Académique Documents

Professionnel Documents

Culture Documents

Deflection of Beam PDF

Transféré par

Salam AlbaradieDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Deflection of Beam PDF

Transféré par

Salam AlbaradieDroits d'auteur :

Formats disponibles

tafila technical university

Faculty of engineering

Exp #6

Beams Deflection

Name: Salam Fayez Albaradie

Lecturer name: Dr.Tamer Alshaqarin

Date of submission: 20/4/2014

1. OBJECTIVE

To determine flexural modulus (Ef) of material

2. Introduction & Background

2.1. General Background

If a beam is supported at two points, and a load is applied anywhere on the beam,

deformation will occur. When these loads are applied either longitudinally outside or inside

of the supports, this elastic bending can be mathematically predicted based on material

properties and geometry.

2.2. Determination of Curvature

Curvature at any point on the beam is calculated from the moment of loading (M), the

stiffness of the material (E), and the first moment of inertia (I.) The following expression

defines the curvature in these parameters as 1/, where is the radius of curvature.

I E

M

1

Equation 1

Equation 1 does not account for shearing stresses.

Curvature can also be found using calculus. Defining y as the deflection and x as the

position along the longitudinal axis, the expression becomes

2

3

2

2

2

1

1

(

(

|

.

|

\

|

+

=

dx

dy

dx

y d

Equation 2

2.3. Simply Supported Beam

Simply Supported Beam on a beam can be thought of as a simple beam with two supports as shown

below.

Figure 1 simply supported beam.

Applying equilibrium to the free body equivalent of Figure 1, several expressions can be derived to

mathematically explain central loading.

( ) ( )

( )

( )

( )

( )

( )

( )

( )

At x=A, y=0 c

1

= -c

2

/A

At x=C, y=0

( )

( )

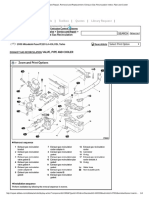

3. Equipments and Experimental procedure

3.1. Equipments

Figure 1: Beam Deflection Apparatus

3.2. PROCEDURE

a) Mark the beams with the same span so that they will be supported near their ends and

also mark the point of the span.

b) Take the beam of largest width, measure the width with the veneer Callipers.

c) Support the beam at the two marked supporting points and measure the height of the

mid-point with the deflection measuring device.

d) Apply the 600 g load as point and once again measure the height at the centre.

4. Result

Table 1: property of beam.

A 20 cm

B 60 cm

C 110 cm

H 3 mm

W 25 mm

Load (p) = 600 gram = 0.6 kg * 10 = 6 N.

= 4.35 mm at x = 400 mm.

()

()

() ()

()

( )

( )

( )

At x=A, y=0 c

1

= -c

2

/A

At x=C, y=0

( )

( )

()

( )

( )

()

Subnational 1 on 2

-0.258

5.175*10

-3

To determine the models of elasticity

( )

( )

( )

At x=0.400 m the deflection (y) = -4.35*10

-3

m

= 56.25*10

-12

m

4

( )

( )

( )

()

Note any bricks give inside a negative sign is neglected

So the equation will by

( )

()

=382.4 Gpa

5. Discussion

1. The relationship between load and deflection.

The line of load versus deflection gives a linear equation, meaning that the relationship

between the two must be linear (P ). This is proven by the equation for the deflection of a

simply supported beam above, in which as load is altered, so does the amount of deflection.

This is also in keeping with Hookes Law which states that the deformation of a body is in

direction proportion to the load applied to it. This is only true however as the beam is loaded

within its elastic limit, above this, in the plastic region, the relationship changes to non-linear

until fracture.

2. Possible sources of inaccuracy in the experiment.

With all experiments there is always will always be an element of inaccuracy to take into

account with the results. With this experiment the possible sources were:

1. Human Error there could potentially be an element of human error in 3 places in the

experiment, placing the load central on the span, measuring the overall span and zeroing

the dial gauge.

2. Mass of the weights the actual mass of the weights were not measured these could

differ slightly from those listed on the weight themselves.

3. Accuracy of gauges (dial gauge, ruler on bench, venire calipers) the temperature and

pressure of the environment the experiment was completed in could have affected the

scale on the ruler and Gauges, which were metal; an increase in either from when it was

manufactured could have resulted in a slightly different ruler scale.

4. Parallax could also be classed as human error, parallax in the placement of the dial

gauge on the center of the beam as the ruler was set away from the gauge itself. If the

gauge was not viewed exactly perpendicular to the ruler it could have been positioned

slightly away from center slightly.

5. Placement of the weights the load could not be applied exactly central to the beam due

to the positioning of the dial gauge being exactly central on the beam. It was always

placed next to the gauge on the left hand side, towards point A.

6. Moment about the supporting points the beam was never the exact span length; there

was always an overhang past the knife support edges. The mass of beam overhanging

will have created a moment about points A and C, therefore the forces acting downwards

were not just that of the load, but should also have

6. References

Books:

1. Craig Mechanics Materials 3rd Edition.

2. Mechanics Of Materials Hibbeler 8th Edition.

Website:

1. www.scribd.com

2. www.structureanalysis.weebly.com/deflection-of-beams.html

3. www.slideshare.net/themyth2010/deflection-of-beams

Vous aimerez peut-être aussi

- Bending Moment For MechatronicsDocument14 pagesBending Moment For MechatronicsMorapedi D. KealebogaPas encore d'évaluation

- Reaction On BeamDocument10 pagesReaction On BeamNurul NadhirahPas encore d'évaluation

- Deflection of Simply Supported BeamDocument3 pagesDeflection of Simply Supported BeamArjun MulluPas encore d'évaluation

- Beam Deflection LabDocument18 pagesBeam Deflection LabLeah Pérez67% (9)

- Bending Moment in A BeamDocument8 pagesBending Moment in A BeamLim Ksoon100% (1)

- s2 Bending MomentDocument22 pagess2 Bending MomentismailPas encore d'évaluation

- Two Hinged Parabolic ArchDocument10 pagesTwo Hinged Parabolic ArchHans Izairi100% (1)

- Structure Lab-Three Hinge ArcDocument13 pagesStructure Lab-Three Hinge ArcFendi Roon100% (1)

- ME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSDocument8 pagesME2113-1 Lab Report DEFLECTION AND BENDING STRESSES IN BEAMSsteven mcqueen67% (15)

- Experiment 4: Deflection of Cantilever Beam TestDocument6 pagesExperiment 4: Deflection of Cantilever Beam Test0728617Pas encore d'évaluation

- Bending Test On WoodDocument8 pagesBending Test On WoodShekharappa MallurPas encore d'évaluation

- Deflection of A Simply Supported BeamDocument15 pagesDeflection of A Simply Supported Beamshuqing heongPas encore d'évaluation

- Lab Report Experiment 5-10Document29 pagesLab Report Experiment 5-10mkashif iqbal100% (1)

- Deflection of BeamDocument21 pagesDeflection of BeamRondell Sinanan100% (1)

- Span Deflection (Double Integration Method)Document14 pagesSpan Deflection (Double Integration Method)Ikhwan Z.88% (8)

- Bending Moment in A Beam Lab Report - Green MechanicDocument9 pagesBending Moment in A Beam Lab Report - Green Mechanicmohdiqbal93Pas encore d'évaluation

- Mechanics of Materials - Principal Stresses and StrainsDocument14 pagesMechanics of Materials - Principal Stresses and StrainsDavid Clark100% (5)

- CVE 230. Lab Report 4 (Torsion Testing) .Document4 pagesCVE 230. Lab Report 4 (Torsion Testing) .Juan Villa100% (1)

- Lab Report Deflection of BeamDocument10 pagesLab Report Deflection of BeamFirash ImranPas encore d'évaluation

- Bending MomentDocument30 pagesBending MomentMuhammad ImranPas encore d'évaluation

- Engineering Laboratory V BDA 3701: Buckling of StrutsDocument29 pagesEngineering Laboratory V BDA 3701: Buckling of StrutsAzfar Azpo100% (1)

- Deflection of BeamDocument13 pagesDeflection of BeamAquw ArishaPas encore d'évaluation

- Shear Force Bending Moment Test ReportDocument5 pagesShear Force Bending Moment Test ReportZahed AbdAzizPas encore d'évaluation

- Lab8-Shear Force (New)Document15 pagesLab8-Shear Force (New)Nur Syamiza Zamri100% (1)

- Beam DeflectionDocument14 pagesBeam DeflectionPrudvi Krishna MaladiPas encore d'évaluation

- Bending Moment in A BeamDocument12 pagesBending Moment in A BeamOdarie HunterPas encore d'évaluation

- Exp 1 G5Document24 pagesExp 1 G5Abdullah Helmi100% (1)

- TrussDocument12 pagesTrussAmirullah Adnan100% (1)

- BendingDocument21 pagesBendingNoel Teh50% (2)

- Beam Bending Lab ReportDocument9 pagesBeam Bending Lab Reportapi-3105192830% (1)

- Shear ForceDocument22 pagesShear ForceGregory MillerPas encore d'évaluation

- EXP 5 TorsionDocument18 pagesEXP 5 TorsionYagami KirigayaPas encore d'évaluation

- Experiment 3 (Bending Moments in Beam)Document13 pagesExperiment 3 (Bending Moments in Beam)Shafiq MahadiPas encore d'évaluation

- Structure Lab-Three Hinge Arc (Example Lab Report)Document13 pagesStructure Lab-Three Hinge Arc (Example Lab Report)NabilZaed0% (2)

- Bending Moment Lab (CES511)Document8 pagesBending Moment Lab (CES511)Alif AkhmizanPas encore d'évaluation

- Bending Moment Lab Sheet Proposal BendingDocument3 pagesBending Moment Lab Sheet Proposal BendingKim Won ShikPas encore d'évaluation

- Som 4Document11 pagesSom 4Ronaldo Ulisi100% (1)

- Shear Force Lab ReportDocument8 pagesShear Force Lab ReportJack WillyPas encore d'évaluation

- Fixed End MomentDocument2 pagesFixed End MomentmuhammadalhafizPas encore d'évaluation

- Lab Report Setting Out PDFDocument10 pagesLab Report Setting Out PDFsaraa sharanPas encore d'évaluation

- LAB 1-Beam DeflectionDocument5 pagesLAB 1-Beam DeflectionNur Astuty100% (1)

- Beam Bending Lab ReportDocument22 pagesBeam Bending Lab Reportimlioh_ih50% (2)

- Duhok Polytechnic University Technical College of Engineering Petrochemical Department Transport Phenomena Fourth Year-2018-2019Document10 pagesDuhok Polytechnic University Technical College of Engineering Petrochemical Department Transport Phenomena Fourth Year-2018-2019Bryar XalilPas encore d'évaluation

- Lab4.Bending MomentDocument9 pagesLab4.Bending MomentOmar Arabi0% (1)

- Bending Beam LabDocument17 pagesBending Beam Labdoremon50% (2)

- Strut BucklingDocument9 pagesStrut BucklingWai Sheng75% (4)

- Theoretical Background of Beam DeflectionDocument3 pagesTheoretical Background of Beam DeflectionSharmaine Gomez FalcisPas encore d'évaluation

- S3-Deflection in Beam and CantileverDocument97 pagesS3-Deflection in Beam and CantileverBruh100% (1)

- Topic 3: Shear Force of A BeamDocument19 pagesTopic 3: Shear Force of A BeamhafizPas encore d'évaluation

- Shear Force and Bending MomentDocument5 pagesShear Force and Bending MomentSudarshan DukePas encore d'évaluation

- Bending Test (Report) eDocument14 pagesBending Test (Report) eWesam Maleh100% (1)

- Introduction of Shear Force Experiment LabDocument2 pagesIntroduction of Shear Force Experiment LabaQuAmiRaPas encore d'évaluation

- Discussion For Shear Centre LabDocument2 pagesDiscussion For Shear Centre Labkevinblache67% (3)

- Centre of Hidrostatic PressureDocument16 pagesCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Continuous Beam Lab G4Document11 pagesContinuous Beam Lab G4Najmuddin Aliff67% (3)

- Bending Moment - Lab 2Document17 pagesBending Moment - Lab 2Yeong Leang50% (2)

- Experiment No: - 01 Name of Experiment: - Deflection of A Simply Supported Beam. ObjectivesDocument6 pagesExperiment No: - 01 Name of Experiment: - Deflection of A Simply Supported Beam. ObjectivesNewton ShikderPas encore d'évaluation

- Euler Buckling Lab 2Document18 pagesEuler Buckling Lab 2Sameer shaikh100% (1)

- General Application To Elastic Materials: AM2540 Spring Sti Ness Test AM 2540: Strength of Materials LaboratoryDocument17 pagesGeneral Application To Elastic Materials: AM2540 Spring Sti Ness Test AM 2540: Strength of Materials LaboratoryAditya KoutharapuPas encore d'évaluation

- Temperature, Buoyancy, and Vertical Motion What Air Temperature?Document7 pagesTemperature, Buoyancy, and Vertical Motion What Air Temperature?Salam AlbaradiePas encore d'évaluation

- HW1Document18 pagesHW1Salam AlbaradiePas encore d'évaluation

- Important Experimental Designs: University of JordanDocument18 pagesImportant Experimental Designs: University of JordanSalam AlbaradiePas encore d'évaluation

- Ae 45900Document8 pagesAe 45900Salam AlbaradiePas encore d'évaluation

- Introduction To Measurement Uncertainty: Date: 2006-3-02 AuthorsDocument27 pagesIntroduction To Measurement Uncertainty: Date: 2006-3-02 AuthorsSalam AlbaradiePas encore d'évaluation

- Similarity Solutions For Boundary Layer Flows On A Moving Surface in Non-Newtonian Power-Law FluidsDocument10 pagesSimilarity Solutions For Boundary Layer Flows On A Moving Surface in Non-Newtonian Power-Law FluidsSalam AlbaradiePas encore d'évaluation

- LibrariesDocument2 pagesLibrariesSalam AlbaradiePas encore d'évaluation

- Java PrintingDocument6 pagesJava PrintingSalam AlbaradiePas encore d'évaluation

- J Z Y Z Z: Section 7.9 Laplace's Equation in A Circular CylinderDocument11 pagesJ Z Y Z Z: Section 7.9 Laplace's Equation in A Circular CylinderSalam AlbaradiePas encore d'évaluation

- Trou W Borst 2014 BSCDocument36 pagesTrou W Borst 2014 BSCSalam AlbaradiePas encore d'évaluation

- HE Elationship Etween Mplant Reload and Crew Oosening On Mplant Supported RosthesesDocument7 pagesHE Elationship Etween Mplant Reload and Crew Oosening On Mplant Supported RosthesesSalam AlbaradiePas encore d'évaluation

- Neuro-Adaptive Design - II:: A Robustifying Tool For Any DesignDocument46 pagesNeuro-Adaptive Design - II:: A Robustifying Tool For Any DesignSalam AlbaradiePas encore d'évaluation

- ABET Syllabus HydraulicsDocument2 pagesABET Syllabus HydraulicsSalam AlbaradiePas encore d'évaluation

- The Geometry of Nature: FractalsDocument16 pagesThe Geometry of Nature: FractalsSalam Albaradie100% (1)

- Fire Fighting Robot: Microprocessors and MicrocontrollersDocument13 pagesFire Fighting Robot: Microprocessors and MicrocontrollersSalam AlbaradiePas encore d'évaluation

- University of Jordan Faculty of EngineeringDocument1 pageUniversity of Jordan Faculty of EngineeringSalam AlbaradiePas encore d'évaluation

- Fractal Geometry: The Mandelbrot and Julia Sets: Stephanie Avalos-Bock July, 2009Document10 pagesFractal Geometry: The Mandelbrot and Julia Sets: Stephanie Avalos-Bock July, 2009Salam AlbaradiePas encore d'évaluation

- 11P Work Energy PrincipleDocument17 pages11P Work Energy PrincipleSalam Albaradie100% (2)

- SD22Document2 pagesSD22It. jinyiPas encore d'évaluation

- b087z Chucks Part1 PDFDocument48 pagesb087z Chucks Part1 PDFGuillermo RamirezPas encore d'évaluation

- Elastic Potential Energy: English For PhysicsDocument2 pagesElastic Potential Energy: English For Physicshaura 30anPas encore d'évaluation

- Ms Productline 2021 n09Document28 pagesMs Productline 2021 n09Francisco NavasPas encore d'évaluation

- Destilasi Binner & Multi KomponenDocument8 pagesDestilasi Binner & Multi KomponenApril Rianto BaktiarPas encore d'évaluation

- Sewatec - SewablocDocument186 pagesSewatec - SewablocmonechePas encore d'évaluation

- Full Download Ebook Ebook PDF Mechanics of Materials An Integrated Learning System 4th PDFDocument41 pagesFull Download Ebook Ebook PDF Mechanics of Materials An Integrated Learning System 4th PDFlillie.christopher194100% (37)

- Mechanical QuestionsDocument6 pagesMechanical QuestionsarupPas encore d'évaluation

- Dokumen - Tips Onshore Pipeline EngineeringpptDocument52 pagesDokumen - Tips Onshore Pipeline Engineeringpptfxoption4057Pas encore d'évaluation

- Presentation - Mee - 4 New1Document29 pagesPresentation - Mee - 4 New1Amal joyPas encore d'évaluation

- Synchronous Motor Operation and ControlDocument2 pagesSynchronous Motor Operation and ControlHéctor AlmodovarPas encore d'évaluation

- Generator AuxiliariesDocument39 pagesGenerator Auxiliariesharry2586Pas encore d'évaluation

- Starter, Ign & Charging PDFDocument1 pageStarter, Ign & Charging PDFIqmalus SyariefPas encore d'évaluation

- Astm A105Document5 pagesAstm A105Ali ArsalanPas encore d'évaluation

- Ibong Tiririt Pipe 1Document75 pagesIbong Tiririt Pipe 1Mc LesterPas encore d'évaluation

- Assignment On Shaft DesignDocument2 pagesAssignment On Shaft DesignRitesh SinghPas encore d'évaluation

- Pellet Mill HandbookDocument21 pagesPellet Mill HandbookBorko Cicovic100% (2)

- 2007 LC4 690 LC8 990 Diagnostic Measurements Failure CodesDocument49 pages2007 LC4 690 LC8 990 Diagnostic Measurements Failure Codeschili_s16Pas encore d'évaluation

- Internal Loading - Quick - FomatDocument12 pagesInternal Loading - Quick - FomatPhúc LÊPas encore d'évaluation

- Homework 1-3 PDFDocument3 pagesHomework 1-3 PDFivan david alvarez herreraPas encore d'évaluation

- Perhitungan Pressure Vessel LengkapDocument70 pagesPerhitungan Pressure Vessel LengkapReo Aditya MahesaPas encore d'évaluation

- MotorDocument4 pagesMotorAlexandru Manea0% (1)

- New Vehicle New Tsbs Toolbox Quotes Library Request Vehicle Information CommunityDocument4 pagesNew Vehicle New Tsbs Toolbox Quotes Library Request Vehicle Information CommunityJohn Mark AcederaPas encore d'évaluation

- Air Drilling With MotorsDocument6 pagesAir Drilling With MotorsGharib HashemPas encore d'évaluation

- S 60 MCC 8Document407 pagesS 60 MCC 8tayzar LynnPas encore d'évaluation

- Chapter 14 - Flight and Ground LimitationsDocument35 pagesChapter 14 - Flight and Ground LimitationsSaleyman El AlaouiPas encore d'évaluation

- Gear 1st 2nd 3rd 4th 5th Reverse: JJJJC C C C55 5 5Document4 pagesGear 1st 2nd 3rd 4th 5th Reverse: JJJJC C C C55 5 5todo manualesPas encore d'évaluation

- DV-5 Deluge Valve With Remote-Resetting Trim 2 To 8 Inch (DN50 To DN200) General DescriptionDocument24 pagesDV-5 Deluge Valve With Remote-Resetting Trim 2 To 8 Inch (DN50 To DN200) General DescriptionAwais AshrafPas encore d'évaluation

- Car Dynamics Using Quarter Model and Passive Suspension, PDFDocument9 pagesCar Dynamics Using Quarter Model and Passive Suspension, PDFwelsya100% (1)

- Rivets GetTRDocDocument149 pagesRivets GetTRDoctfitzgeraldswimPas encore d'évaluation