Académique Documents

Professionnel Documents

Culture Documents

Energy Loss Estimation in Distribution Feeders

Transféré par

Mohamed MusthafaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Energy Loss Estimation in Distribution Feeders

Transféré par

Mohamed MusthafaDroits d'auteur :

Formats disponibles

1092

IEEE TRANSACTIONS ON POWER DELIVERY, VOL. 21, NO. 3, JULY 2006

Energy Loss Estimation in Distribution Feeders

P. S. Nagendra Rao and Ravishankar Deekshit

AbstractEnergy losses in distribution systems are generally estimated rather than measured, because of inadequate metering in these systems and also due to the high cost of data collection. These estimations are generally based on some rules of thumb. This paper presents the results of a joint investigation undertaken in collaboration with a local utility to study this issue. Based on data collected from feeders specially instrumented for this purpose, true losses in some primary and secondary feeders are obtained. These losses are compared with the estimated losses obtained by the methods presently in use. In view of the large discrepancies observed between measured and estimated values, two new schemes for estimating losses in primary and secondary distribution networks have been developed. The measured values are used to highlight the reliability of the new estimation methods. Index TermsDistribution systems, loss estimation, primary and secondary distribution networks, radial feeders.

I. INTRODUCTION

RADITIONALLY, distribution system loss estimation has not received the importance due to it, in Indian utilities. The situation seems to be the same in many other developing countries. Till very recently utilities were generally government controlled and the emphasis was on expanding electrication. Concerns regarding social benets took precedence over prot and efciency. However, now the impact of economic restructuring is being felt in the electricity sector also. There are moves toward divesting government control and operating the utilities as private enterprises. Regulatory mechanisms are being put in place. There is a concerted effort toward improving efciency and protability. The hitherto neglected distribution systems known for their poor efciency have started attracting the attention of utilities seeking to improve their operational efciencies. The local power company KPTCL and its subsidiaries that operate in the State of Karnataka (India) are also going through this phase. These companies together cater to a geographical area of 191 791 square km. The peak demand is about 5400 MW and annual energy produced is about 31 billion units. They own more than 2000 primary distribution feeders which supply about 30% of energy to the vast rural areas of the state. The high voltage (HV) primary distribution is a 3-wire, 11-kV system. The low voltage (LV) secondary distribution is a 4-wire, 440-V system . Except for a small fraction that is used for lighting, this

Manuscript received June 27, 2005; revised August 11, 2005. Paper no. TPWRD-00366-2005. P. S. N. Rao is with the Department of Electrical Engineering, Indian Institute of Science, Bangalore, Karnataka 560012, India. R. Deekshit is with the Department of Electrical and Electronics Engineering, B.M.S College of Engineering, Bangalore, Karnataka 560012, India. Digital Object Identier 10.1109/TPWRD.2005.861240

entire energy in rural areas is used by irrigation pumps driven by three phase induction motors. The companies have become corporations and the tariff xation is now under the jurisdiction of an independent regulatory commission. The regulatory commission is demanding that the losses in the system must be quantied and investments made on system improvement be justied by veriable loss reduction. The present practice of loss estimation is very inaccurate. Only 30% of the total energy consumed is metered. Metering is generally limited to urban areas. Loads in rural areas are rarely metered. The consumption of the un-metered categories of consumer is guessed based on some rules of thumb. The difference between the known generation and the estimated consumption is considered to be loss. Even though it is well known that there are many unauthorized consumers, no mechanism is available to loss) and the commercial losses separate out the technical ( (various forms of theft). These companies need to evolve loss estimation methods which are reliable enough to convince the regulatory commission. The importance of accurate loss estimation schemes has been widely recognized. The near quadratic relationship that exists between load and loss has been used to develop empirical relations for estimation of loss. These relationships relate either the loss and load factors ([1][3]) or the loss and load ([4], [5]). In these methods, using simplied feeder models for computation of the loss, and then adopting a curve tting approach, the coefcients in the quadratic function are determined. Idealized feeder and load models are used to compute loss in [6] and [7]. A comprehensive loss estimation method using detailed feeder and load models in a load-ow program is presented in [8]. However, as remarked by the authors of [8] themselves, the difculty in obtaining accurate load data has a signicant impact on the accuracy of their results. In [9], a combination of statistical and load-ow methods are applied to nd the various types of losses in the Columbian Power System. Here, a radial load-ow program is used to compute the distribution feeder peak load loss. The peak loss is multiplied by a suitable factor to determine the energy losses. Formulas for computation of energy and peak losses of different distribution system components such as substation and line transformers, primary and secondary feeders etc., based on their percentage loading (PL) are developed in [10]. Simplied models of distribution feeder components for use in load-ow calculations are proposed in [11]. An approximate loss formula based on the load-ow model is proposed in [12]. Here, approximations are applied to the power ow equations in order to derive formulas that estimate losses under variation of capacitors and transformer taps. Closed-form formulas for computation of losses using a three phase load-ow model are proposed in [13]. Simulation of distribution feeders with load data estimated from typical customer load patterns is

0885-8977/$20.00 2006 IEEE

Authorized licensed use limited to: The National Institute of Engineering. Downloaded on March 30, 2009 at 06:33 from IEEE Xplore. Restrictions apply.

RAO AND DEEKSHIT: ENERGY LOSS ESTIMATION IN DISTRIBUTION FEEDERS

1093

presented in [14]. A simplied loss model is obtained by carrying out several computer simulations (by varying different parameters of the feeder) and a regression analysis. Loss formulas based on fuzzy-c-number (FCN) clustering of losses and cluster-wise fuzzy regression techniques are presented in [15]. A hybrid top/down and bottom/up approach is applied to estimate losses in [16]. In the rst step (top-down), feature extraction and clustering methods are applied to arrive at a grouping of feeders based on some similarities among them (intensity of consumption and consumption density). Then, feeders that represent each cluster (zone) are selected and then through a number of load-ow simulations, loss functions for each representative feeder are obtained. The losses for each feeder are then calculated based on the load that they carry. It is seen that the nonavailability of comprehensive distribution system data (corresponding to all the feeders in the system) is a major reason for the difculty in computation of losses. Though some authors suggest that loss models obtained from studies on a few representative feeders be extrapolated to estimate losses for the entire system ([4], [14], [16]), it is pointed out in [8] such generalizations should be applied with care because of varying feeder characteristics. This paper, addresses the issue of estimation of distribution feeder losses. The results presented here form a part of a study [17] undertaken in collaboration with the local utility to understand the various issues in planning and operation of their distribution system. One component of the study was intended to assess the validity of the loss estimation methods presently in use and evolve better methods, if the present ones are found wanting. The scheme envisaged for achieving this was as follows. 1) Identify a few feeders representative of the different climatic regions of the state. 2) Monitor the load parameters of feeders over an extended period of time using electronic meters (with data logging features). 3) Compute losses based on these measured readings. 4) Assess the validity of existing estimation schemes by comparing the estimates with actual measurements. 5) Explore the possibility of evolving and validating a scheme for these feeders which can be used to estimate losses when only limited measurements are available. The rest of the paper is organized as follows. We rst focus on the HV system (11 kV). The details of the study system and the instrumentation scheme are presented rst. The loss computation through measurements and the associated difculties are considered next. The validity of the existing scheme against the measured losses is assessed. We then describe as to how a model to facilitate loss estimation, based on limited measurements, is evolved and discuss its features. In Section VIII, we consider the problem of LV loss computation, highlight problems unique

to this subsystem, present a new estimation method and discuss how we have attempted to validate it. II. STUDY SYSTEM For this study, four 11-kV rural distribution feedersBukkasagara, Sharadagi, Devagiri, and Kalasapurafrom different regions of Karnataka state were chosen. Though the recommendations are based on observations from all the feeders, for the discussion here the results corresponding to only one of the feeders- the Bukkasagara feeder is used. The Bukkasagara feeder is a feeder supplying a predominantly rural agricultural region. The feeder is typical of a heavily loaded feeder and the load is mainly due to irrigation pump-sets (IP sets). The Bukkasagara feeder has 70 transformers with an installed transformer capacity of 5183 kVA. The feeder is made up of three types of conductors Squirrel, Weasel and Rabbit, , 30 and having nominal Aluminum areas of 20 , respectively. The total feeder length including laterals 50 is about 38 km and the main segment is about 21.5 km. Of this, about 12 km is made up of Rabbit conductor, 4 km is up of Weasel and the rest is of the Squirrel type. The feeder is subjected to regular load shedding and single phasing as is the case with most rural feeders in India. A. Measurement Scheme The measurement scheme evolved for this study is based on the consideration that the cost of instrumentation must be as small as possible and the equipment purchased for the project must be of use to the utility in their routine operations (subsequent to the project). At the time the project was initiated, a 3-phase electronic energy meter with a capability of logging kWh and kVARh imports and exports every half an hour was already in use to measure the feeder input at the substation. Since one of the main objectives of the study undertaken was to evolve a feeder model that closely correlated with the actual system, it was decided that additional load data be obtained by instruments installed at the distribution transformer (DT) secondary terminals. A digital meter to record energy (both active and reactive), voltage, currents, etc., at half hourly intervals is chosen for this purpose. The data logged are the following. 1) At the main substation(feeder input): Half an hour average of kW and kVAR input to the feeder (The meter keeps track of the increment in the kWh and kVARh over half an hour, multiplies the increment by 0.5, stores the resulting value as power). 2) At each of the distribution transformer secondaries: a) half an hour average of kW and kVAr input to the LV distribution feeders; b) root mean square (rms) values of the voltages of the three phases (3-cycle average measured prior to the logging instant); c) rms values of the currents of the three phases (again, a 3-cycle average). Each instrument has the capacity to store data over a 35-day period. Every month, the data is downloaded to a portable hand held device and then transferred to a computer. Though this

Authorized licensed use limited to: The National Institute of Engineering. Downloaded on March 30, 2009 at 06:33 from IEEE Xplore. Restrictions apply.

1094

IEEE TRANSACTIONS ON POWER DELIVERY, VOL. 21, NO. 3, JULY 2006

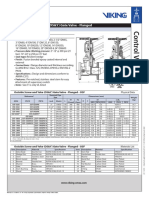

TABLE I MONTHLY MEASURED LOSS

TABLE II MONTHLY ESTIMATED LOSS (KM-KVA METHOD)

scheme is not really ideal because of the need for manual intervention for collecting and transferring the data to the computer, it was resorted to because it was the only feasible option. Needless to say, sophisticated communication options are absent in the remote rural areas supplied by the feeders. III. ACTUAL LOSS COMPUTATION The total HV feeder power loss during any interval is obtained as the difference between the recorded power at the feeder input and the sum of the power output of all distribution transformers. The energy losses can be calculated in the above manner to yield the daily, monthly or annual losses depending on the requirement. Since, individual output measurements are carried out on the secondary side of the distribution transformers, this net energy loss corresponds to the sum of the HV line losses and the transformer losses. The measured energy losses for the Bukkasagara feeder over a period of nine months in 2001 is shown in Table I. Though the computation of energy losses from actual measurements is an ideal situation, the required extensive instrumentation is rarely in place. Also, there are many associated problems. One main difculty is that of installing. maintaining and collecting the readings from meters that are placed at remote locations and hostile terrains. It is easy to see that loss of measured data even from one of the meters would make the loss estimation process error prone (even if meter errors are ignored).

IV. THE LOSS ESTIMATION METHOD IN USE The present practice adopted by the electricity utility for computing line losses is to use what is generally known as the km-kVA method. The annual feeder losses are computed using the following formula given in (1): Annual Loss where ; number of segments of feeder; resistance/ unit length of the feeder segment; length of the feeder segment; ; ; DF LF ; (diversity factor) (load factor) ; ; (1)

; LLF (loss load factor) ; km-kVA . LDF (load distribution factor) For feeders with laterals, this formula is used after reducing the given feeder (with laterals) to a feeder without laterals. If there are some major laterals then the loss in such laterals is computed using the same formula by assuming the quantities P, peak load, energy sent out, etc. to be in the same ratio as the capacity of the transformers connected to the branch to the total kVA of the given feeder transformer. The computed loss value is incremented by a nominal 10% to account for the losses in the smaller laterals. The above formula has been based on several simplifying assumptions such as uniform load distribution; constant feeder voltage (at all nodes at all times). The km-kVA method has been used to estimate the energy losses in the Bukkasagara feeder for each of the nine months. From the measured substation load for nine months, it is found that the overall LF, LLF, DF, and LDF values are 0.27, 0.11, 1.21, and 2.92, respectively. The monthly LF, LLF, and the DF values are computed for each month and the corresponding energy loss values are shown in Table II. Comparing the losses obtained by application of the km-kVA method (Table II) with the measured values (Table I), it is clear that the km-kVA method yields a gross underestimate of losses. This is not surprising in view of the various assumptions inherent in the method. The transformer losses (not included here) are not large enough to account for this difference. It is quite apparent that the km-kVA method presently in use for estimating losses is inadequate. In view of this, the development of a loss estimation technique that can provide a more realistic estimate of losses would be very useful. The subsequent sections describe the development and application of such a method for estimating losses based on limited measurements that are generally available at the sending end substation. V. LOSS MEASUREMENT AND ESTIMATION: ISSUES In order to obtain some insight into the actual system loss variation under various load conditions, the losses during each half hour interval were computed based on the measured values, using the procedure outlined in Section III. These losses for the nine-month period (48 274 points) are plotted in Fig. 1. A perusal of Fig. 1 indicates that (for each load) most of the points are clustered in a small band. However, there are a few points away from this band. Two factors are together responsible for this scattering; The rst is that the feeder switches between 3-phase,

Authorized licensed use limited to: The National Institute of Engineering. Downloaded on March 30, 2009 at 06:33 from IEEE Xplore. Restrictions apply.

RAO AND DEEKSHIT: ENERGY LOSS ESTIMATION IN DISTRIBUTION FEEDERS

1095

Fig. 1.

Measured losses from January 2001 to September 2001.

Fig. 2. Measured and computed voltages (Models 14).

1-phase, and no-power modes of operation several times in a day. The second factor is that the 71 clocks (one in each of the meters) are not synchronized and in addition they have a signicant drift. Therefore, for the whole feeder the data logging (every half an hour) would be spread over an interval of a few minutes instead of being at the same instant across the feeder. If the operation of the feeder changes from one mode to another mode within this interval sometimes outliers are generated in the plot of Fig. 1. However, it must be noted this phenomenon will not affect the calculated monthly/yearly losses. Ignoring the scattered points, Fig. 1 indicates that at every feeder input value, the losses vary over a band. This variation is not completely due to the errors in measurement. Errors would contribute only to a small spread in the measured losses for a given load. The more signicant reason for this feature is the fact that for a given feeder input, the loss component can vary as the spatial distribution of the load along the feeder changes; it can also vary because of the substation voltage variations. Hence, it must be noted that the feeder loss value for a given feeder input power is not unique and varies over a band of values. Therefore, the approach to loss estimation (without detailed measurements) here, is to rst estimate the mean loss corresponding to each value of feeder input and use this information along with the measured feeder input (at the substation) to estimate the losses. The basic premise of this scheme is that even though the estimated losses (power) for any given feeder input could be marginally in error, as several such estimates are aggregated to nd the energy loss (over a month/year), the errors would be compensating and the loss estimate would be quite reliable. The approach adopted to nd the mean loss curve is the following. Using the measured data a load-ow model of the network is developed and validated. This network model, is used to estimate the average loss corresponding to each of the feeder input values. VI. FEEDER MODEL DEVELOPMENT Validating the network model through load-ow studies turned out to be more involved than anticipated. First, data was

Fig. 3. Measured and computed voltages (Models 14).

collected regarding the feeder topology, segment lengths and conductor types used. The rst model considered (Model 1) was the standard load-ow model. All the loads measured on the secondaries of the distribution transformers are referred to the primary side, assuming all transformers to be ideal. Load-ow solutions obtained using this model did not match with the measured voltages at the transformer buses and the computed losses turned out to be quite low. As a renement (Model 2), the transformer core loss is included (as a resistor across the load). Even though this modication helped to reduce the mismatch between the measured and computed values, the mismatches continued to be quite signicant. Model 3 was the next renement where the magnetizing branch was included (in parallel with the load). As this change also turned out to be inadequate, in the next model (Model 4), the transformer series impedance was also included in addition to shunt components resulting in a full transformer model. In order to illustrate the impact of renements, the results of the load-ow solutions obtained for the Bukkasagara feeder, considering each of these models, for two sample cases are presented here. The measured and computed voltages (from Models 14), for two intervals have been plotted in Figs. 2 and 3. One of the intervals (Fig. 2) corresponds to a moderate load

Authorized licensed use limited to: The National Institute of Engineering. Downloaded on March 30, 2009 at 06:33 from IEEE Xplore. Restrictions apply.

1096

IEEE TRANSACTIONS ON POWER DELIVERY, VOL. 21, NO. 3, JULY 2006

TABLE III COMPUTED FEEDER LOSS WITH MODELS 15

TABLE IV RESISTANCE CORRECTION FACTORS

Fig. 4. Measured and computed voltages (Model 5).

condition (1.72 MVA) and the other in Fig. 3 corresponds to a heavily loaded condition (2.9 MVA). The losses corresponding to each load condition computed using the different models discussed above, are shown in Table III. The measured losses for these intervals are 15.64% (moderate load) and 30.1% (heavy load). It can be seen that the computed voltage proles move closer to the measured values as more details are included in the feeder models. With Model 4, it is also seen that the voltage prole and losses match reasonably when the load is moderate whereas there is signicant mismatch during the heavily loaded condition. The fact that Model 4 turns out to be reasonably good only at light loads but is found wanting at higher loads prompted a re-examination of our assumptions regarding the network parameters. One of the key assumptions of our model is that the and parameters of the lines are considered to be constant for all intervals. A closer examination reveals that whereas this is justied as far as the reactances are concerned, it is not so for the line resistances. It is well documented in the literature that the ac resistance of a single-layer ACSR conductor increases signicantly as the current increases [18], [19]. In fact, all the conductors used in this feeder are single-layer ACSR conductors and under heavy load conditions the current in many segments exceed their capacity. The resistance value that is used in Models 1 to 4 is taken from the Indian standards. It is the dc resistance corrected to 32 . Attempts to learn the exact variation of the resistances of these particular conductors with current turned out to be futile. None of the concerned organizations such as the utility, conductor manufacturers, standards institutions, power research institutions, etc., had any data on this. Hence, correction factors for feeder resistance had to be found by trial and error. After a large number of simulations, a set of multiplication factors shown in Table IV were obtained. Recently, it has been learnt that some technical literature (source unknown) found in the utility has a few approximate formulas for the resistance variation of single-layer ACSR conductors and the values found here through simulations compare well with the values computed using these formulas The feeder model with temperature correction factor for resistance in addition to the detailed transformer model is referred to as Model 5. The computed voltage proles using Model 5 for

Fig. 5. Measured and computed voltages (Model 5).

the load-ow solutions are shown in Figs. 4 and 5 for the two cases. The computed loss is shown in the last row of Table III. It is seen that the computed voltages and losses closely match the measured values. It is seen from the voltage proles in Figs. 4 and 5 that the difference between the computed and measured voltages is not quite negligible at some transformer locations. This could be due to one or several of the following reasons.The rst is the absence of time synchronization among the meters. The voltages correspond to the three-cycle average rms value of voltages at the instant of storing. Therefore, the voltage recorded at each meter correspond to a slightly different instant of time. The second is that the loads at each node is the average load over a 30-min interval, whereas the voltages used to verifying the correctness are the instantaneous values recorded at the recording instant. Another source of error is the absence of data regarding transformer taps. VII. PROCEDURE FOR ESTIMATION OF LOSSES A loss table is generated through a sequence of load-ow solutions using Model 5. The feeder loads are varied from zero to more than the peak value in small steps. In this simulation, the load power factor is taken as equal to the average power factor of

Authorized licensed use limited to: The National Institute of Engineering. Downloaded on March 30, 2009 at 06:33 from IEEE Xplore. Restrictions apply.

RAO AND DEEKSHIT: ENERGY LOSS ESTIMATION IN DISTRIBUTION FEEDERS

1097

From Table V, it can be observed that, the difference between this loss estimate (for the nine month period) and the measured loss given in Table I, is quite small considering the several assumptions in our estimate scheme as well as the errors in measurement. The HV loss estimation scheme nally recommended by the study is the following. For each of the distribution feeders, do the following. 1) Collect the network data (length of segment, type of conductor, etc.) and distribution transformer locations and sizes. 2) Compute the loss curve data through a sequence of load-flow studies using Model 5 (In this context it is also recommended that a study must be initiated to find the exact ac resistance variation of the few conductor types in use with respect to current variation). 3) Since all the feeders are fitted with a data logging type of electronic meter at their input, every month the feeder load variation is downloaded onto a computer at the substation. A small program is provided which uses the load profile and the computed loss curve to estimate daily/monthly/yearly losses. 4) The loss curve must be updated whenever there is a change in the network or transformer parameters. VIII. LV SYSTEM LOSSES A. Features of the LV System The LV distribution system is a 440-V, 3-phase, 4-wire system. In rural areas the only signicant loads are the irrigation pump loads. The distribution transformer capacities are generally 25, 63, or 100 kVA, and each DT essentially supplies a few motor loads. However, the LV feeders could be quite long. Many of the DTs cater to only IP loads but some of the feeders in addition supply the rural domestic loads. Even in such feeders, the non-IP load is quite small. The only domestic load common in rural areas is the lighting load for a few hours in the early night hours. Other types of consumptions are extremely rare and not at all signicant. The IP consumption is either free or highly subsidized. When it is subsidized, the charges are based on the hp ratings of the motors and not on their energy consumption. The income received from the categories who pay is also only a small fraction of the billed amount. The net impact of these features is that the utilities have no incentives in installing meters and monitor individual consumption. Moreover, there is a very strong consumer/political opposition for installation of meters. B. LV Loss Measurement The loss measurements in the case of LV feeders was not as straight forward as in the case of the HV feeders. Even though the power fed from each of the distribution transformers was

Fig. 6.

Measured losses and the computed loss curve. TABLE V MONTHLY ESTIMATED LOSS (PROPOSED METHOD)

the feeder and all the distribution transformers are considered to be loaded to the same fraction of their capacity. Corresponding to each load, the losses and the power input at the slack bus (substation) are computed. The computed losses plotted against the feeder power input is the desired loss curve. The loss curve generated for the Bukkasagara feeder is superimposed on the measured losses and is shown in Fig. 6. It is seen from Fig. 6 that the computed loss curve can be considered to provide the mean of the measured loss at all the loads. However, at lower load levels, the estimated losses seem to be underestimated. This is due to an unusual type of load management (termed as Single Phasing), that is resorted to by the utility during certain periods of the day. This is done by short circuiting two of the three lines of the 11-kV feeder and energizing this pair and the remaining conductor. Under the above condition, the three phase supply will not be available for driving the 3-phase Motors (IP-sets). Only the single-phase lighting load is supplied and the energy consumption is considerably reduced. loss under this condition It can be easily shown that the is equal to 1.5 times the loss computed by assuming the same kVA load to be a balanced 3-phase load. The above result has been validated by modeling the single phase condition using a 3-phase load-ow and simulating this condition as an unbalanced 3-phase condition. As the single phase mode is also to be considered in the loss estimation, the losses obtained from the loss graph of Fig. 6 are multiplied by 1.5 during the single phasing periods (which are easily identiable from the substation recordings). The monthly energy losses estimated based on the loss curve using the procedure discussed is shown in Table V.

Authorized licensed use limited to: The National Institute of Engineering. Downloaded on March 30, 2009 at 06:33 from IEEE Xplore. Restrictions apply.

1098

IEEE TRANSACTIONS ON POWER DELIVERY, VOL. 21, NO. 3, JULY 2006

TABLE VI MEASURED LV FEEDER LOSSES

TABLE VII SYSTEM PARAMETERS AND COMPUTED LOSSES

metered continuously, there was no record of consumption (to start with). Though there was stiff opposition from many consumers, some of them were persuaded to allow meters to be installed at their premises and data on a number of feeders could be obtained in this manner (for different periods of time). In such cases, the standard 3-phase electro-mechanical energy meters were installed at the IP loads to measure the individual consumption. These meters were read once in a month. The energy loss in these LV feeders was obtained by subtracting the IP set consumption from the input energy measured at the transformer. Losses obtained in this way for some LV feeders, supplied from the Bukkasagara feeder are tabulated in Table VI. The results correspond to the month of March 2001. C. Loss Estimation: Present Practice Till now the utility has not made any serious effort to estimate the LV losses. When some estimates are needed, it is made using one of the following approaches. The rst approach is to estimate the energy consumption based on some rules of thumb for the average consumption per consumer and multiplying it by the number of consumers of that category. This is done only at the substation level (or sometimes at the feeder level). The other approach is to use the following formula for LV energy loss (EL):

out with , and values assumed to be 0.4, 0.9, and 0.9 kV, respectively. The conductor used for the LV feeders is Squirrel nominal Al. area) and has a resistance/km of 1.476 (20 . The other parameters of the feeders and the losses estimated using this formula are given in Table VII. Comparing the results obtained using the approximate loss formula given in (2) with the measured losses (Table VII with Table VI), it is seen that this formula yields a gross underestimate of energy losses. D. Proposed Method The absence of a method to make at least a reasonable estimate of LV losses motivated us to explore the possibility of evolving a new scheme for this purpose. At the outset, it was clear that the scheme used for the primary feeders could not be extended for the LV case because it would involve upfront cost due to extensive instrumentation and also recurring cost for data collection, data storage, data management and loss computation. It was also clear that the new method must not be based on large number of assumptions similar to those made in (2). A new loss estimation scheme is proposed here which we believe serves these requirements admirably. E. Basis of the Method Consider a 3-phase LV feeder consisting of segments made (if conductors of difup of conductors of resistance ferent resistances are used, their lengths are normalized). The total LV losses occurring in the feeder is the sum of the losses in each of the three phases. The loss occurring in phase- , at any time , is given by (3) where is the phase- current owing in the segment at is the length of the conductor segment. instant and be the total current in phase- , measured at the secLet be ondary of the distribution transformer at time and segment, the proportion of the total current that ows in the . Substituting for in (3), we get i.e., (4) Simplifying (4) by noting that the total current and resistance/km, are independent of the summation, we get (5) The energy loss occurring in phase- over a time by integrating (5) is obtained

(2) where number of conductor segments in the LV feeder; sum of horsepower ratings of IP sets downstream of conductor segment; the length in km of the conductor segment; transformer secondary voltage in kV; average power factor; average efciency of IP sets; feeder resistance ( ); time period of interest (hours); DF diversity factor. The current practice in the utility is to take LLF as for the LV system. It is easy to see that use of (2) requires that we use assumed (estimated) values for each of the parameters in (2). It is almost impossible to make meaningful estimates for parameters such as voltage, DF, and LLF in (2). Hence, one can have very little condence in the estimated values of losses. For the sake of comparison and since these parameter values for these feeders was readily available, the monthly losses were computed using the expression given in (2). The computations have been carried

(6)

Authorized licensed use limited to: The National Institute of Engineering. Downloaded on March 30, 2009 at 06:33 from IEEE Xplore. Restrictions apply.

RAO AND DEEKSHIT: ENERGY LOSS ESTIMATION IN DISTRIBUTION FEEDERS

1099

Now, the factor is dependent on the load that is present downstream of segment and the total load at the secondary of the distribution transformer. Therefore, it is a time-varying quantity. Since the load measurements at the nodes are not available, and also considering the fact that the currents are dependent predominantly on the total ratings of the IP sets, we can simplify the loss estimation by assuming a conforming load variation; This assumption is not new. It is used in deriving all can be the existing loss formulas. With this assumption, . Here, treated as a constant i.e., is the sum of the HP ratings of the connected IP sets downsegment and is the total connected HP load stream of the on the entire LV feeder. Equation (6) can therefore be written as

TABLE VIII LV LOSS ESTIMATES FOR MARCH 2001 (PROPOSED METHOD)

(7) In (7), the term , accounts for the effect of load distribution along the feeder and is represented by . The energy loss equation for phase- then reduces to (8) The total energy loss is the sum of the loss occurring each of the three phases. Hence, the energy loss formula for the feeder can be written as (9) A careful study of the new loss formula shows that it is based on very few assumptions. Given the feeder conguration (basically lengths, topology, location, and ratings of the IP sets), the factor can be calculated which remains constant unless the conguration of the feeder itself is changed. , being the resistance per km of the feeder, is also constant. If the quantity is obtained for any interval of time , the loss corresponding to the interval is readily given by the new loss formula. The applicability of this loss formula lies in how effectively we can obtain this quantity. In order to measure this quantity acmeter has been evolved curately, a design for a 3-phase and a patent is pending for this design [20]. In this patent proposal, two alternate implementations have been described. One implementation is an electro-mechanical type of meter and the other is a digital meter. The cost of the electro-mechanical implementation is very nominal; even the electronic version is quite affordable. The other advantage of the meter is that it can be read at irregular intervals because it is an integrating type of meter. With such a meter installed at the output of the distribution transformer, the change in the readings of this meter over quantity over that interval. The any interval gives the for the feeder need be calculated only once and quantity used as a multiplier with the reading. can be updated if there is any signicant change in load or conguration of the feeder. F. Loss Estimates by Proposed Scheme We have seen that this new scheme is quite reliable, by comparing the measured losses in several distribution feeders with

the value obtained using this formula for a large number of cases. For verifying the result, even though we did not have the new meters in place, the , , and values recorded at every 30 min at the DTs, provided the required values of phase currents. For the sake of illustration, the losses computed for the month of March for the four LV feeders listed in Table VI are given in Table VIII. Comparison of the estimated losses in Table VIII with the measured losses in Table VI gives an idea of the reliability of the proposed method. It must also be pointed out that such estimates are obtained at a number of feeders. Hence, the possible errors in each of the estimates, when combined tend to compensate one another while calculating the total LV system loss thus making the estimate for the total loss of an area very reliable. IX. REMARKS 1) The promising results seen in the case of the proposed LV method, seem to suggest the possibility of using this approach for the HV feeders also. Since the digital meters at the substation do not have the capability of recording half an hourly current and voltage information, at this point we have not been able to verify this hypothesis. Utilities who have not already invested in procuring and installing the usual types of meters at the substation could incorporate this feature while procuring meters in the future. Alternately, one could also think of installing the new type of meters at each of the HV feeders 2) The proposed loss curve for the HV feeders has been generated so as to get the average feeder loss for any specied feeder input. The feeder input considered here is the kVA input, as this measurement is readily available. It is easy to see that in situations where the feeder input kVA measurement is not available but only the input current information is available, the proposed approach is still applicable. In that case the loss curve could be generated with respect to input current 3) The discussions in the paper are limited to estimating the losses in a feeder. In order to apply these schemes for computing the system wide losses, two possibilities exist. The rst is to estimate the losses for all the feeders. The other alternative is to nd some representative feeders (in a way similar to [16]) and estimate the system losses based on the estimates of the chosen sample set. The latter approach requires further investigation X. CONCLUSIONS The results of a joint study conducted in collaboration with the local utility, pertaining to distribution system loss estima-

Authorized licensed use limited to: The National Institute of Engineering. Downloaded on March 30, 2009 at 06:33 from IEEE Xplore. Restrictions apply.

1100

IEEE TRANSACTIONS ON POWER DELIVERY, VOL. 21, NO. 3, JULY 2006

tion has been presented. The results highlight the limitations of the present methods of loss estimation in use and also the major difculties in measuring the losses directly. Two loss estimation schemes are proposed and an assessment of their reliability has been provided by comparing the estimates with measured values. One of the schemes is meant for the 11-kV primary feeders and makes use of the logged data of the electronic meters already installed at the input of these feeders. The second scheme is meant for use with LV feeders. As no metering exists at these feeders, use of a new meter (which is not expensive) is proposed. It is shown that the use of this integrating type of meter when multiplied with a constant gives a good estimate of the LV feeder loss. It is envisioned that the results of this study would be of great interest not only to utilities in the developing world but also to those in the developed countries. ACKNOWLEDGMENT The rst author, P. S. N. Rao, acknowledges the contributions of V. G. Havanagi and H. N. Dattatreya from KPTCL (assistance in instrumentation and data collection); P. S. Nandini and K. Prahlad (assistance in data management); and also thanks Prof. I. Sen and Prof. D. P. Sengupta for several discussions during the project. REFERENCES

[1] F. H. Buller and C. A. Woodrow, Load factor equivalent hours values compared, Electr. World, Jul. 1928. [2] H. F. Hoebel, Cost of electric distribution losses, Electr. Light and Power, Mar. 1959. [3] M. W. Gustafson, J. S. Baylor, and S. S. Mulnix, Equivalent hours loss factor revisited, IEEE Trans. Power Syst., vol. 3, no. 4, pp. 15021507, Nov. 1988. [4] M. W. Gustafson, Demand, energy and marginal electric system losses, IEEE Trans. Power App. Syst., vol. PAS-102, no. 9, pp. 31893195, Sep. 1983. [5] M. W. Gustafson and J. S. Baylor, Approximating the system losses equation, IEEE Trans. Power Syst., vol. 4, no. 3, pp. 850855, Aug. 1989. [6] N. E. Chang, Determination of primary feeder losses, IEEE Trans. Power App. Syst., vol. PAS-87, no. 12, pp. 19911994, Dec. 1968. [7] N. R. Schultz, Distribution primary feeder I r losses, IEEE Trans. Power App. Syst., vol. PAS-97, no. 2, pp. 603609, Mar./Apr. 1978. [8] D. I. H. Sun, S. Abe, R. R. Shoults, M. S. Chen, P. Eichenberger, and D. Ferris, Calculation of energy losses in a distribution system, IEEE Trans. Power App. Syst., vol. PAS-99, no. 4, pp. 13471356, Jul./Aug. 1980. [9] R. Cspedes, H. Durn, H. Hernndez, and A. Rodrguez, Assessment of electrical energy losses in the Colombian power system, IEEE Trans. Power App. Syst., vol. PAS-102, no. 11, pp. 35093515, Nov. 1983.

[10] D. L. Flaten, Distribution system losses calculated by percent loading, IEEE Trans. Power Syst., vol. 3, no. 3, pp. 12631269, Aug. 1988. [11] N. Vempati, R. R. Shoults, M. S. Chen, and L. Schwobel, Simplied feeder modeling for load ow calculations, IEEE Trans. Power Syst., vol. PWRS-2, no. 1, pp. 168174, Feb. 1987. [12] R. Baldick and F. F. Wu, Approximation formulas for the distribution system: The loss function and voltage dependence, IEEE Trans. Power Del., vol. 6, no. 1, pp. 252259, Jan. 1991. [13] H.-D. Chiang, J.-C. Wang, and K. N. Miu, Explicit loss formula, voltage formula and current ow formula for large scale unbalanced distribution systems, IEEE Trans. Power Syst., vol. 12, no. 3, pp. 10611067, Aug. 1997. [14] C. S. Chen, M. Y. Cho, and Y. W. Chen, Development of simplied loss models for distribution system analysis, IEEE Trans. Power Del., vol. 9, no. 3, pp. 15451551, Jul. 1994. [15] Y.-Y. Hong and Z.-T. Chao, Development of energy loss formula for distribution systems using FCN algorithm and cluster-wise fuzzy regression, IEEE Trans. Power Del., vol. 17, no. 3, pp. 794799, Jul. 2002. [16] C. A. Dortolina and R. Nadira, The loss that is unknown is no loss at all: A top-down/bottom-up approach for estimating distribution losses, IEEE Trans. Power Syst., vol. 20, no. 2, pp. 11191125, May 2005. [17] Energy Accounting and Rationalization of Distribution Systems, Final Report, KPTCL, Dept. Elect. Eng., Indian Inst. Sci., Bangalore, India, 2004, submitted for publication. [18] IEEE Standard for Calculating the Current- Temperature Relationship of Bare Overhead Conductors, IEEE standard 7381993. [19] Aluminum Electrical Conductor Handbook, 2nd ed., The Aluminum Association, Washington, DC, 1982. dt Meter for Energy Loss Estimation in Elec[20] P. S. N. Rao, An I trical Power Networks, Indian Patent Application Number: 520/CHE 2004, Jun. 2004.

P. S. Nagendra Rao was born in Periyapatna, Karnataka, India, in 1950. He received the B.E. degree in electrical engineering and the M.E. degree in power systems engineering from the University of Mysore, Mysore, India, in 1971 and 1973, respectively, and the Ph.D. degree from the Indian Institute of Technology, Delhi, India, in 1981. From 1973 to 1984, he was on the faculty of the Department of Electrical Engineering, National Institute of Engineering, Mysore. He joined the Department of Electrical Engineering, the Indian Institute of Science, Bangalore, in 1984, where he is currently a Professor. His elds of interest cover many aspects of power system analysis, design, operation, and control.

Ravishankar Deekshit was born in Bangalore, Karnataka, India, in 1959. He received the B.E. degree in electrical engineering from Bangalore University in 1982 and the M.E. degree in power systems engineering from Anna University in 1989. He is currently pursuing the Ph.D. degree with the Department of Electrical Engineering, Indian Institute of Science, Bangalore. He has been on the faculty of the Department of Electrical and Electronics, B.M.S, College of Engineering, Bangalore, since 1984 and is presently Head of the department. His eld of interest is in the area of power systems.

Authorized licensed use limited to: The National Institute of Engineering. Downloaded on March 30, 2009 at 06:33 from IEEE Xplore. Restrictions apply.

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Msi ms-7222 Rev 3.0 SCH PDFDocument30 pagesMsi ms-7222 Rev 3.0 SCH PDFRodney RibeiroPas encore d'évaluation

- Liquid Gas Absorption ProcessDocument89 pagesLiquid Gas Absorption ProcessMohd Masri A. RazakPas encore d'évaluation

- Foundation Construction Challenges at 100 11th Avenue in Manhattan - Secant Pile Wall by Andrew Cushing, Et. Al.Document8 pagesFoundation Construction Challenges at 100 11th Avenue in Manhattan - Secant Pile Wall by Andrew Cushing, Et. Al.Andrew CushingPas encore d'évaluation

- Calibration of The Calorimeter and HessDocument7 pagesCalibration of The Calorimeter and HessazirPas encore d'évaluation

- Single Col - Tank-2013Document35 pagesSingle Col - Tank-2013Hgagselim SelimPas encore d'évaluation

- CT Terminology LexiconDocument12 pagesCT Terminology LexiconjtbushbergPas encore d'évaluation

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesMark Louie GuintoPas encore d'évaluation

- Foundation Design: Exhaust StackDocument8 pagesFoundation Design: Exhaust Stackmdelacua2Pas encore d'évaluation

- Pre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationDocument3 pagesPre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationEugenio Jr. MatesPas encore d'évaluation

- LDT9965 Dis WasherDocument70 pagesLDT9965 Dis WasherJosé Airton TirakowskiPas encore d'évaluation

- Ehe 07Document286 pagesEhe 07api-348272721Pas encore d'évaluation

- Physical Pharmacy Answer Key BLUE PACOPDocument34 pagesPhysical Pharmacy Answer Key BLUE PACOPprincessrhenettePas encore d'évaluation

- db2v9 EsqlDocument419 pagesdb2v9 EsqlRaphael PugliesiPas encore d'évaluation

- Factors That Affect The Quality of CommunicationDocument9 pagesFactors That Affect The Quality of CommunicationWilliam Paras Inte100% (3)

- Chapter 2 Review of Related LiteratureDocument16 pagesChapter 2 Review of Related LiteratureRodel D Dosano50% (6)

- Parameters by Functional CategoryDocument6 pagesParameters by Functional Categoryapi-3819698Pas encore d'évaluation

- Smoke Alarm Maintenance ChecklistDocument2 pagesSmoke Alarm Maintenance Checklistananthu.u100% (2)

- Tension Capacity of PileDocument8 pagesTension Capacity of Pilenimal179100% (1)

- FD100 CatalogoDocument4 pagesFD100 CatalogoKaren VásconezPas encore d'évaluation

- CFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesDocument7 pagesCFD Analysis of First Stage Nozzle Cooling Optimization in Gas TurbinesMahmood ElnagarPas encore d'évaluation

- Debug 1214Document3 pagesDebug 1214Pandji AsmaraPas encore d'évaluation

- Pakistani Radio MarketDocument72 pagesPakistani Radio MarketNajeeb Anwar100% (1)

- Presented By:: Rafi Sheikh Sheeraz Malik Syed Ahmed Ali Umair Ali Waqar AmeenDocument34 pagesPresented By:: Rafi Sheikh Sheeraz Malik Syed Ahmed Ali Umair Ali Waqar AmeenSyed Ahmed AliPas encore d'évaluation

- Education Abbreviation by AffairsCloudDocument6 pagesEducation Abbreviation by AffairsCloudgsaijanardhanPas encore d'évaluation

- Recommendation Handling of Norit GL 50Document9 pagesRecommendation Handling of Norit GL 50Mátyás DalnokiPas encore d'évaluation

- Fracture in Concrete and Reinforced ConcreteDocument23 pagesFracture in Concrete and Reinforced ConcreteNilay GandhiPas encore d'évaluation

- Starboard Strategies Issue 13-MinDocument28 pagesStarboard Strategies Issue 13-MinkrishnamrutamPas encore d'évaluation

- SAX Brochure - Web ReadyDocument4 pagesSAX Brochure - Web ReadyEng-Ahmad Abo-AledousPas encore d'évaluation

- BC 20s HandbuchDocument173 pagesBC 20s HandbuchmanoharPas encore d'évaluation

- Cable TrenchDocument57 pagesCable TrenchHari Krishna AaryanPas encore d'évaluation