Académique Documents

Professionnel Documents

Culture Documents

The Electrochemical Behavior of Metallic Implant Materials As An Indicator of Their Biocompatibility

Transféré par

jesus00158Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

The Electrochemical Behavior of Metallic Implant Materials As An Indicator of Their Biocompatibility

Transféré par

jesus00158Droits d'auteur :

Formats disponibles

The electrochemical behavior of metallic implant materials as an indicator of their biocompatibility

H. Zitter Department of Chemistry, University of Mining and Metallurgy, A-8700 Leoben, Austria H. Plenk Jr. Bone and Biornaterials Research Laboratory, Histological-Embryological Institute, University of Vienna, A-1090 Vienna, Austria

This study introduces a simple in vitro arrangement to measure current densities of implant metals. The in vivo condition of a metallic implant lying in tissues exhibiting different redox potentials is simulated in so-called straddle tests by applying a constant potential difference of 250 mV in saline containing the stable, fast-reacting redox system K,Fe(CN)6/K3Fe(CN)6. From a variety of corrosion-resistant implant metals and alloys, gold showed the highest current densities, followed by the stainless steel, the cobalt-based alloy, and the TiAIValloy. The pure metals titanium, niobium, and tantalum showed the lowest values. This can be explained by the stable oxide layer on these base metals, preventing an exchange of electrons and thus any redox reaction. This rating of metallic implant materials based on in vitro measurements of current densities is in good accordance with their biocompatibility rating reported from in vivo experiences. It seems that simple and cheap electrochemical tests allow an even more precise differentiation of the suitability of metallic materials for implant purposes than most of the conventional implantation tests, considering that biocompatibility is not only determined by corrosion products, but also by exchange currents and reaction products of redox processes involving tissue compounds.

INTRODUCTION

The biocompatibility of an implant is generally evaluated by the reactions of the surrounding tissue. The interaction between tissue and an implant material is considered adverse if there is evidence of specific damage by corrosion products in the surrounding tissue or other parts of the body. For this reason the biocompatibility of a metallic implant is usually equated with its corrosion resistance. Thus, the biocompatibility of metallic materials is controlled by the chemical, or more precisely the electrochemical interaction that results in the release of metallic ions into the tissue, and the toxicology of these released substances. If this is true, then the intensity of the damage caused by metailosis is proportional to the quantity of (toxic) metallic ions produced by c o r r ~ s i o n . ~ , ~ The literature often intimates that other interactions of a metallic implant material with the tissue can also be of decisive importance to its biocomJournal of Biomedical Materials Research, Vol. 21, 881-896 (1987) 0 1987 John Wiley & Sons, Inc. CCC 0021-9304/87/070881-16$04.00

882

ZITTER AND PLENCK

patibility, but this is seldom clearly formulated. Thus Williams mentions that anodic and cathodic reactions in the corrosion process involve electron movement so that the electrical status of any implanted metal wiIl be important. However, it is not clear here whether the electric current within the metal, or an unspecified electrical condition is considered critical for the biocompatibility. S a n d h a ~ sin , ~promoting the use of aluminium oxide ceramic for dental implants, also put forward a somewhat cryptic formulation, and did not differentiate the factors which determine the apparently inferior biocompatibility of metallic materials either:

. . . as we have already seen, the surface of the implant both in and outside the bone is exposed to different oxygen concentrations, electrolyte displacements and frequently changing pH values. In other words, it is exposed to a variety of factors which may form local galvanic elements. The surface of the implant intercepts these harmful exterior effects, transferring them to the interior and causing corrosion.

Mears5 mentions the possibility of a corrosion process at an implant resulting not only in corrosion products but also in other chemical substances which may affect the biocompatibility of the implant material:

. . . corrosion may be accompanied by changes in the chemical environment of the cell, such as the production of hydrogen ions and hydroxyl ions or the evolution of a gas, such as hydrogen, oxygen or chlorine.

However, even this formulation does not clearly express the fact that in any corrosive electrochemical process the corrosion reaction at the anode is necessarily accompanied by a reaction at the cathode which causes chemical changes in this area. Hench and Ethridge also regard a varying supply of oxygen only as a possible cause of corrosion, but do not consider the effect of galvanic elements on the surrounding tissues when there is no apparent corrosion. Only more recently has reference been made to the fact that a galvanic element may be formed at an implant even in the absence of corro~ion.~ The difference between such an element and that in a corrosive electrochemical process is not merely that the metal but a chemical substance in the tissue is oxidized at the anode. The reaction at the cathode is similar to that involved in corrosion, i.e., oxygen is consumed. The conditions for the formation of such elements-due to a locally variable supply of oxidizable and reducible substances -are most likely to exist after surgical insertion of an implant. Independently of the kind of the electrode reaction, the current density at the surface of the implant is, on the one hand, a measure of the rate of the electrochemical interactions between implant and the redox systems of the tissue. On the other hand, the current density on the implant metal is also a measure of the electrochemical effect on the cell reactions and thus of the degree of chemical changes or damage in the surrounding tissue. The

ELECTROCHEMICAL PROPERTIES OF METALLIC IMPLANTS

883

current density is determined by the potential difference between cathodic reduction and anodic oxidation, as the driving force, and by the sum of all resistances between anode and cathode. This overall resistance is made up of the ohmic resistance of the surrounding medium, the charge transfer resistance at the interface, and the resistance of any layers covering the metallic implant. The electrochemical behavior of a passive metal is predominantly determined by the total charge transfer resistance of the passive layer. In order to measure solely the latter resistance, one has to reduce diffusion controlled processes by offering a fast-reacting redox system in appropriate concentration. In this study, a simple in vitro arrangement is introduced by which the current densities of electrochemical reactions at several commonly used implant metals have been determined under various parameters with the aim to simulate the redox situation of an in vivo implant.

MATERIALS AND METHODS

Test materials

In order to facilitate comparison of the pure metals and alloys currently in use for the manufacture of implants, a specimen of each type was selected for this investigation. Designation, chemical composition, and processing state of the selected metallic materials are shown in Table I. The materials were all in sheet form with trimmed edges, and the samples were electropolished, as is usually the case for implant purposes.

Electrolyte solutions To simulate body fluids, e.g., in corrosion tests, salt solutions such as physiological saline, sea water, or Ringers solution can be used;6 they do not

TABLE I Chemical Composition and Processing State of the Metals Examined

Material designation Abbreviation

AU

Material composition (%) Cr Mo Ni

Standard

A1

Processing state

FeCrNiMo CoCrWNi Ti TiAlV Nb Ta

Fine gold Annealed X3CrNiMoN 17/13/5 16.8 4.2 13.3 Quench annealed (DIN 17440) CoCrWNi 20.3 10.5 15.1 Quench annealed (IS0 58321V) Titanium c.p. Cold worked (IS0 5832iII) Ti-6A14V 6.5 4.3 Hardened (IS0 583YIII) Niobium c.p. Sintered, cold worked Tantalum c.p. Sintered, cold worked (ASTM 560-78)

884

ZITTER AND PLENCK

contain all the organic compounds present in a real body fluid such as serum or plasma,' nor do they have a defined redox potential. However, since sufficient information about the effective redox systems in body fluids was also not available, preliminary tests were carried out. In a set-up similar to the potentiodynamic measurements (see Fig. 1) but using two platinum electrodes, the redox behavior of the following electrolyte solutions was tested: (a) pure saline (0,9% NaCl (bw)), aerated; (b) pure saline, deaerated with nitrogen; (c) saline containing lo-' mol/L of both K,Fe(CN), and K,Fe(CN),, deaerated with nitrogen; (d) tissue culture fluid: MEM (Boehringer, Mannheim, FRG) 160 mL, Fetal calf serum (PAA-Laborges., A-4210 Gallneukirchen, Austria) 40 mL, HEPES-buffer (Serva Feinbiochem., Heidelberg, FRG), 4 mL for adjusting to pH 7.2-7.4. Since, as shown in Figure 2, the resting potential of the tissue culture fluid (=simulated body fluid) resembles more closely that of the saline containing

6

consfont AE

cathode

potentiometer anode

kCm reference

*u

rounter working reference electrode electrode electrode

Figure 1. Lay-out and measuring cell for the electrochemical tests to measure dynamic voltage-current relations (a) or to simulate a galvanic redox element (b).

ELECTROCHEMICAL PROPERTIES OF METALLIC IMPLANTS

885

_...-...

10 -

\soline iaerotedl

I

I

I

---_--_____-10-2-

, C saline ideaerctedl 10. mol/L K, IFelCNi,! ?C2m o i / L K,IFeICNI,I

the redox system, and the latter shows less variable potentials and is faster reacting than the other solutions, all the electrochemical tests were performed with the deaereated saline augmented by the stable redox system Fe(CN)i-/ Fe(CN):-, and, for the sake of comparison, with aerated pure saline.

Electrochemical tests All electrochemical tests were carried out using the vessel and the different electrical circuits illustrated in Figure 1. A constant temperature of 37C and a slow convection of the electrolyte was achieved through a heat exchanger (thermostat) in the outer fluid circuit, where the solution could also be aerated or deaerated. The area of sample immersed in the electrolyte was about 10 cm, the remainder projecting above the electrolyte solution; this arrangement eliminated the risk of crevice corrosion taking place under a cover. A calomel electrode served as reference electrode.

886

ZITTER AND PLENCK

Current density measurements

In order to simulate the electrochemical behavior of a metallic implant forming a circuit between oxidizing and reducing areas of the tissue, a "concentration cell" of the redox system Fe(CN)$-/Fe(CN):- was built up (Fig. 3), in which a concentration ratio of 1/100 to 100/1 was maintained by a porous plug. Since in long-term testing the porous plug between the half-cells caused either a higher resistance or an equalizing of the concentrations, the concentration cell was substituted by a cell with only one electrolyte concentration, the corresponding potential difference being imposed externally, The electrochemical equivalence between the "concentration cell" and this "straddle test" set-up is also demonstrated in Figure 3. Preliminary trials, with applied potential differences between 100 and 750 mV, showed a rapid current increase up to 250 mV, while the higher potential differences resulted only in minor differentiations of current. Therefore, a potential difference of 250 mV was used in the so-called straddle tests, in order to obtain sufficiently high current densities, but still being

Concentration Cell Straddle -Test

10-1 open circuit

1 short

circuit

circuit

Open

'I

I

straddlepotential

nssv

LU

2oo Fe CCNk/Fe

KNg=0,O1

lonodel

Figure 3. Electrochemical equivalence between concentration cell and "straddle tests" using a stable redox system Pt/Fe(CN);- + Fe(CN):-/Pt in 0,9% NaCl at 37C. (For description of details see text.)

ELECTROCHEMICAL PROPERTIES OF METALLIC IMPLANTS

887

realistic in regard to redox potential differences existing in vim at different, more or less aerated tissue sites. The "straddle tests" were carried out for periods up to 48 h. In order to complete the electrochemical characterization of the metallic materials under test, the following tests were also performed:

Open-circuit potential measurements

Open-circuit potentials were recorded for a period of 48 h in pure saline and in saline augmented with the stable redox system.

Pofenfiodynamicmeasurements

Dynamic voltage-current relations were recorded in a potentiodynamic set-up with a polarization rate of 600 mV/h in accordance with ASTM regul a t i o n ~to , ~evaluate the behavior of the metals over other potential ranges.

Polarization resistance measurements

Yet another means of detecting currents flowing on the surface of a metal consists of measuring the polarization resistance. Such measurements have often been used to determine the corrosion rate and have also been applied to implants.8,10,11 However, these authors did not take into account the fact that this method of measurement records not only corrosion processes, but all the redox processes taking place at the electrode." The polarization resistances were determined after adjustment of the open-circuit potential by applying a voltage difference of 10 mV by means of a platinum counter electrode. The readings were taken after the currents stabilized which happened after a few seconds.

RESULTS

Open-circuit potentials

According to Figure 2, the redox potential of the tissue culture fluid lies at 400 mV. The activity of this system is characterized by current densities of about A cm-' at a polarization of *lo0 mV. In aerated saline there was a general tendency for the open-circuit potentials of the materials investigated to increase during the course of the experiment (Fig. 4a). Gold came closest to the theoretical value of an oxygen electrode, whereas the potentials of Ti, TiAlV, Nb, and Ta moved only slowly in this direction. In the stable redox system, all materials with the exception of Ti, Nb, and Ta approached the potential of the redox system in a short space of time (Fig. 4b).

888

ZITTER AND PLENCK

10

20

B d i n e with stable redox system

.I

f lhlFigure 4. Course of the open-circuit potentials of the tested metals in the different salines (a and b).

Voltage-current characteristics The voltage-current characteristics of the materials investigated are reproduced in Figures 5 and 6. In pure saline, all base metals and alloys differed from the noble metal gold in that they exhibited higher anodic current densities up to about +800 mVNHE (to build up passivity), and then lower anodic currents as a result of this passivation (Fig. 5 ) . This indicates that the anodic current densities of tantalum, niobium, and titanium are only due to growth of the oxide layer and that there is no electronic conduction through the passivating film on these metals. In a stable redox system, there was a marked differentiation of the metals in the anodic range, where gold, stainless steel, and the cobalt alloy exhibited the highest current densities (Fig. 6). The behavior of a system with short-circuited anodes and cathodes of the same size can be determined for various potential differences from these curves by entering the points of equal anodic and cathodic current densities against the corresponding potential differences.As shown in Figure 7 for the

ELECTROCHEMICAL PROPERTIES OF METALLIC IMPLANTS

889

Figure saline.

in pure

stable redox system, the differences between the materials investigated are more clearly illustrated in this evaluation. Straddle tests The results of current density measurements in the "straddle tests" carried out with a potential difference expansion of 250 mV are shown in Figure 8 in comparison to the open-circuit potentials. In aerated physiological saline, without the addition of the redox system, there is a rapid drop in the current densities of all materials accompanied by a rise in the potential. After a period of 48 h there are only slight differences between the currents of the different metals. Once again, the different properties of the materials were more clearly manifested in the presence of the stable redox system: the final current densities differ by five orders of magnitude between the highest value (gold) and the lowest (niobium and tantalum). The increasing differentiation as the experiment progressed is apparent when comparing the values measured after 1 and 48 h.

890

ZITTER AND PLENCK

Figure 6. Current density-potential curves of the tested metals in saline with a stable redox system. Polarization rate: 600 mV/h.

Polarization resistance

In measuring the polarization resistances, a noticeable difference in current densities between anodic and cathodic polarization was observed only in a few cases. The mean of anodic and cathodic current density was therefore used to calculate the polarization resistances. All the mean values are given in Table 11. There was only a slight difference between the materials in pure aerated physiological saline at low current densities. This indicates cathodic control by the oxygen reduction reaction, which is likely to be at least partly diffusion controlled and, therefore, independent of material. Again, considerably higher current densities and clear differences between the materials were established in the presence of the stable redox system.

ELECTROCHEMICAL PROPERTIES OF METALLIC IMPLANTS

891

Figure 7 . Current density as a function of the potential difference between the anodic and the cathodic branches of the current-potential curves for the metals tested in saline with a stable redox system.

TABLE I1 Polarization Current ( i ) and Polarization Resistance (R,) of Implant Metals in the Different Salines at 37C (Mean Values)

Pure saline (aerated) Material

Au FeCrNiMo CoCrWNi Ti TiAlV

Saline with stable redox system (deaerated) i (pA/cm2)

~

i (pA/cm2)

0.009 0.006 0.004 0.010 0.008 0.004 0.003

R, (kRcm2) 1100 1670 2500 1000 1250 2500 3300

R, (k0cm2)

N b

Ta

35.800 2.280 3.010 0.014 0.022 0.022 0.007

0.28 4.38 3.32 714.00 455.00 455.00 1430.00

892

ZITTER AND PLENCK

saline with

-400 -200 0 +ZOO +GOO -E lmV H I E ImVf1 Figure 8. Course of current densities and corrosion (anode) potentials for the metals tested in the different aerated salines during 48 h, applying a constant AE-expansion of 250 mV ("straddle tests").

DISCUSSION

Electrochemical test procedures

For the chosen redox system Fe(CN);-/Fe(CN):-, the literature specifies ~,~ neutral ~ redox potentials between 360 and 690 mV in acid s o l ~ t i o n . ' In saline a stable redox potential of 450 mV was measured. Assuming equibar or librium, this corresponds to a partial oxygen pressure of about a y H value of 29, which agrees with published values for t i ~ s u e . Also ' ~ the tissue fluid potentials are in good agreement with the redox potential of the chosen redox system. A question of special interest was the dissolution of gold by complexation. The dissolution rate cannot be deduced from the current densities (Table 11, Fig. 7), because they are due to the redox reaction Fe(CN);Fe(CN)d-

+e

The most simple proof that the current densities of gold do not correspond with a corrosion process is the equivalent behavior of platinum in the same electrolyte (compare Fig. 2 with Fig. 3). Nevertheless, the corrosion rate of gold was checked gravimetrically after polarizing with an anodic current density of 2 x lo3A * cm-'; no loss of mass could be detected after 48 h. This means that an assumed corrosion current would be more than a factor of lo3 lower than the measured redox current. The deduction of a corrosion rate of gold from measured current densities (Fig. 6) would represent the same widespread error as supposing the

ELECTROCHEMICAL PROPERTIES OF METALLIC IMPLANTS

893

equivalence of the current densities from polarization measurements on passivatable metals with their corrosion rates.

Results of electrochemical measurements

Already the course of the open-circuit potentials in the stable redox system gives an indication that there must be a significant difference in the exchange current of gold and the ferrous metals on the one hand and the acid-forming metals on the other. As one could expect from the course of the open-circuit potentials (Fig. 4) and from the redox current densities in saline with and without the stable redox system (Figs. 5 and 6), the measurements in pure saline could not produce current densities significant for the resistance of the metal surfaces. In contrast, all tests with the stable redox system gave material-specific results. In order to compare and classify these testing methods on the one hand and the materials tested on the other, the respective current densities have been plotted together in Figure 9. This diagram shows that the difference between the highest and the lowest measurement is in all methods smaller than in the "straddle test" after 48 h. This means that the latter method, using the redox system, provides the best differentiation of the materials. In the present case, the difference is several orders of magnitude, and there is hardly any overlapping which might result in ambiguity.

pottntiodynamic

AC- expansion fh

tSOmV

C8 h

81

polarization resistance

dE=

250mV

IS f

' f i g 71

Figure 9. Comparison of the current densities measured for the metals tested in the different salines and with the different electrochemical testing methods employed. Pure saline, saline with stable redox system.

1c

(table 2 1

894

ZITTER AND PLENCK

The measurements gave uniformly the following sequence: gold, passivatable steels, cobalt-based alloys, TiAlV alloy, titanium, niobium, and tantalum. This corresponds well to numerous experimental and clinical experiences as, for example, to the results of an in vitvo and in vivo biocompatibility study. l6 In this work, the metals gold, stainless steel, titanium, and tantalum were added in particulate form (particle size ranging from 2-20 pm) to human fibroblast cultures; a significant reduction of the cell growth was observed in the cases of gold and stainless steel, whereas tantalum and titanium did not influence the growth rate. The implantation of sheets of the same metals into the alveolar bone of dogs showed that, again, the initial bone-healing reaction was disturbed around the gold and the stainless-steel implants, leading to progressive bone resorption and implant loss in course of time, while the tantalum and the titanium (plasmaspraycoated) implants were tightly incorporated by the bone. Deducing the biocompatibility of metallic implant materials from their electrochemical behavior With the exception of the formation of an oxidation product specific to the tissue in place of a corrosion product, the effect of a redox reaction taking place without corrosion is same as that of a corrosion reaction: in both cases the most significant chemical changes are an increase in the pH value at the cathode and a decrease in this value at the anode. In both cases there is a flow of electrons in the metal and an equivalent flow of ions through the surrounding tissue. The latter, and certainly not the flow of electrons in the metal, may disturb the existing balance of ions in the tissue. The same applies to the conduction of stimuli by nerve cells, which is also based on ion transport. As the movement of ions is responsible for the conduction of stimuli and probably also for other processes in the cells and tissues, another question arises: to what extent will the physiological ion movement be disturbed by an impressed ion current, or even by a short-circuit via a metallic conductor which reduces the potential differences essential for physiological ion transport? This would mean that even the presence of an electron conductor would have a harmful effect on the surrounding tissue or even nerves. These processes offer the most obvious explanation for the fact that the biocompatibility of gold is worse than that of the base tantalum.16Tantalum, niobium, and titanium all form protective surface layers of semi- or nonconductive oxides which prevent any exchange of electrons and thus any redox reaction at the surface. Other authors have already explained the good biocompatibility of metals with nonconductive protective layers by saying that the corrosion products of these metals are present in the tissue not in form of ions, but as stable oxides.17 This, however, cannot explain the adverse tissue reactions to noncorroding noble metals such as gold. The differentsurface energies of the materials might also be responsible for their different biocompatibilities, especially as these result in a more or less drastic change in the pH values.6 Unfortunately it is impossible to evaluate different implants from this point of view for lack of comparable values.

ELECTROCHEMICAL PROPERTIES OF METALLIC IMPLANTS

895

In the light of existing literature and the above considerations, the question as to which of the two effects described here is decisive for the biocompatibility of a material can be answered as follows: There is no doubt that corrosion adversely affects the biocompatibility of a material due to the toxic effect of the corrosion products. If corrosion can be excluded-which should be the case with the right choice of metallic materials- the most critical factors affecting the tissue are probably reduction and oxidation at separate sites. These not only alter the pH value, but can also produce other reaction products in the tissue. Every electrochemical process is associated with an ion transport, the effects of which may range from impairment of cell reactions to irritation of the nerves. It is obvious that ion concentrations and potential differences specific to tissue are disturbed not only by flowing currents, but by the mere presence of an electron conductor. A similar disturbance is certainly caused by surface charges too, which may also result in an alteration of the pH value in the immediate vicinity of the surface. The different redox current densities measured on various implant materials using a simple electrochemical procedure permit a distinct differentiation of the activities at the metal surfaces in an oxidation-reduction reaction. On the almost self-evident assumption that the higher the current densities at the implant surface the worse the biocompatibility, the electrochemical test introduced here represents a simple and cheap method for screening biocompatibility in vitro. Furthermore, it should be borne in mind that even modern procedures for testing biocompatibility do not allow the same degree of differentiation of material proper tie^'^^'^ as can be achieved with this electrochemical method. However, these results of electrochemical measurements lead also to a critical review of the applicability of conventional methods for testing biocompatibility. Uniform cell cultures or small samples implanted in homogeneous tissue are normally used in these tests. These models do not take into account the possible differences in the redox reactions of the surrounding media. This means that the most critical case in which an implant is situated with one end in a reducing medium and the other in an oxidizing medium is not covered at all by the conventional test for biocompatibility. This is but precisely the situation frequently encountered in osteosynthesis, where one and the same implant is located in different types of tissue. Also, the gradient of the partial oxygen pressure is likely to be particularly steep in the case of dental implants projecting out of the tissue into the oral cavity. This conclusion should prompt us not to regard the results of simple biocompatibility tests too optimistically. At all events, the electrochemical tests demonstrate that different redox conditions should also be taken into consideration when testing the biocompatibility of metallic implant materials.

References

1. D. F. Williams (ed.), Biomaterials and Biocompatibility: An Introduction, in Fundamental Aspects of Biocompatibility, Vol. 1, CRC Press, Boca Raton, FL, 1981, pp. 2-3.

896

ZITTER AND PLENCK 2 . E. Frank and H. Zitter, Mefallische Implantate in der Knochenchirurgie, Springer, WiedNew York, 1971, pp. 2-3. 3. H. H. Grasser, Metallosegefahr durch Osteosynthese-Materialien, Dfsch. Zahnirzfl. Z . , 27, 413-422 (1972). 4. S. Sandhaus, Neue Aspekte der lmplantologie, Medica, StuttgartiWieni ZiirichiAmsterdam, 1975, p. 92. 5. D. C. Mears, Materials and Orfhopaedic Surgery, Williams & Wilkins, Baltimore, 1979, p. 124. 6. L. L. Hench and E. C. Ethridge, Biomaterials. An Interfacial Approach, Academic Press, New YorWLondon, 1982, pp. 8-17, 34. 7 . H. Zitter, Schadigung des Gewebes durch metallische Implantate, Z. Unfallklk., 79, 91-100 (1976). 8. P. J. Aragon and S. F. Hulbert, Corrosion of Ti-6A1-4V in simulated body fluids and bovine plasma, 1, Biomed. Mater. Res., 6, 155-164 (1972). 9. ASTM G5-72; Standard reference method for making potentiostatic and potentiodynamic measurements, in Annual Book of ASTM Standards, ASTM, Philadelphia, 1975, p. 662. 10. N. D. Greene and D. A. Jones, Corrosion of surgical implants, J. Mafer. , 1, 345-352 (1966). fur die Endoprofhetik, Schiele & Schon, Berlin, 11. R. Thull, lmplantafwerksfoffe 1978, pp. 54-56. 12. R. Grauer, I? J. Moreland, and G. Pini, A LiferafureReview of Polarization Resistance Constant ( B ) Values for the Measurement of Corrosion Rate. Nat. Ass. Corrosion Engin., Houston, TX, 1982, pp. 1-7. 13. W. M. Latimer, The Oxidation States of the Elements and Their Potentials in Aqueous Solutions, Prentice-Hall, Englewood Cliffs, NJ, 1952, p. 225. 14. CRC Handbook of Chemisty and Physics, CRC Press, Cleveland, OH, 1974/75, p. D-123. 15. H. Netter, Theoretiscke Biockemie, Springer, Wien/New York, 1959, p. 455. 16. K. Zetner, H. Plenk, and H. Strassl, Tissue and cell reactions zn vivo and in vifro to different metals for dental implants, in Dental Implants, G. Heimke (ed.), Hanser, MiincheniWien, 1980, pp. 15-20. 17. R. Thull, Oberflachenreaktionen an Implantaten unter Funktionsbedingungen, Biomed. Tech., 28 Suppl., 38 (1983). 18. H. Gerber and M. Semlitsch, Tissue tolerance of the wrought CoNiCrMo-alloy Protasul loRcompared to AISI-316 L, pure titanium and titanium-titanium nitrite, tested on organ cultures of embryonic rat femurs, Paper presented at European Meeting on Corrosion and Degradation of Biomaterials, Strasbourg, May 5-7, 1984. 19. S. Nora and T. R. Y. Simonpaoli, La corrosion a dose homeopatique, Paper presented at European Meeting on Corrosion and Degradation of Biomaterials, Strasbourg, May 5-7, 1984.

Received December 16, 1985 Accepted January 5, 1987

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Corrosion Studies at The Interface Between Ceramics and 6061-T6 AluminumDocument1 pageCorrosion Studies at The Interface Between Ceramics and 6061-T6 Aluminumjesus00158Pas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Advances in Refractories and Clean Steel MakingDocument8 pagesAdvances in Refractories and Clean Steel Makingjesus00158Pas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Bipolar Plate CorrDocument9 pagesBipolar Plate CorrIrina PetreanuPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- A Corrosion Analysis of Aluminum Alloys and CoatingsDocument9 pagesA Corrosion Analysis of Aluminum Alloys and Coatingsjesus00158Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Irc - 24-2010 PDFDocument128 pagesIrc - 24-2010 PDFkiranPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- WM 5.4 CLI Reference Guide PDFDocument1 239 pagesWM 5.4 CLI Reference Guide PDFHermes GuerreroPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Air Tool S2 A100 PDFDocument2 pagesAir Tool S2 A100 PDFjhony andreasPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- PraveenKumar - Java Developer - Broadridge - HydDocument4 pagesPraveenKumar - Java Developer - Broadridge - HydAllagadda Mahesh BabuPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Standing Waves Worksheet SolutionsDocument6 pagesStanding Waves Worksheet SolutionsMaher TrabelsiPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- 16CE125-Structural Analysis - IIDocument12 pages16CE125-Structural Analysis - IIAnkur SinhaPas encore d'évaluation

- Thiourea PDFDocument43 pagesThiourea PDFMohamad EshraPas encore d'évaluation

- MWD Log Quality & StandardsDocument168 pagesMWD Log Quality & StandardsHamed Sadeghi100% (1)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Operating Manual Parts List: 1000Vmc (Siemens)Document226 pagesOperating Manual Parts List: 1000Vmc (Siemens)apodshPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Introduction To Oil RigsDocument25 pagesIntroduction To Oil RigsballasreedharPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Performance of tuned mass dampers under wind loadsDocument13 pagesPerformance of tuned mass dampers under wind loadsDhirendra Kumar PandeyPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Software Development Handbook Transforming For The Digital Age PDFDocument75 pagesSoftware Development Handbook Transforming For The Digital Age PDFdreamer4077Pas encore d'évaluation

- Plasmon CD-R ReviewDocument11 pagesPlasmon CD-R Reviewgrudva2Pas encore d'évaluation

- 21 - Al Ghubaiba Bus Station To Al Quoz, Clinical Pathology Dubai Bus Service TimetableDocument26 pages21 - Al Ghubaiba Bus Station To Al Quoz, Clinical Pathology Dubai Bus Service TimetableDubai Q&A100% (3)

- How To Build A Backyard PergolaDocument15 pagesHow To Build A Backyard PergolaMichael Wilkins100% (1)

- 7 Inch Liner Cementing ProgramDocument44 pages7 Inch Liner Cementing ProgramMarvin OmañaPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- NUVE EN 032-055-120 Incubators BrochureDocument2 pagesNUVE EN 032-055-120 Incubators BrochureDinhtrung TruongPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- DP TV Aver 15022 DriversDocument94 pagesDP TV Aver 15022 DriversMohammed Tahver Farooqi QuadriPas encore d'évaluation

- Hardness Vs TextureDocument5 pagesHardness Vs TextureShofa R HaqPas encore d'évaluation

- Boom and Trailer Mounted Boom Annual Inspection Report PDFDocument1 pageBoom and Trailer Mounted Boom Annual Inspection Report PDFlanza206Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

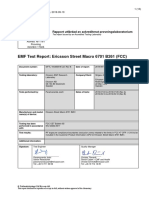

- EMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat ProvningslaboratoriumDocument13 pagesEMF Test Report: Ericsson Street Macro 6701 B261 (FCC) : Rapport Utfärdad Av Ackrediterat Provningslaboratoriumiogdfgkldf iodflgdfPas encore d'évaluation

- Mohr's Circle Analysis of Rock Failure Under StressDocument26 pagesMohr's Circle Analysis of Rock Failure Under StressNitishPas encore d'évaluation

- HSP Power Point PresentationDocument10 pagesHSP Power Point PresentationocintezaPas encore d'évaluation

- Common Base (BJT) - Common Gate (MOSFET) CircuitsDocument3 pagesCommon Base (BJT) - Common Gate (MOSFET) CircuitsUtpal100% (3)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Squeeze Cementing TechniquesDocument22 pagesSqueeze Cementing TechniquesDoni KurniawanPas encore d'évaluation

- Applications of The Infrared Thermography in The Energy Audit of Buildings - A ReviewDocument14 pagesApplications of The Infrared Thermography in The Energy Audit of Buildings - A ReviewDian PsdPas encore d'évaluation

- Sperry Sun - LWD and LWD ServicesDocument8 pagesSperry Sun - LWD and LWD ServicesBAS100% (1)

- Digital Transformation in The Age of The Customer POVDocument12 pagesDigital Transformation in The Age of The Customer POVjasminePas encore d'évaluation

- Manufacturing of Urea Through Synthetic Ammonia Project ReportDocument5 pagesManufacturing of Urea Through Synthetic Ammonia Project ReportvishnuPas encore d'évaluation

- Bricks CalculationDocument3 pagesBricks CalculationAravindanPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)