Académique Documents

Professionnel Documents

Culture Documents

Water Hybrid Engine 0.1 by Arpit Jayaswal

Transféré par

Arpit JayaswalTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Water Hybrid Engine 0.1 by Arpit Jayaswal

Transféré par

Arpit JayaswalDroits d'auteur :

Formats disponibles

Water Hybrid Engine 0.

Chapter: 1 INTRODUCTION

An engine converts the chemical energy of fuel into mechanical work by rotating a shaft (crank shaft) via a piston and connecting rod. In older times a lot of motorcycle engines were based on the 2 Stroke technologies. But due to recent Pollution norms and the maintenance cost and low average of 2 stroke engines have led to the switch over to new age 4 Stroke engines making motorcycles highly efficient and green. Many people claimed the invention of the internal combustion engine in the 1860's, but only one has the patent on the four stroke operating sequence. In 1867, Nikolaus August Otto, a German engineer, developed the four-stroke "Otto" cycle, which is widely used in transportation even today.

1.1 Four Stroke Engine.

The four stroke engine is probably the most common engine type now a day. It powers almost all cars and trucks. Four stoke engine is internal combustion engine. An internal combustion engine is any engine that operates by burning its fuel inside the engine. In contrast an external combustion engine burns its fuel outside the engine like in steam engine. In 4 stroke engine an explosive mixture is drawn into the cylinder on the first stroke and is compressed and ignited on the second stroke; work is done on the third stroke and the products of combustion are exhausted on the fourth stroke.

Figure 1.1 Cross sectional view of 4 stroke engine.

Water Hybrid Engine 0.1

1.1.1 Mechanism of Four Stroke Engine. There are four movements, or strokes, of the piston before the entire engine firing sequence is repeated. The four strokes are described below. 1.1.1.1 Intake stroke: The engine cycle begins with the intake stroke as the piston is pulled towards the crankshaft. During the intake stroke draws a fresh charge of vaporized fuel/air mixture. Piston moves from top dead centre (TDC) to bottom dead centre (BDC) completing one stroke. A poppet intake valve can serve the purpose, it is drawn open by the vacuum produced by the intake stroke. Some early engines worked this way; however, most modern engines incorporate an extra cam/lifter arrangement exhaust valve is held shut by a spring. 1.1.1.2 Compression stroke: With both valves closed, the combination of the cylinder and combustion chamber form a completely closed vessel containing the fuel/air mixture. As the piston is pushed away from shaft toward top dead center (TDC), the volume is reduced and the fuel/air mixture is compressed during the compression stroke. During the compression, no heat is transferred to the fuel/air mixture. As the volume is decreased because of the piston's motion, the pressure in the gas is increased, as described by the laws of thermodynamics. To produce the increased pressure, we have to do work on the mixture, just as you have to do work to inflate a bicycle tire using a pump. During the compression stroke, the electrical contact is kept opened. When the volume is the smallest, and the pressure the highest as shown in the figure, the contact is closed, and a current of electricity flows through the plug. Thus ignition occurs at the end of this stroke. 1.1.1.3 Power stroke: Rapid combustion of the fuel releases heat, and produces exhaust gases in the combustion chamber. Because the intake and exhaust valves are closed, the combustion of the fuel takes place in a totally enclosed (and nearly constant volume) vessel. The combustion increases the temperature of the exhaust gases, any residual air in the combustion chamber, and the combustion chamber itself. From the ideal gas law, the increased temperature of the gases also produces an increased pressure in the combustion chamber. The high pressure of the gases acts on the face of the piston and cause the piston to move towards the shaft and to bottom dead center. This initiates the power stroke. Unlike the compression stroke, the hot gas does work on the piston during the power stroke. The force on the piston is transmitted by Intake stroke Combustion stroke Power stroke Exhaust stroke

Water Hybrid Engine 0.1

the piston rod to the crankshaft, where the linear motion of the piston is converted to angular motion of the crankshaft. The work done on the piston is then used to turn the shaft, and the propellers, and to compress the gases in the neighbouring cylinder's compression stroke. During the power stroke, the volume occupied by the gases is increased because of the piston motion and no heat is transferred to the fuel/air mixture. As the volume is increased because of the piston's motion, the pressure and temperature of the gas are decreased. 1.1.1.4 Exhaust stroke: The exhaust valve is opened and the piston travels back up expelling the exhaust gases through the exhaust valve. At the top of this stroke the exhaust valve is closed. This process is then repeated.

Figure 1.2 The four stroke cycle.

Water Hybrid Engine 0.1

1.1.2 Features of Four Stroke Engine. Important features of internal combustion four stroke engines are as under. 1.1.2.1 More torque.

This is the most important reasons why people choose a 4-stroke engine. The two-stroke boasts its speed and power, but the four-stroke shows extra torque. It is more reliable and quitter. 1.1.2.2 Last longer. Four stroke engines last longer and use much, much less oil. Compared to two-stroke engines, the four stroke engine is durable for use. The more times an engine goes around, the quicker it will wear out. As 2-strokes must rev to very high RPM to make any power, most applications using them are geared toward maintaining that RPM. Thus, they cant live as long as four-stroke engine. 1.1.2.3 Run much cleaner than 2 strokes. A 2 stroke makes a lot of exhaust smoke because it burns oil mixed with fuel. On the contrary, four-stroke engines have a dedicated oiling system thats kept largely separate from the combustion chamber, which help to ensure that the only thing burning in the engine is gasoline. 1.1.2.4 More efficient use of gas. If you have picked up both of them, you may obviously realize the problem. The intake and exhaust accounted 360 crank angle, the exhaust top dead center the piston upward, the residual gas is exhaust forcibly. When a mixture of fuel and air is forced by atmospheric pressure into the cylinder, the piston down to the intake bottom dead center, the incoming fresh mixture almost combust. Substantially, there is no wasted fresh mixture. However, for two-stroke engine, the fresh mixture is escaping with exhaust gases during exhaust stroke.

1.1.3 Application of Four Stroke Engine. Four stroke engines are used in automobile vehicle like car, bike, etc. Four stroke engines are also used in aircraft and ships. It is also used power generation unit as power generator.

Water Hybrid Engine 0.1 1.2 Water Hybrid Engine.

Figure 1.3 Water Hybrid Engine. Water hybrid engine is first ever developed four stroke engine, which is design to works on the mixture of petrol and unsaturated water steam. In this typical engine petrol and steam is allowed to enter into the engines cylinder in the first stroke of four stroke engine through inlet valve, both petrol and steam is compressed TDC (Top Dead Center) of engine cylinder and combustion is held in cylinder with help spark plug, which expand the volume of the petrol and steam, results in the pressure which is applying on the piston head and push it to BDC (Bottom Dead Center) of engine cylinder, hence power stroke is obtain. And at the fourth and the final stroke exhaust gases are removed out from the cylinder through outlet

Water Hybrid Engine 0.1

valve. Due to this consumption of petrol is reduced and equal proportion of steam is used in this engine. Thus due to this unique modification in engine, higher fuel efficiency is obtain, which also reduces the pollutant substance in exhaust gas, which reduces pollution in air. This water hybrid engine is also economical in use as well as eco friendly.

Water Hybrid Engine 0.1

Chapter: 2 PURPOSE OF DEVELOPMENT

2.1 Problem Identification.

Every internal combustion engine are developed to attain maximum efficiency, and to generate maximum power out of less input, in all internal combustion engine fuel + air is injected/sucked in the combustion chamber and a spark plug provide ignition in combustion chamber which burn the fuel inside the combustion chamber, and power is generated through piston and crank shaft. But in order to generate power, fuel consumption is more in IC engine, which is not economical to use. Hence the scarcity of fossil fuel is leading to its extinction, which may lead to hindrance in power production in future, and for automobile industry. Most of the automobile vehicles are working on petroleum fuel like petrol, diesel etc. and with the increasing demand of petrol vehicle, consumption of petrol has increased. So there is need of alternative fuels which can replace the requirement of petrol worldwide. Alternative fuels like CNG and LPG are taken into practice. 2.1.1 Alternative Fuel. There is scope of many other types of fuel in future like 1) Hydrogen gas: Hydrogen is an emission less fuel. The by product of hydrogen burning is water, although some mono-nitrogen oxides NOx are produced when hydrogen is burned with air. 2) HCNG: HCNG (or H2CNG) is a mixture of compressed natural gas and 4-9 percent hydrogen by energy. 3) Liquid Nitrogen: Liquid nitrogen is another type of emission less fuel. 4) Biodiesel: Biodiesel is an eco-friendly fuel that can be made from animal fats, algae, or from recycled vegetable oils like those used by restaurants to cook up French fries and other greasy goodies.

Water Hybrid Engine 0.1

5) Ethanol:

Ethanol is another popular alternative fuel that is usually made from fibrous materials like wood chips or from the starch or sugar found in common crops like corn. Ethanol burns cleaner than gasoline while reducing greenhouse gases. 6) Electricity: Electricity isn't new, but modern science has found interesting and eco-friendly uses for it. Electric vehicles are eco-friendly because they don't produce tailpipe emissions, although the generators producing the electricity used to charge EV batteries do emit pollutants. But engineers are still working to make actually practical and economical in real world. 7) Nuclear power: Nuclear power is any nuclear technology designed to extract usable energy from atomic nuclei via controlled nuclear reactions. The only controlled method now practical uses nuclear fission in a fissile fuel (with a small fraction of the power coming from subsequent radioactive decay). Use of the nuclear reaction nuclear fusion for controlled power generation is not yet practical, but is an active area of research. And many kinds of fuel are under research and still not available in practical use, also to brought this alternative fuel into the practice initial cost of research about in nature in practical and installation of its pump and availability of its also the costly issue. Hence the development automobile vehicle which can run on this new alternative fuel is also the major issue to face before making practical use worldwide. Hence all these conditions make above mention alternative fuel costly and time consuming. Thus it is required to developed new technology which can works on fuel which is easily available and can be brought into practice soon. Its should have availability in future and can be available worldwide easily, the new technology should also be convenient and economical to use.

2.2 General Solution to the Problem.

Water hybrid engine is the first four stroke engine technology that works on using mixture of petrol and water, hence it decreases the consumption of the petrol and equivalent work can be obtain. This engine technology makes an appropriate mixture of waters unsaturated steam and petrol in carburettor. Thus mixture is burn into the engine cylinder with spark plug and pressure is generated, which pushes the piston and power stroke is obtain in engine. The use of this technology reduces the consumption of petrol and the efficiency of the engine is increased.

Water Hybrid Engine 0.1

This technology is the ultimate solution the problem of scarcity of petrol and developing solution to the alternate fuel problem. Water Hybrid Engine technology doesnt require any special change in engine technology, nor any special kind of fuel. For water hybrid engine technology small modification is only required in four stroke engine, with a Water Preheater kit. Water hybrid engine technology is also economical in use, and it is economical in construction, water hybrid engine is ECO FRIENDLY upto some extend. The reduction in consumption of fuel decreases the amount of harmful gases in environment.

Water Hybrid Engine 0.1

10

Chapter: 3 WORKING PRINCIPLE

3.1 Working Principle.

Volumetric Expansion of Unsaturated Steam in Engine cylinder, at time of Combustion in Cylinder produces Pressure, which is applied on Piston, and Power Stroke in obtain in Four Stroke Engine. In this engine, the unsaturated steam gets expanded, due to higher temperature generated at the combustion of petrol in engine cylinder. Temperature produced at the end of burning of fuel in engine range in 1200 to 2000 C.

Figure 3.1 cross sectional view of water Hybrid Technology.

Water Hybrid Engine 0.1

3.1.1 Otto Cycle.

11

The first person to build a working four-stroke engine, a stationary engine using a coal gas-air mixture for fuel (a gas engine), was German engineer Nikolaus Otto. This is why the fourstroke principle today is commonly known as the Otto cycle and four-stroke engines using spark plugs often are called Otto engines. The system is defined to be the mass of air that is drawn from the atmosphere into the cylinder, compressed by the piston, heated by the spark ignition of the added fuel, allowed to expand by pushing on the piston, and finally exhausted back into the atmosphere. The mass of air is followed as its volume, pressure and temperature change during the various thermodynamic steps. As the piston is capable of moving along the cylinder, the volume of the air changes with the position of the cylinder. The compression and expansion processes induced on the gas by the movement of the piston are idealized as reversible i.e. that no useful work is lost through turbulence or friction and no heat is transferred to or from the gas. Energy is added to the air by the combustion of fuel. Useful work is extracted by the expansion of the gas in the cylinder. After the expansion is completed in the cylinder, the remaining heat is extracted and finally the gas is exhausted to the environment. Useful mechanical work is gained during the expansion process and some of that used to compress the air mass of the next cycle. The useful mechanical work gained minus that need for the next compression process is the net work out and can be used for propulsion or for driving other machines. Alternatively the useful work gained is the difference between the heat added and the heat removed. An Otto cycle is an idealized thermodynamic cycle which describes the functioning of a typical spark ignition reciprocating piston engine, the thermodynamic cycle most commonly found in automobile engines. The Otto cycle is constructed out of: Top and bottom of the loop: a pair of quasi-parallel and isentropic processes (frictionless, adiabatic reversible). Left and right sides of the loop: a pair of parallel isochoric processes (constant volume).

The isentropic processes of compression and expansion implies no loss of mechanical energy due to friction and no transfer of heat into or out of the system during those processes, hence the cylinder, and piston are assumed impermeable to heat during those processes. Heat flows into the loop through the left pressurizing process and some of it flows back out through the right depressurizing process, and the difference between the heat added and heat removed is equal to the net mechanical work generated.

Water Hybrid Engine 0.1

12

Figure 3.2 P-V Diagram of Otto Cycle.

The processes are described as under, Process 0-1 a mass of air is drawn into piston/cylinder arrangement at constant pressure. Process 1-2 is an isentropic and adiabatic compression of the air as the piston moves from bottom dead centre (BDC) to top dead centre (TDC). Process 2-3 is a constant-volume heat transfer to the working gas from an external source while the piston is at top dead centre. This process is intended to represent the ignition of the fuel-air mixture and the subsequent rapid burning. Process 3-4 is an isentropic expansion (power stroke). Process 4-1 completes the cycle by a constant-volume process in which heat is rejected from the air while the piston is at bottom dead centre. Process 1-0 the mass of air is released to the atmosphere in a constant pressure process.

The Otto cycle consists of isentropic compression, heat addition at constant volume, isentropic expansion, and rejection of heat at constant volume. In the case of a four-stroke Otto cycle, technically there are two additional processes: one for the exhaust of waste heat and combustion products at constant pressure (isobaric), and one for the intake of cool oxygen-rich air also at constant pressure; however, these are often omitted in a simplified

Water Hybrid Engine 0.1

13

analysis. Even though those two processes are critical to the functioning of a real engine, wherein the details of heat transfer and combustion chemistry are relevant, for the simplified analysis of the thermodynamic cycle, it is more convenient to assume that all of the wasteheat is removed during a single volume change.

3.2 Working of Water Hybrid Engine.

Figure 3.3 Water Hybrid Engine 0.1

Working mechanism of Water Hybrid Engine 0.1 is simple and unique. In this Four Stroke Engine, water is preheated in copper pipe which is winded on exhaust outlet pipe (Silencer). Water is stored in insulated copper cylindrical tank, outlet pipe of water tank is connected to one end of copper winding and other end of copper winding pipe is again connected to the to the water tank. Copper pipe winding on exhaust pipe is filled with water from water tank, which is half filled and other half tank is kept empty for accumulation of pressurised steam. When is engine is running after some period ,water in copper pipe winding get heated due to high temperature of exhaust gas flowing in exhaust pipe, There is a single pipe line inside the exhaust pipe which has direct contact from exhaust gas at end of copper winding.

Water Hybrid Engine 0.1

14

Figure 3.4 Label Figure of Water Hybrid Engine 0.1 Water in the copper pipe winding gets converted into unsaturated steam, and again flown in the water tank, to generate pressurised steam inside the water tank. Pressure gauge meter is attached to the water tank in order to notify the steam pressure inside the water tank. Appropriate pressure of steam is allowed to flow into the carburettors air filter, the steam pressure can be regulated by steam outlet valve. These steam mixes with air in air filter and enter into the carburettor, and in carburettor appropriate ratio of vaporised petrol and steam mixture is flown into the engine cylinder at first stroke of piston and at second stroke petrol and steam mixture is compressed, and with the combustion of petrol in engine by spark through spark plug temperature of 1200 C to 2000 C is generated, which is sufficient to have volumetric expansion of unsaturated steam inside the cylinder. Which indeed induce pressure, due to which force is applied to the piston and power stroke is obtain.

Water Hybrid Engine 0.1

15

Figure 3.5 Label Figure of Water Preheater System in Water Hybrid Engine 0.1

And the remaining gases and steam in the cylinder is exhausted from the cylinder in the last stroke of the engine. The ideal Air/Petrol ratio for the combustion of fuel in the engine is 15:1, the ratio may vary with acceleration, thus in this project, the intake of petrol is reduced to half and intake of air is mixed with unsaturated steam partially at equal proportion, which maintain the ratio of 15:1 for the fuel combustion.

Water Hybrid Engine 0.1 3.3 Block Diagram of Water Hybrid Engine 0.1

16

Figure 3.6 Block Diagram of Water Hybrid Engine 0.1

Water Hybrid Engine 0.1

17

Chapter: 4 CONSTRUCTION DETAIL

4.1 Component Detail.

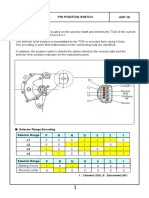

There are various component used in construction of Water Hybrid Engine 0.1, details of component like supporting Frame, Four Stroke Engine, Engine component, to wheel stand, water preheater system, are described below as under. 4.1.1 Four Stroke Engine. Four stroke engine used for this project is 110 cc single cylinder engine, of TVS STAR CITY motor bike, it is double valve four stroke engine, inlet valve for petrol and outlet valve for exhaust gases from the cylinder. The valve in this engine is poppet type as shown in figure below.

Figure 4.1 TVS STAR CITY Four Stroke Engine.

Figure 4.2 Poppet valve .

Water Hybrid Engine 0.1

4.1.2 Water Pre Heater system.

18

Water preheater kit is the most important component of water hybrid technology, as this component is comprises of copper pipe which is winded on exhaust pipe, cylindrical copper tank for water storage, it is also applicable as steam accumulator. Pressure gauge is used for keeping notification of steam pressure. 4.1.2.1 Copper pipe. Copper pipe used is 1/4" copper refrigeration tube with outer diameter 8.110 mm and inner diameter is 7.714 mm with thickness of 0.899 mm. This copper pipe is capable of conducting pressure 90 psi. 2.5 meter copper pipe is used.

Figure 4.3 Copper pipe.

4.1.2.2 Water Tank. Water tank is a copper cylindrical tank, which is used for water storage and accumulation of steam, the working of this copper cylindrical tank is as miniature boiler.

Figure 4.4 Copper Cylindrical Tank.

Water Hybrid Engine 0.1

19

The outer diameter of this tube 55.7 mm and inner diameter is 43.2 mm. The initial length of copper cylindrical tank is 320 mm. This copper tank is selected in order accumulate steam in tank at high pressure. 4.1.2.3 Pressure Gauge. Standard pressure Gauge is used for reading of steam pressure in the water, the maximum limit of pressure gauge is 500 psi. This pressure is attached with pressure outlet valve.

Figure 4.5 Standard Pressure Gauge.

4.1.2.4 Cylindrical Adapters. Cylinder adapter are used as a pipe connector with inner tread .There are 3 cylindrical adapter used for connecting pipe in this project. This cylindrical adaptor is used for air tight fitting in pipes, this adaptor are used for air tight fitting in pipe for leak proof conduction of steam inside the air preheater system.

Water Hybrid Engine 0.1

20

Figure 4.6 Cylindrical Adaptors.

4.1.2.5 Capillary Tube. Capillary tube is small diameter tube used for conduction of steam from water tank to Air filter.1 meter capillary tube is used.

Figure 4.7 Capillary Tube.

Water Hybrid Engine 0.1

4.1.3 Four Wheel Stand.

21

Figure 4.8 Four Wheel Stand. This wheel stand provide support to the engine and its component, it is also carry the frame of engine which reduces the vibration of engine. Four also work as a foundation support from earth, and it also make project movable. The length of wheel stand is 52 cm and 29.5 cm width. It is made from scrap iron with the engine frame. The four wheels is attached to the stand with a clamp welded to the stand frame, cotter pin is used to join wheel with wheel stand. This four wheel are capable of lifting the load of whole engine and its component. Addition copper wires are used to tight hold all the component of project with frame of engine.

4.1.4 Pilot Jet in Carburettor. The jets on a carburettor meter the amount of fuel that enters the throttle bores of the carburettor where it mixes with incoming air.

Water Hybrid Engine 0.1

22

There is change in pilot jet from original jet which is pre installed in carburettor, new pilot jet of 42 mm size is used for this engine in order to enter steam, air and petrol through bigger diameter orifice into throttle bores.

Figure 4.9 42 size pilot Jet. 4.1.5 Fuel Filter.

Figure 4.10 Petrol Filter. Petrol filter is used to filter the petrol from dust in petrol or in petrol tank, before it enter into carburettor, this device is most necessary for proper working of the engine. Petrol filter is general size used for motor bike.

Water Hybrid Engine 0.1

4.1.6 Fuel Regulator.

23

Fuel regulator or petrol choke is used to regulate the flow of fuel in carburettor from petrol tank. Fuel regulator is of general size for motor bike.

Figure 4.11 Fuel Regulator. 4.1.7 Fuel Pipe. Fuel pipe used is simple rubber pipe, which conduct petrol from petrol tank to carburettor. 4.1.8 Nut and Bolt.

Figure 4.12 Nuts and Bolts. Nuts and bolts are used for the purpose of fitting the engine frame, it is also used for the fitting the various parts of the engine and its assembly.

Water Hybrid Engine 0.1 4.2 Working and Assembly of Pre Heater.

24

Copper tube is winded on exhaust pipe, to absorb the maximum heat from exhaust gas. There are 20 turns of copper pipe on exhaust pipe, from bottom to top as shown in figure.

Figure 4.13 Winding of Copper Tube on Exhaust Pipe, (Top View).

Figure 4.14 winding of copper tube exhaust pipe, ( Bottom View).

Water Hybrid Engine 0.1

25

One single tube on copper is placed inside the exhaust pipe for SUPER HEATING of water. This tube has direct contact with flue gas so super heating is possible in that area, construction of this tube is shown in figure.

Figure 4.15 Assembly of Super Heater Copper Pipe.

Water Hybrid Engine 0.1

26

Chapter: 5 EXPERIMENTAL ANALYSIS

5.1 Time Calculations Analysis.

Engine is working on the pure intake of petrol for 26 mint at unit acceleration, from 250 ml of petrol. While, engine is working on the intake of petrol and unsaturated steam at 10 psi for 47 mint at unit acceleration, from 250 ml of petrol. Only required condition is that the acceleration of the engine should be maintain, and all other condition should be same.

Sr no.

Water Injected in water Tank (ml)

Time

Speed in RPM

Petrol Consume

5.2 Visual Observation.

The working of the engine by water and petrol mixture, require high temperature unsaturated steam, with some pressure. For this purpose the pre heater kit is developed for this engine, for the efficient working of this pre heater system, continuous flow of high temperature exhaust gas is required for several minute, so that water inside the copper pipe can be converted into unsaturated steam. After getting pressure generated inside the water tank, appropriate pressure is around 10 psi and more, unsaturated steam is allowed to flow into carburettor through steam outlet valve.

Water Hybrid Engine 0.1

27

After the entry of steam and petrol inside the engine for combustion, engine continue to run at the same RPM and torque at same acceleration, at satisfied condition. Sometimes problem like leakage in copper tube and water tank can be detected, which lead to pressure drop inside the system. As a result appropriate amount of required steam cannot be generated or time consumption will increase for the process. Proper insulation for copper pipe and water tank is required to attain optimum result and efficiency cannot be obtained in the engine. Leakage in exhaust pipe will release the heat, which is required for the heating of water in the copper pipe winding. At high acceleration vibration is increased in the engine, so proper balancing of the wheel is required.

5.3 Conclusion.

By above mention time analysis, it can be concluded that the time duration of working of engine is increase with the intake of appropriate ratio of steam and petrol mixture, in comparison with only petro intake at equal amount of fuel consumption, hence it increases the efficiency of the engine.

Water Hybrid Engine 0.1

28

Chapter: 6 DESIGN & CALCULATION

6.1 Engine Specification.

Displacement (cc) Cylinders Max Power Maximum Torque Bore (mm) Stroke (mm) Valves Per Cylinder Fuel Delivery System Fuel Type Ignition Spark Plugs (Per Cylinder) Cooling System 110 1 8 8 53 49 2 Carburettor Petrol CVTi 1 Air Cooled

The data of engine specification mention above are of new manufactured engine of TVS STAR CITY 110cc. Thus for second hand and used engine may have difference in engine data. Fuel Efficiency Overall (Kmpl) is 67. (Variable data).

6.2 Water Pre Heater System.

Number of turns of copper pipe winding on the exhaust pipe is 20. While, the outer diameter of the exhaust pipe = 3.183 cm. So, Coil used in winding = 20 D (circumference of exhaust pipe) = 20 22/7 (3.183) = 200 cm. Water tank Length = 29 cm diameter 2.7 cm.

Water Hybrid Engine 0.1 6.3 Wheel Stand and Engine Frame.

29

Wheel stand length = 52 cm width = 29.5 cm. Wheel stand Height = 11.5 cm Angle beam of iron for the support to petrol tank, Length = 85cm.

Water Hybrid Engine 0.1

30

Chapter: 7 ADVANTAGES & LIMITATIONS

7.1 Advantages.

Consumption of fuel decreases, hence its efficiency is more in comparison to conventional four stroke petrol engine. Water hybrid engine doesnt require any major change in design of engine or any big modification in engine. Setup cost of water hybrid engine is economical. Material cost is also affordable, and materials are easily available. Water hybrid engine is economical in application, as it reduces the fuel consumption. It is also environment friendly, due to reduction of fuel usage. Air pollution is also reduces in environment. This system can be installed in any four stroke engine, running on petroleum fuel. This system can be installed in multi cylinder engine also. Water hybrid engine can also be used as power generator. This technology will not required additional cost of alternative fuel research, or its fuel pump, because pure water is easily available domestically. No research work is required for environment analysis of fuel, as it steam is not at all harmful for environment.

Water Hybrid Engine 0.1

31

7.2 Limitation.

Water hybrid engine is working on water and petrol mixture, so the required torque cannot be attain in some odd condition. This technology is not much efficient in cold environment, as the formation of steam process will become time consuming process.

There is formation of scale and slug in the copper pipe. Water used in this engine should be pure water, distilled water, so that the formation of scale and slug in the copper tube can be reduced. Leakage in water preheater system can reduced the rate of generation of steam, and required pressure of steam cannot be attain, heavy leakage can result in failure of system.

Proper insulation is required in system to achieve maximum efficiency. Water hybrid engine 0.1 needs few updates and modification, for more efficiency and proper working. It may require frequent Maintenance and cleaning due to insulation and leakage problem of system. Maintenance of the water preheater system is also required for effective functioning of the system.

Water Hybrid Engine 0.1

32

Chapter: 8 COSTING

Bill of Material

SR no. Elements Specification Quantity price per piece Cost (Rs)

4 stroke engine 110cc with carburettor. Fuel tank CVTi spark coil Piston with piston rings

TVS STAR CITY Plastic tank (1 litre) TVS standard TVS standard 110 cc set TVS standard 110 cc set General Hard fibre (10cm dia) Scrap iron TVS standard TVS standard ISI standard TVS standard Pack 1/4 (Meter) Standard capillary (Used for Refrigerator)

8500

8500

2 3 4

1 1 1

120 650 1350

120 650 1350

Poppet valve assembly

550

550

6 7 8 9 10 11 12 13 14 15

Iron clamp wheels Iron bars Exhaust pipe (silencer) Scooty air filter Standard pressure gauge Gasket packing Asbestos thread Copper pipe Copper capillary pipe

6 4 1 1 1 2 1 2.5m 1m

20 75 850 275 750 180 150 170/m 190/m

120 300 900 850 275 750 360 150 425 190

Water Hybrid Engine 0.1

33

40 90 40 100 360 88 150

16 17 18 19 20 21 22 23 24 25 26

Fuel filter Petrol pipe Pilot jet Accelerator wire Engine oil

Standard for Bikes Vulcanise Rubber pipe Size 42mm ISI Standard (pack) Servo oil 4T (pack)

1 1m 1 1 2 4 1 1 1 1 -

40 90/m 40 100 180 22 150 60 180 100 80

Cylindrical adaptor Copper material Water tank Nut & Bolt Mate colour Fuel regulator Fuel float (Carburettor) Copper cylinder Black Motor bike -

180 100 80

TOTAL MATERIAL COST

16,778 Rs

Labour cost

1 2 3 Welding labour Machining labour Operator labour 1900 1400 1450

Total Direct Labour

Labour

4750 Rs 3000

Overhead expense

1 2 3 Machining expenses Welding expenses Cleaning and Servicing 1150 2700 530

Water Hybrid Engine 0.1

34

4 5

Miscellaneous Expense Transport

1460 340

Total Overhead Expenses

6180 Rs

Total Cost = Material Cost + Labour Cost + Overhead Expenses = 16778 + 4750 + 6180 = 27,708 Rs.

Total Project Cost

Selling Price = Profit (30% 0f Total Cost) + Total Cost = 8,312.4 + 27,708 = 36,020.4 Rs.

27,708 Rs

Selling Price of Project

36,020 Rs

Water Hybrid Engine 0.1

35

Chapter: 9 REFERENCE

Website:

www.hydroicesolar.com Hydro Internal Clean Energy, by Matt Copper.

Copper Tube Hand Book:

www.copper.org Copper Development Association Inc

Book:

Thermal Engineering, by P.S. Desai ME (Mech). Topic 5: Internal Combustion Engine.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Technical Bulletin Ltb00566v6Document8 pagesTechnical Bulletin Ltb00566v6Ян ПавловецPas encore d'évaluation

- Chrysler Voyaguer 1994 Service ManualDocument814 pagesChrysler Voyaguer 1994 Service Manualjuan100% (1)

- Argus LNG Daily Market ReportDocument19 pagesArgus LNG Daily Market ReportTPas encore d'évaluation

- Engine System FundamentalsDocument17 pagesEngine System FundamentalsJha PuiPas encore d'évaluation

- Jet - Engine DGCA QuestionsDocument6 pagesJet - Engine DGCA Questionsstuartb4uPas encore d'évaluation

- S70me-C8 5Document406 pagesS70me-C8 5Xahid HasanPas encore d'évaluation

- Plant & MachineryDocument100 pagesPlant & MachinerySatya Yugandhar Gannamani100% (1)

- Diesel Engines Series 4000: Stationary Power GenerationDocument4 pagesDiesel Engines Series 4000: Stationary Power Generationjesus_rs01Pas encore d'évaluation

- Alexia Ls - TdsDocument2 pagesAlexia Ls - TdsBeryl FernandesPas encore d'évaluation

- Transmisión Automática Parte 2Document39 pagesTransmisión Automática Parte 2romeo_mec100% (1)

- MEO CLASS 1 Question Papers 2019Document4 pagesMEO CLASS 1 Question Papers 2019Ajesh MPas encore d'évaluation

- Introduction To DrillingDocument68 pagesIntroduction To DrillingSana Hajri100% (2)

- Configured 2668 Series DatasheetDocument2 pagesConfigured 2668 Series Datasheetmaverick23113636Pas encore d'évaluation

- Group 5 RCV Lever: 1. StructureDocument7 pagesGroup 5 RCV Lever: 1. StructurethierrylindoPas encore d'évaluation

- Biodiesel Fuel Impact On Diesel Engine and The Lubricant: Hiroshi WatanabeDocument34 pagesBiodiesel Fuel Impact On Diesel Engine and The Lubricant: Hiroshi WatanabeAaron ChanPas encore d'évaluation

- Siemens Industrial Steam Turbine SST 040 enDocument4 pagesSiemens Industrial Steam Turbine SST 040 enAdrian García Moyano100% (1)

- Honda General Purpose Engine GX35TDocument76 pagesHonda General Purpose Engine GX35TJuan Pueblo AgachadoPas encore d'évaluation

- Area 1Document62 pagesArea 1Blessie AgutoPas encore d'évaluation

- 250kva Cummins Diesel Generator Silent TypeDocument7 pages250kva Cummins Diesel Generator Silent TypeThumula FernandoPas encore d'évaluation

- KK40UM: Industrial Diesel Generator Set - 60 HZDocument7 pagesKK40UM: Industrial Diesel Generator Set - 60 HZABCD123655Pas encore d'évaluation

- Split Tee Hot Tap Fitting Spec SheetDocument4 pagesSplit Tee Hot Tap Fitting Spec SheetCarlos ShuntaPas encore d'évaluation

- ICE Design & Performance ParametersDocument6 pagesICE Design & Performance Parametersjahir dipokPas encore d'évaluation

- 10-1 - Engine Numbering & IdentificationDocument13 pages10-1 - Engine Numbering & IdentificationRiddhi DasPas encore d'évaluation

- CS 088Document2 pagesCS 088chandu306Pas encore d'évaluation

- Industrial Hemp (Cannabis Sativa L.)Document93 pagesIndustrial Hemp (Cannabis Sativa L.)Tturk87Pas encore d'évaluation

- Service / Parts Manual: Models: Wolfpac 4000Document74 pagesService / Parts Manual: Models: Wolfpac 4000PedroPas encore d'évaluation

- Additional Fire Protection : F-AmcDocument14 pagesAdditional Fire Protection : F-AmcLyubomir LazarovPas encore d'évaluation

- BH35 2Document4 pagesBH35 2muthu85100% (1)

- Determining The Moisture Content of Jatropha Seeds, Iodine Vale and Peroxide Value of Jatropha OilDocument7 pagesDetermining The Moisture Content of Jatropha Seeds, Iodine Vale and Peroxide Value of Jatropha OilCalator Prin MuntiPas encore d'évaluation

- EDL - Engineering AssesmentDocument18 pagesEDL - Engineering Assesmentsudjono100% (1)