Académique Documents

Professionnel Documents

Culture Documents

Piping About

Transféré par

ravi00098Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Piping About

Transféré par

ravi00098Droits d'auteur :

Formats disponibles

PIPING WHAT IS PIPING ABOUT?

We can say PIPING is about designing, fabricating and constructing lines con eying !"UI#S$ W%at is a !"UI#? It can be any of t%e follo&ing a GAS a "I'UI# a (i)ture of GAS and "I'UI# a SUSP*NSION of s(all SO"I# PA+TI,"*S inside a "I'UI#$ Basic -ro-erties of con eyed !"UI#S !"UI# T.P* &it% -articular attention to t%e ,O++OSION c%aracteristics t%e #ANG*+ for H*A"TH and t%e *N/I+ON0*NT !"OW +AT* P+*SSU+* T*0P*+ATU+* W%at is a PIP*"IN*? A PIP*"IN* con eys a fluid fro( one gi en -oint of t%e -lant usually called IN"*T -oint of t%e line, to anot%er -art of t%e -lant usually called OUT"*T -oint of t%e line$ A PIP*"IN* can also connect one PIP*"IN* to anot%er PIP*"IN*$ PIP*"IN*S can also disc%arge t%e con eyed fluid into t%e en iron(ent 1/*NTS and #+AIN2 Basic c%aracteristics of a PIP*"IN* SI3* 1or #IA0*T*+2 WA"" THI,4N*SS T.P* O! 5OINTS B*TW**N PI*,*S &elded 6oints 1butt &elding 7 soc8et &elding2 t%readed 6oints flanged 6oints *9T*+NA" !INISHING Painting Insulation 'UA"IT. ,H*,4S Hydraulic Testing Non #estructi e *)a(ination of 5oints$ Ot%er c%aracteristics of a PIP*"IN* +OUTING T%e routing is %o& t%e Pi-eline is de elo-ed into t%e s-ace$ T%ere are rules and regulations to route a Pi-eline according t%e :Good *ngineering Practice; ,old Pi-elines connecting static ob6ects 1so(et%ing t%at does not (o e li8e Tan8s, /essels, ot%er Pi-elines, Headers2 can be straig%tly routed bet&een t%e inlet and t%e outlet -oint$ ,old Pi-elines connecting 0A,HIN*S t%at ibrate or rotate (ay need a fle)ible -art bet&een t%e inlet and t%e outlet -oint$ Hot Pi-elines (ust be fle)ible enoug% to adsorb t%e t%er(al e)-ansion of t%e Pi-eline fro( cold to %ot condition SUPPO+TING S.ST*0 * ery Pi-eline (ust be su--orted$ Not all Pi-elines are su--orted in t%e sa(e &ay ,old Pi-elines can be su--orted e ery&%ere &it% !I9*# POINTS Hot Pi-elines cannot be su--orted only &it% fi)ed -oints, butcertain -oints (ust be only GUI#*#, (eaning t%at in t%ose -oints t%e Pi-eline retains a certain nu(bers of degree of freedo( in certain directions, &%ile are constrained in certain ot%er directions

PIPING #*SIGN S-ecification of "ines It is a docu(ent t%at su((ari<es all t%e c%aracteristics of a PIP*"IN*$ Starting fro( t%e P+OP*+TI*S of t%e ,ON/*.*# !"UI#, t%e docu(ent s-ecifies all t%e ,HA+A,T*+ISTI,S of t%e PIP*"IN* !"UI# T.P* ,%oice of (aterial =$ Non corrosi e fluids Ser ices &%ere i(-urities are acce-ted industrial &ater lines 1cooling &ater2 stea( lube oil return 7 before filter lines air lines ents and drains ,arbon Steel, "o& Alloy Steel 1Hig% T2 >$ ,orrosi e fluids Ser ices &%ere i(-urities are not acce-ted de(inerali<ed &ater lube oil after filters fuel gas 7 oil sea &ater 1&ater containing ,%lorine2 Stainless Steel No Iron 1!e2 ,o--er7 Nic8el Alloys 1,u? Ni2 @$ Aggressi e ,%e(icals Strong Acids 7 Bases PlasticA P/, B T*!"ON B P* +ubberA NB+, /iton ,o(-ositesA +*SIN G"ASS !"UI# T.P* ,%oice of ,O++OSION A""OWAN,* A T%ic8ness increasing ta8ing into account ,O++OSION Ty-ical corrosion allo&ance for &ater is @ (( t%at affects THI,4N*SS ,%oice of 6ointsA #ANG*+OUS fluids are con eyed in fully &elded -i-es, &ere lea8s cannot occur$ ,%oice of N#* A !or #angerous !luids =CCD of 6oints are li8ely to be 9? +ay e)a(ined !"OW +AT* ,%oice of #ia(eter !or a gi en flo& rate ? S0A"" #IA0*T*+ (eans HIGH*+ /*"O,IT. of t%e con eyed fluid ? BIG #IA0*T*+ (eans S"OW*+ /*"O,IT. of t%e con eyed fluid /elocity of fluids in Pi-elines affects ? Pressure "osses along t%e Pi-eline Pressure "osses are P+OPO+TIONA" to t%e sEuare elocity 1 > 2 ? /ibration of t%e Pi-eline Usual /elocity of !luids inside -i-elines areA GasA >C (7 s ? (a)$ FC 7 GC (7 sec "iEuidA > to F (7 s ? (a)$ =C (7 sec TEMPERATURE Choice of MATERIAL ?Steel for Hig% Te(-erature 1"o& Alloy Steel ,ree- +esistant2 ,alculation of &all THI,4N*SS +outing #esign and calculation of SUPPO+TS 1ST+*SS ANA".SIS2 ?Hot "ines (ust be routed -ro-erly$ Pro isions s%all be ta8en so t%at &%en te(-erature rises fro( a(bient to O-erating Te(-erature t%e t%er(al e)-ansion of Pi-elines does not generate stresses too %ig% for t%e -i-es to &it%stand$ A--lication of T%er(al Insulation ?TH ICJ , Insulation for Personnel Protection is (andatory for all -i-eline -arts t%at can be reac%ed by %ands$ P+*SSU+* A

=$ ,alculation of Wall T%ic8ness >$ ,%oice of t%e 5oint ?"o& -ressure -i-elines can be t%readed or soc8et &elded ?Hig% Pressure -i-elines are Butt Welded F$ *)tension of N#* of t%e 6oints ? Non -rocess Pi-elines 1!or *)a(-le /ents and drain lines2 (ay e en %a e no tests at all ? "o& Pressure Pi-elines can undergo only t%e Hydraulic Test ?!or inter(ediate -ressures a =CD to GCD of 6oints (ust be e)a(ined &it% 9? rays ?Hig% Pressure Pi-elines are usually =CCD 9? ray e)a(ined$ A0*+I,AN STAN#A+#S !O+ PIPING #*SIGN ANSI K A0*+I,AN NATIONA" STAN#A+#I3ATION INSTITUT* AS0* K A0*+I,AN SO,I*T. of 0*,HANI,A" *NGIN**+S ANSI7 AS0* B@=$=A POW*+ PIPING ANSI7 AS0* B@=$@A P+O,*SS PIPING TH*S* STAN#A+#S GI/* T*,HNI,A" +*,O00*N#ATIONS !O+ #*SIGNING PIPING S.ST*0 !O+ POW*+ P"ANTS AN# ,H*0I,A" P"ANTS TH*. ,ONTAINS !O+0U"AS TO ,A",U"AT* TH* 0INI0U0 THI,4N*SS O! PIP*"IN*S TH*. ,ONTAINS O+0U"AS TO ,A",U"AT* TH* *9T+A THI,4N*SS THAT A PIP* 0UST HA/* WH*N A B+AN,H IS ,UT INTO IT$ TH*. ,ONTAINS +*GU"ATIONS !O+ ST+*SS ANA".SIS TH*. ONTAINS TAB"*S THAT GI/* 0A9I0U0 A""OWAB"* ST+*SS !O+ 0*TA""I, 0AT*+IA"S A,,*PT*# B. ANSI !O+ PIP*"IN* ,ONST+U,TION #*P*N#ING ON T*0P*+ATU+*S$ STAN#A+# 0AT*+IA"S !O+ PIPING AST0 K A0*+I,AN SO,I*T. for T*STING 0AT*+IA"S AST0 de elo-ed a collection of docu(ents called 0AT*+IA" SP*,I!I,ATIONS for standardi<ing (aterials of large use in t%e IN#UST+.$ S-ecifications starting &it% :A; are for ST**"$ S-ecifications starting &it% :B; are for non? ferrous alloys 1Bron<e, Brass, ,o--er Nic8el alloys, Alu(inu( alloys and so on2$ S-ecifications starting &it% :#; are for -lastic (aterial, as P/,$ An AST0 S-ecification does not only s-ecify t%e basic ,H*0I,A" ,O0POSITION of (aterial, but also t%e P+O,*SS t%roug% &%ic% t%e (aterial is s%a-ed into t%e final -roduct$ T%is is &%y for a gi en base (aterial S*A0"*SS PIP* %a e a s-ecification, W*"#*# PIP* %a e anot%er s-ecification W+OUGHT !ITTINGS %a e anot%er s-ecification, !O+G*# !ITTINGS %a e anot%er s-ecification, large /A"/* bodies 1nor(ally ,AST2 %a e anot%er s-ecification ,A+BON ST**" Steel is basically a solution of carbon 1,2 into iron 1!e2$ T%e -resence of carbon into t%e crystal structure of t%e iron i(-ro e ery (uc% t%e (ec%anical c%aracteristics of t%e iron alone$ ,arbon steel is a con entional deno(ination for steel t%at %as al(ost no ot%er (etallic ele(ents added into it$ AST0 (ost e(-loyed carbon steel for -i-es are AST0 AG@ Grade A and B and AST0 A=CI Grade A and B$ AG@ used to be c%ea-er t%an A=CI and Grade A c%ea-er t%an Grade B$

Today t%e difference is not so big, so t%at for s(all Euantities AST0 A=CI Gr$ B is usually c%osen$ AST0 S-ecifications belonging to sa(e fa(ily of ,arbon Steel S*A0"*SS PIP*S AST0 AG@ 1Gr$ A 7 B2 or A=CI 1Gr$ A 7 B2 W*"#*# PIP*S AST0 A=@F 7 A=@G 7 A=@L W+OUGHT !ITTINGS AST0 A>@F 1WPA 7 WPB2 !O+G*# !ITTINGS A=CG ,AST PA+TS A>=I 1W,B2 API Standards !or Oil and Gas Industry, anot%er A(erican Standardi<ation Institute is co((on and i(-ortant$ T%is Institute is API K A0*+I,AN P*T+O"*U0 INSTITUT* +ules, Practices and Standards for Oil and Gas Industry are issued by t%is Institute and follo&ed by al(ost all Oil and Gas ,o(-anies in t%e &orld$ A(ong t%e (any Standards issued by t%e Institute t%ere is also a Standard for design of Pi-elinesA API STAN#A+# G" Wit%in t%is Standard 0aterials for Oil and Gas trans-ortation -i-elines are s-ecified, &it% deno(ination API G" T%is is a fa(ily of ,arbon Steels al(ost eEui alent to AST0 AG@ 7A=CI$ "OW A""O. ST**" T%e introduction of ot%er ele(ents into steel can c%ange ery (uc% its (ec%anical c%aracteristics$ Steel is sub6ect to a -rocess called :cree-; at %ig% te(-eratures 1T H GFC J,2 ,ree- is a reduction of strengt% o er ti(e due to %ig% te(-erature$ It (eans t%at if today t%e steel can &it%stand a certain -ressure, after a long ti(e at %ig% te(-erature sa(e steel can &it%stand (uc% lo&er -ressures, since its resistance is decreasing &it% ti(e due to t%e %ig% te(-erature$ Steel beco(es also -articurarly fragile if sub(itted to sudden i(-acts at lo& te(-eratures 1M ? >C J,2$ T%e introduction of s(all -ercentages of c%ro(iu( 1,r2, nic%el 1Ni2, (agnesiu( 10g2, (anganese 10n2, (olybdenu( 10o2, -ro es to i(-ro e t%e strengt% of t%e steel and its resistance to corrosion also at %ig% te(-eratures 1H GCC J,2 or at lo& te(-eraturea 1M ?>C J,2$ "o& Alloy Steel is a con entional deno(ination for steels &%ere t%ere are s(all -ercentages of ele(ents, usually (etallic, ot%er t%an carbon only$ Alloy steels are usually identified &it% deno(inations t%at recall co(-osition$ As for e)a(-le follo&ing %ig% te(-erature resistant steelsA #eno(ination Alloy -ercentage Grade Grade for ,astings G,r?N 0o 1GD ,r B C$GD 0o 2 PG ,G =O ,r?N 0o? Si 1=$>GD ,r B C$GD 0o B Si2 P== 1W,G2 =,r?N 0o 1=D ,r B C$G 0o2 P=> 1W,G2 >O ,r? =0o 1>$>G ,r B =D 0o2 P>> W,L AST0 S-ecifications belonging to sa(e fa(ilies of "o& Alloy Steels S*A0"*SS PIP* A@@G 1PG B P== B P=> B P>>2 W*"#*# PIP* AST0 A@GP W+OUGHT !ITTINGS AST0 A>@F 1WPG B WP== B WP=> B WP>>2 !O+G*# !ITTINGS A=P> 1!G B !== B !=> B ! >>2 ,AST PA+TS A>=Q 1,G B W,G B W,L2 STAIN"*SS ST**" One of (ost i(-ortant -roble(s &it% carbon and lo& alloy steels, is t%at t%e iron e)-osed to air and &ater co(bines &it% o)ygene 1O > 2 and generates rust 1di? iron tri? o)yde !e > O @ 2 t%at -eels out fro( t%e surface$ Hig% -ercentages of c%ro(iu( 1,r2 and nic%el 1Ni2 added into t%e steel sto- t%is -roble($ Stainless Steel is con entional generic deno(ination for steels &it% %ig% -ercentages of c%ro(iu( 1(ini(u( =ID2 and nic%el 1(ini(u( P D2$ Traditional deno(ination for stainless steel &as gi en first fro( AISI

1A(erican Institute for Steel and Iron2 and is still in t%e tradition and retained in t%e Grade of AST0 S-ecifications$ But as usual for alloy steels, a (ore -recise deno(ination can refer to co(-osition$ AISI #eno(ination Alloy Percentage Grade for ,astings @CF 7 @CF" =P,r? PNi 1=PD ,r B PD Ni2 ,!@ 7 ,!P @=I 7 @=I" =I,r? =>Ni? >0o 1=ID ,r B =>D Ni B >D 0o2 ,!@0 7 ,!P0 @>= =P,r? =CNi? Ti 1=PD ,r B =CD Ni B Ti2 Not A ailable T%e :"; suffi) stands for :"o& ,arbon;$ In fact t%e -resence of %ig% -ercentages of ,r and Ni i(-ro es t%e resistance of steel against rust, but at one costA stainless steel is ery difficult to &eld$ Welding of stainless steel can be i(-ro ed by reducing t%e content of carbon in it$ AST0 S-ecifications belonging to sa(e fa(ily of Stainless Steel S*A0"*SS PIP* A@=> TP@CF B @CF" ? @=I ? @=I" ? @>= W*"#*# PIP* AST0 A>FL TP@CF ? @CF" ? @=I ? @=I" ? @>= W+OUGHT !ITTINGS AST0 AFC@ WP@CF ? @CF" ? @=I ? @=I" ? @>= !O+G*# !ITTINGS A=P> !@CF B @CF" ? @=I ? @=I" ? @>= ,AST PA+TS A@G= 1,!@ B ,!@0 7 ,!P B ,!P02 Ho& Pi-eline ,HA+A,T*+ISTI,S are defined by t%e Standards$ SI3* NO0INA" PIP* SI3* A NPS It is a con entional si<e e)-ressed solely in IN,H*S, related to t%e cross section dia(eter of t%e -i-eline$ !or s(aller si<es t%e NPS is not usually e)actly eEual to any real dia(eter, but bigger$ T%is co(es fro( t%e fact t%at for unifor(ity, -i-elines (ust %a e sa(e Outside #ia(eter, and c%ange Inside #ia(eter &it% different t%ic8ness$ But in fluid trans-ortation t%e internal dia(eter is (ore significant, so if t%e Outside #ia(eter is bigger of t%e NPS, ta8ing a&ay t%e t%ic8ness, t%e NPS gi es (ore an idea of t%e internal dia(eter$ NO0INA" #IA0*T*+ A #N Sa(e as NPS, but in (($ It is t%e usual deno(ination of Si<e in *uro-e &%ere S$ I$ is ado-ted$ All e)ternal dia(eters -i-es according *U+OP*AN Standards 1#IN ? Ger(any, UNI ? Italy, A!NO+ B !rance2 are e)actly eEual of t%e eEui alent NPS Si<es according A0*+I,AN and B+ITISH Standars 1BS2 *9,*PT G; 1#N=>G2 WA"" THI,4N*SS 1=2=$ !or PIP*S and W+OUGHT BW !ITTINGS, &all t%ic8ness is gi en in IN,H*S or (($ So(e series of t%ic8nesses are standardi<ed$ T%ere are t&o series of syste(s of standardi<ed t%ic8nesses$ ,arbon Steel ANSI B=I$=C G, =C, >C, @C, FC, IC, PC, =CC, =>C, =IC$ Sc%edule Stainless Steel ANSI B=I$=L GS, =CS, >CS, @CS, FCS, ICS, PCS$ Std Standard 9S *)tra Strong Weig%t Series 99S *)tra *)tra Strong It %a--ens t%at for a gi en dia(eter t%e t%ic8ess of one Sc%edule is eEual to t%e t%ic8ness of one Weig%t Series$ !or e)a(-le for s(all dia(eters, Sc%$ FC is eEual to Std Weig%t$ THIS IS NOT A +U"*, and t%is idea is one of t%e (ost co((on (ista8es in -i-ing design$ WA"" THI,4N*SS 1>2>$ !or !"ANG*S, /A"/*S and !O+G*# !ITTINGS, a different syste( of indicating t%e &all t%ic8ness is used$ T%is is called P+*SSU+* +ATING$ It is a

NU0B*+ e)-ressed in POUN#S -er S'UA+* IN,H 1PSI sy(bol R2 t%at refers to t%e (a)i(u( internal -ressure acce-table for nor(al o-eration inside t%at -art$ =>GR =GCR @CCR FCCR ICCR PCCR ,ast Iron !langes S /al es 1Not in NP Standards2 !l$ S /al es !orged S(all /al es 1 >;2 LCCR =GCCR >GCCR @CCCR ICCCR LCCCR ! l a n g e s S / a l e s !orged !ittings T%is con entional nu(ber is not e)actly t%e actual (a)i(u( -ressure acce-table inside t%e -art$ T%e (a)i(u( -ressure allo&ed for a gi en rating is tabulated in t%e ANSI standards and de-ends on Te(-erature AST0 0aterial T.P* O! 5OINTS B*TW**N PI*,*S 1=2 BUTT? W*"#ING *N#S T%e end is (ac%ined to allo& %ead to %ead full -enetrating &elding T.P* O! 5OINTS B*TW**N PI*,*S 1>2 SO,4*T W*"#ING *N#S A soc8et is -ro ided &%ere -i-e can be inserted T.P* O! 5OINTS B*TW**N PI*,*S 1@2 @$ TH+*A#*# *N#S Parts to be connected are t%readed$ !or ser ices &%ere lea8s are strongly undesired, a lig%t &eld is carried out at t%e surface, t%is is called :Seal Weld;$ :Seal; &eld STAN#A+#I3*# PIPING OB5*,TS PIP*S !ITTINGS !"ANG*S /A"/*S GAS4*TS BO"TS AN# NUTS PIP*SA ANSI B@I$=C ,S 7 B@I$=L SS Sea(less *lectric +esistance Welded No (aterial is added during &elding -rocess *lectric !usion Welded 0aterial 1!iller 0etal2 is added during t%e -rocess of &elding HOW TO I#*NTI!. A PIP* SI3* NPS =>; 1#IA0*T*+2 1#N @CC2 WA"" THI,4N*SS Sc%$ FC 0AT*+IA" AST0 A=CI Gr$ B BW !ITTINGS A ANSI B=I$L Bends @CJ ? FG J ? ICJ ? LCJ "ong +adius +K =$G # S%ort +adius +K # Tees Straig%t !ull Tees $ +educing Tees$ +educers ,oncentric +educers$ *ccentric +educers$ ,a-s HOW TO I#*NTI!. A BW !ITTING =$ Straig%t !ittings T.P* B*N# LCJ "+ SI3* NPS =>; 1#IA0*T*+2 1#N @CC2 WA"" THI,4N*SS Std 0AT*+IA" AST0 A>@F WPB >$ +educing !ittings

T.P* +*#U,ING T** SI3* NPS =>; )P; 1#IA0*T*+2 1#N @CC)>CC2 WA"" THI,4N*SS Sc%$ @C)>C 0AT*+IA" AST0 A>@F WPB !O+G*# !ITTINGS ANSI B=I$== HOW TO I#*NTI!. A !O+G*# !ITTING T.P* *"BOW LCJ SI3* NPS =; 1#IA0*T*+2 1#N >G2 WA"" THI,4N*SS +ating @CCCR 5OINT NPT 0AT*+IA" AST0 A=CG PIP* NIPP"*S T%ey are standardi<ed s%ort -ieces of -i-e usually GC (( or =CC (( long nor(ally used bet&een t&o close fittings$ T%ey can co(e in straig%t si<e or in reducing si<e and can %a e one end (ac%ined in a different &ay t%an t%e ot%er$ Suc% a ariety of co(binations is su((ari<ed using abbre iations B K Be elled P K Plain T K T%readed " K "arge S K S(all * K *nd Pi-e ni--les can be used to c%ange a(ong 6oint ty-es$ !or e)a(-le a P*)B* Pi-e Ni--le c%anges a Soc8et Welding "ine into a Butt&elding "ine Be eled *nd Plain *nd BW SW !"ANG*S ANSI B=I$G =$ Pi-e ,onnection Welding Nec8 Sli- On "a- 5oint Soc8et Welding T%readed >$ 0ating !lat !ace +aised !ace +ing 5oint W*"#ING N*,4 Used for all si<es, t%ey allo& full -enetration &eld bet&een -i-e and flange$ !or t%is eason t%ey are used for se ere a--lications &%ere failure of &elda cannot be acce-ted$ T%is does not co(e free of cost, since t%e s%a-e of t%e flange obliges to start fro( a %ea y forging and &aste a lot of (aterial fro( (ac%ining$ S"IP ON Used for all si<es, t%ey are ery (uc% econo(ical because t%ey are flat and can be obtained fro( s%eets or -lates &it% (ini(u( &aste of (aterial fro( (ac%ining$ But t%ey do not allo& full -enetration &eld, so t%at t%ey are use for lo& ratings 1usually =GCR only2 and unse ere a--lications TH+*A#*# ,an be used for all si<ed, but are -referably used for s(all si<es 1M or eEual to >;2$ ,%ea(anufacturing, c%ea- installation 1no &eld is reEuired2 but li(ited to t%readel lines, t%at (eans unse ere a--lications &%ere lea8s are not a (a6or issue

LAP JOINT A Stub *nd is &elded on t%e -i-e after t%e flange insertion of it$ T%is solution is used for Stainless Steel lines at lo& -ressure, since t%e %ea y flange does not co(e in contact &it% t%e con eyed fluid and can be -ro ided in (uc% c%ea-er ,arbon Steel (aterial$ 0oreo er no &eld is reEuired, also a good t%ing for Stainless Steel lines$ SO,4*T W*"#ING Used for s(all si<es 1M or eEual to >;2 for unse ere ser ices on Soc8et Welding lines$ !lat !ace Gas8etA !ull !ace !lat It co ers t%e entire surface of t%e flange +aised !ace Gas8etA !lat It co ers t%e raised surface of t%e flange S-iral Wound Also 8no&n as S-iro(etallic, or S-irotallic, its a &ounded s-iral of Stainless Steel and Gra-%ite to &it%stand %ig% te(-eratures or se erely aggressi e fluids +ing 5oint Gas8etA 0etallic +ing It is nor(ally (ade u- of Steel$ It defor(s inside t%e ring 6oint groo es assuring sealing at ery %ig% -ressures$ Surface !inis%ing of !langes To i(-ro e t%e sealing effect of -lane gas8ets, t%e surface of a flange can be (ac%ined$ A set of circular scares is (ac%ined in t%e surface$ W%en t%e gas8et is tig%tly sEuee<ed et&een t%e flanges, it -enetrates into t%e scares i(-ro ing sealing$ HOW TO I#*NTI!. A !"ANG* 5OINT T.P* ?S"IP ON SI3* ?NPS I; 1#IA0*T*+2 ?1#N =GC2 WA"" THI,4N*SS ?+ating @CCR 0ATINGT!INISH ? +! B +L 0AT*+IA"? AST0 A=CG A,TUATION O! /A"/*S To o-en and close a al e, Hands, *lectric Po&er, ,o(-ressed Air, Hig% Pressure Oil you can use in &%ic% case you need Hand&%eel, *lectric Actuator, Pneu(atic ctuator, Hydraulic Actuator And is called 0anual, *lectric, Pneu(atic, Hydraulic ,ONT+O" /A"/*S T%ese al es are used to ,ONT+O" one or (ore of t%e P+OP*+TI*S of t%e con eyed fluid in order to (ention t%e /A"U*S of t%e controlled -ro-erty &it%in a s-ecific ange$ T%e internal -arts of t%ese al es are s-ecially designed tu suit t%e -articular control tas8 and are non sub6ect to -articular Standards$ Any&ay, t%e (a6ority of ,ontrol /al e 0anufacturers try to res-ect at least t%e end to end di(ensions gi en in ANSIB=I$>G$ Also connections follo&s t%e recogni<ed international standards$ SA!*T. AN# +*"I*! /A"/*S T%ese al es are installed on -i-elines &%ere -ressure can e)ceed by accident t%e #*SIGN P+*SSU+* of t%e -i-eline$ T%ese al es are designed to o-en and disc%arge t%e con eyed fluid &%en t%e -ressure in t%e -i-eline beco(es greater t%an a -ecified alue called S*T$ +*"I*! T%e al e o-ens &%en t%e -ressure goes o er t%e S*T, but close again &%en t%e -ressure returns under t%e S*T SA!*T. T%e al e o-ens &%en t%e -ressure goes o er t%e S*T, but ne er closes again$ Personnel inter ention is reEuired on t%e -i-eline to c%ec8 t%e e ent and t%e condition of t%e area, before re? ar(ing t%e al e and starting o-eration again TUBING

A TUB* is a circular section of gi en #IA0*T*+ and THI,4N*SS$ It is nor(ally s-ecified gi ing t%e Ouside #ia(eter 1O#2 and t%e t%ic8ness$ But it can also be s-ecified gi ing t%e Inside #ia(eter 1I#2 and t%e t%ic8ness$ T%e gi en nu(bers corres-ond e)actly to t%e geo(etrical di(ension t%ey refer$ So A >; O# TUB* %as e)actly a >; Outside #ia(eters$ #i(ensionally, t%ere are t&o big fa(ilies of tubing =$ !+A,TIONA" TUB*S T%e IN,H is t%e unit of (easure, and since tubes for -i-ing -ur-ose 1+*0*0B*+A ,ON/*.ING !"UI#SU2 are s(all, usually less t%an =;, !+A,TIONS of inc% are used, %ence t%e na(e !+A,TIONA"0*T+I, TUB*S As -er SI reEuire(ents, (( is t%e unit of (easure$ Again t%e alue in (( is t%e actual ouside dia(eter of t%e tube, so t%at a #N=G -i-e %as a rat%er different O# t%en a =G (( tube$ TUB*S in PIPING #*SIGN$ Tubes are not usually used in PIPING #*SIGN e)ce-t for so(e ery -articular ser ices$ In ty-ical Oil and Gas 0ac%inery installations, li8e Nuo o PignoneVs, TUB*S are basically used forA =$ Parts of HP Hydraulic "ines >$ Instru(ent connecting "ines Pneu(atic "ines T%ese "ines are s(all si<e 1usually less t%an =;2$ ,O0P+*SSION !ITTINGS Tubing is usually B*NT$ A large ariety of fittings are a ailable for =$ detac%(ent of B+AN,H*S 1Tees2 >$ Passing t%roug% steel &alls 1Bul8 Unions2 @$ Unite tube to tube 1tubing is not &elded2 F$ ,onnecting Tubing to PIP*S 1,onnectors2 G$ ,onnecting Tubes to !le)ible Hoses ,onnection of TUBING &it% t%e fitting is ac%ie ed t%roug% a -articular loc8ing syste( &%ere a +ING 1: !*++U"*;2 is forced to ,O0P+*SS t%e Tube &alls for sealing and 6oining$ T%ese fittings are not STAN#A+#I3*#, but are branding based and -atented$ 0ost -o-ular (anufacturers of co(-ression fittings are PA+4*+, SWAG*"O,4, GA+I"O,4$

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Barbara Delinsky-The Wedding Night PDFDocument217 pagesBarbara Delinsky-The Wedding Night PDFravi00098Pas encore d'évaluation

- Con AirDocument156 pagesCon Airravi00098Pas encore d'évaluation

- Blyton Enid Noddy 5 Well Done Noddy! 1952Document71 pagesBlyton Enid Noddy 5 Well Done Noddy! 1952carlosathinopolos75% (12)

- Hotel Sales Strategies To Effectively Increase RevenueDocument38 pagesHotel Sales Strategies To Effectively Increase Revenueravi00098Pas encore d'évaluation

- NDT Radio Graphy Notes PDFDocument18 pagesNDT Radio Graphy Notes PDFravi00098Pas encore d'évaluation

- RadioGraph Book 1Document33 pagesRadioGraph Book 1Vicky SinghPas encore d'évaluation

- Impact TestingDocument27 pagesImpact Testingapi-3764139100% (2)

- Fundamentals of Professional WeldingDocument213 pagesFundamentals of Professional Weldingapi-3856939Pas encore d'évaluation

- Kou2003 PDFDocument6 pagesKou2003 PDFGe EffgenPas encore d'évaluation

- 009 The Great Airport MysteryDocument67 pages009 The Great Airport Mysteryomar omarPas encore d'évaluation

- Practices PipeDocument4 pagesPractices PipeParag Naik100% (2)

- Paint DefectsDocument129 pagesPaint Defectsmohammad100% (6)

- Coating Faults AADocument82 pagesCoating Faults AAAbrianto Akuan100% (5)

- 20 Welding RevisedDocument104 pages20 Welding Revisedravi00098Pas encore d'évaluation

- Stainless Pocket GuideDocument36 pagesStainless Pocket GuidePukhraj DagaPas encore d'évaluation

- 20 Welding RevisedDocument104 pages20 Welding Revisedravi00098Pas encore d'évaluation

- Weld Chart 1Document4 pagesWeld Chart 1ravi00098Pas encore d'évaluation

- Coating Failure Presentation 01 PDFDocument32 pagesCoating Failure Presentation 01 PDFravi00098Pas encore d'évaluation

- Welding of Duplex SSDocument20 pagesWelding of Duplex SSHermansyah PutraPas encore d'évaluation

- Welding Reference To Sec-IXDocument22 pagesWelding Reference To Sec-IXVijayananda AnandaPas encore d'évaluation

- An Introduction To RadiographyDocument52 pagesAn Introduction To RadiographyAmit PalaliyaPas encore d'évaluation

- Measure Optical Density of X-Ray FilmsDocument2 pagesMeasure Optical Density of X-Ray FilmsthisisghostactualPas encore d'évaluation

- Schubert PDFDocument66 pagesSchubert PDFdattu33Pas encore d'évaluation

- Valves and PipingDocument118 pagesValves and PipingMahdi Daly100% (1)

- PaintCure PDFDocument8 pagesPaintCure PDFmahendraPas encore d'évaluation

- W Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523Document18 pagesW Section 2 Tig Welding Saf Fro General Catalogue3005009245853932523ravi00098Pas encore d'évaluation

- ESAB Puls Mig Welding Hand BookDocument20 pagesESAB Puls Mig Welding Hand BookLeonardo De La HudiPas encore d'évaluation

- Husain Al Muslim Saudi Aramco PDFDocument34 pagesHusain Al Muslim Saudi Aramco PDFravi00098Pas encore d'évaluation

- Welding Power SourcesDocument6 pagesWelding Power SourcesM.IBRAHEEMPas encore d'évaluation

- Elcometer 456 User Manual PDFDocument76 pagesElcometer 456 User Manual PDFchaparal100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- FrontendDocument1 pageFrontendEren DhoheiriPas encore d'évaluation

- Case StudyDocument23 pagesCase Studysatyam gupta100% (1)

- Solar Water HeatingDocument2 pagesSolar Water HeatingCatherine Diccion LaciapagPas encore d'évaluation

- Crown Solutions Presentation PDFDocument19 pagesCrown Solutions Presentation PDFSuresh KumarPas encore d'évaluation

- Oracle Nosql Database,: 12.1.3.5, COMMUNITY EDITIONDocument5 pagesOracle Nosql Database,: 12.1.3.5, COMMUNITY EDITIONCarlos Mario HerreraPas encore d'évaluation

- DPR-1061 Compatible Lists For PS-Link Printing 20110615Document28 pagesDPR-1061 Compatible Lists For PS-Link Printing 20110615JCSALINAS10Pas encore d'évaluation

- Hot Tap Contractor Service Overview Brief FurmaniteDocument4 pagesHot Tap Contractor Service Overview Brief FurmaniteDavid Rios CruzPas encore d'évaluation

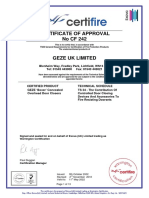

- Certificate of Approval No CF 242Document13 pagesCertificate of Approval No CF 242Florin RazvanPas encore d'évaluation

- Hunter Catalog emDocument236 pagesHunter Catalog emReziksufi NaszazuliPas encore d'évaluation

- ColtDocument2 pagesColtMuhidin KozicaPas encore d'évaluation

- Bai Tap Tieng Anh Lop 3 Unit 12 This Is My House Co Loi GiaiDocument5 pagesBai Tap Tieng Anh Lop 3 Unit 12 This Is My House Co Loi GiaiThu HồngPas encore d'évaluation

- Network DiagramDocument26 pagesNetwork DiagramMay Myoe KhinPas encore d'évaluation

- High Efficiency Concrete Curing Compound EstocureDocument2 pagesHigh Efficiency Concrete Curing Compound Estocuremyke_0101Pas encore d'évaluation

- Roof truss detailsDocument1 pageRoof truss detailsRassal KarimPas encore d'évaluation

- Quickly set up your network video recorderDocument8 pagesQuickly set up your network video recorderLilli-Anne HansenPas encore d'évaluation

- Draw-Peeling Improves Wire Quality: Surface TreatmentDocument1 pageDraw-Peeling Improves Wire Quality: Surface TreatmentYahyaMoummouPas encore d'évaluation

- Msbi PDFDocument7 pagesMsbi PDFhkdashin100% (1)

- Technical Architect CV TemplateDocument2 pagesTechnical Architect CV TemplateAdil AhmadPas encore d'évaluation

- CCBM 2 AssignmentDocument2 pagesCCBM 2 Assignmentsaarthak srivastavaPas encore d'évaluation

- Dev Studio InstallDocument114 pagesDev Studio InstallhellboysatyaPas encore d'évaluation

- I SCSICake LogDocument750 pagesI SCSICake LogSyam EliasPas encore d'évaluation

- ElotrixX Leveling & Farming ScriptDocument4 pagesElotrixX Leveling & Farming ScriptCristian Bustamante CarrascoPas encore d'évaluation

- Basics Configuration of PBX Nortel Meridain 81cDocument26 pagesBasics Configuration of PBX Nortel Meridain 81cGil HalePas encore d'évaluation

- The Insecurity of 802.11Document10 pagesThe Insecurity of 802.11afsfddasdPas encore d'évaluation

- 3g 4g InterworkingSupportDocument34 pages3g 4g InterworkingSupportsyed100% (1)

- CIS 2154 - Ch. 2 WorksheetDocument8 pagesCIS 2154 - Ch. 2 WorksheetStrider PutnamPas encore d'évaluation

- The Betyls of Petra. Robert WenningDocument17 pagesThe Betyls of Petra. Robert WenningRubén Montalbán LópezPas encore d'évaluation

- IBC 2016 TABLE 1604.3 DEFLECTION LIMITSDocument1 pageIBC 2016 TABLE 1604.3 DEFLECTION LIMITSMuhammad Najam AbbasPas encore d'évaluation

- Daniel Libeskind's iconic designs for the Jewish Museum and One World Trade CenterDocument34 pagesDaniel Libeskind's iconic designs for the Jewish Museum and One World Trade CenterShubha50% (2)