Académique Documents

Professionnel Documents

Culture Documents

Designing MSE Walls at Pile-Supported Bridges

Transféré par

Ljubomir JocicDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Designing MSE Walls at Pile-Supported Bridges

Transféré par

Ljubomir JocicDroits d'auteur :

Formats disponibles

The Reinforced Earth Company

8614 Westwood Center Drive Suite 1100 Vienna, Virginia 22182-2233 Telephone: (703) 821-1175 Telefax: (703) 821-1815 www.reinforcedearth.com

Design of MSE Walls At Pile-Supported Abutments Technical Bulletin: MSE - 3

August 1, 1992

Atlanta Boston Dallas/Ft. Worth Irvine, CA Lafayette, IN Orlando Seattle Vienna, VA

TABLE OF CONTENTS

Page No.

List of Photographs and Drawings...ii

I.

Background......................................................................1

II.

Typical Pile Conflict Conditions............................2

III.

Common Shortfalls.............................................................................4

IV.

Alternative Approach9

V.

Procedure for Designing MSE Structures for Pile Conflicts..10

Recommended Special Provision for MSE Walls at Pile-Supported Abutments11

LIST OF PHOTOGRAPHS AND DRAWINGS

Page No.

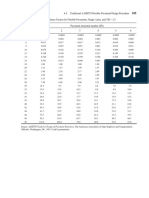

MSE Wall Under Construction at Pile-Supported Abutment1 Completed Walls and Bridge on Pile-Supported End Bent. 1 Typical Location of Piles Relative to an MSE Wall Facing...2 Skewing of Reinforcing Strips with Bolted Connections.. 2 Pile in Conflict with Bar Mat or Mesh Reinforcement.. 3 Pile in Conflict with Strip Reinforcement.. 3 Commonly Used Detail for Bar Mat System 4 Actual Conflict Condition 4 Bar Mat Reinforcement with Longitudinal Members Severed 5 Mesh with Transverse Members Cut, Reinforcements Skewed to Avoid Piles.. 6 Mesh with Transverse Members Cut, Reinforcements Rotated at Connection (pinned-type) and Bent to Avoid Pile 7 Sketch Showing Unacceptable Bending of Soil Reinforcements and Connection. 8 Sketch Showing Severely Skewed Reinforcements and The Unacceptable Approach of Connecting to the Pile 8 Georgia DOT Standard Detail of Extension for Mesh Type Reinforcement 9 Cutting and Skewing of Mesh can be Eliminated by Using the Extension Detail and Positioning the Intact Mesh Behind the Pile. 9

ii

I.

Background Construction of mechanically stabilized earth (MSE) structures such as Reinforced Earth at pile-supported abutments is standard practice in many States. Supporting a bridge on piles positioned just behind the wall facing makes for a cost-efficient, functional, and aesthetically pleasing structure. It also makes for one of the most common conflicts in the construction of MSE walls: piles obstructing standard placement of soil reinforcing elements and their connections to the wall facing.

It is critical that the design of the wall system address the pile/reinforcement conflict in a manner that does not compromise service life or safety of the structure. Such a design can be accomplished; the actual steps necessary will depend on the wall system and the type of soil reinforcing elements and facing connections used. Unfortunately, this conflict has often been left to be resolved in the field during construction without consideration for the affect this may have on the longterm wall performance. This technical bulletin addresses appropriate requirements for the design, detailing and construction of an MSE system reinforced with either strips, wire mesh or bar mats. Properly implemented, these guidelines will help assure that the MSE wall system constructed at a pile supported abutment provides suitable factors of safety for reinforcement bond and stress to ensure the full service life of the structure.

II.

Typical Pile Conflict Conditions The typical construction sequence involves excavating and proof rolling, driving piles and placing pile cans (where applicable) before beginning wall construction. Wall facing panels and soil reinforcements are placed in a repetitive sequence progressing upward simultaneously with the placement of wall backfill in horizontal lifts. A conflict occurs when a pile is in the path of the reinforcement, perpendicular to the wall face. A typical reinforcement configuration is shown below for reinforcing strips and bar mats.

Note that the spacing of piles does not match that of the wall panels and reinforcements. Therefore, conflict can be encountered at several locations along the wall length. The degree of conflict can vary greatly depending on the type of soil reinforcement and connection used. Generally, the frequency of conflict tends to be greater for wide reinforcing elements such as wire mesh and bar mats when compared with discrete reinforcing strips. Likewise, pinned and fixed connections are less adaptable than bolted connections that are able to rotate.

III.

Common Shortfalls To develop design details for pile conflicts, it is important to learn from the solutions used in the past that have compromised internal stability factors of safety and the service life of the structures. Some of the inadequacies of past practice are documented below: 1. Detailing Not Consistent with Construction Perhaps the greatest threat to safety is the practice of using details that are not representative of the actual conflicts encountered during construction. In this scenario, the contractor will typically need to make more severe modifications than those shown on the plans, and they will be based on verbal communication with the project engineer. The threat to safety is that a complete design addressing the as built condition is never performed, and therefore, the performance and professional engineering responsibility for the actual detail will be in question. Given the frequency and critical nature of the pile/reinforcement conflict, this approach is not acceptable.

2. Cutting of Soil Reinforcements to Avoid Piles Two types of cutting have been observed as a means of working around pile conflicts. The first involves cutting longitudinal members of the soil reinforcements, i.e. cutting the longitudinal members of mesh or bar mats that run perpendicular to the wall and carry the load which stabilizes the mass and restrains the panels. These cuts are used to terminate the soil reinforcement short of the pile conflict or to notch the reinforcement to fit around the pile. While this type of cut may simplify construction, it clearly increases stresses in the remaining wires/bars and can reduce the service life and integrity of the wall.

The second type of cut involves severing the transverse members of grid and bar mat reinforcements. This practice divides the grid configuration into separate longitudinal members to be splayed around the pile. This basic reconfiguration of the soil reinforcing elements changes their soil interaction characteristics and requires that pullout testing be performed on the exact elements resulting from the cutting.

In order to safely design for reinforcement pullout, it is especially important that representative data be provided for low overburden pressures (reinforcement levels near the top of the structure) and for fine-grained backfills since these represent more critical situations. Such data typically is not available or not reported in design submittals. Cutting of transverse members is sometimes used in conjunction with skewing and bending as discussed later in this document.

Allowing the cutting of transverse members of mesh or mats in the field can result in dangerous conditions as shown in the photo above. The theoretical design condition and the reality of the as-built condition can differ dramatically. The original intent of just having a few mats with just one bar cut, can turn into multiple cuts, severe bending and skewing being the rule as opposed to the exception.

3. Bending of Soil Reinforcements and Connections Bending in a manner that produces permanent horizontal deformation of the reinforcing element should not be allowed for avoiding pile conflicts. When placed under stress in the structure, the bend will tend to straighten, resulting in wall movement and potentially creating stresses not accounted for in the design. Bending in the horizontal direction should be distinguished from gradual curvature of the reinforcement in the vertical direction, which does not appreciably affect stress levels or pullout resistance. Bending of the connection to facilitate skewing of the reinforcement can have a significant effect on stress transfer and distribution in the connection device and should not be allowed. Connections should be designed to rotate without bending to accommodate skewing of reinforcements.

4. Connecting Reinforcing Elements to Piles Connecting soil reinforcements to piles creates the potential for a serious problem resulting from the differential settlement of the wall and backfill relative to the pile. The shearing force could greatly increase reinforcement stress that could lead to a sudden failure at the connection. Connecting to the piles or wrapping around the piles is not an acceptable approach to resolving the pile/reinforcement conflict.

5. Severely Skewing Reinforcements Without Increasing their Length Skewing the soil reinforcing elements within limits is an acceptable approach if the connections are designed to allow rotation as shown above (bolted connection). However, for severe skews (greater than 15 degrees), it is often necessary to increase the reinforcement length and load carrying capacity to achieve the desired resistance normal to the wall face. In addition, when a significant number of the reinforcing elements do not reach the limit of the reinforced soil volume as designed, the overall stability of the wall system is reduced.

IV.

Alternative Approach A consistent and reliable approach for use with mesh or bar mat reinforcements at pile conflicts is the use of a structural yoke as an extension. The extension may be designed and constructed with structural steel plates to allow the typical reinforcement connection to be made behind the pile instead of at the facing. This approach has been adopted by the Georgia Department of Transportation as a standard for use with mesh type reinforcements based on extensive experience with MSE structures, pile conflicts and mesh reinforcements.

V.

Procedure For Designing MSE Structures for Pile Conflicts The person specifying can implement the following requirements to provide for a reliable means of designing for pile conflicts. 1. Representative Detailing: Require that construction not proceed until representative details (details drawn to scale) and corresponding calculations are provided, signed and sealed by a Registered Professional Engineer, registered in the state where the work is being performed. 2. Cutting: Prohibit the cutting of soil reinforcements. Require that a structural yoke be used for mesh and bar mat systems to extend reinforcements behind the pile and eliminate conflicts. 3. Bending: Prohibit bending of the reinforcement at the facing connection and any bending in the horizontal direction that produces permanent deformation of the reinforcing element. 4. Connection to Piles: Prohibit connection of the soil reinforcements to the piles and wrapping of reinforcements around the piles. 5. Rotation at Connection: Prohibit skewing of reinforcements at the connections unless connections are designed to allow rotation. 6. Skewing of Reinforcements: Limit skewing of reinforcements to 15 degrees from normal to the wall facing except at acute corners, and when calculations are provided that justify a greater skew angle. 7. Shifting of Connections: Allow for shifting of connections on panel faces to avoid conflicts with piles provided that these connections are acceptable in terms of panel stresses and stability of the individual panel.

Important note regarding cutting of transverse wires or bars: If No. 2 above, is not effectively implemented and transverse wires or bars are cut, then detailed project specific testing, measurements and calculations, must be performed and signed by a Professional Engineer. The testing must include pullout testing of the altered reinforcement configurations using project specific backfill. All metal surfaces exposed by cutting, shall be coated in the field to provide corrosion protection. A summary of the above procedures is provided in the form of a special provision on page 11 of this document.

10

RECOMMENDED SPECIAL PROVISION FOR MSE WALLS AT PILE-SUPPORTED ABUTMENTS 1.0 SCOPE

This Special Provision covers the design, detailing, submittal and construction requirements for the use of mechanically stabilized earth (MSE) structures where piles or similar obstacles conflict with the typical placement of soil reinforcing elements. 2.0 DESIGN AND DETAILING

The special design and detailing at the conflict shall meet the minimum wall design requirements established for this project, including requirements for service life, pullout resistance and allowable stress levels in soil reinforcements and connections to facing. Representative data shall be provided to support the design for the actual project conditions. 2.1 CONNECTING SOIL REINFORCEMENTS TO PILES

The connecting of any soil reinforcement to a pile and the bending of the soil reinforcement in such a manner as to wrap around a pile shall not be permitted. 2.2 BENDING OF SOIL REINFORCEMENTS

The bending of any soil reinforcement in the horizontal direction (plane of the reinforcement) producing a permanent deformation in its alignment shall not be allowed. Gradual bending which does not produce permanent deformation is allowable; however, the design shall consider the effect of bending on pullout resistance and reinforcement stress including any potential uneven stress distribution. Gradual bending in the vertical direction is acceptable. 2.3 SKEWING OF SOIL REINFORCEMENTS

The skewing of soil reinforcements by rotating on a horizontal plane at the connection to facing will be allowed with the following limits: 1. The connection shall be structurally designed to rotate without bending and without altering the stress distribution at contact points. 2. Skew angles shall not exceed 15 degrees, unless calculations are provided that justify use of a greater skew angle.

11

2.4

SHIFTING OF FACING CONNECTION LOCATIONS

Extra connection devices may be cast into the facing panels or the connection locations may be shifted to reduce conflicts between the soil reinforcements and the piles. However, any imbalance in the restraint of a panel, caused by asymmetry of the reinforcement connection locations, shall be considered in determining the local equilibrium of individual facing panels. Additional steps may be required to provide balanced restraint of each panel. 2.5 CUTTING OF SOIL REINFORCEMENTS

The cutting of soil reinforcements shall not be allowed. Where piles can not be avoided by skewing or shifting as in 2.3 or 2.4 above, a structural yoke shall be constructed to provide an extension and position the reinforcement connection behind the pile. Reinforcements and plates shall be positioned so that they do not come into contact with the pile. Higher stress levels within the extensions and reinforcements shall conform to the requirements for this project, including those for service life and stress levels in reinforcements and connections. 3.0 SUBMITTALS

The Contractor shall submit the following for review and approval by the Engineer prior to construction: wall design calculations, data and representative construction details and notes conforming to the above requirements, signed and sealed by a Professional Engineer licensed in this State and qualified and experienced in designs of this type. If the conditions of construction are found to be inconsistent with the design and detailing, the Contractor shall resubmit an appropriate design as necessary to demonstrate compliance with the above requirements. 4.0 CONSTRUCTION

Construction at the conflict shall be in accordance with the requirements for the wall construction in general, except as amended by the details and notes pertaining to the conflict as approved by the Engineer.

12

Vous aimerez peut-être aussi

- Bioethanol From CornDocument13 pagesBioethanol From Cornpricett100% (1)

- Maintenance Manual: Models 7200/7300/7310 Reach-Fork TrucksDocument441 pagesMaintenance Manual: Models 7200/7300/7310 Reach-Fork TrucksMigue Angel Rodríguez Castro100% (2)

- 9040 - User ManualDocument236 pages9040 - User ManualWallie Billingsley77% (13)

- Rubble Mound Breakwater: Christian Linde OlsenDocument11 pagesRubble Mound Breakwater: Christian Linde OlsenFoong Tong WengPas encore d'évaluation

- GEO Updated-CheatsheetDocument3 pagesGEO Updated-CheatsheetGiovanni LinPas encore d'évaluation

- CPT based p-y curves for laterally loaded piles in soft clayDocument8 pagesCPT based p-y curves for laterally loaded piles in soft claybusyspiderPas encore d'évaluation

- CINTEC Design Guide European VersionBDocument29 pagesCINTEC Design Guide European VersionBDavid MiguelPas encore d'évaluation

- Payables Open Interface Import in Oracle Apps R12Document11 pagesPayables Open Interface Import in Oracle Apps R12sudharshan79Pas encore d'évaluation

- Coastal Infrastructure Design Course Chapter on Structural DesignDocument57 pagesCoastal Infrastructure Design Course Chapter on Structural Designvasanthk81Pas encore d'évaluation

- Do 050 S2007-Mse SpecsDocument12 pagesDo 050 S2007-Mse SpecsCarol SantosPas encore d'évaluation

- ESALDocument8 pagesESALfaizalramadhan16100% (1)

- Design of Soil Nail Zamboanga CityDocument30 pagesDesign of Soil Nail Zamboanga CityJasonCooPas encore d'évaluation

- Civl2210 2008 NotesDocument26 pagesCivl2210 2008 NotesJackLikesTomatoesPas encore d'évaluation

- Handbook CMA PDFDocument8 pagesHandbook CMA PDFEmilianoPas encore d'évaluation

- Evaluation of Longshore Sediment Transport Formulas Using Large-Scale Model DataDocument14 pagesEvaluation of Longshore Sediment Transport Formulas Using Large-Scale Model DatajmmPas encore d'évaluation

- Soil Embankment Settlement 3d AnalysisDocument15 pagesSoil Embankment Settlement 3d AnalysisSajid IqbalPas encore d'évaluation

- Example of Stress Absorbing Membrane InterlayerDocument7 pagesExample of Stress Absorbing Membrane Interlayershanil3001Pas encore d'évaluation

- CHAPTER 3 Shear StrengthDocument30 pagesCHAPTER 3 Shear StrengthnurhaslizanaPas encore d'évaluation

- A-Pile Description SheetDocument2 pagesA-Pile Description SheetUnwanus Sa'adahPas encore d'évaluation

- Module-2: 3.1.1. Design Criteria of Earthen DamDocument9 pagesModule-2: 3.1.1. Design Criteria of Earthen DamsakshiPas encore d'évaluation

- SPECIFICATIONS MASTERLIST-A3 Format - UPDATEDDocument10 pagesSPECIFICATIONS MASTERLIST-A3 Format - UPDATEDmhaye1405746Pas encore d'évaluation

- Radial Consolidation TheoriesDocument13 pagesRadial Consolidation TheoriesSidi Yéhia SounfountéraPas encore d'évaluation

- Numerical Modeling of Geogrid Reinforced Flexible Pave 2016 Construction andDocument17 pagesNumerical Modeling of Geogrid Reinforced Flexible Pave 2016 Construction andHanamant HunashikattiPas encore d'évaluation

- A Plasticity Model For Swedish Weight Sounding TestsDocument8 pagesA Plasticity Model For Swedish Weight Sounding TestsKieu Le Thuy ChungPas encore d'évaluation

- ACIDocument13 pagesACILuis GuerraPas encore d'évaluation

- Computers and Geotechnics: Sari W. Abusharar, Jun-Jie Zheng, Bao-Guo ChenDocument10 pagesComputers and Geotechnics: Sari W. Abusharar, Jun-Jie Zheng, Bao-Guo ChenIrvin AlbertoPas encore d'évaluation

- Important Note On Slope Stability AnalysisDocument23 pagesImportant Note On Slope Stability AnalysisJerry FtPas encore d'évaluation

- @ - Breakwater Foundation StabilityDocument9 pages@ - Breakwater Foundation Stabilityapi-3709579100% (1)

- Flexible Pavement DesignDocument39 pagesFlexible Pavement DesignSaurabh KumarPas encore d'évaluation

- Triaxial Test 2850Document2 pagesTriaxial Test 2850Mostafa MagdyPas encore d'évaluation

- Pile Capacity Hanumante RevisedDocument4 pagesPile Capacity Hanumante RevisedAmit VarmaPas encore d'évaluation

- Cem Part Vi Chap 7Document92 pagesCem Part Vi Chap 7ainaPas encore d'évaluation

- Riprap Shear Stress DesignDocument5 pagesRiprap Shear Stress DesignphatmatPas encore d'évaluation

- Soil and Rock Classification GuideDocument6 pagesSoil and Rock Classification GuideEdvin Neil Huamanguillas ParavecinoPas encore d'évaluation

- An M.Sc. Thesis On Bangladeshi Embankment Design PDFDocument246 pagesAn M.Sc. Thesis On Bangladeshi Embankment Design PDFMd. Yeasin MostafizPas encore d'évaluation

- CEM Part VI Chap 5 Pt2Document84 pagesCEM Part VI Chap 5 Pt2raly1Pas encore d'évaluation

- Table 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5Document6 pagesTable 4.1 Axle-Load Equivalency Factors For Flexible Pavements, Single Axles, and TSI 2.5fadi eidPas encore d'évaluation

- Calculation of Earth Retaining Structure: To CesDocument31 pagesCalculation of Earth Retaining Structure: To CesMongkol JirawacharadetPas encore d'évaluation

- New guidance for predicting wave forces on exposed jettiesDocument21 pagesNew guidance for predicting wave forces on exposed jettiessergioPas encore d'évaluation

- BEARING CAPACITY GUIDEDocument16 pagesBEARING CAPACITY GUIDEsks_242Pas encore d'évaluation

- Slope Stability PDFDocument13 pagesSlope Stability PDFZac Francis DaymondPas encore d'évaluation

- Seismic Design and Liquefaction Policy for Transportation InfrastructureDocument74 pagesSeismic Design and Liquefaction Policy for Transportation InfrastructureNadim527Pas encore d'évaluation

- Failure Mechanism of Geosynthetic-Encased Stone Columns in Soft Soils Under EmbankmentDocument8 pagesFailure Mechanism of Geosynthetic-Encased Stone Columns in Soft Soils Under EmbankmentJianfeng XuePas encore d'évaluation

- Computation of allowable settlement from plate load testDocument1 pageComputation of allowable settlement from plate load testSheril ChandrabosePas encore d'évaluation

- consolidationشارع النيلDocument2 pagesconsolidationشارع النيلabdallah abdurhman aliPas encore d'évaluation

- Ch4 Settlement of Buildings (1-34) - 2016Document36 pagesCh4 Settlement of Buildings (1-34) - 2016Rafi SulaimanPas encore d'évaluation

- Prefabricated Vertical DrainsDocument26 pagesPrefabricated Vertical DrainsMayank Prakash100% (1)

- CBR Test ManualDocument6 pagesCBR Test ManualmmPas encore d'évaluation

- Suction caisson foundations for offshore wind turbines subjected to wave and earthquake loadingDocument15 pagesSuction caisson foundations for offshore wind turbines subjected to wave and earthquake loadingdennisPas encore d'évaluation

- Part VI Chap 5 PDFDocument378 pagesPart VI Chap 5 PDFFrank RmDettPas encore d'évaluation

- Manual: ShoreDocument164 pagesManual: Shorenonopimentel100% (1)

- Mechanics of Materials 4 Exam CoverageDocument14 pagesMechanics of Materials 4 Exam CoverageJay Vee EstradaPas encore d'évaluation

- AASHTO FLexible Pavement Design Procedure (Tables 1-6 To 1-10)Document4 pagesAASHTO FLexible Pavement Design Procedure (Tables 1-6 To 1-10)Chezka C. BernabePas encore d'évaluation

- Properties of Soils: C.1 Soil TestsDocument4 pagesProperties of Soils: C.1 Soil TestsbarouniaminePas encore d'évaluation

- SettlementDocument30 pagesSettlementimamPas encore d'évaluation

- Soil Shear Strength Selection for Stability AnalysisDocument86 pagesSoil Shear Strength Selection for Stability AnalysisLuciano JuniorPas encore d'évaluation

- Coastal Shoreline Defence StructuresDocument19 pagesCoastal Shoreline Defence StructuresdjajadjajaPas encore d'évaluation

- Breakwaters DeSmet2016 PDFDocument191 pagesBreakwaters DeSmet2016 PDFMahdi FekiPas encore d'évaluation

- Aci 318-08 Development and Splices of Reinforcement - Editing ProtectedDocument6 pagesAci 318-08 Development and Splices of Reinforcement - Editing Protectedbryamdv23Pas encore d'évaluation

- Specifications of The Application of Class Concrete Paving BlocksDocument10 pagesSpecifications of The Application of Class Concrete Paving BlockshonneyValadasPas encore d'évaluation

- Khowpa Engineering College: Purbancal UniversityDocument8 pagesKhowpa Engineering College: Purbancal UniversitySudan ShresthaPas encore d'évaluation

- Tek 03-02aDocument13 pagesTek 03-02aSana UllahPas encore d'évaluation

- STRUCTURE Magazine - Crack Control Measures For Tilt-Up Concrete PanelsDocument8 pagesSTRUCTURE Magazine - Crack Control Measures For Tilt-Up Concrete PanelsMichael ChewPas encore d'évaluation

- Tek 03-02aDocument13 pagesTek 03-02aRaquelPas encore d'évaluation

- Soils ClassificationDocument1 pageSoils ClassificationLjubomir JocicPas encore d'évaluation

- Reco Newsletter Spring 2012Document8 pagesReco Newsletter Spring 2012Ljubomir JocicPas encore d'évaluation

- TechSpan Arch - North Kiama Case StudyDocument2 pagesTechSpan Arch - North Kiama Case StudyLjubomir JocicPas encore d'évaluation

- Loading To Box-CulvertsDocument20 pagesLoading To Box-CulvertsLjubomir JocicPas encore d'évaluation

- Mining Sector - KSA PDFDocument8 pagesMining Sector - KSA PDFLjubomir JocicPas encore d'évaluation

- Sunscreen FabricDocument36 pagesSunscreen Fabricfakhrurr44Pas encore d'évaluation

- Manual de Partes y Operación de Trituradora Vsi Canica Modelo 65Document105 pagesManual de Partes y Operación de Trituradora Vsi Canica Modelo 65Jose AlfaroPas encore d'évaluation

- Meshing Methods (ANSYS Meshing) - Everyone Is Number OneDocument14 pagesMeshing Methods (ANSYS Meshing) - Everyone Is Number Oneicemage1991Pas encore d'évaluation

- Motivation and Leadership in Engineering ManagementDocument24 pagesMotivation and Leadership in Engineering ManagementChen Marie DyPas encore d'évaluation

- TUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILDocument4 pagesTUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILFaturrachman Nanu Rengga WisnuPas encore d'évaluation

- Netsys NVF-200EKIT User Guide 1.0.6Document19 pagesNetsys NVF-200EKIT User Guide 1.0.6pkramellaPas encore d'évaluation

- COMEC Modular Storage SolutionsDocument8 pagesCOMEC Modular Storage SolutionsPedro ChapadoPas encore d'évaluation

- NHA 2430 Design Analysis Reporting FEADocument7 pagesNHA 2430 Design Analysis Reporting FEAASIM RIAZPas encore d'évaluation

- Ci-2001 Ab OmDocument30 pagesCi-2001 Ab OmEnrique FlowersPas encore d'évaluation

- Insulation Coordination 52 kV SystemDocument5 pagesInsulation Coordination 52 kV SystemSahil BhagatPas encore d'évaluation

- Quality Criterion of Road Lighting Measurement and ExploringDocument96 pagesQuality Criterion of Road Lighting Measurement and ExploringNitin UpadhyayPas encore d'évaluation

- Tetra Cardboard Packer 70 - CopyDocument808 pagesTetra Cardboard Packer 70 - CopyOmar AlneasPas encore d'évaluation

- Çimsa Eco White TDS (EN)Document1 pageÇimsa Eco White TDS (EN)Babu NysemerePas encore d'évaluation

- J320 Maintenance Spare Parts ListDocument1 pageJ320 Maintenance Spare Parts ListKeith ChengPas encore d'évaluation

- Klasifikasi Material: Myrna Ariati Wahyuaji Narottama PutraDocument49 pagesKlasifikasi Material: Myrna Ariati Wahyuaji Narottama Putrachink07Pas encore d'évaluation

- L Uk SulphDocument24 pagesL Uk SulphypyeePas encore d'évaluation

- En 808D Commissioning Guide 2013-09Document98 pagesEn 808D Commissioning Guide 2013-09Sam eagle goodPas encore d'évaluation

- Manual E-Claw EngDocument18 pagesManual E-Claw Engshyampillai2007Pas encore d'évaluation

- Calcium Sulfate Crystallization in Phosphoric Acid PDFDocument133 pagesCalcium Sulfate Crystallization in Phosphoric Acid PDFabderrahimnPas encore d'évaluation

- Tacloban Master Training Schedule (January-June 2012) For Web New FormatDocument5 pagesTacloban Master Training Schedule (January-June 2012) For Web New FormatFariq AdlawanPas encore d'évaluation

- Robohawks Team HandbookDocument11 pagesRobohawks Team Handbookapi-376756259Pas encore d'évaluation

- Conversion Factors GuideDocument2 pagesConversion Factors GuideAndri MPPas encore d'évaluation

- Ansys Fluent 14.0: Workbench GuideDocument86 pagesAnsys Fluent 14.0: Workbench GuideAoife FitzgeraldPas encore d'évaluation

- Sublimation of CaffeineDocument3 pagesSublimation of CaffeineNabil ShaikhPas encore d'évaluation

- Electrical Power Transmission & DistributionDocument18 pagesElectrical Power Transmission & DistributionMd Saif KhanPas encore d'évaluation

- Landscape - Cut & Fill StopingDocument24 pagesLandscape - Cut & Fill StopingRAJIV VINOD CONJEEVARAM 1961714Pas encore d'évaluation