Académique Documents

Professionnel Documents

Culture Documents

Performance Prediction of A Faulty Marine Diesel Engine Under Dif-Ferent Governor Settings

Transféré par

waleedyehiaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Performance Prediction of A Faulty Marine Diesel Engine Under Dif-Ferent Governor Settings

Transféré par

waleedyehiaDroits d'auteur :

Formats disponibles

PERFORMANCE PREDICTION OF A FAULTY MARINE DIESEL ENGINE UNDER DIF-

FERENT GOVERNOR SETTINGS

Giovanni Benvenuto, Dipartimento di Ingegneria Navale e Tecnologie Marine, Universit di Genova, Italy

Ugo Campora, Dipartimento di Macchine, Sistemi Energetici e Trasporti, Universit di Genova, Italy

ABSTRACT

Various methods are proposed in literature for the engine faults detection, based on the combination of simulation models

with measured engine data. In order to be effective, these methods must be based, in authors opinion, on detailed, reliable

and validated simulation models, able to predict the faulty engine performance, by reproducing its actual work conditions.

This is particularly important in case the simulator is used for the diagnosis of faults or for the engine maintenance staff

training.

The aims of the paper are: firstly, to verify the suitability of the authors diesel engine model to be used for the faults simu-

lation; secondly, to analyse and compare the influence of the engine governor logic on the performance alterations of a

faulty four stroke turbocharged marine diesel engine.

The adopted diesel engine simulation model is based on a two-zone cylinder combustion scheme, which allows a detailed

calculation of the thermodynamic processes inside the cylinders. The thermodynamic study of the in-cylinder phenomena

is combined with a simulation of the behaviour of the turbocharger, of the intake and exhaust systems (intercooler, mani-

folds, etc.) and of the fuel pump.

The engine faults analysed in the paper, selected on the basis of indications given by the engine maintenance staff and

drawn from bibliography observations, are related to the fuel injection system and to the exhaust manifold behaviour.

The reported analysis and the presented results, relative to the engine performance variation as a consequence of the simu-

lated faults (at different intensity levels), show the validity and the flexibility of the used diesel engine simulator in predict-

ing fault situations. In particular the simulated engine working parameters present a different variation depending on the

adopted engine governor logic.

1 INTRODUCTION

The turbocharged diesel engines, thanks to their higher

efficiency, power density, lifetime and lower cost in com-

parison with other thermal engines, are the most widely

used prime movers in the ship propulsion plants. There-

fore it is very important, for the safety and economy of the

navigation, to ensure a perfect efficiency of these engines,

including their auxiliary systems, by means of suitable

techniques directed to the prevention and detection of en-

gine faults. Various methods are proposed in literature for

the diesel engines faults detection and diagnosis. Among

the many available papers and the few considered in this

study [1-14], two basic approaches are substantially used

for marine diesel engine fault diagnosis, the mainly statis-

tical methods [1-4] and those based on diesel engine simu-

lation models [5-14], these last more recent and probably

more useful today.

This second approach, to which also our paper is re-

ferred, requires the availability of a detailed, reliable and

validated diesel engine simulation model, including also

the engine auxiliary components (turbocharger, fuel

pump, etc.). In fact the ability of the model to reproduce

the effective engine working conditions is very important

as far as faults prediction and maintenance staff training

are concerned.

From the literature analysis it is observed that in a few

cases (for instance [11]) the diesel engine faults simula-

tion is based on the hypothesis of engine running at con-

stant fuel pump setting and engine speed (condition that

can be verified in an engine test bench). In practical situa-

tions, typical of ship propulsion plants, the engine work-

ing conditions correspond to the hypothesis of engine

running at constant torque and speed. This last hypothesis

is assumed in [5,13,14] for the prediction of marine diesel

engine faults by means of simulation models.

The aims of the paper are: firstly, to verify the suitabil-

ity of the authors diesel engine model to be used for the

faults simulation; secondly, to analyse and compare the

influence of the engine governor logic on the performance

alteration of a faulty four stroke turbocharged marine die-

sel engine. As regards this last aspect, two governor logics

are considered in particular: constant engine torque and

speed (typical of a ship sailing at a constant speed in calm

sea) and constant fuel pump setting and engine speed (that

can be assumed in an engine test bench)

The adopted diesel engine simulation model, already

presented and validated in previous papers [15-21], is

based on a two-zone cylinder combustion scheme, which

allows a detailed calculation of the thermodynamic proc-

esses inside the cylinders. The thermodynamic study of

the in-cylinder phenomena is combined with a simulation

of the behaviour of the turbocharger and of the intake and

exhaust systems (intercooler, manifolds, etc.). A filling

and emptying method is adopted in each engine compo-

nent. The calculation procedure has been validated by

Session C 35

comparisons with experimental data obtained from the

engine Manufacturer. In this study the model is applied to

the simulation of the four stroke Wrtsil 8L46A marine

diesel engine.

The engine faults analysed in the paper (at different in-

tensity levels) are related to the fuel injection system and

to the exhaust manifold behaviour. The considered faults

have been selected on the basis of indications given by the

engine maintenance staff and drawn from bibliography

observations.

In order to verify the suitability of the developed simu-

lator to be used for the detection of engine faults, the re-

sults of the simulations, regarding the shifting of impor-

tant engine parameters from their corrected values, have

been compared with indications given by the engine main-

tenance staff.

2 DIESEL ENGINE MODEL

The mathematical model developed by the authors for

the simulation of medium speed, four stroke turbocharged

marine diesel engines has been presented in a previous

paper [15]. Here only a brief description of the used

methodology is given. For a more detailed explanation the

interested reader is referred to [15,20].

The diesel engine model is developed, in modular

form, in SIMULINK

[22] (MATLAB

Toolbox) lan-

guage. Each block consists of a set of algebraic and dif-

ferential equations describing the subsystem behaviour.

The overall diesel engine model includes the following

main modules:

1) cylinder

2) intercooler and air receiver

3) exhaust gas receiver

4) turbocharger

5) fuel pump.

A filling and emptying approach is applied to each

block. A real gas model is used for the fluid properties

calculation. Specific internal energy and enthalpy are as-

sumed to be functions of both temperature and fluid com-

position.

2.1 CYLINDER MODULE

An actual cycle two zone combustion calculation

scheme is adopted for the in cylinder phenomena simula-

tion. Assuming the crank angle () as the independent

variable, the piston displacement from the TDC is calcu-

lated from geometrical considerations as [23]:

(

(

|

|

\

|

cos - sen - -

1

+ 1 =

1/2

2

2

2

r

l

r

r x

(1)

The inlet air mass (M

a

) in the cylinder is given by:

M

a

=

i

V

v

(2)

where

i

is the fluid density in the air receiver.

The air compression process is determined by the en-

ergy equation:

( ) P H m H m H m

V dt

U d

f f o o i i

- + -

1

=

) (

+

(3)

where the inlet and outlet masses (m

i

and m

o

) are in this

application put equal to zero.

In order to evaluate the heat flow term in the previous

equation, the convective gas-cylinder wall heat transfer, in

the calculation step (d), is determined as follows:

dQ

w

= h A

w

(T

g

- T

w

) dt (4)

where the convective heat transfer coefficient (h) is ob-

tained as indicated in [24] and the heat transfer area (A

w

)

is expressed as function of the piston position (x) defined

in equation (1).

The ignition delay angle (

id

) is given by [25]:

( )

|

|

\

|

|

\

|

cy

cy id id

T CN

p n K

4.644

exp

40

=

69 . 0

0.388 - (5)

When the combustion process starts, the cylinder vol-

ume is split into two parts, a burning zone and a non burn-

ing one. At each calculation step (d), the heat released

(dQ

f

) by the combustion process is given by:

dQ

f

= M

f

dx

b

H

f

(6)

where M

f

is the total mass of fuel injected in the cycle and

dx

b

is the fuel fraction burned during the calculation step

(d), this last determined by means of the Wiebe equation

[24] :

(

(

|

|

\

|

+1

exp 1 =

m

K

ign

a b

K dx

(7)

where the combustion angle length () is evaluated by

means of the mass flow rate across the injector holes [26]:

( )

4

2 =

2

0.5

d

p p

K m

f

cy in

f in f

(

(

(8)

In the burning zone, the inlet air mass term (dM

i

), in

the energy equation (3), is evaluated as function of the

fuel mass burned (dM

b

) during the current calculation step

(d):

dM

i

= dM

b

s

K

exc

(9)

where the air excess term (K

exc

) is imposed on the basis of

data reported in literature [27].

Session C 36

With reference to the burning zone, the heat transfer

between the fluid and the cylinder wall is computed by

means of the Annand equation [23]:

dQ

w

= A

b

[K

con

k/B Re

Kre

(T

g

- T

w

) + K

ra

(T

g

4

- T

w

4

)] dt (10)

which includes the effect of both convection and radia-

tion. In the non burning zone only the convective heat

transfer between fluid and cylinder wall is considered.

The heat transfer between wall and coolant fluid is com-

puted, therefore the cylinder wall temperature is deter-

mined.

The work done onto the piston in the energy equation

(3), for each calculation step (d), is evaluated as:

dW = p

cy

dV (11)

where p

cy

is the mean cylinder pressure (pressure balance

is assumed between burning and non burning zone) during

the step (d), and dV is the cylinder volume change in the

same step.

From the application of the energy equation (3) to the

burning and non burning zones, the fluid temperature in

each zone is determined. Hence, by means of the perfect

gas state equation, applied to burning and non burning

zones, and taking into account the constraint:

V

T

= V

b

+ V

ub

(12)

the cylinder pressure (p

cy

in equation 11) is determined.

The new pressure value is compared with the pressure

value used before in equation (11); then a trial and error

procedure is used to seek the final p

cy

value.

The described calculation scheme is repeated for each

crank angle ().

2.2 INTERCOOLER AND AIR RECEIVER MODULE

These two components are grouped into a single block.

The air cooling effect is simply computed by the expres-

sion:

T

o

= T

i

- E (T

i

- T

coo

) (13)

where the heat exchanger efficiency (E) is kept constant

[15].

The pressure drop of the whole set is evaluated as fol-

lows:

p

ia

= Kp

ia

m

2

(14)

The mass and energy accumulation in the control vol-

ume is considered, respectively, with the continuity equa-

tion:

) - m (m

V dt

d

o i

1

=

(15)

and with the energy equation (3).

2.3 EXHAUST GAS RECEIVER MODULE

In this module the effect of blow-down through the

exhaust valve is considered, by calculating the average

inlet temperature in the receiver with the equation [29]:

T

i ex

= T

i

[1 - ((k

g

-1)/k

g

) (1 - p

o

/p

i

)] (16)

This block is treated in a very similar way to the air

receiver module, i.e. by applying the continuity (15) and

energy (3) equations. The pressure drop in the exhaust gas

receiver is determined with an equation analogous to (14).

2.4 COMPRESSOR MODULE

A steady state compressor map given by the Manufac-

turer is employed in 2D matrix form.

Compressor pressure ratio ( = p

o

/p

i

) and isentropic

efficiency (

C

) are evaluated as functions of the corrected

volume flow rate:

a

ref

C Cc

T

T

= V' V'

(17)

and of the corrected rotational speed:

a

ref

TC Cc

T

T

= n n

(18)

2.5 TURBINE MODULE

The turbine block is very similar to that used for the

compressor.

A turbine steady state map is also in this case given in

2D matrix form, flow rate and efficiency being functions

of the expansion ratio (

T

= p

i

/p

o

) and of the kinematic ra-

tio (u

t

/c

o

). By the dynamic equation:

Q

J

=

dt

d

1

(19)

the turbocharger shaft speed is determined.

2.6 FUEL PUMP MODULE

The approach adopted for the simulation of the fuel

pump is the same reported in [19]. The fuel pump block

gives, as output variables, the fuel mass injected in the

cylinder at each cycle (M

f

, eq. 6) and the fuel injection

pressure (p

in

, eq. 8). Both variables, assumed to be func-

tions of the engine rotational speed (n

E

) and of the fuel

rack position (frp), are evaluated by means of two 2D ma-

trices.

2.7 ENGINE TORQUE

The friction loss is calculated as described in [15], hence

the torque delivered by the engine shaft is determined in

terms of brake mean effective pressure (b.m.e.p.) by

means of the expression (in case of four stroke engines):

4

1

) ( =

E

V b.m.e.p. Q

(20)

Session C 37

3 MODEL APPLICATION AND VALIDATION

The diesel engine model has been applied to the simu-

lation of the Wrtsil 8L46A, an eight cylinders medium

speed four stroke diesel engine, specifically developed for

ship propulsion plants applications, whose main character-

istics at Maximum Continuos Rating (MCR) are: 7240

kW of brake power at 500 rpm.

The model validation has been obtained by comparing

simulation results with sea trials data supplied by the ship

owner and by the engine manufacturer, referred to steady

state working conditions.

As shown by the data reported in table 1, the mis-

matches between simulation and reference data are ac-

ceptable for all of the monitored parameters, particularly

at high engine load and speed.

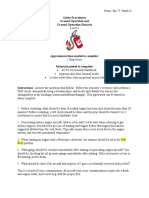

As further engine model validation, Figure 1 shows the

comparison between calculated results and reference val-

ues relative to cylinder pressure and combustion heat, ver-

sus crank angle, at 90 % of the engine MCR. As it can be

seen from the figure, the confidence level is very good.

0

0.2

0.4

0.6

0.8

1

180 270 360 450 540

crank angle []

p

c

y

0

0.2

0.4

0.6

0.8

1

Q

p ref

p calc

Q ref

Q calc

Q

p

TDC

Fig. 1 - Cylinder pressure and heat release prediction

validation.

The results of the validation, carried out for different

working conditions, confirm the suitability of the model to

be used for the performance decrease prediction of the en-

gine when running under faulty conditions.

4 SIMULATION OF DIFFERENT ENGINE GOV-

ERNOR SETTINGS

As said before, a purpose of this study was to verify the

influence, on the faulty engine behaviour, of two different

governor logics: constant engine torque and speed and

constant fuel pump setting and engine speed.

In order to simulate these different working conditions,

two different models have been developed.

4.1 CONSTANT ENGINE TORQUE AND SPEED

GOVERNOR LOGIC

This governor logic is typical of the constant speed

ship sailing in calm sea. The SIMULINK simulator

scheme corresponding to this situation is shown in figure

2.

Fig. 2 Constant engine torque and speed governor logic.

The figure shows the layout of the connections be-

tween the main blocks of the simulator. The DIESEL EN-

GINE module, already described, calculates the engine

torque(Q

E

). The engine speed (n

E

) is determined by solv-

ing equation (19) in the SHAFT DYNAMIC module, where

the input variable brake torque (Q

br

in the figure) comes

from the BRAKE block, whose output (ship propeller

torque) is determined by the simple equation:

Q

br

= K

p

n

p

2

(21)

where the propeller rotational speed (n

p

) is deduced from

the engine speed by means of a reduction constant.

The GOVERNOR module compares the actual engine

speed (n

E

) with the requested speed (n

E_req

), received as

input from the GOVERNOR SETTING block, and, in order

to minimize the difference, determines, as output variable,

the fuel pump rack position (rack), entering as input vari-

able in the FUEL PUMP module.

In this engine governor scheme, therefore, the required

engine speed is obtained acting on the delivered engine

torque. When the diesel engine works in faulty conditions,

with consequent delivered torque variation, the corrected

value of this last variable is restored (in order to maintain

the required engine speed) by the engine governor. It is

important to observe that this governor logic maintains the

engine power to a constant value.

The GOVERNOR module reproduces the main func-

tions of the engine governor typically installed in ship

propulsion plants, generally working according to a three

terms (PID) control action [20].

4.2 CONSTANT FUEL PUMP SETTING AND EN-

GINE SPEED GOVERNOR LOGIC

This diesel engine governor logic (that can be assumed

in an engine test bench), is reproduced in the SIMULINK

simulator scheme shown in figure 3.

Fig. 3 Constant fuel pump setting and engine speed gov-

ernor logic.

Session C 38

The component modules shown in figure 3 are the

same as in figure 2, with the only exception of the GOV-

ERNOR and BRAKE modules, whose characteristics will

be described below.

According to this scheme the diesel engine is not directly

governed, because the fuel pump rack position (rack

variable in figure 3) is put to a constant value. So, an en-

gine torque (Q

E

) variation caused by engine faults deter-

mines a torque unbalance in the engine shaft, involving an

engine speed (n

E

) variation.

In the governor scheme of figure 3 the engine speed is re-

stored to the correct value (n

E_req

) by varying the brake

torque (Q

br

in figure). This correction is determined by the

GOVERNOR module action, that changes the brake torque

setting value (Q

tic

) entering as input variable in the

BRAKE block.

The GOVERNOR module is very similar to that previ-

ously described, with the difference that in this case the

governed variable is the brake torque (Q

tic

) instead of the

fuel pump rack position (rack). It is to be observed that in

this case the governor logic does not maintain the engine

power to a constant value.

The brake torque (Q

br

) is determined in the BRAKE block

as linear function of the inlet variable (Q

tic

), by means of

the simple equation:

Q

br

= K

B

Q

tic

(22)

5 SIMULATED ENGINE FAULTS AND RESULTS

The simulated diesel engine faults have been selected,

among the many realistically conceivable, in accordance

with the considered diesel engine maintenance staff indi-

cations and by collecting information from the available

bibliography [11,23,26,29]. The considered breakdowns

refer to the fuel injection system and to the exhaust mani-

fold. The engine faults (at different intensity levels) are

generated by adding a perturbation or multiplying for a

constant value the engine simulator variable related to the

considered fault.

By imposing constant values of the setting parameters

(n

E_req

in the constant engine torque and speed governor

logic simulator of fig. 2, n

E_req

and rack in the constant

fuel pump setting and engine speed governor logic simu-

lator of fig. 3), transient situations are simulated, in order

to obtain, at the end of the transient behaviour, a steady

state work condition. This last corresponds to a speed of

98.5% and to a power of 95% of the MCR conditions for

the engine working without faults.

The results of the engine faults simulation are pre-

sented in the following figures, where the percent varia-

tion of the considered variable is displayed and compared

with its value obtained when the engine is running without

faults. The engine performance variations are shown for

different intensity levels of the breakdowns.

5.1 FUEL INJECTION START CRANK ANGLE ER-

ROR

As known, the fuel injection start crank angle has a

strong effect on the diesel engine performance. In the en-

gine simulator the correct value of this parameter is de-

termined, by means of a SIMULINK 2D table, as function

of engine speed and load. For the fault simulation an error

in the fuel injection start crank angle has been assumed,

ranging in a -6 to +6 degrees shifting interval.

Figure 4 shows the results of the considered fault simu-

lation in case of constant engine torque and speed gover-

nor logic, while figure 5 shows the analogous results in

case of constant fuel pump setting and engine speed gov-

ernor logic.

By comparing the cylinder pressure versus crank angle

variations (figures 4a and 5a) it can be deduced that the

difference in the assumed engine governor logic produces

an appreciable effect on the results only in case of start in-

jection error of +6 degrees. The analysis of the analogous

data obtained for the cylinder temperatures (figures 4b

and 5b), does not show any appreciable difference be-

tween the two cases.

On the contrary, the results obtained for some engine

parameters (figures 4c and 5c), show interesting differ-

ences according to the adopted engine governor logic. As

example the engine Brake Specific Fuel Consumption

(BSFC), when the error in the start injection crank angle is

negative, increases more in the case of constant engine

torque and speed governor logic, than in the other case.

Instead, when the error in the start injection crank angle is

positive, the behaviour is about the same in the two cases.

Similar considerations can be expressed also for the

variables displayed in figures 4c and 5c, that is for cylin-

der air mass flow variation and turbocharger (TC) speed.

The effects of the considered fault and of the engine gov-

ernor logic adopted are confirmed in the analysis of the

working point shift shown in the turbocharger compressor

map (figures 4d and 5d).

The analysis of pressure and temperature variations in

different engine components, as a consequence of the con-

sidered fault and governor logic, is reported in figures 4c

and 5c, showing a similar behaviour even if with some

differences in the calculated values. Only in the case of

exhaust gas receiver temperature a substantial difference

is observed between the two different engine governor lo-

gics, when the start injection error assumes a negative

value (shifting of different sign in the two cases of figures

4c and 5c).

The results shown in figure 4 are in agreement with the

qualitative indications given by the engine maintenance

staff.

5.2 EXHAUST MANIFOLD FAULT

This damage, considered of particular concern by the

engine maintenance staff, consists in a pressure loss in-

crease in the pipes connecting the exhaust manifold with

the turbine of the turbocharger, loss caused by dirt or

breakdowns in the pipes. As a consequence, the inlet tur-

bine pressure has a reduction, proportional to the damage

intensity.

In the developed model this fault is simulated by an in-

crease of the exhaust manifold-turbine pipe pressure loss

coefficient (Kp

ia

) in equation (14). This coefficient as-

sumes increasing values until the turbine inlet pressure is

the 70% of its value without fault. The analysis of the

Session C 39

Fig. 4a Cylinder pressure vs. crank angle.

Fig. 4b - Cylinder temperature vs. crank angle.

Fig. 4c Engine parameters.

Fig. 4d Compressor map and working points.

Fig. 4 - Fuel injection start crank angle error

Constant engine torque and engine speed

governor logic simulation, results.

Fig. 5a Cylinder pressure vs. crank angle.

Fig. 5b - Cylinder temperature vs. crank angle.

Fig. 5c Engine parameters.

Fig. 5d Compressor map and working points.

Fig. 5 - Fuel injection start crank angle error

Constant fuel pump setting and speed

governor logic simulation, results.

Session C 40

Fig. 6a Cylinder pressure vs. crank angle.

Fig. 6b - Cylinder temperature vs. crank angle.

Fig. 6c Engine parameters.

Fig. 6d Compressor map and working points.

Fig. 6 Exhaust pipe fault

Constant engine torque and engine speed

governor logic simulation, results.

Fig. 7a Cylinder pressure vs. crank angle.

Fig. 7b - Cylinder temperature vs. crank angle.

Fig. 7c Engine parameters.

Fig. 7d Compressor map and working points.

Fig. 7 - Exhaust pipe fault

Constant fuel pump setting and speed

governor logic simulation, results.

Session C 41

simulation results of this damage (reported in figures 6

and 7) is more simple than the previous one.

The simulation results presented in figure 7, relative to

the engine working conditions determined by a constant

fuel pump setting and speed governor logic, show a pro-

gressive increase of both pressure and temperature in the

exhaust gas receiver (see figure 7c), when the fault inten-

sity increases.

The other engine parameters (with the exception of the

BSFC), do not present significant variations (see figure 7).

This fact is confirmed by the results displayed in figures

7a, 7b and 7d, where it can be observed that the consid-

ered fault does not change substantially the working con-

ditions of both cylinder and turbocharger.

The engine power instead undergoes a reduction, con-

sequence of the cylinder pumping loss increase due to the

exhaust gas receiver pressure variation. In figure 7c this

fact is put into evidence by the BSFC increase, because,

with the here adopted governor logic, the engine working

is characterized by constant fuel mass flow conditions.

When the same fault is simulated with the engine run-

ning conditions determined by a constant torque and

speed governor logic, the engine variables undergo more

significant variations, as put into evidence in figure 6.

With this governor scheme in fact the engine is running at

constant power, so in order to compensate the engine

power loss, consequent to the considered fault, the gover-

nor increases the fuel mass flow, determining in this way

a variation of the engine working conditions. This fact is

testified by the results shown in figures 6a and 6b, relative

to cylinder pressure and temperature variations induced by

the fault, and is confirmed by figure 6d, showing the

compressor working point variations consequent to the

considered fault.

Analogous considerations can be expressed by analys-

ing the results presented in figure 6c, relative to the varia-

tion of other engine parameters.

Also for this fault, as for the previous one, the simula-

tion results obtained assuming a constant engine torque

and speed governor logic are in good agreement with the

qualitative indications given by the diesel engine mainte-

nance staff.

6 CONCLUSIONS

In the paper a complex and reliable simulation model

describing a four stroke turbocharged marine diesel en-

gine, developed by the authors and already presented in

previous publications, is applied to the simulation of two

typical engine faults: fuel injection start crank angle error

and exhaust manifold damage.

The main goals of the study, that is to verify the suit-

ability of the authors diesel engine model to be used for

the faults simulation and to analyse and compare the in-

fluence of the engine governor logic on the performance

alterations of a faulty marine diesel engine, appear to be

reached.

The presented simulation results, concerning the con-

sidered faults, are in good agreement with the (qualitative)

indications given by the diesel engine maintenance staff,

in particular when the diesel engine running conditions

are determined by a constant engine torque and speed

governor logic (typically adopted in case of ship naviga-

tion at constant speed).

The analysis of the faulty engine simulation results

shows clearly the great influence of the engine governor

logic on the engine performance alterations. This confirms

the authors opinion that, for a reliable prediction of the

diesel engine faults by means of computer simulation, it is

very important that the simulator is able to reproduce the

effective engine working conditions.

The great number of output data (only few of them re-

ported in the paper) made available by the computer code,

applied to the evaluation of engine performance altera-

tions in case of breakdowns, makes the developed diesel

engine model a useful tool for the diagnosis of faults or

for the engine maintenance staff training.

AKNOWLEDGMENTS

The authors wish to gratefully aknowledge Eng. Giulio

Capezzuoli and Mr. Alessandro Morgia of the Wrtsil

Navim Diesel srl (Italy) for the support and the informa-

tion received.

NOMENCLATURE

A cylinder area

c

o

isentropic expansion velocity

CN cetane number

d injector hole diameter

e error

h thermal conductivity

H specific enthalpy

H

f

fuel lower heating value

k

g

ratio of specific heats

K constant

J inertia of rotor

l connecting rod length

m mass flow rate

M mass

n rotational speed

p pressure

P power

Q torque

Q heat

r crank radius

Re Reynolds number

t time

T temperature

u

t

turbine rotor tip speed

U specific internal energy

V volume, displaced volume

V volumetric flow rate

W work

Session C 42

x piston displacement from TDC

x

b

fuel mass burned fraction

air/fuel ratio

difference

efficiency

heat flow

angular velocity

crank angle

density

Subscripts

a ambient, advance

b burned, burning zone

c corrected

con convective

coo coolant

cy cylinder

C compressor

E engine

ex exhaust gas receiver

exc excess

f fuel

fo formation

i inlet

id ignition delay

ign ignition

in injector

o outlet

p propeller

Q torque

ra radiation

ref reference

T turbine

ub unburning zone

v volumetric

w wall

REFERENCES

[1] T. Terano: Trouble Diagnosis System of Marine

Engine-its System Analysis Ship Operation

Automation, 1976.

[2] P. S. Fredriksen: Advanced Condition Monitoring

System Based on Microprocessor Components

Ship Operation Automation, 1976.

[3] J. Holtrop, G. J. Menner: A Statistical Power Pre-

diction Method International Shipbuilding Pro-

gress 25 (290), 1978.

[4] B. Inz, A. N. Perakis: Statistical Analysis of Fail-

ure Time Distributions for Great Lakes Marine Die-

sels Using Censored Data Journal of Ship Re-

search, March 1991, pp 73-82.

[5] N. P. Kyartos: A Microcomputer Based Diesel En-

gine Simulator for Advanced Ship Propulsion Moni-

toring and Control Systems Naval Engineers Jour-

nal, January 1989, pp 66-72.

[6] A. N. Perakis, B. Inz: Reliability Analysis of

Great Marine Diesels: State of the Art and Current

Modeling Marine Technology, July 1990, pp 237-

249.

[7] D. A. Kouremenos, C. D. Rakopoulos, D. T. Hounta-

las: Developed and Validation of a Diagnosis

Method for Diesel Engines Proceedings of the

ASME Advance Energy Systems Division, AES-

Vol. 36, 1996, pp 527-539.

[8] D. A. Kouremenos, D. T. Hountalas, P. N. Kotsio-

poulos: Developed of a Thermodynamic Method for

Diagnosis and Tuning of Diesel Engines and its Ap-

plication on marine Engines Proc. Instn Mech

Engrs Vol. 209, Part. A: Journal of Power and En-

ergy, 1995, pp 125-139.

[9] D. A. Kouremenos, D. T. Hountalas: Diagnosis and

Condition Monitoring of Medium-Speed Marine

Diesel Engines Tribotest Journal, September

1997, pp 63-91.

[10] D. T. Hountalas, D. A. Kouremenos: Development

and Application of a Fully Automatic Troubleshoot-

ing Mehod for Large Marine Diesel Engines Ap-

plied Thermal Engineering 19, 1999, pp 299-324.

[11] D. T. Hountalas: Prediction of Marine Diesel En-

gine Performance Under Fault Conditions Applied

Thermal Engineering 20, 2000, pp 1753-1783.

[12] N. B. Jones, Yu-Hua Li: A Review of Condition

Monitoring and Fault Diagnosis for Diesel Engines

Tribotest Journal, March, 2000, pp 267-291.

[13] K. Logan, B. Inozu, P. Roy, J. F. Hetet, P. Chesse,

X. Tauzia: Real-Time Marine Diesel Engine Simu-

lation for Fault Diagnosis Marine Technology,

January 2002, pp 21-28.

[14] P. Chesse, D. Chalet, X. Tauzia, J. F. Hetet, B.

Inozu: Real-Time Performance Simulation of Ma-

rine Diesel Engines for the Training of Navy Crews

Marine Technology, July 2004, pp 95-101.

[15] G. Benvenuto, U. Campora, G. Carrera, P. Casoli: A

Two-Zone Diesel Engine Model for the Simulation

of Marine Propulsion Plant Transients MARIND

98, Second International Conference on Marine In-

dustry, Varna, Bulgaria, September 28 October 2,

1998.

[16] G. Benvenuto, U. Campora, M. Figari. Reduction of

NO

x

Emissions from Marine Diesel Engine by

Means of Exhaust Gas Recirculation Technique: a

Numerical Approach IMAM 2000 Conference,

Ischia, Italy, April 2-6, 2000.

[17] G. Benvenuto, U. Campora: Modelling of Sequen-

tially Turbocharged Marine Diesel Engines

Session C 43

IMAM 2002 Conference, Rethymnon, Crete, Hellas,

May 13-17, 2002.

[18] G. Benvenuto, U. Campora: Dynamic Simulation of

a High Performance Sequential Turbocharged Ma-

rine Diesel Engine International Journal of Engine

Research (I Mech E), vol. 3 No 3, 2002, pp 115-125.

[19] G. Benvenuto, U. Campora: Dynamic Behaviour

Analysis of a Sequentially Turbocharged Marine

Diesel Engine Third International Shipbuilding

Conference ISC2002, St. Petersburg, Russia, Octo-

ber 8-10, 2002.

[20] U. Campora, M. Figari: Numerical Simulation of

Ship Propulsion Transients and Full Scale Valida-

tion Proc. Instn Mech Engrs Vol 217 Part M:

Journal of Engineering for the Maritime Environ-

ment, 2003.

[21] G. Benvenuto, U. Campora, G. Carrera, M. Figari:

Simulation of Ship Propulsion Plant Dynamics in

Rough Sea 8 International Conference on Marine

Engineering Systems (ICMES/SNAME 2000), New

York, USA, May 22-23, 2000.

[22] SIMULINK Users Guide The MathWorks, inc,

1993.

[23] R. S. Benson, N. D. Whiteouse: Internal Combustion

Engines - Pregamon Press International Library,

Oxford, England, 1979.

[24] G. Benvenuto, U. Campora: A Calculation Proce-

dure of the Real Cycle for Four-Stroke Diesel En-

gines - 52 A.T.I. National Congress, Cernobbio,

Italy, September 22-26, 1997, (in Italian).

[25] S. C. Sorenson: Simple Computer Simulations for

Internal Combustion Engine Instruction - Interna-

tional Journal of Mechanical Engineering Educa-

tion, Vol. 9 n 3, 1981.

[26] N. D. Whitehouse, B. K. Sareen: Prediction of Re-

lease in a Quiescent Chamber Diesel Engine Allow-

ing for Fuel/Air Mixing - SAE 740084, Automo-

tive Engineering Congress, Detroit, Michigan,

February 25 - March 1, 1974.

[27] B. Xiaoping, H. Shu: Prediction of Transient Ex-

haust Soot for a Turbocharged Diesel Engine -

SAE 952434, 1995.

[28] G. Benvenuto, U. Campora: A Computer Model for

the Dynamic Simulation of Turbocharged Diesel

Engine - 1

st

International Conference on Control

and Diagnostics in Automotive Applications,

Genoa, Italy, October 3-4, 1996.

[29] G. Ferrari: Motori a combustione interna - Il Capi-

tello, Torino, March, 1992.

PROPULSION PLANT VARIABLES ENGINE LOADS

Engine power mismatches [% MCR] 100 90 85 75 50 25

Engine speed

[% MCR] 100 96.6 94.8 90.8 79.4 66

MISMATCHES

Specific fuel consumption mismatches

[%] -0.1 0.3 0.3 0.7 1.9 -3.1

Turbocharger speed mismatches [%] 0.7 -1.4 -1.3 -2.7 -4.6 -6.4

Outlet compressor temperature

mismatches [%] 1.8 -2.7 -2.9 -3.3 -4.9 -3.7

Inlet cylinder pressure

p

c

-p

exp

[bar] 0.15 0.15 0.21 0.23 0.32 .41

Inlet cylinder temperature

mismatches [%] 1.0 0.6 0.7 0.1 -1.1 -2.5

Inlet turbine pressure p

c

-p

exp

[bar] -.05 0.01 0.11 0.22 0.32 0.39

Inlet turbine temperature

mismatches [%] -0.8 -0.4 -0.9 1.9 2.2 -1.4

Outlet turbine temperature mismatches [%] 0.3 1.9 2.9 3.1 3.4 2.4

Maximum cylinder pressure

p

c

-p

exp

[bar] -0.08 -2.2 -3.1 -3.4 -4.6 -3.6

Tab. 1 Steady state engine conditions, comparison between reference and simulation results.

Session C 44

Vous aimerez peut-être aussi

- At Zero-Dimensional Combustion SimulationDocument4 pagesAt Zero-Dimensional Combustion SimulationAhmed Mohamed IbrahimPas encore d'évaluation

- 14 - Jmse 07 00138Document19 pages14 - Jmse 07 00138Ali ElmaihyPas encore d'évaluation

- Full 2870Document14 pagesFull 2870dantePas encore d'évaluation

- Modeling and Energy Analysis of A Diesel and Biodiesel Fuelled EngineDocument5 pagesModeling and Energy Analysis of A Diesel and Biodiesel Fuelled EngineMikael Bezerra Cotias Dos SantosPas encore d'évaluation

- 12 Development of A Zero Dimensional ModelDocument10 pages12 Development of A Zero Dimensional ModelAli ElmaihyPas encore d'évaluation

- Estimation of Gasoline-Engine Parameters Using Higher Order Sliding ModeDocument8 pagesEstimation of Gasoline-Engine Parameters Using Higher Order Sliding ModeenginehardwarePas encore d'évaluation

- 2003 01 1060Document13 pages2003 01 1060Jeremy DiazPas encore d'évaluation

- Computer Simulation of Compression Ignition Engine Through MATLABDocument17 pagesComputer Simulation of Compression Ignition Engine Through MATLABiaetsdiaetsdPas encore d'évaluation

- Simulation of The Dynamics of A Marine Diesel EngineDocument16 pagesSimulation of The Dynamics of A Marine Diesel EngineFlorian DraguPas encore d'évaluation

- Predicition of Marine Diesel Engine Performance Under Fault ConditionDocument31 pagesPredicition of Marine Diesel Engine Performance Under Fault ConditionDhanaPas encore d'évaluation

- Model-Based Approach to Engine CalibrationDocument8 pagesModel-Based Approach to Engine CalibrationbiopoweredPas encore d'évaluation

- Illustration of The Use of An Instructional Version of A Thermodynamic Cycle Simulation For A Commercial Automotive Spark-Ignition EngineDocument15 pagesIllustration of The Use of An Instructional Version of A Thermodynamic Cycle Simulation For A Commercial Automotive Spark-Ignition EngineJose Luis RattiaPas encore d'évaluation

- Four-Stroke Diesel Engine Characteristic Curve and EfficiencyDocument10 pagesFour-Stroke Diesel Engine Characteristic Curve and EfficiencyYosra RamadhanPas encore d'évaluation

- Mean Value Modelling of A S.i.: EngineDocument19 pagesMean Value Modelling of A S.i.: EnginesamarjitpatnaikPas encore d'évaluation

- Dynamic Modeling and Simulation On GE90 EngineDocument10 pagesDynamic Modeling and Simulation On GE90 EnginetheijesPas encore d'évaluation

- A Simplified Model For The Spatial Distribution of Temperature in A Motored DI Diesel EngineDocument17 pagesA Simplified Model For The Spatial Distribution of Temperature in A Motored DI Diesel EnginePariotis EfthimiosPas encore d'évaluation

- Investigating Diesel Engine Performance and Emissions Using CFDDocument10 pagesInvestigating Diesel Engine Performance and Emissions Using CFDmfmechanics2020Pas encore d'évaluation

- 224 AbstractPaperFileIEOMDocument9 pages224 AbstractPaperFileIEOMAbdisa BirUKPas encore d'évaluation

- Availability Analysis of A Turbocharged Diesel Engine Operating Under Transient Load ConditionsDocument20 pagesAvailability Analysis of A Turbocharged Diesel Engine Operating Under Transient Load ConditionsParth JaggiPas encore d'évaluation

- Real Time Simulation For Control ApplicationDocument6 pagesReal Time Simulation For Control ApplicationKousik MandalPas encore d'évaluation

- Flow Simulation - CFD - & Fatigue Analysis - Fea - of A Centrifugal PumpDocument17 pagesFlow Simulation - CFD - & Fatigue Analysis - Fea - of A Centrifugal PumpIAEME PublicationPas encore d'évaluation

- Modelling Diesel Engine Combustion and NO Formation For Model Based Control and Simulation of Engine and Exhaust Aftertreatment SystemsDocument12 pagesModelling Diesel Engine Combustion and NO Formation For Model Based Control and Simulation of Engine and Exhaust Aftertreatment Systemsrajeev50588Pas encore d'évaluation

- ECOS 2011 Pariotis Kosmadakis RakopoulosDocument18 pagesECOS 2011 Pariotis Kosmadakis RakopoulosPariotis EfthimiosPas encore d'évaluation

- Prediction of Heat Transfer To The Walls in Direct Injection (DI) Diesel EnginesDocument16 pagesPrediction of Heat Transfer To The Walls in Direct Injection (DI) Diesel EnginespeterPas encore d'évaluation

- QQQQQQQQQQQQQQQQQQQQDocument8 pagesQQQQQQQQQQQQQQQQQQQQreal_paladinePas encore d'évaluation

- 144 0067Document4 pages144 0067Antony BanderasPas encore d'évaluation

- A Critical Analysis On The Lubrication Circuit of A Non-Road Diesel Engine by Adopting A 3D and 1D ApproachesDocument11 pagesA Critical Analysis On The Lubrication Circuit of A Non-Road Diesel Engine by Adopting A 3D and 1D ApproacheshamidrezachamaniPas encore d'évaluation

- Impact of Late and Early Fuel Injection On Main Engine Efficiency and Exhaust Gas EmissionsDocument5 pagesImpact of Late and Early Fuel Injection On Main Engine Efficiency and Exhaust Gas EmissionsRyandri YudiantoPas encore d'évaluation

- Stepped PistfonDocument12 pagesStepped PistfonSrikanth DesaiPas encore d'évaluation

- Super Computing Applications in Internal Combustion Engine Design andDocument8 pagesSuper Computing Applications in Internal Combustion Engine Design andMadhusudan BarotPas encore d'évaluation

- New Approach For Gas Turbine Performance AnalysisDocument17 pagesNew Approach For Gas Turbine Performance AnalysisJung Kyung WooPas encore d'évaluation

- Sae 2001-01-1235Document17 pagesSae 2001-01-1235Efthimios PariotisPas encore d'évaluation

- A26 23 Moses2019Document8 pagesA26 23 Moses2019Minn Siss PaingPas encore d'évaluation

- Design of Air Conditioning System Using CFD Combined With Refrigeration Cycle SimulatorDocument9 pagesDesign of Air Conditioning System Using CFD Combined With Refrigeration Cycle SimulatorssemzamilPas encore d'évaluation

- Mathematical Modelling and Simulation of Spark Ignition Engine For Predicting Engine Performance CharacteristicsDocument5 pagesMathematical Modelling and Simulation of Spark Ignition Engine For Predicting Engine Performance CharacteristicsInnovative Research PublicationsPas encore d'évaluation

- FuelDocument30 pagesFuelrakhikishorePas encore d'évaluation

- Genetic-Fuzzy Model of Diesel Engine Working Cycle: M. Kekez and L. RadziszewskiDocument7 pagesGenetic-Fuzzy Model of Diesel Engine Working Cycle: M. Kekez and L. RadziszewskiJai SankarPas encore d'évaluation

- Development and Validation of A Crank Angle Model of An Automotive Turbocharged Engine For Hil ApplicationsDocument10 pagesDevelopment and Validation of A Crank Angle Model of An Automotive Turbocharged Engine For Hil Applicationsarun kumarPas encore d'évaluation

- A Method of Performance Estimation For Axial FlowDocument9 pagesA Method of Performance Estimation For Axial FlowmidgardsothothPas encore d'évaluation

- UNIT III Material Advance Theory of IC EnginesDocument17 pagesUNIT III Material Advance Theory of IC EnginesRajkamal PPas encore d'évaluation

- Engine AFR ModelDocument6 pagesEngine AFR ModelIkhwanul KhairiPas encore d'évaluation

- Plugin-11745 Egedy PaperDocument5 pagesPlugin-11745 Egedy PaperMuhammad ImranPas encore d'évaluation

- An Approach For Predicting The Specific Fuel Consumption of Dual-Fuel Two-Stroke Marine EnginesDocument12 pagesAn Approach For Predicting The Specific Fuel Consumption of Dual-Fuel Two-Stroke Marine EnginesNgizuddin Masro'iPas encore d'évaluation

- Chaquet&CarmonaDocument19 pagesChaquet&CarmonaUNsha bee komPas encore d'évaluation

- Diesel Engine Performance Simulation Using a Quasi-Dimensional Combustion ModelDocument11 pagesDiesel Engine Performance Simulation Using a Quasi-Dimensional Combustion Modelalireza1941Pas encore d'évaluation

- Technical Note A FORTRAN Program For Calculating The Evaporation Rates in Diesel Engine Fuel SpraysDocument5 pagesTechnical Note A FORTRAN Program For Calculating The Evaporation Rates in Diesel Engine Fuel Spraysim19rahulPas encore d'évaluation

- Investigation of Fuel Injection Strategi PDFDocument7 pagesInvestigation of Fuel Injection Strategi PDFVladPas encore d'évaluation

- (Petroleum) - UOP Fluid Catalytic Cracking UnitDocument25 pages(Petroleum) - UOP Fluid Catalytic Cracking UnitSölangs QüntellaPas encore d'évaluation

- Theotokatos 2018Document46 pagesTheotokatos 2018hideki hidekiPas encore d'évaluation

- Mavrelos Theotokatos 5RT-FLEX50DFDocument35 pagesMavrelos Theotokatos 5RT-FLEX50DFNapoleon MpPas encore d'évaluation

- Comprex SuperDocument9 pagesComprex SuperEslam MedhatPas encore d'évaluation

- Beltrami 2003Document6 pagesBeltrami 2003alijannounPas encore d'évaluation

- Journal of Advanced Research Altitude Performance and Fuel Consumption ModellingDocument8 pagesJournal of Advanced Research Altitude Performance and Fuel Consumption ModellingshayanjadoonPas encore d'évaluation

- A Dynamic Model For Automotive Engine Control AnalysisDocument7 pagesA Dynamic Model For Automotive Engine Control Analysisekitani6817Pas encore d'évaluation

- Article Citation InfoDocument6 pagesArticle Citation InfotranvanhoadhspktPas encore d'évaluation

- 8 - Shen Et Al 2021 Modeling and Performance Analysis of Diesel Engine Considering The Heating Effect of Blow by OnDocument15 pages8 - Shen Et Al 2021 Modeling and Performance Analysis of Diesel Engine Considering The Heating Effect of Blow by OnAli ElmaihyPas encore d'évaluation

- Matecconf mms18 01010Document7 pagesMatecconf mms18 01010Raja KarPas encore d'évaluation

- Data Analysis and Performance Model Calibration of A Small Turbojet EngineDocument24 pagesData Analysis and Performance Model Calibration of A Small Turbojet EngineFathima J100% (1)

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsD'EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsPas encore d'évaluation

- Tor - Model ModelDocument1 pageTor - Model ModelwaleedyehiaPas encore d'évaluation

- SPJVortragDocument37 pagesSPJVortragwaleedyehiaPas encore d'évaluation

- Gragen - Offshore IndustryDocument30 pagesGragen - Offshore Industrywaleedyehia100% (1)

- GeneralDocument50 pagesGeneralwaleedyehia100% (2)

- STP133 PDFDocument5 pagesSTP133 PDFwaleedyehiaPas encore d'évaluation

- Service Activities SET 2000Document41 pagesService Activities SET 2000waleedyehiaPas encore d'évaluation

- ReadmeDocument1 pageReadmewaleedyehiaPas encore d'évaluation

- STP133 PDFDocument5 pagesSTP133 PDFwaleedyehiaPas encore d'évaluation

- STP 1212Document22 pagesSTP 1212waleedyehiaPas encore d'évaluation

- SRP 200 Rudderpropeller technical details and constructionDocument21 pagesSRP 200 Rudderpropeller technical details and constructionwaleedyehiaPas encore d'évaluation

- SRP170Document23 pagesSRP170waleedyehia100% (1)

- Handbook 1 PDFDocument3 pagesHandbook 1 PDFwaleedyehiaPas encore d'évaluation

- Status Scale Alteration Index Drawing No. / Ident No. Section / PageDocument15 pagesStatus Scale Alteration Index Drawing No. / Ident No. Section / PagewaleedyehiaPas encore d'évaluation

- STP330Document14 pagesSTP330waleedyehiaPas encore d'évaluation

- GeneralDocument50 pagesGeneralwaleedyehia100% (2)

- SRP 1212Document27 pagesSRP 1212waleedyehia100% (4)

- El - SRP - STP 550 Up To 4500Document44 pagesEl - SRP - STP 550 Up To 4500waleedyehiaPas encore d'évaluation

- STP 1010Document26 pagesSTP 1010waleedyehiaPas encore d'évaluation

- STT Type SheetsDocument15 pagesSTT Type SheetswaleedyehiaPas encore d'évaluation

- STP550Document22 pagesSTP550waleedyehia0% (1)

- SRP 4500Document15 pagesSRP 4500waleedyehiaPas encore d'évaluation

- SRP 4500Document15 pagesSRP 4500waleedyehiaPas encore d'évaluation

- SRP 1010Document29 pagesSRP 1010waleedyehiaPas encore d'évaluation

- SRP 3030Document25 pagesSRP 3030waleedyehia100% (1)

- SRP 2020Document25 pagesSRP 2020waleedyehiaPas encore d'évaluation

- SRP 1212Document27 pagesSRP 1212waleedyehia100% (4)

- SRP550Document23 pagesSRP550waleedyehia100% (1)

- SRP 1212Document27 pagesSRP 1212waleedyehia100% (4)

- Handbuch 4Document57 pagesHandbuch 4waleedyehia100% (2)

- SRP 200 Rudderpropeller technical details and constructionDocument21 pagesSRP 200 Rudderpropeller technical details and constructionwaleedyehiaPas encore d'évaluation

- Cummins - ISX15 CM2350 (2013-17)Document17 pagesCummins - ISX15 CM2350 (2013-17)ramsi17100% (6)

- AJ Duratec and L3 Engine Systems GuideDocument53 pagesAJ Duratec and L3 Engine Systems GuideNguyễn Chánh SĩPas encore d'évaluation

- Gener. Inverter, Kipor, KGE3500TiDocument1 pageGener. Inverter, Kipor, KGE3500TiManuel SierraPas encore d'évaluation

- 4,5 and 6,8L Engine AlarmsDocument2 pages4,5 and 6,8L Engine AlarmsmarceloPas encore d'évaluation

- BSIV Spare Parts Catalogue for Pulsar NS 160 MotorcycleDocument78 pagesBSIV Spare Parts Catalogue for Pulsar NS 160 MotorcycleWilly Mansilla A100% (4)

- Engine Analyzer Pro v3.9 SupplementDocument16 pagesEngine Analyzer Pro v3.9 SupplementMortada AlsonniPas encore d'évaluation

- VW Passat b5 Maintenance EngDocument189 pagesVW Passat b5 Maintenance EngMarian NedelcuPas encore d'évaluation

- Codigos de Falla ODBDocument12 pagesCodigos de Falla ODBVictor Hugo CordonPas encore d'évaluation

- HONNY POWER Diesel Generator DatasheetDocument4 pagesHONNY POWER Diesel Generator DatasheetAmpolPas encore d'évaluation

- Cryogenic Rocket EngineDocument59 pagesCryogenic Rocket EngineVikramPas encore d'évaluation

- C13 Ind - MHX 08846Document6 pagesC13 Ind - MHX 08846Yudhi CiamorienPas encore d'évaluation

- Kohler Magnum Twin Cylinder Engine Torque Values and Specs For Fasteners PDFDocument4 pagesKohler Magnum Twin Cylinder Engine Torque Values and Specs For Fasteners PDFBillW56Pas encore d'évaluation

- DTC P055B-P055D: Applies ToDocument5 pagesDTC P055B-P055D: Applies ToWillie AustinePas encore d'évaluation

- Spark Plug Pictures For Lean To Rich Running EnginesDocument2 pagesSpark Plug Pictures For Lean To Rich Running EnginesSajjad Rasheed QureshiPas encore d'évaluation

- Page: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-1000001784-015 PDFDocument3 pagesPage: M-1 of M-3 © 2018 Caterpillar All Rights Reserved MSS-IND-1000001784-015 PDFeaglego00Pas encore d'évaluation

- Pantalla Anterior Bienvenido: r120pm2Document2 pagesPantalla Anterior Bienvenido: r120pm2Eliecer godoyPas encore d'évaluation

- Fundamentals Shop Safety Procedures Structures LabDocument3 pagesFundamentals Shop Safety Procedures Structures LabEric Hardy100% (1)

- 4082 ArticleText 20334 1 10 20210105Document15 pages4082 ArticleText 20334 1 10 20210105AxBDPas encore d'évaluation

- Technical Service Guide CT LB TWM Uv VH 6990005 EnUS TSG 09-11Document244 pagesTechnical Service Guide CT LB TWM Uv VH 6990005 EnUS TSG 09-11Henry HuayhuaPas encore d'évaluation

- Coelmo 20 KVA PDT44DaDocument2 pagesCoelmo 20 KVA PDT44DaEmily BullockPas encore d'évaluation

- 1.2 3cyl EngineDocument17 pages1.2 3cyl Engineeurohaus100% (4)

- Emission Control System TestsDocument2 pagesEmission Control System TestsSebastian DamianPas encore d'évaluation

- For Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingDocument2 pagesFor Intermittent Service: TEEF 3x5 For Well Servicing Performance RatingcacaunpsPas encore d'évaluation

- Manual de Moto SoldadorDocument78 pagesManual de Moto SoldadorYimmy Alexander Parra Marulanda100% (1)

- 13Document18 pages13Catherine GuthriePas encore d'évaluation

- Wiring Diagram HFM-SFI Sequential Multiport Fuel Injection - Ignition System2 w202Document4 pagesWiring Diagram HFM-SFI Sequential Multiport Fuel Injection - Ignition System2 w202mathexscribdPas encore d'évaluation

- Chevrolet Pinout PCM 8Document5 pagesChevrolet Pinout PCM 8Javier Inzaurgarat100% (1)

- 2TNE68Document23 pages2TNE68Teddy NsPas encore d'évaluation

- AB35049U English VersionDocument214 pagesAB35049U English VersionsaifulPas encore d'évaluation

- PCM Inspection (Skyactiv-G 2.5)Document39 pagesPCM Inspection (Skyactiv-G 2.5)Esteban LefontPas encore d'évaluation