Académique Documents

Professionnel Documents

Culture Documents

Access Hatch Cover Slab Design-02!01!2014

Transféré par

SureshKumarDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Access Hatch Cover Slab Design-02!01!2014

Transféré par

SureshKumarDroits d'auteur :

Formats disponibles

STATE OF KUWAIT SABAH AL SALEM UNIVERSITY CITY

COLLEGE OF EDUCATION FOR WOMEN

PRECAST CONCRETE SLAB FOR ACCESS HATCH COVER

DESIGN CALCULATIONS FOR PRECAST CONCRETE SLABS

Main Contractors: ARABTEC COMBINED GROUP JV. KUWAIT

Drawings Attached: C0800-SD-0103-01-ST-PR-03-GF-205-001 C0800-SD-0104-01-ST-PR-03-GF-107-001 C0800-SD-0104-01-ST-PR-04-GF-303-002 C0800-SD-0104-01-ST-PR-04-GF-104-002 Rev. R1 Date.

Dec., 31, 2013 First Submission.

FOR APPROVAL

NOTE No. : RE DC - HS TOTAL 05 + 1 SHEETS.

(Excluding pages of Codes & Dwgs.)

Description.

PRECAST CONCRETE SUB-CONTRACTOR:

Real Estate Construction & Fabrication CO., (RECAFCO)

P. O. Box 24478, SAFAT, 13105, KUWAIT. Tel.: 23260054. Fax.: 23260067. e-mail: fm@ recafco.com

SABAH AL SALEM UNIVERSITY CITY

COLLEGE OF ARTS FOR WOMEN / MEN PRECAST CONCRETE SLABS FOR ACCES HATCH COVER 1

INDEX 1. General.. 2. Data .. 3. Precast slab for Access Hatch Cover 4. Deflection of Access Hatch Cover slab Sheet 2 Sheet 2 Sheet 3 Sheet 5

Copy of relevant pages from ACI 318 and PCI Design Handbook Sixth Edition are also enclosed.

SABAH AL SALEM UNIVERSITY CITY

COLLEGE OF ARTS FOR WOMEN / MEN PRECAST CONCRETE SLABS FOR ACCES HATCH COVER 2

General:The objective of this design note is to illustrate the design of the precast concrete slab panel. In general, the precast concrete units are designed following the principles given in the PCI Design Handbook& ACI 318M-11. Copies of relevant pages are enclosed herewith for ready reference. The slab panels are designed to support their self-weight, Finishes and Live loads.

Data:Density of concrete SIDL for Finishes Live Load = 25 kN/M3 = 3.5 kN/M2 (100mm thick finish only as in DWG) = 5 kN/M2

Clear span of slab in Both campuses = 3.50 m. Max. Effective span of slab = 3.70 m c/c of Supports. Cube strength of concrete at 28 days = 50 MPa. Cube strength of concrete at time of stripping = 25 MPa. As per clause 1.3.1.2, 5.3.3.2 & Eq.5.3.3.1 of PCI Design Handbook, allowable tensile stress in concrete = 5fc For a cube strength of 25 MPa; ft = 5 x 0.82x(25 x 144.86) / 144.86 = 1.88 MPa. For a cube strength of 50 MPa; ft = 2.66 MPa. As per ACI 318M-11 clause 10.5.4 & 7.12.2.1 Minimum reinforcement to be provided = 0.0018 x Cross-section area. As At At At per Table 5.3.3.1 of PCI Design Handbook, impact factor considered time of stripping = 1.3 time of handling = 1.2 time of transport = 1.5

SABAH AL SALEM UNIVERSITY CITY

COLLEGE OF ARTS FOR WOMEN / MEN PRECAST CONCRETE SLABS FOR ACCES HATCH COVER 3

Precast slab panel:The 250mm thick slab panel is cast on steel mould. It will be stripped, stacked & transported horizontally. At the site, it will be erected in position. At all these stages, the slabs will be handled using the same set of hooks embedded in the slab. Check for stress conditions at all these stages is carried out in this design note in the following: At Stripping Stage:(Refer fig. 5.2.5 of PCI Design Handbook copy attached for ready reference.) Using Two point pick-up, w = 1.3 x 0.25 x 25 = 8.13 kN/m2. a = 1.4m; b = 3.86m; b/2 = 1.93m; 15t = 15 x 0.25 = 3.75m. Mx = 0.0107 x 8.13 x 1.42 x 3.86 / 1.93 = 0.34 kN-m/m. My = 0.0107 x 8.13 x 1.4 x 3.862 / 0.7 = 2.59 kN-m/m. Hence, maximum extreme fibre stress = Mmax / Z = 2.59 x 106 /(1000 x 2502 /6) = 0.25 MPa. << 1.88 MPa.

IMPACT FACTOR

Hence, plain concrete section will be safe. However, as advised by clause 10.5.4 & 7.12.2.1 of ACI 318M-11, provide minimum reinforcement of 0.0018 x cross section area. Area of steel required = 0.0018 x 250 x 1000 = 450 mm2 / m width. At Transportation Stage:The unit will be supported at the same points as at stripping stage. The only difference in the loading details is the impact factor to be considered in this case is 1.5 as against 1.3 at stripping stage. Hence, maximum extreme fibre stress = 1.5 x 0.25 / 1.3 = 0.29 MPa. This stress is far lesser than the permissible tensile stress of 2.66MPa. Hence it is safe. At Erection Stage:At this stage, the unit will be lifted from the horizontal position using the lifting hooks at top face of the panel at locations corresponding to the stripping hooks. Maximum bending moment and stresses at this stage is same as at the transportation stage.

SABAH AL SALEM UNIVERSITY CITY

COLLEGE OF ARTS FOR WOMEN / MEN PRECAST CONCRETE SLABS FOR ACCES HATCH COVER 4

Hence, it is safe as plain concrete section. Provided reinforcement will be adequate. At Service Stage:At this stage, the unit is supported by the RCC frames and the full effective span is active. The panel is subject to Live loads in addition to the self weight. Live load = 5.0 kN/m2. Self weight of Slab Finishes Loads Live Loads Total service loads = 1.4x0.25x25 = 1.4 x 3.5 = 1.4 x 5.0 = = 8.75 kN/m. = 4.90 kN/m. = 7.00 kN/m. = 20.65 kN/m.

Moment due to total service loads = 20.65 x 3.72 / 8 = 35.34 kN-m. Therefore maximum extreme fibre stress = 35.34x106/(1400x2502/6) = 2.42 MPa. < 2.66 MPa.

However, the panel is designed as RCC slab as per ACI 318M11. ( & ACI SP-17M (09) for design Tables)

Ultimate Loads = 1.2 x (8.75+4.90) + 1.6 x 7.00 = 27.58 kN/m. Mu = 27.58 x 3.72 / 8 = 47.20 kN-m. B = 1400mm; D = 250mm; d = 250-20-10-8 = 212mm Provide 716 stirrups. fc = 40 MPa. Mu / bd2 = 47200000 / (1400 x 2122) = 0.75 MPa. = 0.20%(Flexure 1) Ast min. required = 0.33 x 212 x 1400 / 100 = 979.5 mm2. Ultimate Shear force at critical section =27.58x(3.7/2 0.212) = 45.18 kN. (=1407mm2) main bars at bottom and 8 @ 150mm c/c

Bv = 1400 mm; d = 212 mm; From Clause 11.2.1.1 of ACI 318M-11, Vc = 0.17 x 1 x (40)1/2 x 1400 x 212 / 1000 = 319.11 kN. Vc = 0.75 x 319.11 = 239.33 kN. >> Vu Hence no need for shear reinforcement as per clause 11.4.6 of ACI 318M-11.

SABAH AL SALEM UNIVERSITY CITY

COLLEGE OF ARTS FOR WOMEN / MEN PRECAST CONCRETE SLABS FOR ACCES HATCH COVER 5

Check for Deflection:Ref. Clause 8.5.1, 9.5 & sub-clauses thereof of ACI 318M-11. Ec = 24001.5 x 0.043 x 400.5 = 31975 MPa. Ig = 1000 x 2503/12 = 13.02x108 mm4. (This is on the conservative side) fr = 0.62 x 1 x 400.5 = 3.92 MPa. Mcr = 3.92 x 13.02e8 / 125 = 40.83 kN-M. Ma = (13.65+7.00) x 3.72 / 8 = 35.34 kN-M. Ie = 13.02x108 mm4. Max. Deflection = 5wL4/384EI = 5 x 20.65x37004/(384x31975x13.02e8) = 1.21 mm. = 7x48.5/(1400x250) = 0.97e-3 2.0 / (1+50x0.97e-3) = 1.908 Total Long-term deflection = 1.908 x 1.21 = 2.31 mm. L / 240 = 3700 / 240 = 15.42 mm. > 2.31 mm. Hence OK.

Vous aimerez peut-être aussi

- Lintel BeamDocument3 pagesLintel BeamJosephPas encore d'évaluation

- Electrical SOQ EVDocument16 pagesElectrical SOQ EVjaiPas encore d'évaluation

- 1.0 Objectives of Covered LinkwaysDocument4 pages1.0 Objectives of Covered LinkwaysDavid WangPas encore d'évaluation

- Leighton Contractors Submission for Painting and FRP SystemDocument81 pagesLeighton Contractors Submission for Painting and FRP SystemChan Kin CheungPas encore d'évaluation

- Genset Concrete Pad Detail-SignedDocument1 pageGenset Concrete Pad Detail-SignedJOSEPH ANTHONY VINCE MOICOPas encore d'évaluation

- AWC Beam FormulasDocument26 pagesAWC Beam FormulasR ASTUSPas encore d'évaluation

- Sor HDB 2021Document137 pagesSor HDB 2021Lai Kok UeiPas encore d'évaluation

- Detailing For Intermediate Seismic HazardDocument47 pagesDetailing For Intermediate Seismic HazardjonathanPas encore d'évaluation

- Philosophy of Limit State Design and Classification of SectionsDocument96 pagesPhilosophy of Limit State Design and Classification of Sectionsybm987100% (1)

- Power Electronics - MITDocument210 pagesPower Electronics - MITVasco RodriguesPas encore d'évaluation

- En B 373 Project 2012Document9 pagesEn B 373 Project 2012April IngramPas encore d'évaluation

- Publication Hilti RebarDocument234 pagesPublication Hilti RebarRedwan HendiPas encore d'évaluation

- Apec Engineer Manual 04Document41 pagesApec Engineer Manual 04jopaypagas100% (1)

- Method Statement - Soil InvestigationDocument10 pagesMethod Statement - Soil InvestigationKamal Deo ShahPas encore d'évaluation

- Becoming An Apec Professional EngineersDocument6 pagesBecoming An Apec Professional EngineersLucille Gacutan AramburoPas encore d'évaluation

- F-500 Encapsulator TechnologyDocument6 pagesF-500 Encapsulator TechnologyBdSulianoPas encore d'évaluation

- Bachelor of Technology In: Seminar Report On Architectural and Structural Design Blast Resistant BuildingsDocument43 pagesBachelor of Technology In: Seminar Report On Architectural and Structural Design Blast Resistant BuildingsAr Nitin AggarwalPas encore d'évaluation

- MOS Trial Trench WorkDocument20 pagesMOS Trial Trench Workg.chandra mohanPas encore d'évaluation

- BOQ NEOM Sport Sector 5000 SQ.M: SRL Description Unit QTYDocument1 pageBOQ NEOM Sport Sector 5000 SQ.M: SRL Description Unit QTYrizwan qureshiPas encore d'évaluation

- Mezzanine Slab Structural Calculation DesignDocument25 pagesMezzanine Slab Structural Calculation Designmjnasar khan jamalPas encore d'évaluation

- Text Linguistics and Classical Studies - Facebook Com LinguaLIBDocument129 pagesText Linguistics and Classical Studies - Facebook Com LinguaLIBEnglish Buzz100% (1)

- Welded ReinforcingDocument2 pagesWelded Reinforcingvisvisvisvis100% (1)

- RNE Brochure (Compatibility Mode)Document6 pagesRNE Brochure (Compatibility Mode)TedPas encore d'évaluation

- First Summative Test in Math 5 (First Quarter)Document1 pageFirst Summative Test in Math 5 (First Quarter)Marlene Tagavilla-Felipe Diculen100% (1)

- CO2 Production PlantsDocument4 pagesCO2 Production PlantsBoojie Recto100% (1)

- İsrail Deprem Yönetmeliği EkiDocument18 pagesİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanPas encore d'évaluation

- MEP Connection For Seismic ZoneDocument217 pagesMEP Connection For Seismic Zonesyed AffanPas encore d'évaluation

- Cemtec AL PU CoatingDocument2 pagesCemtec AL PU CoatingPageduesca RouelPas encore d'évaluation

- Download Ram Connection V8i CrackDocument2 pagesDownload Ram Connection V8i CrackMichael LumauigPas encore d'évaluation

- Barrier GateDocument12 pagesBarrier GatewillysketchPas encore d'évaluation

- Grade Beam Design CalculationDocument4 pagesGrade Beam Design CalculationArnold VercelesPas encore d'évaluation

- Wind Induced Balcony Railing Vibrations and NoiseDocument6 pagesWind Induced Balcony Railing Vibrations and Noisezane92Pas encore d'évaluation

- Kirby Building Systems: Preventive Maintenance ManualDocument12 pagesKirby Building Systems: Preventive Maintenance ManualLalaine RamosPas encore d'évaluation

- Two-Way Slab Design Based On ACI 318-14 Using Finite Element Method Input Data & Design SummaryDocument4 pagesTwo-Way Slab Design Based On ACI 318-14 Using Finite Element Method Input Data & Design SummaryJordy Lopes DiazPas encore d'évaluation

- WLG2445 - Chain Link FenceDocument38 pagesWLG2445 - Chain Link FenceIho1Pas encore d'évaluation

- Gir Gai Trading Hot Rolled Steel Sections PDFDocument4 pagesGir Gai Trading Hot Rolled Steel Sections PDFtpop1707Pas encore d'évaluation

- Can Csa S806-02 (115-119)Document5 pagesCan Csa S806-02 (115-119)JEISON CALIXTO VARGASPas encore d'évaluation

- Annex 06 - UNOPS Minimum Health and Safety Requirements For ContractorsDocument57 pagesAnnex 06 - UNOPS Minimum Health and Safety Requirements For Contractorsabdu al enabPas encore d'évaluation

- Self-Compacting Concrete: The Benefits of SCCDocument4 pagesSelf-Compacting Concrete: The Benefits of SCCKhaja MohiddinPas encore d'évaluation

- Tate Grid: Metric Tate Grid SpecificationsDocument9 pagesTate Grid: Metric Tate Grid Specificationsguillote_666Pas encore d'évaluation

- Chemrite PEJ FillerDocument2 pagesChemrite PEJ FillerghazanfarPas encore d'évaluation

- Instability of Slender Concrete Deep BeamDocument12 pagesInstability of Slender Concrete Deep BeamFrederick TanPas encore d'évaluation

- Bearing Pad - AASHTO Grade: Hohmann & Barnard, IncDocument1 pageBearing Pad - AASHTO Grade: Hohmann & Barnard, IncRiyuRazePas encore d'évaluation

- Site SurveyDocument7 pagesSite Surveypunk cmPas encore d'évaluation

- Mechanical Force of Short Circuit On Steel Structure For Terminator Inside EGATDocument9 pagesMechanical Force of Short Circuit On Steel Structure For Terminator Inside EGATApichartj JusuayPas encore d'évaluation

- Transport Lifting Manual REV00Document15 pagesTransport Lifting Manual REV00ANTONIO MANGACHAIAPas encore d'évaluation

- vr1 Verification Request Form v3 2106162192016461440Document2 pagesvr1 Verification Request Form v3 2106162192016461440Richu PaliPas encore d'évaluation

- Fischer Technical DataDocument6 pagesFischer Technical DataAnonymous CgJzschPas encore d'évaluation

- Model K580: ResistiveDocument2 pagesModel K580: Resistivegsantosh06Pas encore d'évaluation

- 187 NanoGrout EGDocument2 pages187 NanoGrout EGTristan Irvin Asi100% (3)

- Mivan Formwork System OverviewDocument85 pagesMivan Formwork System OverviewAbhi Jain100% (1)

- Tender Drawings Merged and Numbered - Final - 153 PagesDocument153 pagesTender Drawings Merged and Numbered - Final - 153 PagesTamilkumar D (Tamil)Pas encore d'évaluation

- Base Transceiver Station: Trans-Receiving Antenna For Communication PurposeDocument1 pageBase Transceiver Station: Trans-Receiving Antenna For Communication PurposeemmanuelPas encore d'évaluation

- Pnap 071Document14 pagesPnap 071Cheung LeePas encore d'évaluation

- Plan Sump and Pump HouseDocument1 pagePlan Sump and Pump Housevenkatesh19701Pas encore d'évaluation

- CPT Brochure 1Document12 pagesCPT Brochure 1jose antonio becerra mosqueraPas encore d'évaluation

- Motor Core Loss Test Sets: Test Electric Motors From Fractional To 20,000 HPDocument4 pagesMotor Core Loss Test Sets: Test Electric Motors From Fractional To 20,000 HPAlbertPas encore d'évaluation

- Cover Slab and Cast Iron Grating For Channels: Typical Section Plan of SlabDocument1 pageCover Slab and Cast Iron Grating For Channels: Typical Section Plan of SlabExile PeachPas encore d'évaluation

- LiteDeck Book 2013-1 WebDocument48 pagesLiteDeck Book 2013-1 WebGonzalo Gomez CastilloPas encore d'évaluation

- FA QCDD Exam Questions KIC by TrekaDocument7 pagesFA QCDD Exam Questions KIC by TrekaSHERIF KHATTABPas encore d'évaluation

- Runway and airfield pavement designDocument18 pagesRunway and airfield pavement designspruhatechPas encore d'évaluation

- Duct Runs Through Open Web JoistDocument11 pagesDuct Runs Through Open Web JoistWilliam GrecoPas encore d'évaluation

- STAAD Advanced ConcreteDocument36 pagesSTAAD Advanced ConcreteElvin SandajanPas encore d'évaluation

- Difference Beetween Is 800-2007 & Is 800-1984Document96 pagesDifference Beetween Is 800-2007 & Is 800-1984ayazmadPas encore d'évaluation

- Review For Mastery: VocabularyDocument3 pagesReview For Mastery: VocabularyHala EidPas encore d'évaluation

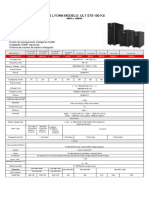

- Ups Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVADocument1 pageUps Lyonn Modelo: Ult St5-100 KS: 10KVA A 120KVASebastian Matias CruzPas encore d'évaluation

- Innovative Injection Rate Control With Next Generation Common Rail Fuel Injection SystemDocument8 pagesInnovative Injection Rate Control With Next Generation Common Rail Fuel Injection SystemRakesh BiswasPas encore d'évaluation

- Libro de FLOTACIÓN-101-150 PDFDocument50 pagesLibro de FLOTACIÓN-101-150 PDFIsaias Viscarra HuizaPas encore d'évaluation

- Triac BT137-600DDocument6 pagesTriac BT137-600DEverton AlvesPas encore d'évaluation

- 2011 Nov P1 Maths L2Document9 pages2011 Nov P1 Maths L2nhlanhlamhlambi3Pas encore d'évaluation

- PAI Industries, Inc. - Catalog Polea de MotorDocument2 pagesPAI Industries, Inc. - Catalog Polea de MotorAlexis VallePas encore d'évaluation

- UNIT IV: Calculating Probability Using Fundamental ConceptsDocument15 pagesUNIT IV: Calculating Probability Using Fundamental ConceptsGaurav SonkarPas encore d'évaluation

- Skripsi #2 Tanpa HyperlinkDocument19 pagesSkripsi #2 Tanpa HyperlinkindahPas encore d'évaluation

- Timetable Saturday 31 Dec 2022Document1 pageTimetable Saturday 31 Dec 2022Khan AadiPas encore d'évaluation

- St. Michael'S High SchoolDocument5 pagesSt. Michael'S High SchoolHoniel PagoboPas encore d'évaluation

- UntitledDocument135 pagesUntitledtaraji dawlaPas encore d'évaluation

- 0620 Chemistry: MARK SCHEME For The March 2015 SeriesDocument6 pages0620 Chemistry: MARK SCHEME For The March 2015 SeriesDark GreenPas encore d'évaluation

- UDP Control and Monitoring With PIC Microcontroller - StudentCompanion PDFDocument14 pagesUDP Control and Monitoring With PIC Microcontroller - StudentCompanion PDFVport PortPas encore d'évaluation

- Refining of MaterialsDocument38 pagesRefining of MaterialsJAWAD AHMAD BURTPas encore d'évaluation

- TR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3Document3 pagesTR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3AzeedPas encore d'évaluation

- 8 - Chitapon - TR Winding Buckling - Paper PDFDocument5 pages8 - Chitapon - TR Winding Buckling - Paper PDFbcqbaoPas encore d'évaluation

- in 01 en KATALOGDocument50 pagesin 01 en KATALOGSigma Ragam ManunggalPas encore d'évaluation

- CT-1 (Paper-1) - 09-Aug-15Document63 pagesCT-1 (Paper-1) - 09-Aug-15HhjPas encore d'évaluation

- Engg Mechanics Paper Dec 2019 As Per CODocument4 pagesEngg Mechanics Paper Dec 2019 As Per COPiyush BhandariPas encore d'évaluation

- Beyond SVGFDocument66 pagesBeyond SVGFLiliana QueiroloPas encore d'évaluation

- HP Application Lifecycle Management Readme: What's New Installation InstructionsDocument36 pagesHP Application Lifecycle Management Readme: What's New Installation InstructionsBrandon GarciaPas encore d'évaluation

- SK EngineeringDocument16 pagesSK EngineeringOmkar waghulePas encore d'évaluation

- SUDOKU DocumentDocument37 pagesSUDOKU DocumentAmbika Sharma33% (3)

- AS TRONIC, The ZF-AS TRONIC Software Can Be: 4.7.6 EOL Programming Documentation of The EOL ProgrammingDocument3 pagesAS TRONIC, The ZF-AS TRONIC Software Can Be: 4.7.6 EOL Programming Documentation of The EOL ProgrammingThylanePas encore d'évaluation