Académique Documents

Professionnel Documents

Culture Documents

Peb Indiamart

Transféré par

Fahad KhanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Peb Indiamart

Transféré par

Fahad KhanDroits d'auteur :

Formats disponibles

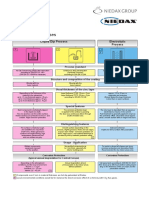

About PEB's Pre-engineered buildings are the state-of-the-art steel solution to developing an efficient and cost-effective infrastructure.

PEBs offer ultimate design flexibility and an extremely short construction time (right from initial design to completion). They are supplied as a fully finished product along with steel structure, building accessories and roof cladding. They require no on-site fabrication or welding they can simply be bolted together as per specifications. PEBs are best suited for warehouses, sports halls, factories, workshops, distribution centers, cold storages, supermarkets, aircraft hangars or any ground + two-storey construction. Strengths of our PEBs are: Advantages of Our PEBs are:

Clear spans up to 100m without internal columns Flexibility in building dimensions ISO 9001 quality accreditation Easy expansion Fixed deadlines and costs Weather-tight roof and wall coverings with accessories for long maintenance free exteriors

Single source responsibility Low initial cost Engineering flexibility Faster overall project completion Low maintenance Fast modular expandability

Our PEBs include: Primary structures: H/I Beams H/I Beams in the PEB industry often refer to primary built-up members. Primary members consist of columns, rafters, beams etc. These are fabricated from high strength Gr. 50 HR plates. Plates are cut to size and shape. Built up sections are made form these plates in Automatic Beam Welding Line using submerged arc welding. Secondary Members : Secondary Members in the PEB industry refer mostly to longitudinal roof and wall members that are roll formed from galvanized coils. Secondary members used in a PEB include steel purlins, side runners, fascia channels, door posts, window posts, rafter stays, and column stays base angles and other miscellaneous structural parts. Z sections acting as longitudinal roof purlins and longitudinal wall girts that connect to columns & rafters and support exterior roof and wall panels. "C sections used primarily in framed openings and as a transition member between partial block walls and wall panels. Steel Deck used to support concrete slabs in second level flooring.

Base angles, gable angles, and mezzanine edge angles. Roofing & Cladding Systems We offer you choice of 5 different types of roofing and cladding systems that enhance the aesthetic appeal of the building and are ideally suited for rapid and low cost construction. Exterior Facades Single Skin Panels are trapezoidal ribbed sheets roll formed from thin mill finish or pre-painted Zn-Al coated steel and aluminum coils and cut-to-length to meet the requirements of a specific building Sandwich Panels have a polyurethane foam core sandwiched between two single skin metal panels (or an exterior single skin metal panel and an interior aluminum faced laminate).

PEB Accessories Trims and Flashing include eave trim, eave gutters, downspouts, gable trim, curved eave panels, flashing around building accessories, etc. which are produced from pre-painted Zn-Al coated steel or aluminum sheets that are bent to the required shape. Building Accessories include sliding doors, rollup doors, personnel doors, fiberglass insulation, sand-trap louvers, windows, ridges ventilators.

Girt Joint

Purlin Butt Joint

Purlin Lap Joint

PLANT FACILTIES

An ISO 9000:2008 Certified Company 2500 MT/year Production capacity 10,000 square feet top covered Fabrication shop & 8,000 square feet fully covered fabrication shop at Thirumalayampalayam (40 kms from Coimbatore City Airport & 4 km from Ettimadai Railway station) ONE STOP Solution to complete PEB needs along with Design & Development Team 6,000 square feet machine shop with conventional World Class machineries. All staff trained in complete safety and quality measures Our State-of-the-art manufacturing facility houses special equipments to produce quality pre-engineered buildings Well defined process on the shop floor ensures smooth flow of material and productivity All structural components to complete Pre-engineered building are produced in-house and go through stringent quality checks prior to dispatch. All major raw materials and bought out items are sourced from a Panel of approved supplier to ensure quality and timely supplies.

Dedication to Quality and Safety Quality is the hallmark of the products designed and manufactured by Aromen. Aromen is certified as a ISO 9001:2008. Some of the quality practices followed by the company which has led to continuous improvements in processes, procedures and products are as follows.

All products meet the national/International standard requirements. To ensure quality all products are passed through stringent quality checks in all the stages of manufacturing. An established quality management system and continuously seek to improve the same which will satisfy the relevant national quality management system. Source of the material are certified to ensure consistency in quality. Our production team converts these in to superior products through the use of advanced equipment and highly skilled manpower.

Vous aimerez peut-être aussi

- 260-Photoshop Module v7c-PC For WEB-2 PDFDocument68 pages260-Photoshop Module v7c-PC For WEB-2 PDFRaquel JavinezPas encore d'évaluation

- Adobe Photoshop Cs3 TutorialDocument37 pagesAdobe Photoshop Cs3 TutorialMOhammad ZOhaib100% (3)

- What Is Graphic Design?Document24 pagesWhat Is Graphic Design?Fahad KhanPas encore d'évaluation

- Virtual University of Pakistan: Evaluation Sheet For ProjectDocument44 pagesVirtual University of Pakistan: Evaluation Sheet For ProjectMuhammad IqbalPas encore d'évaluation

- Leadership Style and Organizational Performance A Comparative Study Between Transformational and Transactional Leadership StylesDocument9 pagesLeadership Style and Organizational Performance A Comparative Study Between Transformational and Transactional Leadership StylesFahad KhanPas encore d'évaluation

- Leadership & Team Management - MGMT623 Fall 2007 Quiz 01 SolutionDocument2 pagesLeadership & Team Management - MGMT623 Fall 2007 Quiz 01 SolutionFahad KhanPas encore d'évaluation

- Leadership Style and Organizational Performance A Comparative Study Between Transformational and Transactional Leadership Styles PDFDocument18 pagesLeadership Style and Organizational Performance A Comparative Study Between Transformational and Transactional Leadership Styles PDFFahad KhanPas encore d'évaluation

- 477 PDFDocument16 pages477 PDFFahad KhanPas encore d'évaluation

- Equity Theory Motivation ExplainedDocument22 pagesEquity Theory Motivation ExplainedFahad KhanPas encore d'évaluation

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Leadership and Team Management Quiz AnswersDocument6 pagesLeadership and Team Management Quiz AnswersFahad KhanPas encore d'évaluation

- Spring2018 MGT201 1Document3 pagesSpring2018 MGT201 1Fahad KhanPas encore d'évaluation

- Eng 301Document4 pagesEng 301Fahad KhanPas encore d'évaluation

- Virtual University Prospectus 2016-17Document107 pagesVirtual University Prospectus 2016-17Fahad KhanPas encore d'évaluation

- Petroskills Online Facilitiescatalog 2016-17Document46 pagesPetroskills Online Facilitiescatalog 2016-17Fahad KhanPas encore d'évaluation

- YFT-D400 Operation ManualDocument20 pagesYFT-D400 Operation ManualFahad KhanPas encore d'évaluation

- PEB Product enDocument22 pagesPEB Product enFahad KhanPas encore d'évaluation

- AMegaFileofMGT402 Solved MCQS Solved PapersDocument641 pagesAMegaFileofMGT402 Solved MCQS Solved PapersZeeshan Ahmed100% (2)

- ShowdocwDocument7 pagesShowdocwFahad KhanPas encore d'évaluation

- Mackinnons Building CV FormDocument2 pagesMackinnons Building CV FormFahad KhanPas encore d'évaluation

- 3.3 Compressed Air SystemDocument9 pages3.3 Compressed Air SystemstephenPas encore d'évaluation

- Green For LifeDocument6 pagesGreen For LifeFahad KhanPas encore d'évaluation

- Catalago Cat Pumps PDFDocument20 pagesCatalago Cat Pumps PDFkathePas encore d'évaluation

- 9100 Flanged BrochureDocument16 pages9100 Flanged Brochureanugrah_dimas5441Pas encore d'évaluation

- Flex Spiral Wound GasketsDocument49 pagesFlex Spiral Wound GasketsJomer J Simpson100% (1)

- Whypeb 2012 eDocument4 pagesWhypeb 2012 eFahad KhanPas encore d'évaluation

- Wear MetalsDocument3 pagesWear MetalsFahad KhanPas encore d'évaluation

- Chiller SizingDocument9 pagesChiller Sizingmizu82Pas encore d'évaluation

- Reciprocating Compressor CalculationDocument10 pagesReciprocating Compressor CalculationVIJAYIOCLPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Table Ucs 56 3 (P.no.4)Document1 pageTable Ucs 56 3 (P.no.4)Anonymous AyDvqgPas encore d'évaluation

- Copper Alloys InfoDocument18 pagesCopper Alloys InfoPhung Tuan AnhPas encore d'évaluation

- Kerr1960 CalciumDocument4 pagesKerr1960 Calciumpriscila_hdzvPas encore d'évaluation

- Specification for Piping Materials Rev B3Document52 pagesSpecification for Piping Materials Rev B3shervinyPas encore d'évaluation

- Catalogo de Papel Filtro PDFDocument45 pagesCatalogo de Papel Filtro PDFmarilu lizanaPas encore d'évaluation

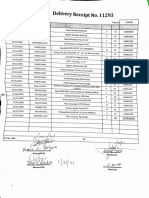

- Delivery Receipt No. 11293: DayiecdaDocument2 pagesDelivery Receipt No. 11293: Dayiecdaaldrin catilodPas encore d'évaluation

- Bourdon Tube Pressure Gauges Stainless Steel Series Type 232.50 - Dry Case Type 233.50 - Liquid-Filled CaseDocument2 pagesBourdon Tube Pressure Gauges Stainless Steel Series Type 232.50 - Dry Case Type 233.50 - Liquid-Filled CaseSachin GuptaPas encore d'évaluation

- A 1028-03 Stainless Steel Bars For Compressor and Turbine AirfoilsDocument4 pagesA 1028-03 Stainless Steel Bars For Compressor and Turbine Airfoilsalucard375100% (1)

- ISCAR Industries BrochureDocument92 pagesISCAR Industries BrochureAnonymous CYdagIPas encore d'évaluation

- Case Study 1 Bench ViseDocument7 pagesCase Study 1 Bench ViseChetan100% (1)

- Laserkatalog CentricutDocument155 pagesLaserkatalog CentricutAdrian IliePas encore d'évaluation

- Electrolytic Etching by Dauvit AlexanderDocument15 pagesElectrolytic Etching by Dauvit AlexanderDexter HullezaPas encore d'évaluation

- A New Continuous Cooling Transformation Diagram For AISI M4 High-Speed Tool SteelDocument6 pagesA New Continuous Cooling Transformation Diagram For AISI M4 High-Speed Tool SteelRonald MesinaPas encore d'évaluation

- Pull Wire and Trip Switch PDFDocument76 pagesPull Wire and Trip Switch PDF450gasgas100% (1)

- Navy M BronzeDocument1 pageNavy M BronzeDeepak KumarPas encore d'évaluation

- Diesel Engine Exhaust Valve Design, Analysis and Manufacturing ProcessesDocument9 pagesDiesel Engine Exhaust Valve Design, Analysis and Manufacturing ProcessesNandNPas encore d'évaluation

- Galvanizing Processes ComparisonDocument3 pagesGalvanizing Processes ComparisonAlin MoicaPas encore d'évaluation

- Aws Welding MetallurgyDocument48 pagesAws Welding MetallurgyBonumDie Mariano100% (3)

- Rolling ProcessDocument22 pagesRolling ProcesssamcbsivPas encore d'évaluation

- Surface TreatmentDocument35 pagesSurface TreatmentAnshul VermaPas encore d'évaluation

- ARMOR SPECDocument22 pagesARMOR SPECpradellesPas encore d'évaluation

- BS en - 1011 1 2009Document12 pagesBS en - 1011 1 2009Paco0% (1)

- Latihan SoalDocument3 pagesLatihan SoalDaus100% (1)

- Bag Filtration Systems FTDocument51 pagesBag Filtration Systems FTMartin ŠimurdaPas encore d'évaluation

- (Koroze A Ochrana Materialu) Corrosion Problems and Solutions in Oil Gas Refining and Petrochemical IndustryDocument18 pages(Koroze A Ochrana Materialu) Corrosion Problems and Solutions in Oil Gas Refining and Petrochemical IndustryDiệp Ngọc ThànhPas encore d'évaluation

- p8 BB 6000Document4 pagesp8 BB 6000Ramesh KrishnanPas encore d'évaluation

- Metal Matrix CompositesDocument43 pagesMetal Matrix CompositesapatelPas encore d'évaluation

- Microsoft Word - CarpentryDocument2 pagesMicrosoft Word - CarpentrykokueiPas encore d'évaluation

- American Welding Society User 039 S Guide To Filler MetalsDocument127 pagesAmerican Welding Society User 039 S Guide To Filler MetalsCarlos Bermejo Alvarez100% (1)

- Specialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Document3 pagesSpecialty Materials Hastelloy C-276 ALLOY: Certified To Iso 9001Jarbas MoraesPas encore d'évaluation