

- Heavy Duty Engine Oils-Field TrialsDocument51 pagesHeavy Duty Engine Oils-Field TrialsJuan Luis RojasPas encore d'évaluation

- OEM Approval GuideDocument8 pagesOEM Approval GuideEsteban Fernando Meza IbacetaPas encore d'évaluation

- Comparison - Shell HTO S2 Vs Competitor Fluids - 2018Document1 pageComparison - Shell HTO S2 Vs Competitor Fluids - 2018Vipul GodsePas encore d'évaluation

- Lubricants For Buses and TrucksDocument16 pagesLubricants For Buses and Trucksvijay9994Pas encore d'évaluation

- Preventing Turbomachinery "Cholesterol": The Story of VarnishD'EverandPreventing Turbomachinery "Cholesterol": The Story of VarnishPas encore d'évaluation

- 1-1 What Is PoliticsDocument9 pages1-1 What Is PoliticsMostafa MohamedPas encore d'évaluation

- B W P P C: Arriers To Omen'S Olitical Articipation in AnadaDocument16 pagesB W P P C: Arriers To Omen'S Olitical Articipation in AnadaMostafa MohamedPas encore d'évaluation

- Improving Gender Representation in Canadian Federal Politics and ParliamentDocument6 pagesImproving Gender Representation in Canadian Federal Politics and ParliamentMostafa MohamedPas encore d'évaluation

- Women's Representation in Canadian Politics: Obstacles Towards ProgressDocument12 pagesWomen's Representation in Canadian Politics: Obstacles Towards ProgressMostafa MohamedPas encore d'évaluation

- Women's Representation in The House of Commons: A Stalemate?Document6 pagesWomen's Representation in The House of Commons: A Stalemate?Mostafa MohamedPas encore d'évaluation

- 4 Parties and Party Systems in PoliticsDocument18 pages4 Parties and Party Systems in PoliticsMostafa MohamedPas encore d'évaluation

- Awaiting The Watershed: Women in Canada's Parliament: by Matthew K. GodwinDocument6 pagesAwaiting The Watershed: Women in Canada's Parliament: by Matthew K. GodwinMostafa MohamedPas encore d'évaluation

- 1-3 What Is PoliticsDocument21 pages1-3 What Is PoliticsMostafa MohamedPas encore d'évaluation

- Achall WebDocument85 pagesAchall WebSathish PPas encore d'évaluation

- 5-1 Democracy 民主Document26 pages5-1 Democracy 民主Mostafa MohamedPas encore d'évaluation

- 3 Governments, Systems and RegimesDocument16 pages3 Governments, Systems and RegimesMostafa MohamedPas encore d'évaluation

- 2 The StateDocument25 pages2 The StateMostafa MohamedPas encore d'évaluation

- TD-lecture NotesDocument135 pagesTD-lecture NotesAbdelkader Faklani Dou100% (1)

- TD-lecture NotesDocument135 pagesTD-lecture NotesAbdelkader Faklani Dou100% (1)

- Conversion de La EnergiaDocument6 pagesConversion de La EnergiaPaula Camila Baron TovarPas encore d'évaluation

- Keep Helping Others, Don't Be SelfishDocument130 pagesKeep Helping Others, Don't Be SelfishMostafa MohamedPas encore d'évaluation

- Time Integration: Application To Unsteady Transport ProblemsDocument2 pagesTime Integration: Application To Unsteady Transport ProblemsMostafa MohamedPas encore d'évaluation

- Fluid Mechanics&Machines Q&A PDFDocument307 pagesFluid Mechanics&Machines Q&A PDFUmesh ShresthaPas encore d'évaluation

- Fluid Mechanics&Machines Q&A PDFDocument307 pagesFluid Mechanics&Machines Q&A PDFUmesh ShresthaPas encore d'évaluation

- Time Integration: Two Level and Multi-Level Methods For First Order IvpsDocument3 pagesTime Integration: Two Level and Multi-Level Methods For First Order IvpsMostafa MohamedPas encore d'évaluation

- Heat Transfer: YEAR 2012 One Mark MCQ 7.1Document44 pagesHeat Transfer: YEAR 2012 One Mark MCQ 7.1Mostafa MohamedPas encore d'évaluation

- Fluid Mechanics&Machines Q&A PDFDocument307 pagesFluid Mechanics&Machines Q&A PDFUmesh ShresthaPas encore d'évaluation

- Heat Transfer Fundamentals and ApplicationsDocument72 pagesHeat Transfer Fundamentals and ApplicationsDEEPMALA KUMARIPas encore d'évaluation

- Refrigeration and Air-Conditioning - S K Mondal 1Document122 pagesRefrigeration and Air-Conditioning - S K Mondal 1Guru Ravindra ReddyPas encore d'évaluation

- Heat Transfer IES GATE IAS 20 Years Question and Answers by S KDocument97 pagesHeat Transfer IES GATE IAS 20 Years Question and Answers by S KManmath SontakkePas encore d'évaluation

- Power-Plant-Q-A 12 PDFDocument106 pagesPower-Plant-Q-A 12 PDFYogesh Kumar GuptaPas encore d'évaluation

- Thermodynamics SK MondalDocument265 pagesThermodynamics SK MondalSãröj ShâhPas encore d'évaluation

- ##Exsol - Mech - 3.basic ThermodynamicsDocument162 pages##Exsol - Mech - 3.basic ThermodynamicsMostafa MohamedPas encore d'évaluation

- Pipe TL T'Uck FL: /oblzotsDocument1 pagePipe TL T'Uck FL: /oblzotsNimesh PereraPas encore d'évaluation

- CSA PM Calculation - 07.2019 - FormuleDocument45 pagesCSA PM Calculation - 07.2019 - FormulejogremaurPas encore d'évaluation

- Port Fuel, LubeDocument1 pagePort Fuel, LubeBabungulanPas encore d'évaluation

- Bottom of Barrel Processing: Chapters 5, 6, & 8Document20 pagesBottom of Barrel Processing: Chapters 5, 6, & 8Оскар ЛинаресPas encore d'évaluation

- Lista de Aceites Aprobados Por Detroit, Especificación 93K214Document1 pageLista de Aceites Aprobados Por Detroit, Especificación 93K214Ing. Julio Cesar Rodriguez LeonPas encore d'évaluation

- Industri Hilir Kelapa Sawit Indonesia & PTPN Group PrintDocument14 pagesIndustri Hilir Kelapa Sawit Indonesia & PTPN Group PrintAzhari RizalPas encore d'évaluation

- SPE 18977 Summary Results of EOR Field Tests, 1972-1987Document10 pagesSPE 18977 Summary Results of EOR Field Tests, 1972-1987dion gunawanPas encore d'évaluation

- Edible Oil Processing Second EditionDocument11 pagesEdible Oil Processing Second Editionsutareja100% (1)

- Edible Oils FDocument15 pagesEdible Oils FPallavi OakPas encore d'évaluation

- Synthetic D1 FE 0W-20 Engine Oil for GM Opel CarsDocument1 pageSynthetic D1 FE 0W-20 Engine Oil for GM Opel CarsEzraKitrieGunawanPas encore d'évaluation

- GO-J Plus Gear Oil, Listing of Approved Oils March 03Document2 pagesGO-J Plus Gear Oil, Listing of Approved Oils March 03Luis Carlos Garcia UmañaPas encore d'évaluation

- Step - 50400 - 50700 2Document6 pagesStep - 50400 - 50700 2Kostya KonchakovskyPas encore d'évaluation

- Solvent DeasphaltingDocument1 pageSolvent DeasphaltingTheiva GanesPas encore d'évaluation

- Syrian Petroleum Company (SPC) : SubsidiariesDocument5 pagesSyrian Petroleum Company (SPC) : SubsidiariesAiham AltayehPas encore d'évaluation

- Voyager Silver 10W/40: DescriptionDocument1 pageVoyager Silver 10W/40: DescriptionTangguhPas encore d'évaluation

- A JCB Gyári Kenőanyagainak Átváltó Segédlete A KenőanyagokraDocument4 pagesA JCB Gyári Kenőanyagainak Átváltó Segédlete A KenőanyagokrakotvasilevPas encore d'évaluation

- Fuel Pricing Mechanism in India: BY B.RanjaniDocument10 pagesFuel Pricing Mechanism in India: BY B.RanjaniVîshësh ÄñâñdPas encore d'évaluation

- Titan Atf 6400 enDocument4 pagesTitan Atf 6400 enAlyXe SyDPas encore d'évaluation

- Memo 097.7 - 051822 - Fuel and Oil Lubricant Consumption of Commonly Used EquipmentDocument14 pagesMemo 097.7 - 051822 - Fuel and Oil Lubricant Consumption of Commonly Used EquipmentAce LangPas encore d'évaluation

- Full Corporate Offer: PrincipalDocument3 pagesFull Corporate Offer: PrincipalGrigory Vladimirovich TishkinPas encore d'évaluation

- Gas Production and Utilization Data (Provisional) April, 2023Document1 pageGas Production and Utilization Data (Provisional) April, 2023Rich WisdomPas encore d'évaluation

- Oil and Gas 231006 SU KenangaDocument4 pagesOil and Gas 231006 SU KenangaShankhadeep MukherjeePas encore d'évaluation

- Asian Oil and Gas-November-December 2010Document28 pagesAsian Oil and Gas-November-December 2010EcoPrasinosPas encore d'évaluation

- Astm 3699Document3 pagesAstm 3699Ali ShahPas encore d'évaluation

- JVC GR-DF550US - PartDocument19 pagesJVC GR-DF550US - PartsilictronicPas encore d'évaluation

- Vacouline 528Document1 pageVacouline 528Ha PhuongPas encore d'évaluation

- Cdu 3Document76 pagesCdu 3Duong PhamPas encore d'évaluation

- PT Pertamina: Indonesia's State-Owned Oil and Gas CompanyDocument4 pagesPT Pertamina: Indonesia's State-Owned Oil and Gas CompanyKresna Putri HantariPas encore d'évaluation