Académique Documents

Professionnel Documents

Culture Documents

Vek m1h Manual

Transféré par

dante48rusDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Vek m1h Manual

Transféré par

dante48rusDroits d'auteur :

Formats disponibles

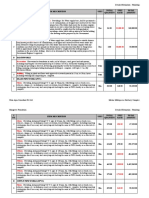

Loop Detector Layout

22.50

0V 24V 28

low high

Terminal Connections

74.00 0V 24V

s: sensitivity h: holding time r: function relay 1 5min. / (reset on change) normally close / normally open

0V 24V 28

79.50

h r

Connect Loop to these terminals

Operating Instructions 1. Connect the power, ground, loop & output. (See Terminal Connections). 2. Sensitivity of the Loop is set by switches `S`. (See Function Settings). 3. Connect loop to terminals indicated. (See Diagram above). Frequency Settings

L.E.D. Functions Green OFF, Red OFF: Green Flashing, Red OFF: Green ON, Red OFF: Green ON, Red ON: Green OFF, Red ON:

1 2 3 4

16 15 25

Link Controls Limited

INDUSTRIAL DOOR AND GATE OPERATORS ACCESS CONTROL & SECURITY EQUIPMENT

STUART ROAD, MANOR PARK, RUNCORN, WA7 1TS Tel: 01928 579050 Fax: 01928 579259

ON DIP

5'

relay 1: presenceoutput relay 2: pulseoutput

LED green on on flashing flashing off

15 15

16 16

Pulse Signal

16 15 25

25 LED red off on off ---on

28

loop free loop covered detector is tuning signalizing frequency after tuning loop failure

Presence Signal

operating voltage: relay contacts:

24V AC/DC 10 % 250mA / 24VAC/DC (min. 1mA / 5V)

Note:- For additional information see side of loop detector

Function Settings DIP Switches 'S' :- Sensitivity (4 steps)

MIN

ON ON ON

MAX

ON

= HIGH Frequency

DIP Switch 'h':- Holding Time (5 mins - infinity)

h

= 5mins

= INFINITE

DIP Switch 'r':- Presence Relay = LOW Frequency

r

= Normally Closed (N/C)

= Normally Open (N/O)

Power OFF Calibration or Output of Frequency Detector Ready for Operation, Loop Free Detector Ready for Operation, Loop Covered Loop Failure

Title:VEK M1H LOOP DETECTOR MODULE (STOCK CODE: 37-4077)

Drawing No:- LC-1686 Revision No:- A Drawn By:S.B.P

Page No:-

1 of 2

Rev Date:- 13/02/07 Date:26/11/99

Checked By:- A.M.

Appr' By:- F.T.

Typical Example of Loop Installation Loop Cable:

Installing a Loop Rubberised insulated wire of 0.75-1.50 sq.mm (awg 20 - awg 16), preferably multi-stranded. Note:- High bed vehicles require larger loops.

LOOP CIRCUMFERENCE 2 - 4m 4 - 7m 7 - 12m 12 - 25m NUMBER OF TURNS 6 5 4 3

LOOP

Loop Size: No. of Turns in Loop:

min. 1.2m

Loop Slot:

Door min. 1.2m

Feed Cable in to 20mm Plastic Conduit

Recommended depth to top of loop cable 25-50mm. (Maximum depth 65mm) Loop slot MUST be sealed after cable has been installed and tested. Use a flexible, weather proof sealant (i.e. Hot bitumen, Rubberised bitumen sealant). CAUTION! Never use cement / concrete, etc... The feeder cable MUST be twisted a minimum 10 times per meter & can be up to 100m long. The loop must be placed at least 5m away from high tension cables and at least 1m away from low tension cables. If the loop is placed in an area with reinforcing iron (typically a concrete floor), the loop must be placed at least 50mm above the reinforcement. If the detector is used for detecting high vehicles (lorries etc.) use only one loop for each detector, otherwise it is possible to connect two loops to a single detector. Series coupling the loops will give the largest sensitivity, parallel coupling gives the fastest reaction.

Feeder Cable: Loop Placement:

1.0m

LOOP

Two or More Loops:

2.0m

Concrete / Tarmac

Sealant 25-50mm

Block Paving

Block Plastic Conduit with Loop Cable Inside

Sand Loop Cable 5-10mm

Base

Link Controls Limited

INDUSTRIAL DOOR AND GATE OPERATORS ACCESS CONTROL & SECURITY EQUIPMENT

STUART ROAD, MANOR PARK, RUNCORN, WA7 1TS Tel: 01928 579050 Fax: 01928 579259

Title:VEK M1H LOOP DETECTOR MODULE (STOCK CODE: 37-4077)

Drawing No:- LC-1686 Revision No:- A Drawn By:S.B.P

Page No:-

2 of 2

Rev Date:- 13/02/07 Date:26/11/99

Checked By:- A.M.

Appr' By:- F.T.

Vous aimerez peut-être aussi

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Pas encore d'évaluation

- The 360 Degree Leader J MaxwellDocument2 pagesThe 360 Degree Leader J MaxwellUzen50% (2)

- Equity ValuationDocument2 424 pagesEquity ValuationMuteeb Raina0% (1)

- FAT Test FormDocument4 pagesFAT Test FormMohamedPas encore d'évaluation

- TPy3 415480 280L 2B TYPACT SERVO DRIVE KLOCKNER MOELLER MANUAL PDFDocument63 pagesTPy3 415480 280L 2B TYPACT SERVO DRIVE KLOCKNER MOELLER MANUAL PDFdozer_kamilPas encore d'évaluation

- VTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFDocument176 pagesVTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFIbrahim AwadPas encore d'évaluation

- Electroducto Square DDocument44 pagesElectroducto Square DEulalio HortaPas encore d'évaluation

- Rm7890a1015 PDFDocument12 pagesRm7890a1015 PDFHéctor VelásquezPas encore d'évaluation

- Enerpac PATG1102NDocument72 pagesEnerpac PATG1102NAnonymous G6ceYCzwtPas encore d'évaluation

- Model 43AP Pneumatic Controller, Style B: Installation and OperationDocument16 pagesModel 43AP Pneumatic Controller, Style B: Installation and OperationMathieu RibeiroPas encore d'évaluation

- Horner Manual Básico Programación CsCape y XLe PDFDocument112 pagesHorner Manual Básico Programación CsCape y XLe PDFUlises100% (2)

- P3 NRJCAT17764EN v16 072019 PDFDocument122 pagesP3 NRJCAT17764EN v16 072019 PDFHoang Bao ThaiPas encore d'évaluation

- GMDS - Course - FinalDocument282 pagesGMDS - Course - FinalLuisPazPerdomo100% (1)

- Cautions, Warnings, and Regulatory Information: Abort and Maintenance Switch Installation InstructionsDocument8 pagesCautions, Warnings, and Regulatory Information: Abort and Maintenance Switch Installation InstructionsJOHN FREDY SIMANCAS FIERROPas encore d'évaluation

- Manual Español Relevador 489Document40 pagesManual Español Relevador 489fersa581021Pas encore d'évaluation

- Book LoRa LoRaWAN and Internet of ThingsDocument140 pagesBook LoRa LoRaWAN and Internet of ThingsNguyễn Hữu HạnhPas encore d'évaluation

- Crane Cab Paging StationDocument6 pagesCrane Cab Paging StationJWilson73Pas encore d'évaluation

- Sonos 5500 Service ManualDocument565 pagesSonos 5500 Service ManualScott Fergusson50% (2)

- Manual 250-Hp 300-Hp 350-Hp Cleaver-Brooks EquipmentDocument194 pagesManual 250-Hp 300-Hp 350-Hp Cleaver-Brooks EquipmentAlexis CruzPas encore d'évaluation

- Idealarc DC-600: Rugged Multi-Process Power For Industrial ManufacturingDocument4 pagesIdealarc DC-600: Rugged Multi-Process Power For Industrial Manufacturingmkpasha55mpPas encore d'évaluation

- Tilt Switch OldDocument2 pagesTilt Switch OldAngel Francisco NavarroPas encore d'évaluation

- Dilip - SFDC CPQ Architect14 GCDocument5 pagesDilip - SFDC CPQ Architect14 GCmariareddy17100% (1)

- S 1 WPDocument6 pagesS 1 WPAdam PegielPas encore d'évaluation

- Timer Off DelayDocument8 pagesTimer Off DelayNatanael MarquezPas encore d'évaluation

- BOTON NO TOUCH K1-1en PDFDocument1 pageBOTON NO TOUCH K1-1en PDFTas DtPas encore d'évaluation

- User Manual All JET-TECH ModelsDocument32 pagesUser Manual All JET-TECH ModelsAllen ZhangPas encore d'évaluation

- Weidmuller DRAC Series AC Receptacles Flyer LIT0915 072016v1 PDFDocument2 pagesWeidmuller DRAC Series AC Receptacles Flyer LIT0915 072016v1 PDFeuqehtb100% (1)

- EC Centrifugal Module: K3G630-AB21-02Document6 pagesEC Centrifugal Module: K3G630-AB21-02Sharath KotaPas encore d'évaluation

- Catalogo Celdas Demitas DmeDocument28 pagesCatalogo Celdas Demitas DmeRobert GalarzaPas encore d'évaluation

- TachometerDocument2 pagesTachometerKreshia CuasayPas encore d'évaluation

- Regulador AxialDocument12 pagesRegulador Axialluis_d_mPas encore d'évaluation

- MPR 6 Instruction Manual SolconDocument26 pagesMPR 6 Instruction Manual Solconcchung147554Pas encore d'évaluation

- Series 47K Gas Detector: Operation ManualDocument32 pagesSeries 47K Gas Detector: Operation ManualGunawan MSPas encore d'évaluation

- Sitrans LR250 Radar Transmitter Instruction ManualDocument175 pagesSitrans LR250 Radar Transmitter Instruction ManualVinay TuliPas encore d'évaluation

- Dinli ATV Electrical System ManualDocument15 pagesDinli ATV Electrical System ManualgryzzlyPas encore d'évaluation

- LMAIM1306Document132 pagesLMAIM1306Yasser Badr100% (1)

- Control de Flama Honeywell 215Document12 pagesControl de Flama Honeywell 215Moreno NuevoPas encore d'évaluation

- AVFM-II Manual Series A.10 SpanishDocument47 pagesAVFM-II Manual Series A.10 SpanishVíctor Hugo Concha OrmeñoPas encore d'évaluation

- XMT 308 ManualDocument4 pagesXMT 308 Manualzivko13Pas encore d'évaluation

- Diagrama de Carga PlumaDocument1 pageDiagrama de Carga PlumaSantiago Velasquez SylvaPas encore d'évaluation

- GMP17PX6Document5 pagesGMP17PX6filolocoPas encore d'évaluation

- 11 - LZT - SPEC-RotametersWaterDocument3 pages11 - LZT - SPEC-RotametersWaterHeinium DannemannPas encore d'évaluation

- RH XDGVDocument120 pagesRH XDGVRAJ NAYAAKPas encore d'évaluation

- Catalogo de BateriasDocument16 pagesCatalogo de BateriasPedro Gutierrez100% (1)

- Oil Sample GuideDocument16 pagesOil Sample GuideMike RosemanPas encore d'évaluation

- Carlin 40200Document2 pagesCarlin 40200luzvid alejo ochoaPas encore d'évaluation

- Eac 805Document1 pageEac 805Charles TineoPas encore d'évaluation

- Mvt6 and MVT 8 Version 06 OriginalDocument113 pagesMvt6 and MVT 8 Version 06 OriginalCletoCruzLPas encore d'évaluation

- DCR Web PDFDocument4 pagesDCR Web PDFMahmoud AyadPas encore d'évaluation

- AstatDocument4 pagesAstatpayolin77Pas encore d'évaluation

- DCA45SSIU2 Rev 7 STD ManualDocument160 pagesDCA45SSIU2 Rev 7 STD ManualRahmat Nur IlhamPas encore d'évaluation

- Orca Manual PDFDocument92 pagesOrca Manual PDFEmilio EspinozaPas encore d'évaluation

- LCM & LEM 320 Control and Expander Modules Data SheetDocument2 pagesLCM & LEM 320 Control and Expander Modules Data SheetGabriel OsorioPas encore d'évaluation

- Overfill Prevention: Automation Solutions For Oil & Gas, Defense and Aviation ApplicationsDocument4 pagesOverfill Prevention: Automation Solutions For Oil & Gas, Defense and Aviation ApplicationsAntonio FullerPas encore d'évaluation

- SKF Tmeb2 Alineador Poleas Laser Manual UsoDocument136 pagesSKF Tmeb2 Alineador Poleas Laser Manual UsoDaniel_Ali_bPas encore d'évaluation

- EMR-5000 User Manual Eaton enDocument760 pagesEMR-5000 User Manual Eaton enMayel MartinPas encore d'évaluation

- 2017 Hisense VRF General CatalogueDocument84 pages2017 Hisense VRF General Cataloguemurat100% (2)

- Catalogue Brushless DC Drives GB 02 2007Document56 pagesCatalogue Brushless DC Drives GB 02 2007Bianca CerveiraPas encore d'évaluation

- AD Oracle ManualDocument18 pagesAD Oracle ManualAlexandru Octavian Popîrțac100% (2)

- Nvf300 ManualDocument5 pagesNvf300 Manualjohnny paredes100% (2)

- A 1018 A 1019 A 1033 Current Clamp MultilingualDocument32 pagesA 1018 A 1019 A 1033 Current Clamp MultilingualAmarK90Pas encore d'évaluation

- Spec For AS3693B1Document33 pagesSpec For AS3693B1tomlee888Pas encore d'évaluation

- Cyl Tel CutsheetDocument2 pagesCyl Tel CutsheetaLeXiNPas encore d'évaluation

- 2b-Matrixiis110 - Manual - One TechDocument6 pages2b-Matrixiis110 - Manual - One TechAGA30Pas encore d'évaluation

- Users Guide Digital Inductive Loop Sensors: MatrixDocument6 pagesUsers Guide Digital Inductive Loop Sensors: MatrixEliseu DiasPas encore d'évaluation

- 8750 - Transmitter 2 EnglishDocument12 pages8750 - Transmitter 2 EnglishJorge CastilloPas encore d'évaluation

- Signet 8550-3 Flow Transmitter: 3-8550.090-3 EnglishDocument8 pagesSignet 8550-3 Flow Transmitter: 3-8550.090-3 Englishrimmer kaltimPas encore d'évaluation

- Bank Reconciliation and Proof of CashDocument2 pagesBank Reconciliation and Proof of CashDarwyn HonaPas encore d'évaluation

- Surveillance of Healthcare-Associated Infections in Indonesian HospitalsDocument12 pagesSurveillance of Healthcare-Associated Infections in Indonesian HospitalsRidha MardiyaniPas encore d'évaluation

- CV HariDocument4 pagesCV HariselvaaaPas encore d'évaluation

- Unit III Sales and Retail ManagementDocument16 pagesUnit III Sales and Retail ManagementMitali MishraPas encore d'évaluation

- Catalogo AMF Herramientas para AtornillarDocument76 pagesCatalogo AMF Herramientas para Atornillarabelmonte_geotecniaPas encore d'évaluation

- BloodDocument22 pagesBloodGodd LlikePas encore d'évaluation

- HTTP ProtocolDocument16 pagesHTTP ProtocolHao NguyenPas encore d'évaluation

- 2012 Brochure Keltan Final en PDFDocument20 pages2012 Brochure Keltan Final en PDFJorge Zegarra100% (1)

- Dy DX: NPTEL Course Developer For Fluid Mechanics Dr. Niranjan Sahoo Module 04 Lecture 33 IIT-GuwahatiDocument7 pagesDy DX: NPTEL Course Developer For Fluid Mechanics Dr. Niranjan Sahoo Module 04 Lecture 33 IIT-GuwahatilawanPas encore d'évaluation

- Validation TP APPO R12Document3 pagesValidation TP APPO R12Suman GopanolaPas encore d'évaluation

- Serial Number Microsoft Office Professioanal 2010Document6 pagesSerial Number Microsoft Office Professioanal 2010Kono KonoPas encore d'évaluation

- BA5411 ProjectGuidelines - 2020 PDFDocument46 pagesBA5411 ProjectGuidelines - 2020 PDFMonisha ReddyPas encore d'évaluation

- Buyer Persona TemplateDocument18 pagesBuyer Persona TemplateH APas encore d'évaluation

- A033Document24 pagesA033PRANAV GOYALPas encore d'évaluation

- Lesson 2 - Graphing Rational Numbers On A Number LineDocument9 pagesLesson 2 - Graphing Rational Numbers On A Number Linehlmvuong123Pas encore d'évaluation

- 03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019Document52 pages03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019samir bendrePas encore d'évaluation

- NYPE93Document0 pageNYPE93gvsprajuPas encore d'évaluation

- Fadm Project 5 ReportDocument4 pagesFadm Project 5 ReportVimal AgrawalPas encore d'évaluation

- 7779 19506 1 PBDocument24 pages7779 19506 1 PBAyessa FerrerPas encore d'évaluation

- 2010 LeftySpeed Oms en 0Document29 pages2010 LeftySpeed Oms en 0Discord ShadowPas encore d'évaluation

- Satisfaction Attributes and Satisfaction of Customers: The Case of Korean Restaurants in BataanDocument10 pagesSatisfaction Attributes and Satisfaction of Customers: The Case of Korean Restaurants in BataanMaraPas encore d'évaluation

- Software Requirement SpecificationDocument10 pagesSoftware Requirement SpecificationSushil SarrafPas encore d'évaluation

- Executive Order No. 786, S. 1982Document5 pagesExecutive Order No. 786, S. 1982Angela Igoy-Inac MoboPas encore d'évaluation