Académique Documents

Professionnel Documents

Culture Documents

HVAC System Design

Transféré par

NisarCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

HVAC System Design

Transféré par

NisarDroits d'auteur :

Formats disponibles

HVAC System Design- Formulae

Posted: December 1, 2012 in Airconditioning System Design Tags: climate, science

1 I have been approached by lot of people to teach them system design for the HVAC&R product development and I thought it fit for them to start from basics as without a solid foundation there can be no building.So I thought of compiling the basic formulae first and then go for the system design aspects.It has taken me considerable time to compile these formulae. I would like to thank Ms. Ashima Saxena for helping me in editing the list of the compilation. Thermodynamic Design Formulae EQUATION FORMULAE F=ma Newtons law of motion P=F/A =m/V W=Fd PE = m g H KE = m V2 Q = m Cp( t2 t1 ) Q = m ( h2 h1 ) W Q = dE Cpa =1.005 kJ/kgK Cpw =4.193 kJ/kgK Cpv =1.884 kJ/kgK Q = k A dt/dx Q = hc A ( ts tf ) Q= A F FA (t1-t2) Re = V Dh / Pr = Cp / k Nu = hc D / k Pressure Density Work Potential energy Kinetic energy Sensible heat Total heat 1st law of thermodynamics Heat capacity of dry air Heat capacity of water Heat capacity of water vapor

Sr.No. 1 2 3 4 5 6 7 8 9 10 11 12

Heat Transfer Formulae 13 14 15 16 17 18 Conduction Convection Radiation Reynolds number Prandtl number Nusselt number

19

Nu = 0.023 Re0.8 Pr0.4 Moist Air Phase Formulae

Dittus-Boelter Daltons Law of partial pressure Perfect gas law Gas constant of dry air Gas constant of water vapor Humidity Vapor pressure from humidity True density of moist air Magnus saturation pressure Dew point temperature using the Magnus equation Relative humidity Carrier vapor pressure Enthalpy Latent heat of water vapor

20 21 22 23 24 25 26 27 28 29 30 31 32

P = Pa + Pv Pv = R T Ra = 0.287 kJ/kgK Rv = 0.4615 kJ/kgK W = 0.622 Pv / (P Pv) Pv =P / [1+0.622/W] r = (1+W) / v Ps =0.6105 exp [ 17.27 t / (237.3+t) ] t = 237.3 / [17.27 / -1] where = ln (Ps / 0.6105) f = Pv/ Ps Pv = Psw-1.8(P-Psw)(db-wb)/(2800-1.3 wb ) H = 1.005db+W[2500.6+1.85 db-0.023 wb] hfg = 2501.9 2.4189 t ma = Qa Qs = ma Cpm ( t2 t1 ) Cpm = 1.023 kJ/kgK Qt = ma (h2 h1 ) SHR = Qs / Qt b = ( db0 adp ) / ( dbi adp ) Qs = h A (db wb) Ql = hd A (Ws,w W) hfg,w hd = hc / Cpm

Air Psychometric Formulae 33 34 35 36 37 38 39 40 41 Mass flow of dry air Sensible duty at typical air-conditioning conditions Total duty Sensible heat ratio Bypass factor Sensible heat at wet wick Latent heat at wet wick Mass transfer coefficient

Room Heat Formulae 42 43 Q = Uo Ao ( to ti ) r = ro+ t/K + ri Heat conduction through a wall Wall resistance

44 45

Qsg = SHGF SC A CLF Q = U A CLTD

Solar heat gain

Cooling load temperature difference method Cold Room Formulae Pull down load Latent load Heat of respiration

46 47 48

Qpulldown = m C dT Qlatent= m W Qrespiration= m R Solar Angle Formulae

49 50

d = 23.45 sin ( 360 (284+n) / 365) LST = CT + (Lstd Lloc)/15 + E + DT

Solar Declination Local Solar Time Equation of Time Parameter in E Hour angle Altitude angle Solar Azimuth Angle to surface normal

51 E = 0.165 sin 2B -0.126 cos B -0.025 sin B 52 53 54 55 56 B = 360 (n- 81) / 364 h = 15 (LST 12) sin = cos lcosh cosd + sin l sin d cos = (cos d sin l cosh sin d cos l) / cos cos = cos cos sin + sin cos IDN =A e -B / sin IdH = C IDN ID = IDN cos dQ = hd dA ( ha hi ) dQ = hr dAi ( ti tr ) dQs = hc dA ( ta ti ) Q = U A lmtd Lmtd = (dti dto) / Ln( dti / dto ) Q = e Qmax e = (1 exp(- Ntu (1- Cr)) / (1 Cr exp(Ntu (1-Cr)) Cr = Cmin / Cmax Solar Radiation Formulae 57 58 59

Direct Normal Solar Flux Diffuse Horizontal Solar Flux Direct Solar Flux on Surface

Coil Calculation Formulae 60 61 62 63 64 65 66 67 Heat flow on the c oil air side Heat flow on the coil fluid side Air sensible heat Duty from UA LMTD method Log mean temperature difference Effectiveness method Counter-flow effectiveness Capacity ratio

68

Ntu = U A / Cmin

Number of transfer units

69 70

Steam Formulae Latent heat of vaporization at 2 bar = 2164 kJ/kgK gauge pressure = 333.6 kJ/kg dPfriction = L V2/ Dh 1/ = -2 Log [ / (3.7 Dh) + 2.51 / (Re ) ] Dh = 4 A / P P + V2 + g H = constant P1 + V2 + r g H1 = P1 + V2 + g H1 + Ploss dP = Vd2 [ 0.4 ( 1 - Vd/Vu)2 ] Def = 1.3 (ab)0.625 / (a+b)0.25 dP = V2 [ (A1/A2)2 - 1 ] dP = V2 [ 1 - (A1/A2) ]2 Re 67 V Dh Latent heat of freezing DArcy Weisbach friction equation Colebrook friction factor Hydraulic diameter Fluid Flow in Pipes Formulae

71 72 73

Duct Design Calculation Formulae 74 75 76 77 78 79 81 Bernoulli equation Modified Bernoulli Branch straight through dp Effective diameter of rectangular duct dP for ideal flow through a nozzle dP for sudden enlargement standard air with V (m/s) and Dh (mm)

Natural Refrigerant Hydrocarbon

Posted: September 24, 2012 in Natural Refrigerants Tags: Air conditioning, Butane, Chlorofluorocarbon, HVAC, Hydrocarbon, Isobutane, Propane, Refrigerant

0 Hydrocarbons are refrigerants that can be used as an alternative to fluorocarbon refrigerants in some refrigeration and air conditioning applications. The term Hydrocarbon encompasses following: A) Ethane (R170) B) Propane(R290) C) Butane (R600) D) Isobutane (R600a) E) Propylene (R1270) Properties 1) Hydrocarbons are highly flammable. 2) They have a low toxicity.

3) Hydrocarbon refrigerants are fully compatible with nearly all lubricants commonly used in refrigeration and air conditioning systems. One major exception to this rule is lubricants containing silicone and silicate. Comparison with HCFC 1) HVAC professionals have made a comparative study on the performance of hydrocarbon refrigerants R290, R600a and R1270 with that of HFC refrigerant R22 and found that in comparison to R22, hydrocarbon refrigerants have similar or better ability. 2) An experiment on a new refrigerant blend comprising R134a (a HFC) and hydrocarbon refrigerants R600a and R290, with a view to finding a replacement for the CFC refrigerant R12 in domestic refrigerators. The experiment concluded that the blend has been identified as a promising alternative to be used as a refrigerant in a conventional R12 system and that the blend reduced energy consumption by 4 to 11%. 3) Hydrocarbon refrigerants generally are compatible with the materials used in systems designed for R22 and often can use the same or similar lubricants, however, their substitution requires significant attention to safety issues including application specific considerations. 4) It has been observed that no (one) refrigerant has been identified as a suitable alternative for most applications,though they identify that some refrigerant blends offer good options. Blends can be HFC/HFC or HFC/HC. 5) Hydrocarbons may be suitable in some applications, and may not be in others, so every application needs to be carefully assessed on its merits. Safety Issues 1) As mentioned above, hydrocarbon refrigerants are flammable and therefore certain restrictions are placed on their use to ensure safety. 2) All electrical contacts must be sealed or non-sparking. 3) The refrigerant charge in a system below ground level must not exceed 1.0 kg. 4) Sealed systems not exceeding 0.25 kg can be cited in any location. 5) Systems with charges exceeding 0.25 kg must not be located anywhere where a sudden loss of refrigerant will raise the concentration in the room or occupied compartment above the practical limit (0.008 kg/m) 6) Piping for systems exceeding 1.5 kg must be restricted to the room containing the refrigerant. Hospitals, prisons, theaters, supermarkets, schools, hotels, restaurants, dwellings Offices, small shops, small restaurants, Refrigerant charge must not exceed 1.5 kg per sealed system Refrigerant charge must not exceed 5.0 kg in special machinery rooms for indirect systems Refrigerant charge must not exceed 2.5 kg per sealed system Refrigerant charge must not exceed 10.0 kg in special

places for general manufacturing and where people work Industrial, cold stores, dairies, abattoir, non public areas of supermarkets

machinery rooms for indirect systems

Refrigerant charge must not exceed 10.0 kg in humanly occupied spaces Refrigerant charge must not exceed 25.0 kg for systems with high pressure side in special machinery rooms No restrictions are placed on the charge size if all parts of the system containing refrigerant are in a special machinery room or in open air

Corporate Acceptance 1) In Europe, many models of domestic refrigerators are charged with hydrocarbon refrigerant in the factory. It is estimated that there are at least 100,000,000 household refrigerators in use around the world containing hydrocarbon refrigerants. 2) Hydrocarbons have also been used in small air conditioning systems and cold drinking water dispensers. 3) Hydrocarbon refrigerants are also commonly used in large process refrigeration systems in the oil and gas industries.

Natural Refrigerant Carbon dioxide

Posted: September 24, 2012 in Natural Refrigerants Tags: Air conditioning, Chlorofluorocarbon, HVAC, Hydrocarbon, Isobutane, Propane, Refrigerant

2

The use of Carbon dioxide as a refrigerant declined for a number of reasons, including changes in technology and the introduction of fluorocarbon refrigerants, which were seen as safety refrigerants.

Properties A) Carbon dioxide has an ozone depletion potential (OPD) of zero and a global warming potential (GWP) of 1. B) It is generally regarded as a cheap and easily available refrigerant, and many regard it as an

ideal refrigerant. C) Carbon dioxide is non-toxic. It has low toxicity and is non-flammable. D) Carbon dioxide is colorless, odorless and is also heavier than air.If enough carbon dioxide builds up in an enclosed space it will begin to displace oxygen and can cause asphyxiation in anyone present within the space. As carbon dioxide is colorless and odorless,a person in the space will not be able to tell unless proper detectors and alarms are installed. E) As a refrigerant, carbon dioxide operates at a higher pressure than fluorocarbon and other refrigerants. While this presents design challenges it can usually be overcome in systems designed specifically in suction and discharge tubing. F) Carbon dioxide is not compatible with commonly used refrigeration system lubricants.It is not suited for use with polyols ester (POE) and poly vinyl ether (PVE) lubricants, and it has only limited applications with poly alkylene glycol (PAG) lubricants. Safety Issues A) Some restrictions are placed on the size of the refrigerant charge, with additional allowances made for systems with detectors and alarms fitted, and as carbon dioxide is heavier than air the standard requires suitable precautions to be taken to prevent the undue accumulation of refrigerant in occupied spaces in the event of a leak. B) As with fluorocarbon refrigerants, the standard also requires the system to be designed to withstand the refrigerants maximum operating pressure. C) The International Institute of Refrigeration (IIR) identified carbon dioxides high working pressure as the main drawback to its use.

Thermodynamic Properties 1) Carbon dioxide is colorless. At low concentrations, the gas is odorless. At higher concentrations it has a sharp, acidic odor. 2) At standard temperature and pressure, the density of carbon dioxide is around 1.98 kg/m3, about 1.5 times that of air. 3) Carbon dioxide has no liquid state at pressures below 5.1 standard atmospheres (520 kPa). At 1 atmosphere the gas deposits directly to a solid at temperatures below 78.5 C and the solid sublimes directly to a gas above 78.5 C. In its solid state, carbon dioxide commonly called dry ice. 4) Liquid carbon dioxide forms only at pressures above 5.1 atm; the triple point of carbon dioxide is about 518 kPa at 56.6 C.The critical point is 7.38 MPa at 31.1 C. Corporate Acceptance Coca Cola company stated that the companys preliminary field tests proved the technology to be reliable, in real life circumstances the equipment often used less energy than equivalent equipment using HFC as a refrigerant. Till 2006, the company was market testing a range of drinks fridges and vending machines using carbon dioxide refrigerants.

Natural Refrigerant Ammonia

Posted: September 23, 2012 in Natural Refrigerants Tags: Ammonia, Atmospheric pressure, Global-warming potential, List of thermodynamic properties, Ozone depletion potential, Parts-per notation, Player versus environment, Refrigerant

0 Most of the refrigeration and air conditioning equipments in the world today uses fluorocarbon refrigerants to facilitate the heat transfer process.Fluorocarbon refrigerants are synthetic chemicals which causes a high global warming potential,and are a greater threat to the ozone layer as well if released to the atmosphere.There are alternatives to these HFCs that can help to mitigate some of the environmental risks.These are called natural refrigerants because the substances also occur in nature, these alternatives are: 1) Ammonia, 2) Carbon Di Oxide, 3) Hydrocarbons

Ammonia (R717) Ammonia is a naturally occurring substance that can be used as a substitute to fluorocarbon refrigerants in refrigeration systems. Properties A) Ammonia (NH3)- R717 is a colorless gas with high pungent smell at atmospheric pressure, and possesses the ideal environmental properties for a refrigerant it has both a zero ozone depletion potential (ODP) and a zero global warming potential (GWP). B) These properties make ammonia an attractive prospect as a refrigerant, given that fluorocarbon (HFC) refrigerants can have global warming potentials as high as 3900. C) Many people are familiar with ammonia as an ingredient in fertilizers and other products. Ammonia carries a B2 safety classification,meaning that it has a high toxicity, and also carries a medium flammability risk. D) Ammonia is not compatible with commonly used refrigeration system lubricants.It is not suited for use with polyol ester (POE) and poly vinyl ether (PVE) lubricants and it has only limited applications with poly alkylene glycol (PAG) lubricants. Safety Issues A) A glass of drinking water can contain as much as 1 mg of ammonia,a 200gms steak as much as 13mg, and some food additives can contain as much as 18 mg.cigarette smoke and even the air we breathe also contains ammonia in small amounts. B) This demonstrates that the human body can deal with ammonia in small quantities. Generally, any amount in the atmosphere below 20 parts per million (ppm) is regarded as not dangerous. At amounts of up to 53 ppm, ammonias characteristic odor will be noticeable. C) In amounts of 300-400ppm, prolonged exposure will become unpleasant, and in amounts over 700 ppm it can cause burns and serious damage to eyes. In amounts of 5000 ppm or above, exposure can be lethal to humans within five minutes. Thermodynamic Properties A) Vapor mass is lighter than air ( 0.6 compared to air 1.0). B) Ignition will occur at 651 C when vapor concentration is between 15% and 28%. C) Ammonia corrodes galvanized metals, cast iron, copper, brass & copper alloys. D) It weighs 5.15 pounds(2.34Kgs) per gallon(3.78 Liter) in liquid conditions (water weight 8.33 pounds per gallon). E) Boiling point of liquid ammonia at atmospheric pressure is -2.22 C. F) Liquid ammonia expands 850 times its liquid volume at atmospheric pressure.

Vous aimerez peut-être aussi

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideD'EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuidePas encore d'évaluation

- Hvac DesignDocument256 pagesHvac DesignMSUEGA IORPENDA100% (1)

- Air Handling Units: CatalogueDocument157 pagesAir Handling Units: CatalogueHendri Chikal0% (1)

- Ventilation Lecture 4 PH Alleen LezenDocument25 pagesVentilation Lecture 4 PH Alleen LezenNazimAhmedPas encore d'évaluation

- Hvac SyllabusDocument4 pagesHvac SyllabusgulmuhrPas encore d'évaluation

- Carrier Cooling Load Hand Book-1 PDFDocument16 pagesCarrier Cooling Load Hand Book-1 PDFAsep Uhan SugandiPas encore d'évaluation

- Trane ENL ASHRAE 62.1 90.1 VAVDocument54 pagesTrane ENL ASHRAE 62.1 90.1 VAVgary_robinsonPas encore d'évaluation

- Air To Air HX Ventilation SystemDocument12 pagesAir To Air HX Ventilation SystemGopinath GopiPas encore d'évaluation

- Part E - 2 - (HVAC) Engineering DesignDocument69 pagesPart E - 2 - (HVAC) Engineering Designkeya2020Pas encore d'évaluation

- Ashrae Standard Safety Standard For Refrigeration SystemsDocument5 pagesAshrae Standard Safety Standard For Refrigeration SystemsMarcos Eletricidade RefrigeraçãoPas encore d'évaluation

- ASHRAE Standard 62-2007Document26 pagesASHRAE Standard 62-2007schiZ0prEni100% (1)

- Im j1 Personnel Cooling Load Estimation 2014Document40 pagesIm j1 Personnel Cooling Load Estimation 2014Melvin SanchezPas encore d'évaluation

- Ducts and Diffusers Design PDFDocument106 pagesDucts and Diffusers Design PDFsiroliver39Pas encore d'évaluation

- HVACDocument9 pagesHVACMailisa FitriaPas encore d'évaluation

- AT4 HumidifierDocument64 pagesAT4 Humidifiermdalt9180Pas encore d'évaluation

- AHU Types, Components, and ConfigurationsDocument14 pagesAHU Types, Components, and ConfigurationsKumudu PereraPas encore d'évaluation

- HVAC LOAD CalculationDocument2 pagesHVAC LOAD Calculationbookjaman100% (1)

- Chapter 2 - ChillersDocument33 pagesChapter 2 - ChillersRajesh VenkiteswaranPas encore d'évaluation

- Air Curtain Guide DesignDocument8 pagesAir Curtain Guide Designanton7786Pas encore d'évaluation

- ERV Sizing PDFDocument18 pagesERV Sizing PDFAnonymous XhkjXCxxsTPas encore d'évaluation

- ALNOR HVAC HandbookDocument54 pagesALNOR HVAC HandbookYash Karkhanis100% (1)

- Air ConditioningDocument37 pagesAir Conditioningfirst lastPas encore d'évaluation

- Selecting Cooling Coils Without Proprietary Software - Issue Oct-Dec 2002Document12 pagesSelecting Cooling Coils Without Proprietary Software - Issue Oct-Dec 2002dokundot100% (2)

- HVAC Overview of The Underfloor Air Distribution (UFAD) PDFDocument49 pagesHVAC Overview of The Underfloor Air Distribution (UFAD) PDFnitin guptaPas encore d'évaluation

- Specifications For Fire Rated Gi Duct WorksDocument2 pagesSpecifications For Fire Rated Gi Duct Workspsn_kylmPas encore d'évaluation

- 02 Cooling Load Calculation - HAPDocument2 pages02 Cooling Load Calculation - HAPU DEEPAKPas encore d'évaluation

- SPD4121 1617 05-Load PDFDocument60 pagesSPD4121 1617 05-Load PDFMukti WibowoPas encore d'évaluation

- SECTION 15850 Air Outlets and Inlets Rev 0Document31 pagesSECTION 15850 Air Outlets and Inlets Rev 0Munir RasheedPas encore d'évaluation

- Air Diffuser Architecture PDFDocument28 pagesAir Diffuser Architecture PDFBranislavPetrovicPas encore d'évaluation

- Hvac PG DiplomaDocument5 pagesHvac PG DiplomaThava SelvanPas encore d'évaluation

- Heat LoadDocument15 pagesHeat Loadsachinsaklani23Pas encore d'évaluation

- AHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetDocument17 pagesAHRI Standard 885-2008 Duct Discharge Calculation SpreadsheetJagatjeetMPas encore d'évaluation

- Ashrae ChartDocument1 pageAshrae Chartalone160162lPas encore d'évaluation

- Ashrae 15-34-Rev 3 MitsubishiDocument7 pagesAshrae 15-34-Rev 3 MitsubishiJosho SandovalPas encore d'évaluation

- Technical Career Institute (Tci) Hvac Interview QuestionsDocument2 pagesTechnical Career Institute (Tci) Hvac Interview QuestionsSYED MUDASSIR NAZARPas encore d'évaluation

- HVAC Technical SpecificationsDocument132 pagesHVAC Technical Specificationsمهيب سعيد الشميري100% (1)

- Ashrae Standard For GymDocument2 pagesAshrae Standard For GymignatiadiskPas encore d'évaluation

- Ashrae ChartDocument1 pageAshrae ChartSMBEAUTYPas encore d'évaluation

- How You Can Own ASHRAE Standard 170Document95 pagesHow You Can Own ASHRAE Standard 170Luis Eduardo Carmona VasquezPas encore d'évaluation

- Guide To Air Change EffectivenessDocument7 pagesGuide To Air Change EffectivenessAnonymous tgCsXLnhIIPas encore d'évaluation

- HVAC - Space Heating SystemsDocument114 pagesHVAC - Space Heating Systemsnitin guptaPas encore d'évaluation

- 78 Return Grille LocationsDocument2 pages78 Return Grille LocationsKyaw San OoPas encore d'évaluation

- Ductwork DesignDocument26 pagesDuctwork DesignHafiz Hassan100% (1)

- Average Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Document7 pagesAverage Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Alexandre HugenPas encore d'évaluation

- HVAC SyllabusDocument1 pageHVAC SyllabusHumaid Shaikh100% (1)

- HVAC Psychrometric Analysis To Avoid Moisture ProblemsDocument30 pagesHVAC Psychrometric Analysis To Avoid Moisture ProblemsmohdrashidPas encore d'évaluation

- Chapter 22Document22 pagesChapter 22Kenneth Bryan Miguel Villagoneza100% (1)

- IsolationBase CatalogDocument8 pagesIsolationBase CatalogarturslavePas encore d'évaluation

- VAV Fundamentals ASHRAEDocument24 pagesVAV Fundamentals ASHRAEheartbreakkid132Pas encore d'évaluation

- ASHRAE-VRF Standard15Document7 pagesASHRAE-VRF Standard15jijijadjoe100% (1)

- Cooling Load1111 PDFDocument43 pagesCooling Load1111 PDFJason PaquibulanPas encore d'évaluation

- Adenda Guideline 36 Ashrae 2018 v1Document30 pagesAdenda Guideline 36 Ashrae 2018 v1Isaias BravoPas encore d'évaluation

- ADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.Document8 pagesADC Flexible Duct Performance & Installation Standards. Installation Guidelines. 4th Ed.John EvansPas encore d'évaluation

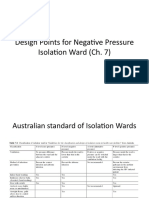

- Design Points For Negative PressureDocument23 pagesDesign Points For Negative PressureShohei Namjoon LetoPas encore d'évaluation

- MECH4880-Assignment1 S2 2017 v1 - 01Document25 pagesMECH4880-Assignment1 S2 2017 v1 - 01charitha RanwalaPas encore d'évaluation

- CO2 Sensor RoomDocument8 pagesCO2 Sensor RoomTrần Khắc ĐộPas encore d'évaluation

- Co2 Solar RankieDocument25 pagesCo2 Solar RankiewtwarPas encore d'évaluation

- Heat Exchanger PerformanceDocument31 pagesHeat Exchanger PerformanceFA AyPas encore d'évaluation

- Assgmnt Thermal MEC551Document9 pagesAssgmnt Thermal MEC551khazwanPas encore d'évaluation

- Pressure Independent Control ValvesDocument52 pagesPressure Independent Control ValvesDarren LeongPas encore d'évaluation

- AeroCross Flow Sensor Application Guide (Used in VAV)Document7 pagesAeroCross Flow Sensor Application Guide (Used in VAV)NisarPas encore d'évaluation

- Insulation RequirementsDocument6 pagesInsulation RequirementsNisarPas encore d'évaluation

- Arabic WordsDocument4 pagesArabic WordsNisarPas encore d'évaluation

- Arabic WordsDocument4 pagesArabic WordsNisarPas encore d'évaluation

- PhysioEx Ex. 9 Act. 2Document4 pagesPhysioEx Ex. 9 Act. 2Juvy Anne LozanoPas encore d'évaluation

- Chemical Principles Notes Chapter 7Document86 pagesChemical Principles Notes Chapter 7Robert GardnerPas encore d'évaluation

- An Ecient Uniform-Cost Normalized Edit Distance AlgorithmDocument12 pagesAn Ecient Uniform-Cost Normalized Edit Distance Algorithmanon-75650Pas encore d'évaluation

- CS405PC JP Unit-3Document44 pagesCS405PC JP Unit-3MEGHANA 3Pas encore d'évaluation

- Atomic Structure ActivityDocument4 pagesAtomic Structure ActivityClarisse BonaobraPas encore d'évaluation

- Fujitsu APMDocument2 pagesFujitsu APMLuis D100% (1)

- Report OmarDocument14 pagesReport OmarYasir KhursheedPas encore d'évaluation

- Chinese Journal of Traumatology: Geley Ete, Gaurav Chaturvedi, Elvino Barreto, Kingsly Paul MDocument4 pagesChinese Journal of Traumatology: Geley Ete, Gaurav Chaturvedi, Elvino Barreto, Kingsly Paul MZilga ReginaPas encore d'évaluation

- Sampling in Research in EducationDocument18 pagesSampling in Research in EducationV.K. MaheshwariPas encore d'évaluation

- LAB211 Assignment: Title Background ContextDocument2 pagesLAB211 Assignment: Title Background ContextDuong Quang Long QP3390Pas encore d'évaluation

- Panasonic MINAS A5Document478 pagesPanasonic MINAS A5Vaikuntam Ramamurthy100% (1)

- Parola A Do ZDocument8 pagesParola A Do ZjovicaradPas encore d'évaluation

- Jee Advanced PaperDocument3 pagesJee Advanced PaperGaurav YadavPas encore d'évaluation

- Calculation of Section Modulus PDFDocument4 pagesCalculation of Section Modulus PDFAnthony Gravagne40% (5)

- A Generic Circular BufferDocument3 pagesA Generic Circular BufferSatish KumarPas encore d'évaluation

- FAR21x7 28x7 Operator's Manual P 4-8-11Document312 pagesFAR21x7 28x7 Operator's Manual P 4-8-11Miguel PerezPas encore d'évaluation

- PowerPoint Practice Exercise 1 InstructionsDocument3 pagesPowerPoint Practice Exercise 1 InstructionsErick OumaPas encore d'évaluation

- Astm C97/C97M-09Document3 pagesAstm C97/C97M-09Azuriak150% (2)

- Module 2 Notes - PSOCDocument24 pagesModule 2 Notes - PSOCpriyaPas encore d'évaluation

- UntitledDocument33 pagesUntitledapi-235198167Pas encore d'évaluation

- Gree Dehumidifier Service ManualDocument58 pagesGree Dehumidifier Service Manualjdv1234Pas encore d'évaluation

- MICOM P12x-TechnicalDataSheetDocument28 pagesMICOM P12x-TechnicalDataSheetSeba GonzálezPas encore d'évaluation

- FMC - Novolastic Subsea Thermal Insulation - LOW RESDocument3 pagesFMC - Novolastic Subsea Thermal Insulation - LOW RESalphading50% (2)

- Data Sheet Cummins BT5,9-G6Document4 pagesData Sheet Cummins BT5,9-G6acere18100% (1)

- Name: Class Number: - Date: - Section: - ScheduleDocument11 pagesName: Class Number: - Date: - Section: - ScheduleErica AguirrePas encore d'évaluation

- About Planets - Vaishali's ProjectDocument3 pagesAbout Planets - Vaishali's ProjectRaj KumarPas encore d'évaluation

- AIR IOS ReadmeDocument2 pagesAIR IOS ReadmeHeir TatamiPas encore d'évaluation

- HKV-8 Valve Catalog SPLRDocument128 pagesHKV-8 Valve Catalog SPLRCabrera RodriguezPas encore d'évaluation

- Is 4031 Part 4 - ConsistencyDocument4 pagesIs 4031 Part 4 - ConsistencyCrypto AbhishekPas encore d'évaluation

- Practical 3 CGR PDFDocument4 pagesPractical 3 CGR PDFKalpesh PilorePas encore d'évaluation